display ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3359 of 6020

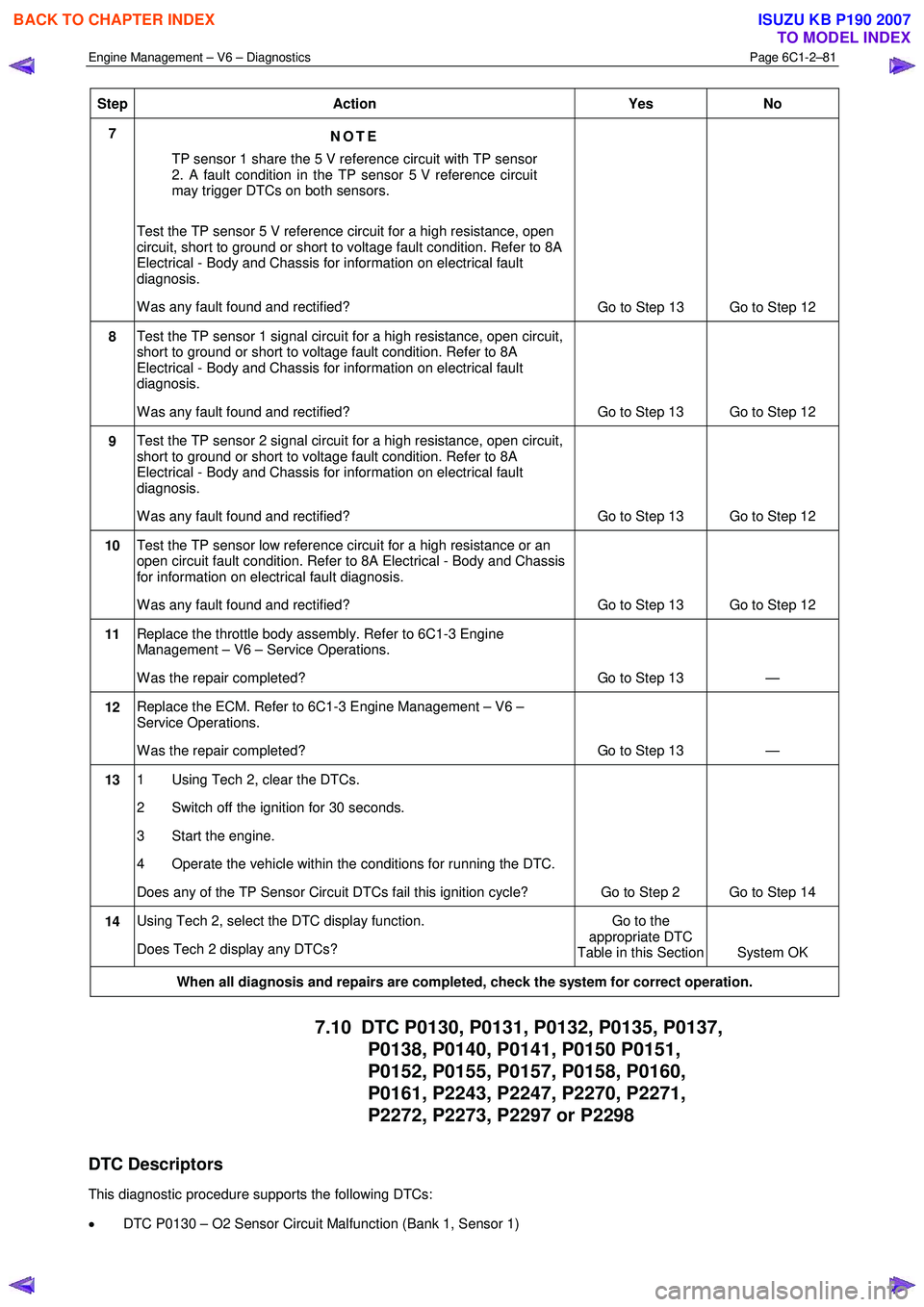

Engine Management – V6 – Diagnostics Page 6C1-2–81

Step Action Yes No

7

NOTE

TP sensor 1 share the 5 V reference circuit with TP sensor

2. A fault condition in the TP sensor 5 V reference circuit

may trigger DTCs on both sensors.

