torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 488 of 6020

4B-44 REAR AXLE

Confirmation of Operation

• Using the side gear holder : 5-8840-2682-0,

measure the starting torque of the side gear.

Starting torque : 29-45 N ⋅m (3.0-4.6 kgf ⋅m/22-33

lb ⋅ft)

425RW 065

Legend

1. Side Gear Holder : 5-8840-2682-0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 496 of 6020

4B-52 REAR AXLE

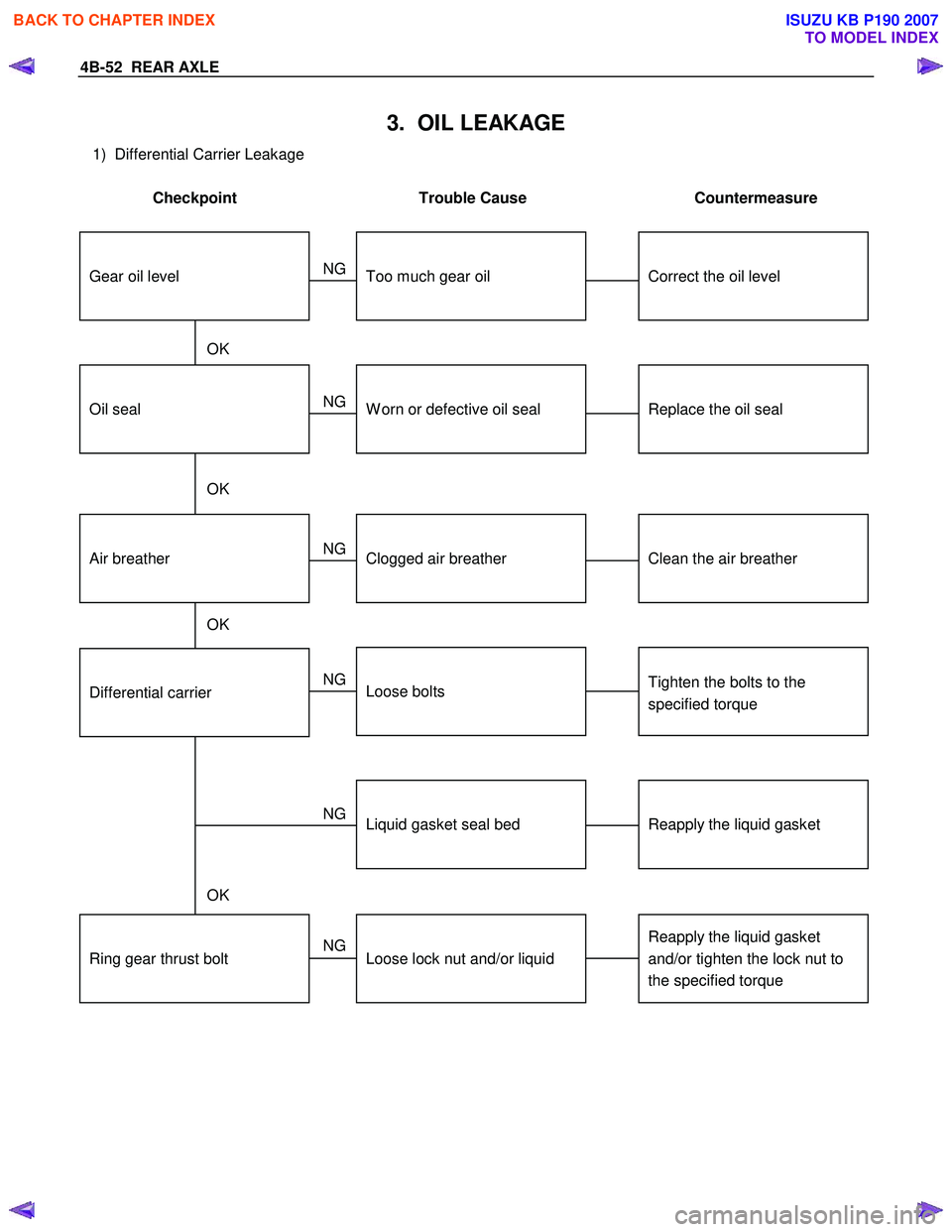

3. OIL LEAKAGE

1) Differential Carrier Leakage

Checkpoint Trouble Cause Countermeasure

Correct the oil levelToo much gear oil

NG

Reapply the liquid gasket

and/or tighten the lock nut to

