ESP ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4443 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-159

Based on each transmission fluid pressure (TFP)

switch signal and each speed sensor signal and the

accelerator pedal angle, the duty cycle type shift

solenoid valve adjusts the clutch pressure to match the

engine load and vehicle running conditions. Controlling

the engagement and disengagement of the clutch and

brake pressure is directly and accurately controlled via

TCM, which is different to the conventional accumulator

type. Instead of the conventional system (On/ Off type

shift solenoid valve and shift valve), the combination of

the duty cycle type solenoid valve and the amplifier

(AMP) valve are used to adjust the clutch pressure to

match the engine load and vehicle driving conditions,

based on the signal from the TCM. Also, the TFP

switch provided in the fluid passage of the control valve

transmits to TCM, enabling the engagement and

disengagement control of the clutch and brake to be

directly and finely. When the gear is shifted from the

2nd to 3rd, 3rd to 4th, 4th to 3rd and 3rd to 2nd, the

clutch pressures on the engagement side and

disengagement side are simultaneously controlled. As

a result, engine racing or clutch drag is prevented

which enables a smooth and quick shift response.

Learning Control

Solenoid valve outputs

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

TCM

Sensor inputs Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Low & reverse brake transmission fluid

pressure (TFP) switch

2-4 brake transmission fluid pressure (TFP)

switch

High clutch transmission fluid pressure (TFP)

switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4457 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-3

Cold Level

The vehicle must not have been driven so that the

temperature reaches around 20 °C (68 °F) before the

cold level check is made.

1. Park the vehicle on a level surface.

2. Apply the parking brake firmly.

3. Start the engine and allow it to warm up.

The engine coolant temperature gauge needle should be midway between the “C” mark and “H”

mark.

4. Let the engine run at idle.

Move the select lever slowly through all the gea

r

ranges.

Stop in each range just long enough for the transmission to engage.

5. Return the select lever either “P” or “N”.

6. Remove the ATF level dipstick.

7. W ipe the dipstick clean with a paper towel.

8. Reinsert the dipstick and wait several seconds.

9. Remove the dipstick.

The ATF level should be inside the “C” range on the dipstick.

If the ATF level is below the “C” range, ATF must be added.

242R300002

ATF CHANGE

1. Park the vehicle on level ground and block the rear

wheels.

2. Start the engine and allow it to idle until the ATF reaches a temperature of 40-50 °C (104-122 °F).

3. Stop the engine.

4. Raise the front to the vehicle and support with suitable safety stands.

5. Remove the drain plug from the oil pan and drain the ATF (approximately 6 liters).

6. Remove the oil pan.

7. Inspect the oil pan (details written below).

8. Install the oil pan.

Note:

Use a new gasket. Clean the oil pan and magnet.

Oil pan bolt torque : 8 N ⋅m (0.8 kgf ⋅m/69 lb ⋅in)

9. Replace the gasket and install the drain plug.

Drain plug torque : 35 N ⋅m (3.6 kgf ⋅m/26 lb ⋅ft)

Note:

Do not reuse the old washer (gasket).

Clean the drain plug (especially the threaded section).

10.Remove the safety stands and wheel blocks.

11.Pour about 5 liters of new ATF.

12. Start the engine. W ith your foot on the brake, move the shift lever through each gear range, and shift to

“P” range.

13.Check the ATF level. Add more ATF carefully as necessary using the dipstick. Refer to “ATF LEVEL”

preciously in this section.

Note:

Keep the engine idle (do not stop it) during the ATF level

adjustment.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4732 of 6020

Manual Transmission (MUX) 7B1-13

16. Install the front propeller shaft. (4x4 model)• Tighten the front propeller shaft bolts to thespecified torque.

Torque: 59 N ⋅m (6.0 kgf ⋅m/43 lb ⋅ft)

17. Install the rear propeller shaft.

• Tighten the rear propeller shaft bolts to thespecified torque.

Torque

Rear flange: 59 N ⋅m (6.0 kgf ⋅m/43 lb ⋅ft)

Center bearing: 69 N ⋅m (7.0 kgf ⋅m/51 lb ⋅ft)

18. Connect harness clip on the transmission left side bracket.

Install the harness bracket bolt.

• Tighten the harness bracket bolt to the specified torque.