Test the TP sensor 5 V reference circuit for a high resistance, open

circuit, short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 13 Go to Step 12

8 Test the TP sensor 1 signal circuit for a high resistance, open circuit,

short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 13 Go to Step 12

9 Test the TP sensor 2 signal circuit for a high resistance, open circuit,

short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 13 Go to Step 12

10 Test the TP sensor low reference circuit for a high resistance or an

open circuit fault condition. Refer to 8A Electrical - Body and Chassis

for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 13 Go to Step 12

11 Replace the throttle body assembly. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 13 —

12 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 13 —

13 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the TP Sensor Circuit DTCs fail this ignition cycle? Go to Step 2 Go to Step 14

14 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.10 DTC P0130, P0131, P0132, P0135, P0137,

P0138, P0140, P0141, P0150 P0151,

P0152, P0155, P0157, P0158, P0160,

P0161, P2243, P2247, P2270, P2271,

P2272, P2273, P2297 or P2298

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0130 – O2 Sensor Circuit Malfunction (Bank 1, Sensor 1)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3364 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–86

DTC P2243 and P2247

The ECM detects the internal HO2S signal voltage is not 0.2 – 4.7 V.

DTC P2270 and P2272

W hen the ECM detects the HO2S 2 is less than 650 mV for 100 seconds, the ECM enriches the fuel mixture up to 30

percent for 10 seconds. This DTC sets if the ECM detects the HO2S 2 is still less than 650 mV.

DTC P2271 and P2273

W hen the ECM detects the HO2S 2 is greater than 650 mV for 100 seconds, the ECM leans the fuel mixture up to -7

percent for 10 seconds. If this signal voltage is still greater than 650 mV, the ECM tests the HO2S at the next decel fuel

cut-off. This DTC sets if the ECM detects the HO2S 2 signal voltage is greater than 200 mV after 4 seconds in decel fuel

cu-off mode.

DTC P2297 and P2298

The ECM detects the internal HO2S 1 signal voltage is greater than 3.7 V for longer than 10 seconds.

Conditions for Clearing the DTC

The HO2S reference circuit DTCs are Type B DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when Type B DTC sets and conditions for clearing Type B DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the HO2S system operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• The HO2S must be tightened correctly. A loose HO2S will trigger these DTCs.

• A fault condition in the fuel delivery system, air intake system or exhaust system may trigger these DTCs.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P0130 to P0132, P0135 to P0138, P0140, P0141, P0150 to P0152, P0155, P0157, P0158,

P0160, P0161, P2243, P2247, P2270 to P2273, P2297 or P2298 Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been performed? Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Start the engine.

3 Allow the engine to reach the normal operating temperature.

4 Increase the engine speed to 2,000 rpm for 10 seconds or operate the vehicle within the conditions for setting the DTC.

5 Using Tech 2, select the DTC display function.

Does DTC P0130, P0131, P0132, P0135, P0137, P0138, P0140,

P0141, P0150, P0151, P0152, P0155, P0160, P0161, P2243, P2247,

P2270, P2271, P2272, P2273, P2297 or P2298 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Are DTCs relating to the heater circuit of the O2 sensor, also set?

(e.g. P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051,

P0052, P0056, P0057 or P0058) Go to the

appropriate DTC

Table in this Section Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3365 of 6020