the specified torque

Reapply the liquid gasket

Tighten the bolts to the

specified torque

Replace the oil seal

Ring gear thrust boltLoose lock nut and/or liquid

Liquid gasket seal bed

Loose bolts

Oil sealW orn or defective oil seal

Differential carrier

Clean the air breatherAir breatherClogged air breather

NG

NG

NG

NG

NG

OK

OK

OK

OK

Gear oil level

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 497 of 6020

REAR AXLE 4B-53

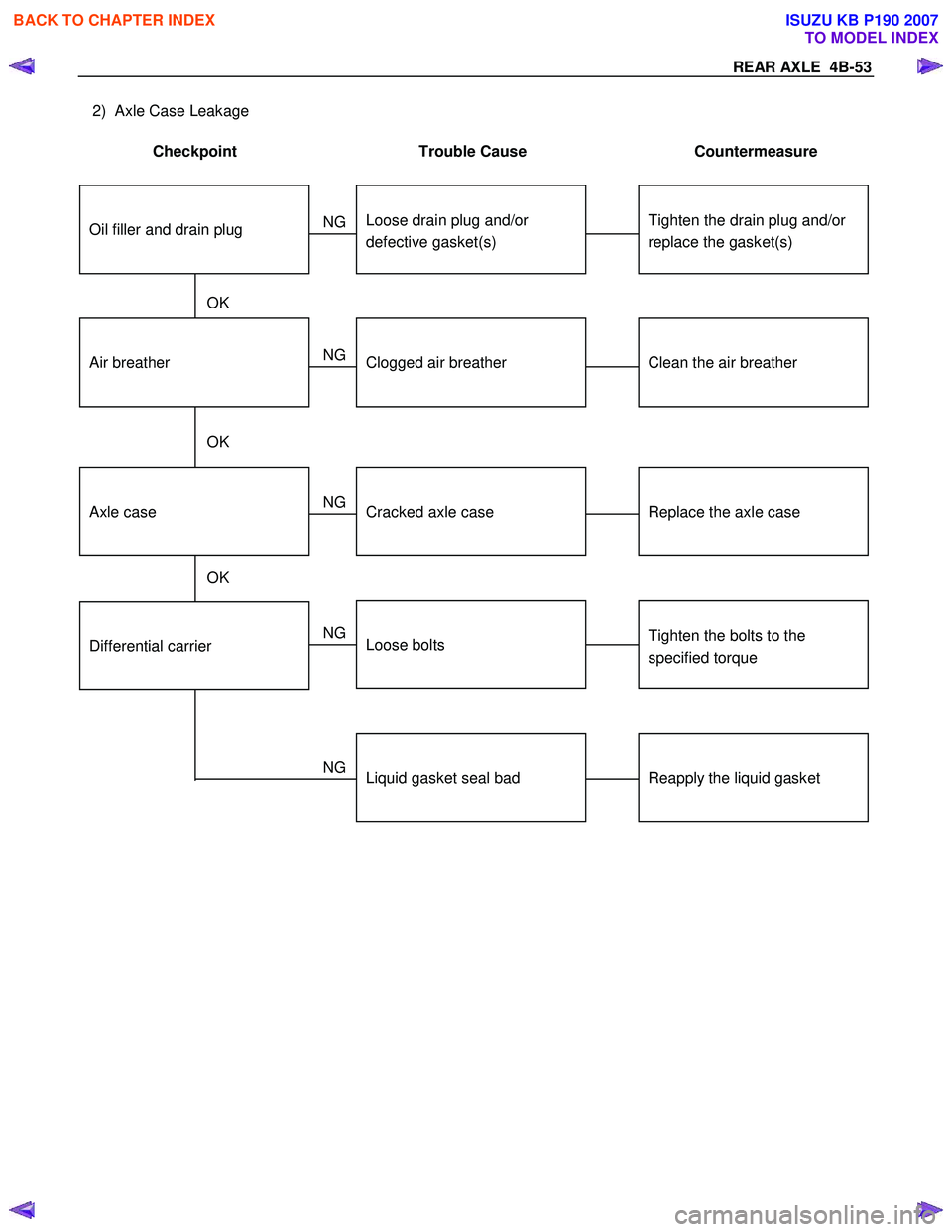

2) Axle Case Leakage

Checkpoint Trouble Cause Countermeasure

Tighten the drain plug and/or

replace the gasket(s)Loose drain plug and/or

defective gasket(s)