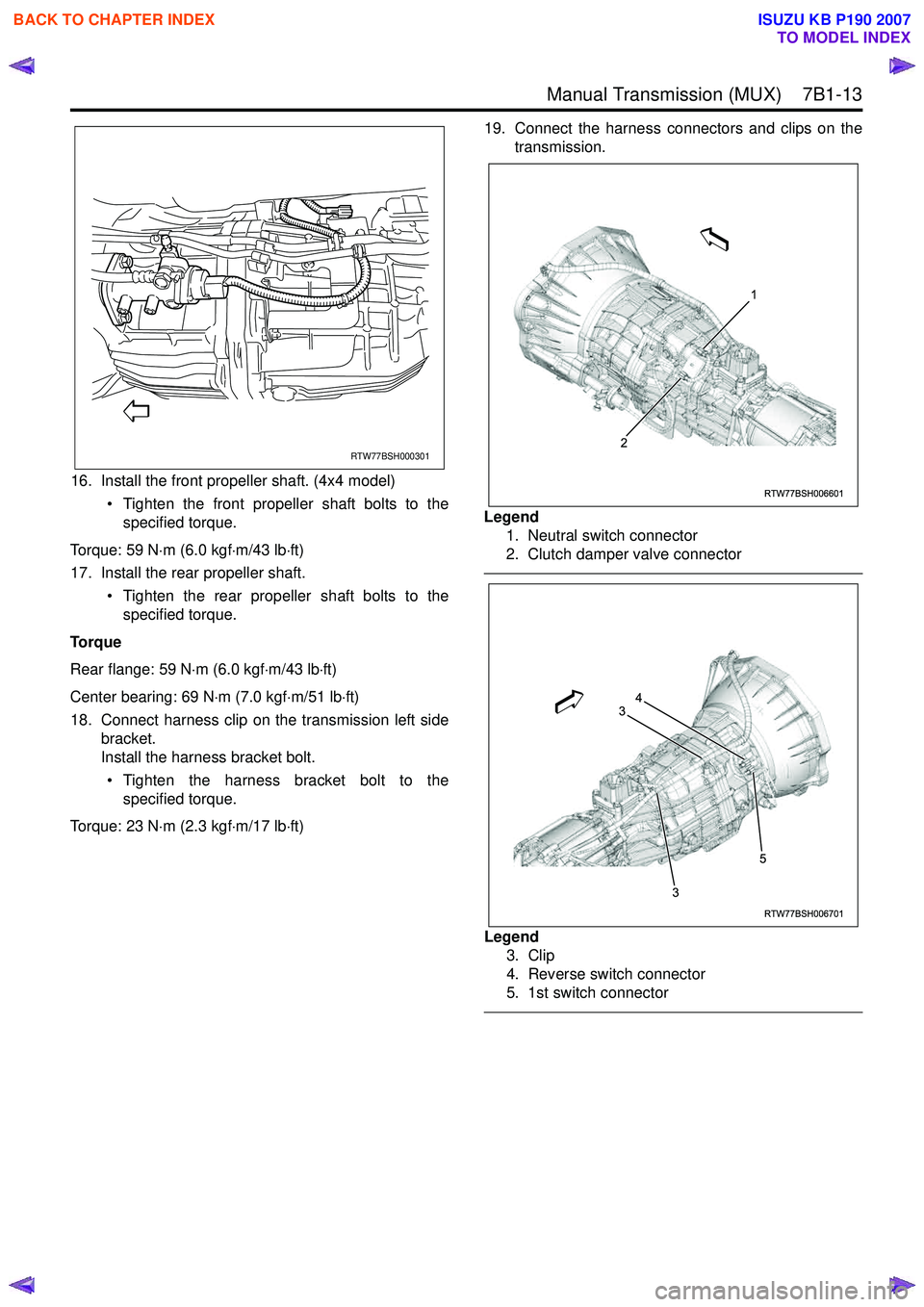

Torque: 23 N ⋅m (2.3 kgf ⋅m/17 lb ⋅ft) 19. Connect the harness connectors and clips on the

transmission.

Legend 1. Neutral switch connector

2. Clutch damper valve connector

Legend 3. Clip

4. Reverse switch connector

5. 1st switch connector

RTW77BSH000301

RTW77BSH006601

1

2

RTW77BSH006701

3

3 54

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4733 of 6020

7B1-14 Manual Transmission (MUX)

Legend6. Car speed sensor conector

7. Clip

8. 2-4 switch connector (4x4 model)

9. Neutral switch connector (4x4 model)

10. Transfer actuator connector (4x4 model)

20. Install the clutch housing cover and clutch bearing dust cover.

• Tighten the clutch housing cover bolts and clutch bearing dust cover bolts to the specified

torque.