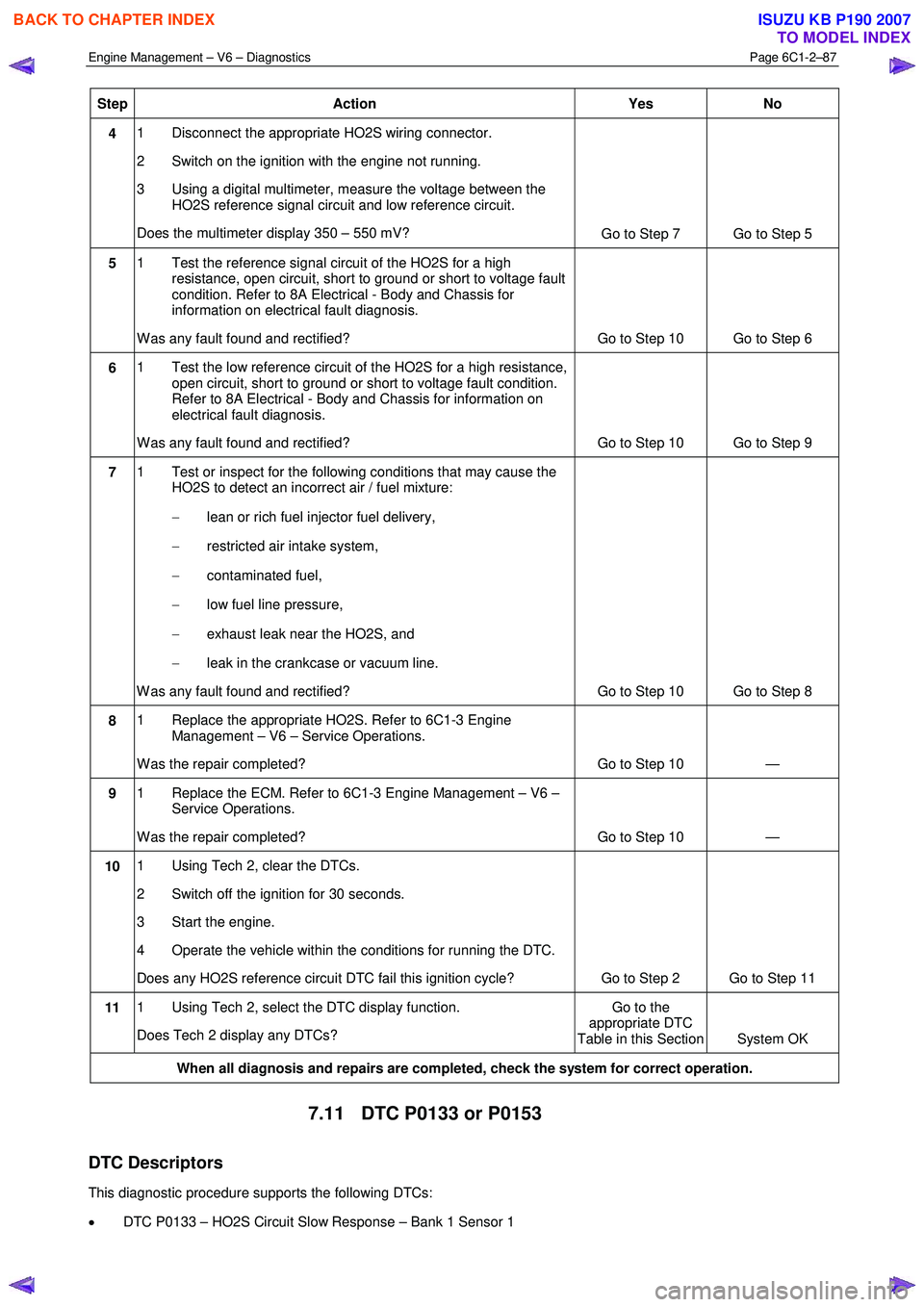

Engine Management – V6 – Diagnostics Page 6C1-2–87

Step Action Yes No

4 1 Disconnect the appropriate HO2S wiring connector.

2 Switch on the ignition with the engine not running.

3 Using a digital multimeter, measure the voltage between the HO2S reference signal circuit and low reference circuit.

Does the multimeter display 350 – 550 mV? Go to Step 7 Go to Step 5

5 1 Test the reference signal circuit of the HO2S for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 6

6 1 Test the low reference circuit of the HO2S for a high resistance,

open circuit, short to ground or short to voltage fault condition.

Refer to 8A Electrical - Body and Chassis for information on

electrical fault diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 9

7 1 Test or inspect for the following conditions that may cause the

HO2S to detect an incorrect air / fuel mixture:

− lean or rich fuel injector fuel delivery,

− restricted air intake system,

− contaminated fuel,

− low fuel line pressure,

− exhaust leak near the HO2S, and

− leak in the crankcase or vacuum line.

W as any fault found and rectified? Go to Step 10 Go to Step 8

8 1 Replace the appropriate HO2S. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 10 —

9 1 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 10 —

10 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any HO2S reference circuit DTC fail this ignition cycle? Go to Step 2 Go to Step 11

11 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.11 DTC P0133 or P0153

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0133 – HO2S Circuit Slow Response – Bank 1 Sensor 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3366 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–88

• DTC P0153 – HO2S Circuit Slow Response – Bank 2 Sensor 1

Circuit Description

The wide band heated oxygen sensor (HO2S) measures the amount of oxygen in the exhaust system and provides

more information than the switching style HO2S. The wide band sensor consists of an oxygen sensing cell, an oxygen

pumping cell, and a heater.