NG

Reapply the liquid gasket

Tighten the bolts to the

specified torque

Clean the air breather

Liquid gasket seal bad

Loose bolts

Air breatherClogged air breather

Differential carrier

Replace the axle caseAxle caseCracked axle case

NG

NG

NG

NG

OK

OK

OK

Oil filler and drain plug

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 510 of 6020

4C1-6 FRONT WHEEL DRIVE

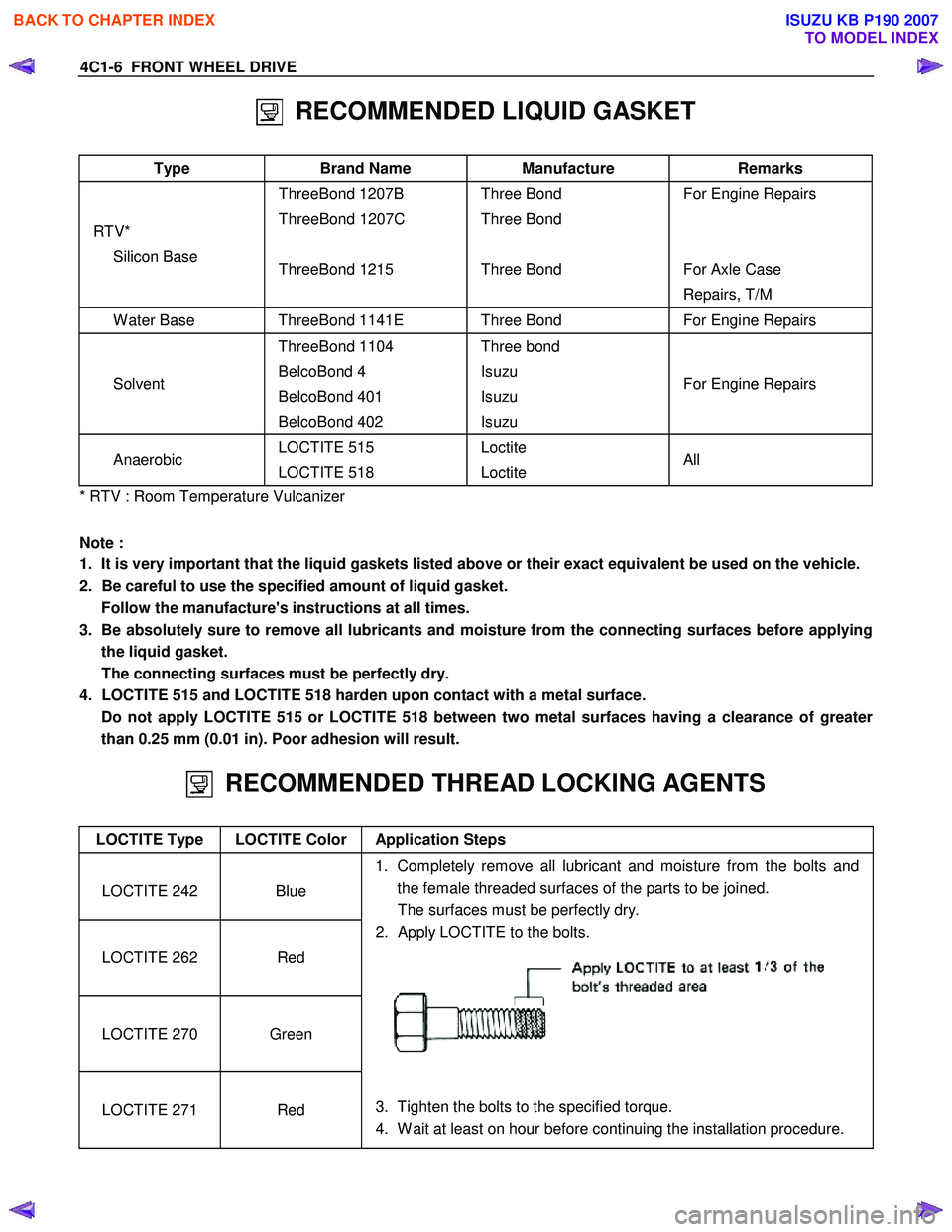

RECOMMENDED LIQUID GASKET

Type Brand Name Manufacture Remarks

RTV* Silicon Base ThreeBond 1207B

ThreeBond 1207C

ThreeBond 1215

Three Bond

Three Bond

Three Bond

For Engine Repairs

For Axle Case

Repairs, T/M

W ater Base ThreeBond 1141E Three Bond For Engine Repairs

Solvent ThreeBond 1104

BelcoBond 4

BelcoBond 401

BelcoBond 402 Three bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobic LOCTITE 515

LOCTITE 518 Loctite

Loctite All

* RTV : Room Temperature Vulcanizer

Note :

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the vehicle.