Torque: 8 N ⋅m (0.8 kgf ⋅m/69 lb ⋅in)

21. Install the gear control lever (1). • Tighten the gear control lever bolts to thespecified torque.

Torque: 19 N ⋅m (1.9 kgf ⋅m/14 lb ⋅ft)

22. Install the grommet assembly. • Tighten the grommet bolts to the specifiedtorque. Torque

Screw: 1.4 N ⋅m (0.14 kgf ⋅m/12 lb ⋅in)

Nut: 7 N ⋅m (0.7 kgf ⋅m/61 lb ⋅in)

Legend 1. Grommet Assembly

2. Floor Panel

3. Front

23. Install the front floor console. Refer to the section "Floor Console".

24. Install the rear floor console. (Bucket seat) Refer to the section "Floor Console".

RTW77BSH006801

10 9

6

7 8

7

RTW77BSH007101

1

RTW77BMH000101

1

2

3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4751 of 6020

7B1-32 Manual Transmission (MUX)

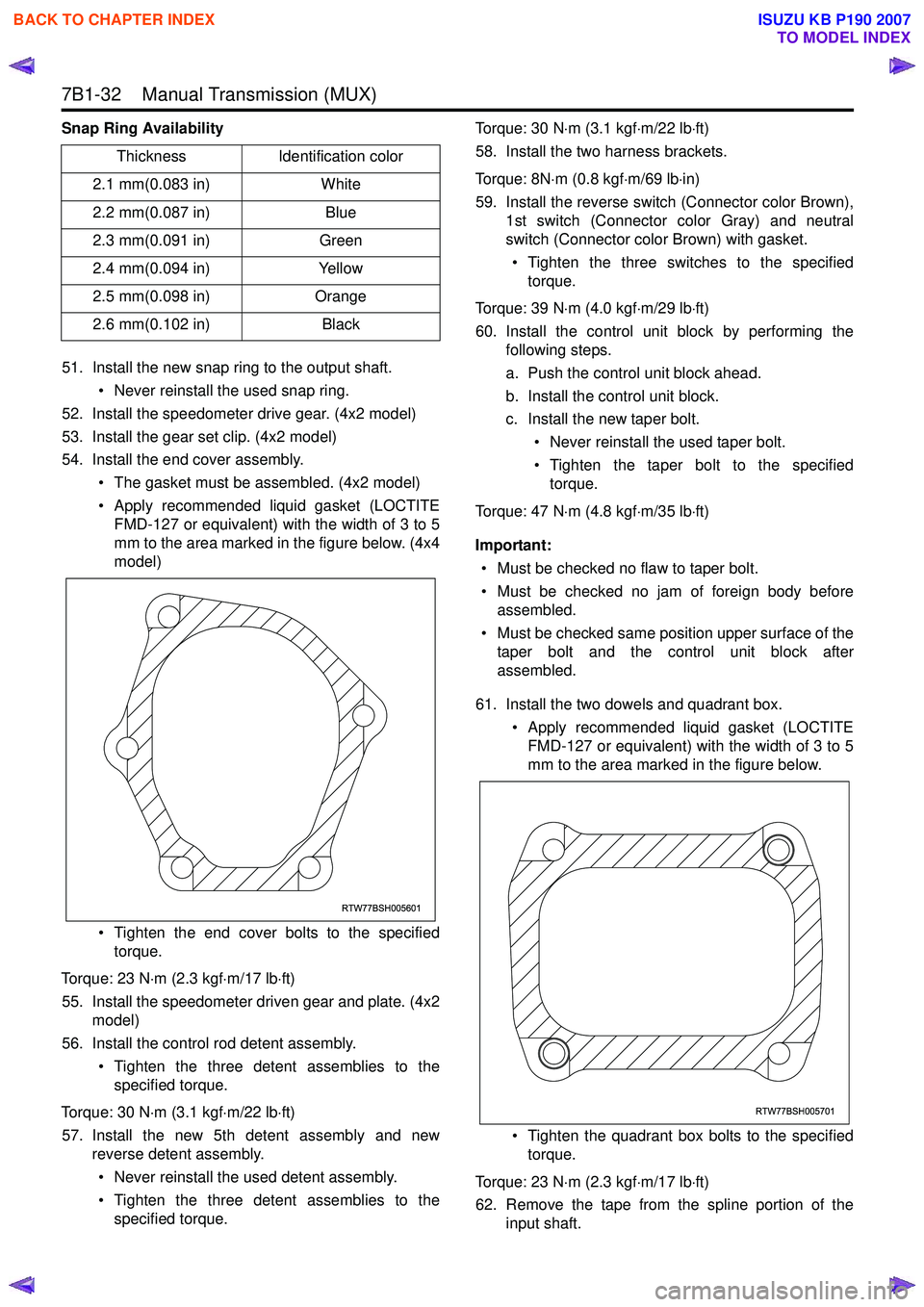

Snap Ring Availability51. Install the new snap ring to the output shaft. • Never reinstall the used snap ring.

52. Install the speedometer drive gear. (4x2 model)

53. Install the gear set clip. (4x2 model)

54. Install the end cover assembly.

• The gasket must be assembled. (4x2 model)

• Apply recommended liquid gasket (LOCTITE FMD-127 or equivalent) with the width of 3 to 5

mm to the area marked in the figure below. (4x4

model)

• Tighten the end cover bolts to the specified torque.

Torque: 23 N ⋅m (2.3 kgf ⋅m/17 lb ⋅ft)

55. Install the speedometer driven gear and plate. (4x2 model)

56. Install the control rod detent assembly.

• Tighten the three detent assemblies to thespecified torque.

Torque: 30 N ⋅m (3.1 kgf ⋅m/22 lb ⋅ft)

57. Install the new 5th detent assembly and new reverse detent assembly.