The exhaust gas sample passes through a diffusion gap between the sensing cell and the pumping cell. The engine

control module (ECM) supplies a voltage to the HO2S and uses this voltage as a reference to the amount of oxygen in

the exhaust system. An electronic circuit within the ECM controls the pump current through the oxygen pumping cell to

maintain a constant voltage in the oxygen sensing cell. The ECM monitors the voltage variation in the sensing cell and

attempts to keep the voltage constant by increasing or decreasing the amount of current flow, or oxygen ion flow, to the

pumping cell.

By measuring the amount of current required to maintain the voltage in the sensing cell, the ECM can determine the

concentration of oxygen in the exhaust. The HO2S voltage is displayed as a lambda value. A lambda value of 1 is equal

to a stoichiometric air fuel ratio of 14.7:1. Under normal operating conditions, the lambda value will remain around 1.

W hen the fuel system is lean, the oxygen level will be high and the lambda signal will be high or more than 1. W hen the

fuel system is rich, the oxygen level will be low, and the lambda signal will be low or less than 1. The ECM uses this

information to maintain the correct air / fuel ratio.

Conditions for Running the DTC

• Before the ECM can report DTC P0133 or P0153 failed, DTCs P0121, P0122, P0123, P0221, P0222, P0223,

P0336, P0338, P2237, and P2240 must run and pass.

• DTCs P0030, P0031, P0032, P0050, P0051, P0052, P0053, P0059, P0130, P0131, P0132, P0135, P0150, P0151,

P0151, P0152, P0155, P0442, P0443, P0446, P0455, P0458, P0459, P0496, P167A, P167B, P2096, P2097,

P2098, P2099, P2231, P2234, P2243, P2247, P2251, P2254, P2297, P2298, P2626, and P2629 are not set.

• The HO2S is at operating temperature.

• The HO2S is between 0.94 – 1.06 lambda.

• The engine speed is between 1,480 – 2,040 rpm.

• The volumetric efficiency is between 16.5 – 38.3 percent.

• The change in volumetric efficiency is less than 3 percent.

• The evaporative emission (EVAP) purge is not active, or the ECM determines the EVAP hydrocarbon (HC)

concentration is less than a predetermined amount when EVAP purge is active.

• The long term fuel trim correction is active.

• DTCs P0133 and P0153 run continuously once the above conditions are met for 10 minutes.

Conditions for Setting the DTC

• The ECM has determined that the dynamic value of the affected HO2S is less than a predetermined threshold.

• The above condition is met for more than 4 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that the

diagnostic runs and fails.

• The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic

fails, the control module stores this information in the Failure Records. If the diagnostic reports a failure on the

second consecutive ignition cycle, the control module records the operating conditions at the time of the failure.

The control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the MIL/DTC

• The ECM turns OFF the malfunction indicator lamp (MIL) after four consecutive ignition cycles that the diagnostic

runs and does not fail.

• A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3369 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–91

Step Action Yes No

7 NOTE

If both DTCs are set, determine and correct the cause of

the contamination before replacing a sensor.

1 Inspect for the following conditions:

• Fuel contamination – refer to 6.5 Alcohol / Contaminants

in Fuel Diagnosis in this Section.

• The correct RTV sealant.

• Engine oil consumption – refer to 6A1 Engine Mechanical

– V6.

• Engine coolant consumption – refer to 6B1 Engine Cooling

– V6.

2 Replace the HO2S. Refer to 6C1-3 Engine Management – V6 – Service Operations.

Did you complete the replacement? Go to Step 8 —

8 1 Use Tech 2 to Clear the DTCs.

2 Turn OFF the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you

observed from the Freeze Frame / Failure Records.

Did the DTC fail this ignition? Go to Step 2 Go to Step 9

9 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.12 DTC P0139 or P0159

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0139 – O2 Sensor Circuit Slow Response (Bank 1 Sensor 2)

• DTC P0159 – O2 Sensor Circuit Slow Response (Bank 2 Sensor 2)

Circuit Description

The post catalytic converter heated oxygen sensor (HO2S) produces a voltage that varies between 100 – 900 mV under

normal operating conditions. The engine control module (ECM) produces a bias voltage on the HO2S signal circuit of

420 – -480 mV. The reference ground for the sensor is provided through the ECM.