2. Be careful to use the specified amount of liquid gasket. Follow the manufacture's instructions at all times.

3. Be absolutely sure to remove all lubricants and moisture from the connecting surfaces before applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance of greater than 0.25 mm (0.01 in). Poor adhesion will result.

RECOMMENDED THREAD LOCKING AGENTS

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242

Blue 1. Completely remove all lubricant and moisture from the bolts and

the female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

LOCTITE 262

Red 2. Apply LOCTITE to the bolts.

LOCTITE 270

Green

LOCTITE 271

Red

3. Tighten the bolts to the specified torque.

4. W ait at least on hour before continuing the installation procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 516 of 6020

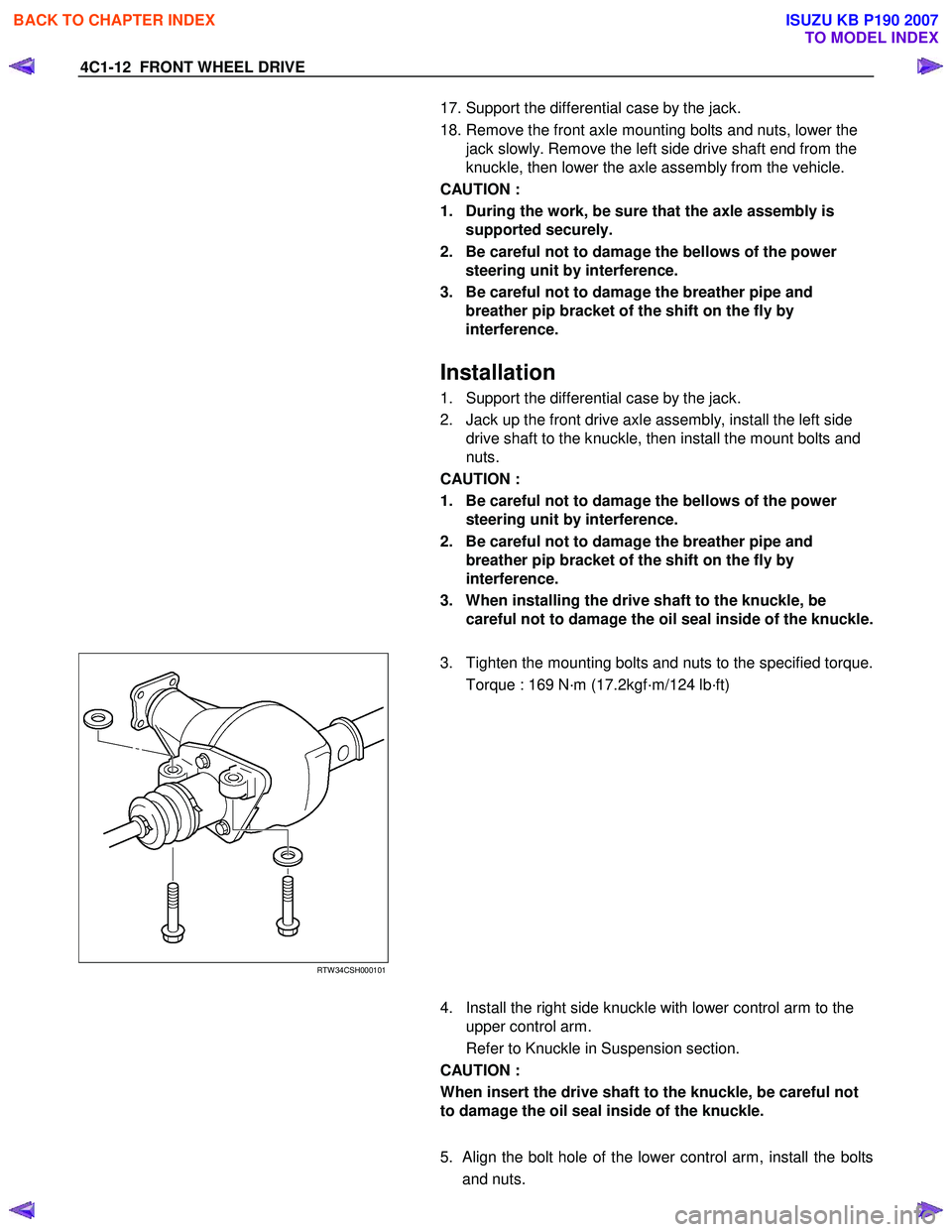

4C1-12 FRONT WHEEL DRIVE

17. Support the differential case by the jack.

18. Remove the front axle mounting bolts and nuts, lower the jack slowly. Remove the left side drive shaft end from the

knuckle, then lower the axle assembly from the vehicle.