• Never reinstall the used detent assembly.

• Tighten the three detent assemblies to the specified torque. Torque: 30 N

⋅m (3.1 kgf ⋅m/22 lb ⋅ft)

58. Install the two harness brackets.

Torque: 8N ⋅m (0.8 kgf ⋅m/69 lb ⋅in)

59. Install the reverse switch (Connector color Brown), 1st switch (Connector color Gray) and neutral

switch (Connector color Brown) with gasket.

• Tighten the three switches to the specified torque.

Torque: 39 N ⋅m (4.0 kgf ⋅m/29 lb ⋅ft)

60. Install the control unit block by performing the following steps.

a. Push the control unit block ahead.

b. Install the control unit block.

c. Install the new taper bolt.

• Never reinstall the used taper bolt.

• Tighten the taper bolt to the specified torque.

Torque: 47 N ⋅m (4.8 kgf ⋅m/35 lb ⋅ft)

Important: • Must be checked no flaw to taper bolt.

• Must be checked no jam of foreign body before assembled.

• Must be checked same position upper surface of the taper bolt and the control unit block after

assembled.

61. Install the two dowels and quadrant box. • Apply recommended liquid gasket (LOCTITEFMD-127 or equivalent) with the width of 3 to 5

mm to the area marked in the figure below.

• Tighten the quadrant box bolts to the specified torque.

Torque: 23 N ⋅m (2.3 kgf ⋅m/17 lb ⋅ft)

62. Remove the tape from the spline portion of the input shaft.

Thickness

Identification color

2.1 mm(0.083 in) White

2.2 mm(0.087 in) Blue

2.3 mm(0.091 in) Green

2.4 mm(0.094 in) Yellow

2.5 mm(0.098 in) Orange

2.6 mm(0.102 in) Black

RTW77BSH005601

RTW77BSH005701

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4773 of 6020

7B1-54 Manual Transmission (MUX)