The ECM monitors the signal voltage to determine if the exhaust is lean or rich. The oxygen sensor voltage is high when

the exhaust is rich, and low when the exhaust is lean. The ECM constantly monitors the HO2S signal during the Closed

Loop operation. If the ECM detects that the decel fuel cut-off rich-to-lean transition time is too long, DTC P0139 will set

for bank 1 sensor 2, or DTC P0159 will set for bank 2 sensor 2.

Conditions for Running the DTC

• DTCs P0021, P0024, P0030, P0031, P0032, P0036, P0037, P0038, P0050, P0051, P0052, P0056, P0057, P0058,

P0101, P0102, P0103, P0106, P0107, P0108, P0116, P0117, P0118, P0121, P0122, P0123, P0125, P0128,

P0131, P0132, P0135, P0137, P0138, P0139, P0140, P0141, P0151, P0152, P0155, P0157, P0158, P0159,

P0160, P0161, P0201-P0208, P0221, P0222, P0223, P0261, P0262, P0264, P0265, P0267, P0268, P0270,

P0271, P0273, P0274, P0276, P0277, P0279, P0280, P0282, P0283, P0300, P0301-P0308, P0335, P0336,

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3373 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–95

16 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? —

Go to the

appropriate DTC Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.13 DTC P0196, P0197 or P0198

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0196 – Engine Oil Temperature Sensor Range / Performance

• DTC P0197 – Engine Oil Temperature Voltage Low

• DTC P0198 – Engine Oil Temperature Voltage High

Circuit Description

The ECM applies a positive 5 V reference voltage to the engine oil temperature (EOT) sensor through the 5 V reference

circuit and the ground through the low reference circuit.

The EOT sensor is a variable resistor that measures the temperature of the engine oil. This sensor provides signal

voltage to the ECM that is proportional to the oil temperature off the engine.

The ECM monitors and compares the EOT sensor signal voltage against a specified range. An EOT sensor circuit DTC

sets if the ECM detects the EOT sensor signal voltage is outside the specified range.

Conditions for Running the DTC

DTC P0196, P0197 and P0198 run continuously when the engine is running.

Conditions for Setting the DTC

DTC P0196

The ECM detects the engine oil temperature sensor is not within 100 °C of the modelled temperature

NOTE

The modelled temperature is the temperature

that the ECM expects to see given current engine

operating conditions.

DTC P0197

The ECM detects the engine oil temperature is less than -35 °C for longer than 3 seconds.

DTC P0198

The ECM detects the engine oil temperature is greater than 170 °C for longer than 3 seconds.

Conditions for Clearing DTC

The EOT sensor circuit DTCs are Type C DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when a Type C DTC sets and conditions for clearing Type C DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the EOT sensor operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3374 of 6020