CAUTION :

1. During the work, be sure that the axle assembly is supported securely.

2. Be careful not to damage the bellows of the power steering unit by interference.

3. Be careful not to damage the breather pipe and breather pip bracket of the shift on the fly by

interference.

Installation

1. Support the differential case by the jack.

2. Jack up the front drive axle assembly, install the left side drive shaft to the knuckle, then install the mount bolts and

nuts.

CAUTION :

1. Be careful not to damage the bellows of the power steering unit by interference.

2. Be careful not to damage the breather pipe and breather pip bracket of the shift on the fly by

interference.

3. When installing the drive shaft to the knuckle, be careful not to damage the oil seal inside of the knuckle.

RTW 34CSH000101

3. Tighten the mounting bolts and nuts to the specified torque.

Torque : 169 N·m (17.2kgf·m/124 lb·ft)

4. Install the right side knuckle with lower control arm to the

upper control arm.

Refer to Knuckle in Suspension section.

CAUTION :

When insert the drive shaft to the knuckle, be careful not

to damage the oil seal inside of the knuckle.

5.

Align the bolt hole of the lower control arm, install the bolts

and nuts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 517 of 6020

FRONT WHEEL DRIVE 4C1-13

NOTE :

Adjust the buffer clearance before tighten the bolts and nuts of

the lower control arm.

6. Install the breather hose of the front axle.

7. Install the actuator connector of the shift on the fly.

8. Install the tie-rod end of the power steering unit to the knuckle, tighten the nut to the specified torque.

Torque : 98 N·m (10.0kgf·m/73 lb·ft)

9. Install lower bolts and nuts of the shock absorber, tighten it to the specified torque.

Torque : 93 N·m (9.5kgf·m/69 lb·ft)

10. Install lower nuts of the stabilizer link, tighten it to the specified torque.

Torque : 50 N·m (5.1kgf·m/37 lb·ft)

11. Install the suspension crossmember.

12. Install the torsion bar.

Refer to Torsion Bar in Suspension section.

13. Install the front propeller shaft.

Refer to Front Propeller Shaft in this section.

14. Install the hub and disc assembly and adjust the bearing preload.

Refer to Front Hub and Disc in this section.

15. Install the wheel speed sensor of the antilock brake system.

16. Install the brake caliper. Tighten the bolt of the caliper bracket to the specified torque.

Torque : 226 N·m (23.0kgf·m/166 lb·ft)

17. Install the stone guard.

18. Install the tire and wheel.

19. Lower the vehicle, adjust the trim height.

Refer to Trim Height Adjustment in Front Alignment section.

20. Tighten the bolts and nuts of the lower control arm to the specified torque.

Refer to Lower Control Arm in Suspension section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 521 of 6020

FRONT WHEEL DRIVE 4C1-17

Bushing Replacement

• Remove the bushings using a remover 5-8840-2309-0 and

hammer.

•

By using installer and base 5-8840-2309-0, press fit the

bushings into the bracket.

Reassembly

1. Install DOJ case to bracket.

2. Install oil seal and fix snap ring.

Discard the used oil seal, snap ring and install a new one.

3. Install bearing and fix snap ring.

Discard the used snap ring and install a new one.

4. Install bracket to axle case. Tighten the bracket bolt to the specified torque.

Torque : 116 N·m (11.8kgf·m/85 lb·ft)

5. Apply 135g of the specified grease in UJ.

6. Install dust seal for UJ.

Discard the used dust seal and install a new one.

Legend

1. Bellows

2. Shaft

7.

Apply a thin coat of grease to the shaft for smooth

installation then install bellows.

CAUTION :

During bellows assembly, be sure to insert both ends of

the bellows into the case and shaft grooves.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 529 of 6020