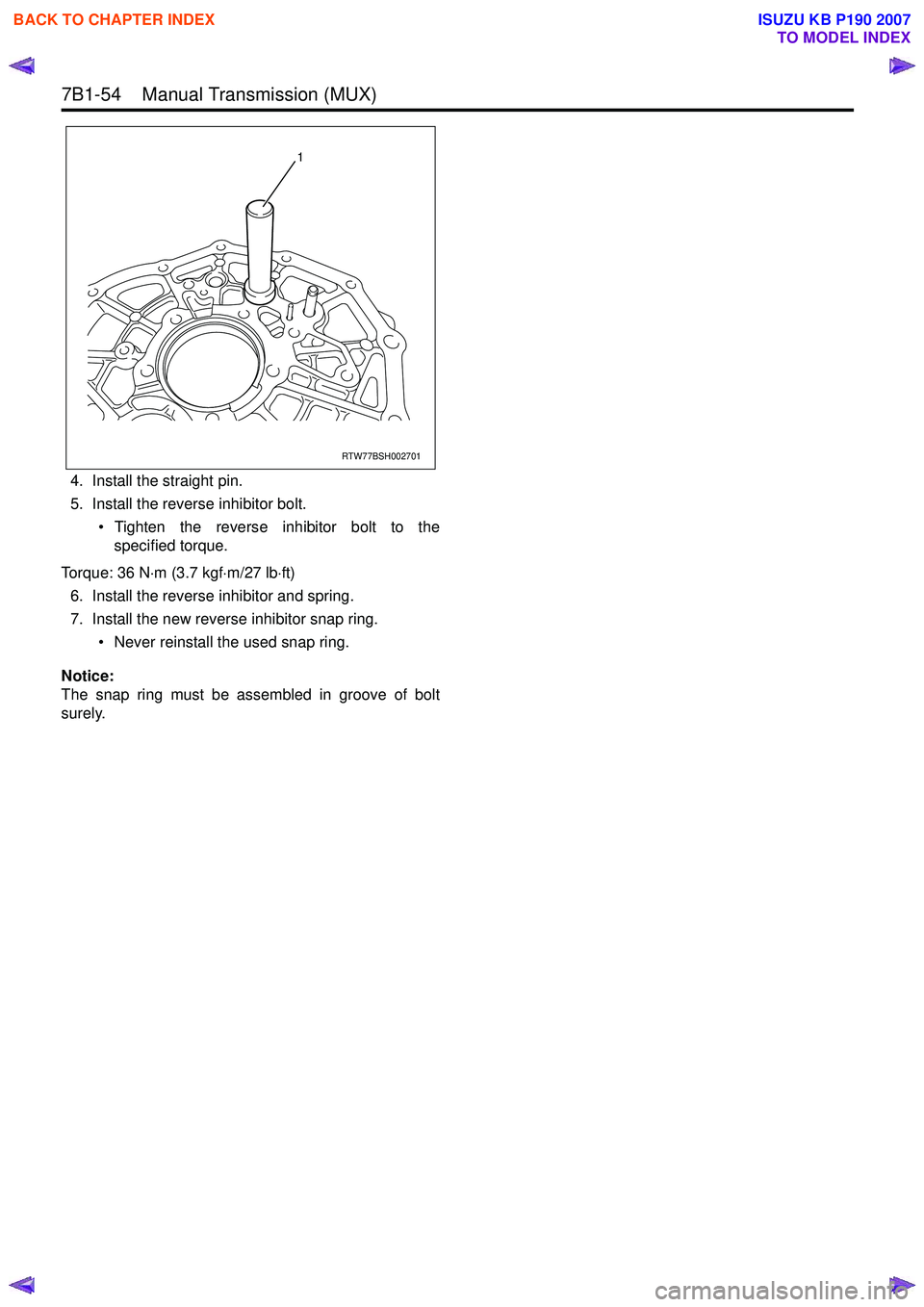

4. Install the straight pin.

5. Install the reverse inhibitor bolt.

• Tighten the reverse inhibitor bolt to thespecified torque.

Torque: 36 N ⋅m (3.7 kgf ⋅m/27 lb ⋅ft)

6. Install the reverse inhibitor and spring.

7. Install the new reverse inhibitor snap ring.

• Never reinstall the used snap ring.

Notice:

The snap ring must be assembled in groove of bolt

surely.

RTW77BSH002701

1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4929 of 6020

TRANSFER CONTROL SYSTEM 7D1-55

Cannot shift from 2WD to 4H or 4L.

When shifting from 2H to other position, the indicator (4WD, 4Lo, Check4WD, neutral)

does not respond.

Step Action Yes No

1 Is the ignition switch ON? Go to step 2.

Turn the ignition switch ON and

trace this chart from the

beginning.

2 Does the transfer-related

indicators (4W D, 4Lo, Check

4W D, neutral) light up for 2

seconds when the ignition switch

is turned ON? Failed operation switch. Or,

Failed controller. Indicator lamp burnt out.

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

Even after correction step 1-1(*), 4WD indicator blinks at 4Hz and changes to 2H after 10

seconds.

Step Action Yes No

1 Is the ignition switch ON? Go to step 2.

Turn the ignition switch ON and

trace this chart from the

beginning.

2 Does the transfer-related

indicators (4W D, 4Lo, Check

4W D, neutral) light up for 2

seconds when the ignition switch

is turned ON? Go to step 3.