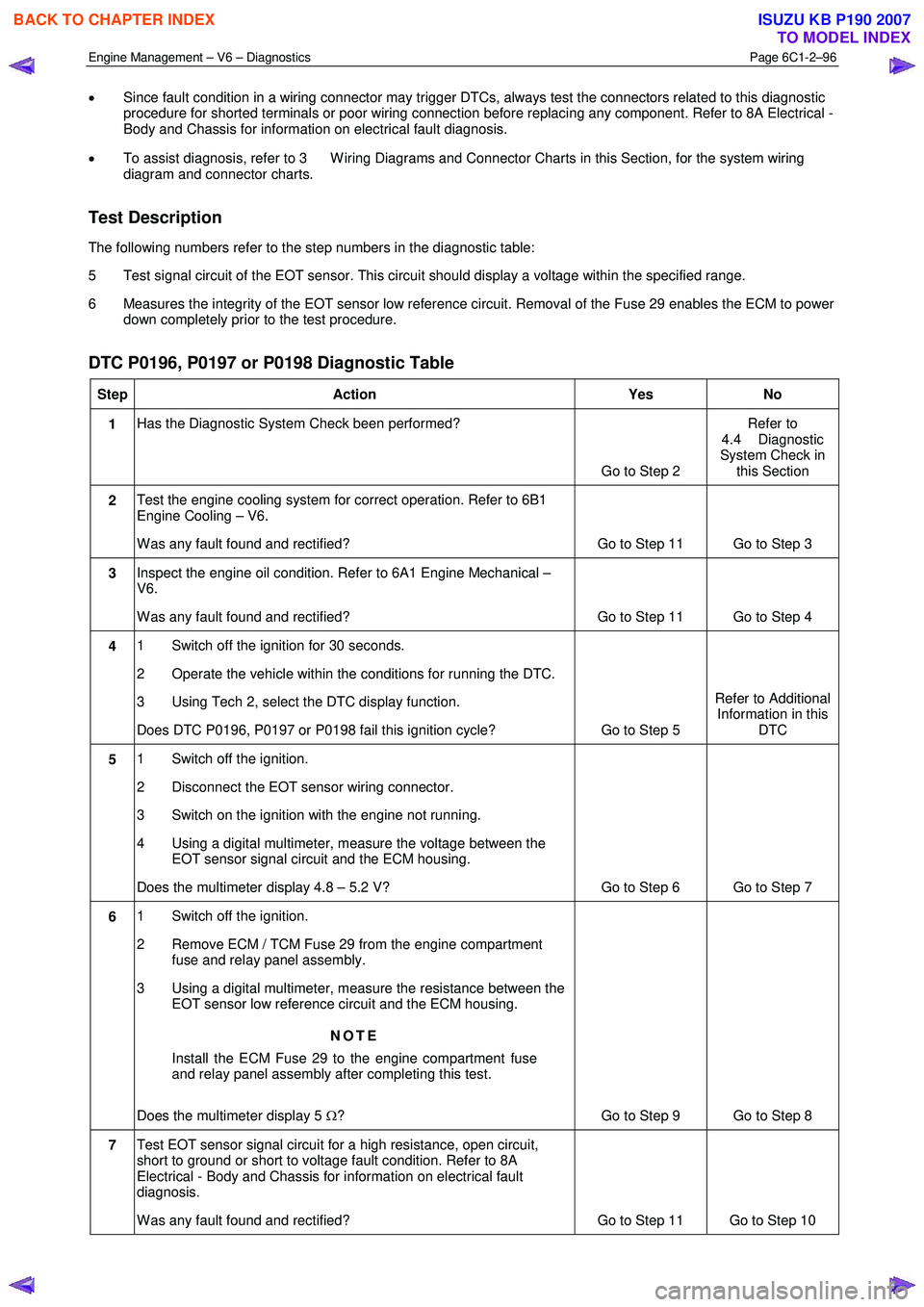

Engine Management – V6 – Diagnostics Page 6C1-2–96

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

5 Test signal circuit of the EOT sensor. This circuit should display a voltage within the specified range.

6 Measures the integrity of the EOT sensor low reference circuit. Removal of the Fuse 29 enables the ECM to power down completely prior to the test procedure.

DTC P0196, P0197 or P0198 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 Test the engine cooling system for correct operation. Refer to 6B1

Engine Cooling – V6.

W as any fault found and rectified? Go to Step 11 Go to Step 3

3 Inspect the engine oil condition. Refer to 6A1 Engine Mechanical –

V6.

W as any fault found and rectified? Go to Step 11 Go to Step 4

4 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0196, P0197 or P0198 fail this ignition cycle? Go to Step 5 Refer to Additional

Information in this DTC

5 1 Switch off the ignition.

2 Disconnect the EOT sensor wiring connector.

3 Switch on the ignition with the engine not running.

4 Using a digital multimeter, measure the voltage between the EOT sensor signal circuit and the ECM housing.

Does the multimeter display 4.8 – 5.2 V? Go to Step 6 Go to Step 7

6 1 Switch off the ignition.

2 Remove ECM / TCM Fuse 29 from the engine compartment fuse and relay panel assembly.

3 Using a digital multimeter, measure the resistance between the EOT sensor low reference circuit and the ECM housing.

NOTE

Install the ECM Fuse 29 to the engine compartment fuse

and relay panel assembly after completing this test.

Does the multimeter display 5 Ω? Go to Step 9 Go to Step 8

7 Test EOT sensor signal circuit for a high resistance, open circuit,

short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3375 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–97

Step Action Yes

No

8 Test the EOT sensor low reference circuit for a high resistance and

open circuit fault condition. Refer to 8A Electrical - Body and Chassis

for information on electrical fault diagnosis.