FRONT WHEEL DRIVE 4C1-25

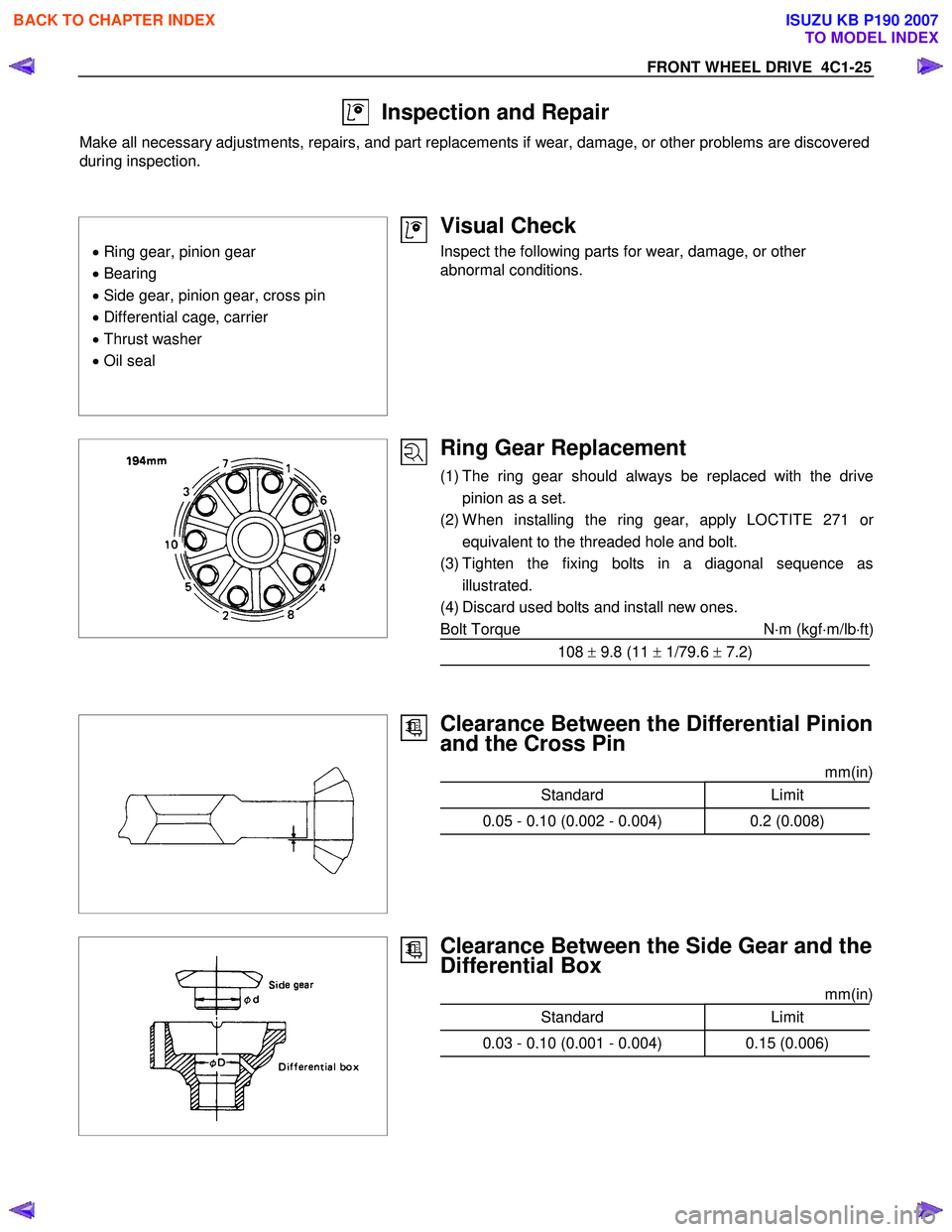

Inspection and Repair

Make all necessary adjustments, repairs, and part replacements if wear, damage, or other problems are discovered

during inspection.

• Ring gear, pinion gear

• Bearing

• Side gear, pinion gear, cross pin

• Differential cage, carrier

• Thrust washer

• Oil seal

Visual Check

Inspect the following parts for wear, damage, or other

abnormal conditions.

Ring Gear Replacement

(1) The ring gear should always be replaced with the drive pinion as a set.

(2) W hen installing the ring gear, apply LOCTITE 271 o

r

equivalent to the threaded hole and bolt.

(3) Tighten the fixing bolts in a diagonal sequence as illustrated.

(4) Discard used bolts and install new ones.

Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

108 ± 9.8 (11 ± 1/79.6 ± 7.2)

Clearance Between the Differential Pinion

and the Cross Pin

mm(in)

Standard Limit

0.05 - 0.10 (0.002 - 0.004) 0.2 (0.008)

Clearance Between the Side Gear and the

Differential Box

mm(in)

Standard Limit

0.03 - 0.10 (0.001 - 0.004) 0.15 (0.006)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 532 of 6020