Indicator lamp burnt out.

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3 After 2 seconds, check that the

Check4W D lamp is ON or OFF.

Is the Check4W D lamp OFF? Go to step 4.

Failed actuator position detection

switch (LS1, LS2, LS3, LS4,

GND).

Short or disconnection of harness

of this detection switch.

After repairing, trace this chart

from the beginning.

4 Press the 4H button.

Is sound of relay heard from the

transfer control? Go to step 5.

Failed controller.

Replace the controller and trace

this chart from the beginning.

5 Is the sound of a running motor

heard? Failed control system of the

transfer mechanism. Check and

repair and trace this chart from

the beginning. Failed actuator motor.

Disconnected controller motor

drive output circuit, GND short

circuit. +B fuse blown out.

Disconnection of that harness.

After repairing, trace this chart

from the beginning.

*Before determining a trouble (Non-trouble mode)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4932 of 6020

7D1-58 TRANSFER CONTROL SYSTEM

Transfer cannot shift to another position (Except “Check 4WD” failure).

When shifting to another position, indicator (4WD, 4Lo, Check4WD, neutral) does not

respond (Current condition keeping).

Step Action Yes No

1 Is the ignition switch ON? Go to step 2.

Failed indicator and harness

(W hen lighting).

After repairing, trace this chart

from the beginning.

2 Does the transfer-related

indicators (4W D, 4Lo, Check

4W D, neutral) light up for 2

seconds when the ignition switch

is turned ON? Go to step 3.

All indicators are burnt out

(Check for GND short circuit

between the indicator and

transfer controller).

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3 Press the other positions button.

Is the sound of relay heard from

under the seat, and the sound of

a running motor heard? Failed controller.

After replacing the controller,

trace this chart from the

beginning. *Failed operation switch. Or

harness for the operation switch

has disconnected or shorted.

* The operation switch is an analog type switch which reads the internal composite resistance value at the time of operation. If an abnormal value is detected, it is kept at the home position (The position before operating it).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4934 of 6020

7D1-60 TRANSFER CONTROL SYSTEM

Though the indicator responds when shifting from 4H to 2H(or other position), it returns

to 4H.

Step Action Yes No

1 Is the ignition switch ON? Go to step 2.

Turn the ignition switch ON and

trace this chart from the

beginning.

2 Does the transfer-related

indicators (4W D, 4Lo, Check

4W D, neutral) light up for 2

seconds when the ignition switch

is turned ON? Go to step 3.

Indicator lamp burnt out.

Disconnected harness wire.

After repairing, trace this chart

from the beginning.

3 After 2 seconds, check if the

Check4W D lamp lights up.

Is the Check4W D lamp OFF? Go to step 4.

Failed actuator position detection

(limit) switch (LS1, LS2, LS3,

LS4, GND).

Short or disconnection of harness

of this detection switch.

Refer to paragraph of

Check4W D.

After repairing, trace this chart

from the beginning.

4 Press the 2H button.

Is the sound of relay heard from

the transfer controller? Go to step 5.

Failed controller.

Replace the controller and trace

this chart from the beginning.

5 Is the sound of a running motor

heart? Failed control system of the

transfer mechanism. Check and

repair and trace this chart from

the beginning. Failed actuator motor.

Disconnection of controller motor

drive output circuit or GND short.

After repairing, trace this chart

from the beginning.

If the motor does not or cannot run at all (stuck transfer mechanism, disconnected motor, failed drive circuit), the

lamp blinks at 4Hz when the position is shifted to other position by pressing the button for more 10 seconds (20

seconds in case of neutral position).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4956 of 6020

8A-18 ELECTRICAL-BODY AND CHASSIS

CONNECTOR

The connector pin shape determines whether the connector is

male or female.

The connector housing configuration does not determine

whether a connector is male or female.

The symbol illustrated in the figure is used as connector in the

circuit this section.

RTW 78ASH003101

Connector is identified with a number.

RTW 78ASH003201

The applicable terminal number is shown for each connector.

Connector terminal numbers are clearly shown.

Male side connector terminal numbers are in sequence from

upper right to lower left.

Female side connector terminal numbers are in sequence from

upper left to lower right.

NOTE:

For those connectors on which specific terminal numbers

on symbols are shown, the terminal numbers or symbols

are used in the circuit diagram, irrespective of the above

rule.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007