NOTE

The EOT sensor shares the low reference circuit with

other sensors. A fault condition in the low reference circuit

may trigger DTCs on sensors that share this circuit. Refer

to 3 W iring Diagrams and Connector Charts in this

Section, to assist diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

9 Replace the EOT sensor. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 11 —

10 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 11 —

11 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the conditions for the engine oil pressure sensor circuit

DTCs fail this ignition cycle? Go to Step 2 Go to Step 12

12 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.14 DTC P0201, P0202, P0203, P0204, P0205,

P0206, P0261, P0262, P0264, P0265,

P0267, P0268, P0270, P0271, P0273,

P0274, P0276 or P0277

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0201 – Injector 1 Control Circuit Malfunction

• DTC P0202 – Injector 2 Control Circuit Malfunction

• DTC P0203 – Injector 3 Control Circuit Malfunction

• DTC P0204 – Injector 4 Control Circuit Malfunction

• DTC P0205 – Injector 5 Control Circuit Malfunction

• DTC P0206 – Injector 6 Control Circuit Malfunction

• DTC P0261 – Injector 1 Control Circuit Low Voltage

• DTC P0262 – Injector 1 Control Circuit High Voltage

• DTC P0264 – Injector 2 Control Circuit Low Voltage

• DTC P0265 – Injector 2 Control Circuit High Voltage

• DTC P0267 – Injector 3 Control Circuit Low Voltage

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3377 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–99

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 Determines if there is a fault condition in the ignition voltage supply circuit. The fuel injectors for each bank of the engine are fused separately. If all DTCs for a single bank are set, there may be a fault in one of the ignition supply

circuits.

5 Verifies the ECM is sending control voltage to the fuel injector.

6 Tests if the feed back voltage circuit within the ECM is providing the correct voltage.

DTC P0201 to P0206, P0261, P0262, P0264, P0265, P0267, P0268, P0270, P0271, P0273,

P0274, P0276 and P0277 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Start the engine.

3 Using Tech 2, select the DTC display function.

Does DTC P0201, P0202, P0203, P0204, P0205, P0206, P0261,

P0262, P0264, P0265, P0267, P0268, P0270, P0271, P0273, P0274,

P0276 or P0277 set? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Disconnect the fuel injector interconnect harness connector.

Refer to 6C1-3 Engine Management – V6 – Service Operations.

2 Switch on the ignition with the engine not running.

3 Connect a test lamp between the ignition voltage circuit of the appropriate fuel injector, ECM side of the interconnect

connector, and the ECM housing.

Does the test lamp illuminate? Go to Step 4 Go to Step 5

4 1 Switch on the ignition with the engine not running.

2 Using a digital multimeter, measure the voltage between the appropriate fuel injector control circuit, ECM side of the

interconnect connector, and the ECM housing.

Does the multimeter display 2.6 – 4.6 mV? Go to Step 7 Go to Step 6

5 Repair the open circuit or short to ground fault condition in the ignition

voltage circuit of the appropriate fuel injector. Refer to 8A Electrical -

Body and Chassis for information on electrical wiring repair

procedures.

W as the repair completed? Go to Step 10 —

6 Test the control circuit of the appropriate fuel injector, between the

interconnect connector and the ECM, for a high resistance, open

circuit, short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3378 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–100

Step Action Yes No

7 1 Remove the upper intake manifold. Refer to 6A1-Engine

Mechanical – V6.

2 Test the control circuit and the ignition voltage circuit of the appropriate fuel injector, between the interconnect connector

and the appropriate fuel injector connector, for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 8

8 Replace the appropriate fuel injector. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 10 —

9 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 10 —

10 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the fuel injector control circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 11

11 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.15 DTC P0219

DTC Descriptor

This diagnostic procedure supports DTC P0219 – Engine Overspeed Condition.

Circuit Description

The ECM continually monitors the engines operating environment. A engine over-speed condition DTC sets if the ECM

detects an engine speed in excess of 7200 RPM.

NOTE

An over-speed condition will occur when a low

gear on a manual transmission vehicle has been

selected whilst the vehicle is travelling at high

road speed. This DTC will not set if the engine is

free-revved as the ECM will limit engine speed.

Conditions for Running the DTC

DTC P0219 runs continuously when the following conditions are met:

• The vehicle is fitted with a manual transmission

• The engine is running.

• The ignition voltage is between 10.0 – 16.0 V.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007