4C1-28 FRONT WHEEL DRIVE

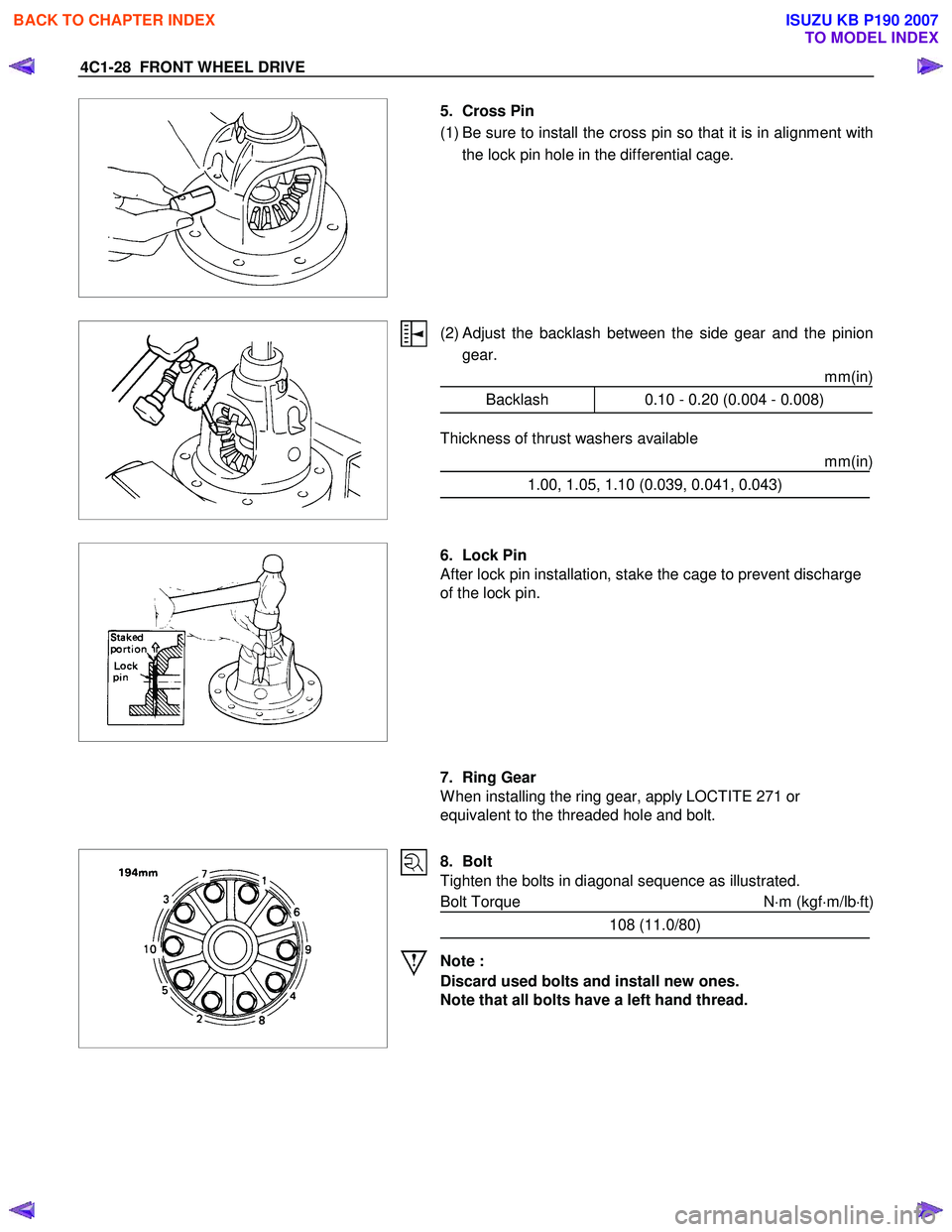

5. Cross Pin

(1) Be sure to install the cross pin so that it is in alignment with the lock pin hole in the differential cage.

(2) Adjust the backlash between the side gear and the pinion

gear. mm(in)

Backlash 0.10 - 0.20 (0.004 - 0.008)

Thickness of thrust washers available

mm(in)

1.00, 1.05, 1.10 (0.039, 0.041, 0.043)

6. Lock Pin

After lock pin installation, stake the cage to prevent discharge

of the lock pin.

7. Ring Gear

W hen installing the ring gear, apply LOCTITE 271 or

equivalent to the threaded hole and bolt.

8. Bolt

Tighten the bolts in diagonal sequence as illustrated.

Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

108 (11.0/80)

Note :

Discard used bolts and install new ones.

Note that all bolts have a left hand thread.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 535 of 6020

FRONT WHEEL DRIVE 4C1-31

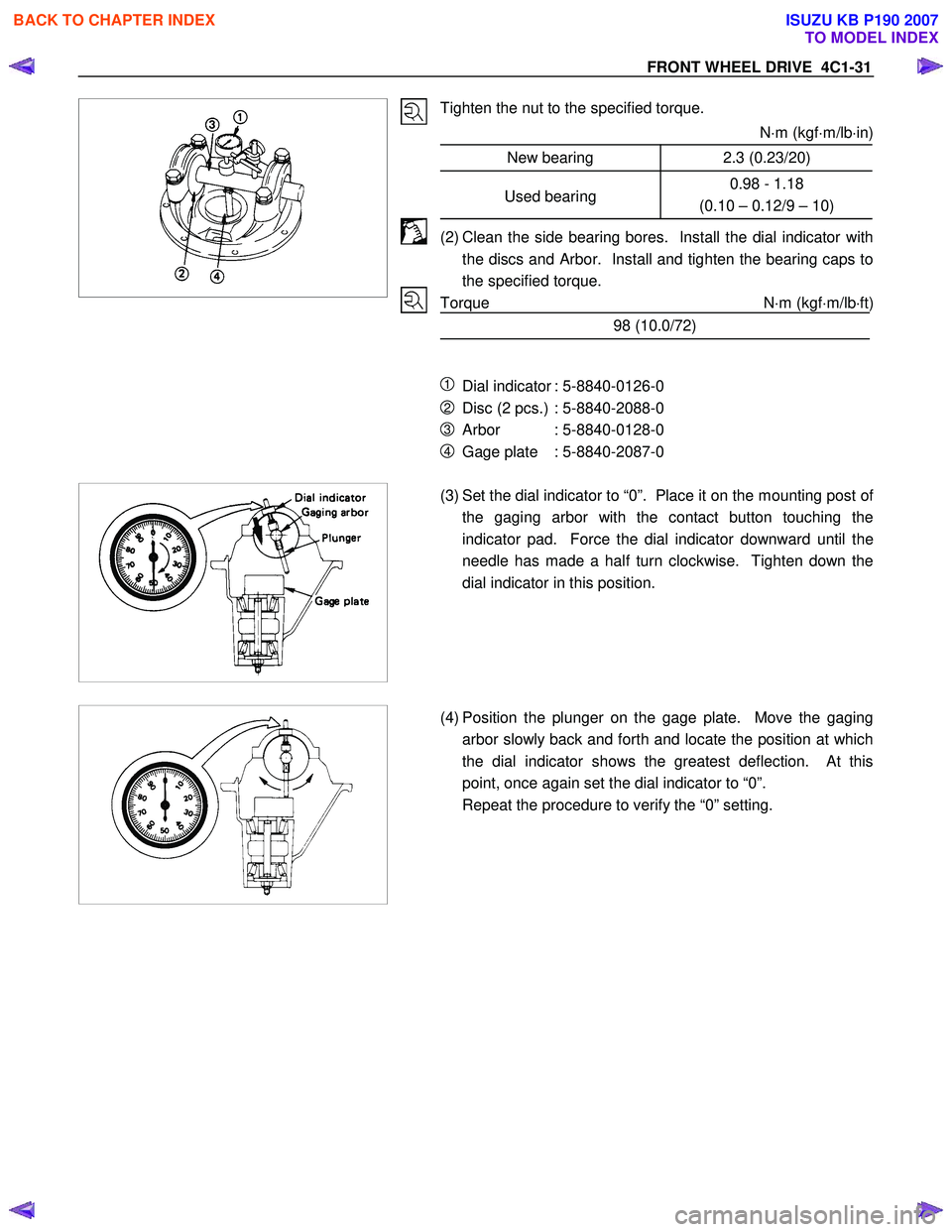

Tighten the nut to the specified torque.

N⋅m (kgf ⋅m/lb ⋅in)

New bearing 2.3 (0.23/20)

Used bearing 0.98 - 1.18

(0.10 – 0.12/9 – 10)

(2) Clean the side bearing bores. Install the dial indicator with the discs and Arbor. Install and tighten the bearing caps to

the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

98 (10.0/72)

1 Dial indicator : 5-8840-0126-0

2 Disc (2 pcs.) : 5-8840-2088-0

3 Arbor : 5-8840-0128-0

4 Gage plate : 5-8840-2087-0

(3) Set the dial indicator to “0”. Place it on the mounting post of

the gaging arbor with the contact button touching the

indicator pad. Force the dial indicator downward until the

needle has made a half turn clockwise. Tighten down the

dial indicator in this position.

(4) Position the plunger on the gage plate. Move the gaging

arbor slowly back and forth and locate the position at which

the dial indicator shows the greatest deflection. At this

point, once again set the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007