engine coolant ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1728 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-111

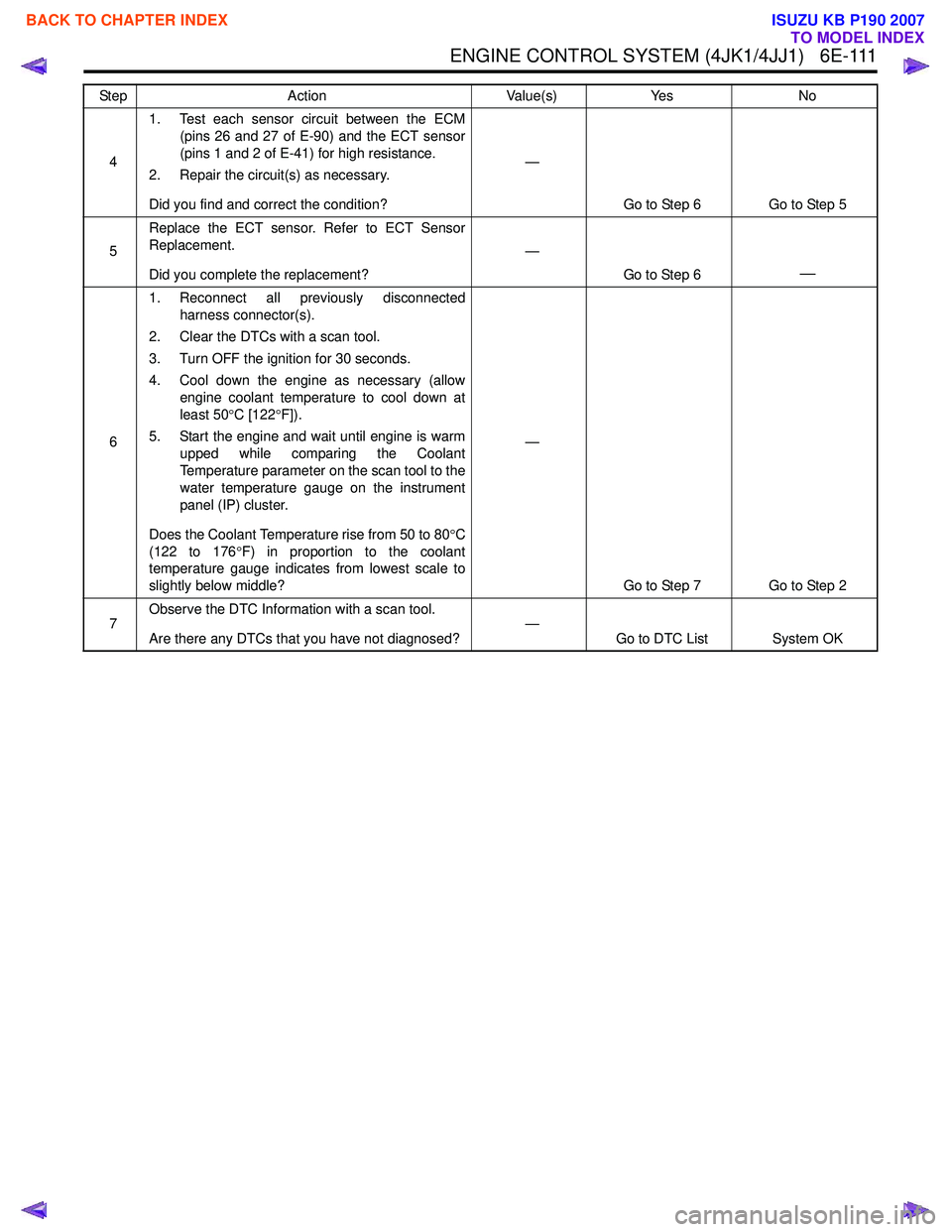

41. Test each sensor circuit between the ECM

(pins 26 and 27 of E-90) and the ECT sensor

(pins 1 and 2 of E-41) for high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Step 5

5 Replace the ECT sensor. Refer to ECT Sensor

Replacement.

Did you complete the replacement? —

Go to Step 6

—

61. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Cool down the engine as necessary (allow engine coolant temperature to cool down at

least 50 °C [122 °F]).

5. Start the engine and wait until engine is warm upped while comparing the Coolant

Temperature parameter on the scan tool to the

water temperature gauge on the instrument

panel (IP) cluster.

Does the Coolant Temperature rise from 50 to 80 °C

(122 to 176 °F) in proportion to the coolant

temperature gauge indicates from lowest scale to

slightly below middle? —

Go to Step 7 Go to Step 2

7 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1729 of 6020

6E-112 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0117 or P0118 (Flash Code 23)

Circuit Description

The engine coolant temperature (ECT) sensor is

installed to the thermostat housing. The ECT sensor is

a variable resistor and it measures the temperature of

the engine coolant. The sensor has a signal circuit and

a low reference circuit. The ECM supplies 5 volts to the

signal circuit and a ground for the low reference circuit.

When the ECT sensor is cold, the sensor resistance is

high. When the engine coolant temperature increases,

the sensor resistance decreases. With high sensor

resistance, the ECM detects a high voltage on the

signal circuit. With lower sensor resistance, the ECM

detects a lower voltage on the signal circuit. If the ECM

detects an excessively low or high signal voltage, DTC

P0117 or P0118 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine run time is longer than 3 minutes. (DTC P0118)

Condition for Setting the DTC • The ECM detects that the ECT sensor signal voltage is less than 0.1 volts for 3 seconds. (DTC

P0117)

• The ECM detects that the ECT sensor signal voltage is more than 4.75 volts for 3 seconds.

(DTC P0118) Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM uses an ECT substitution of default value.

• The ECM limits fuel injection quantity.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Use the Temperature vs. Resistance table to test the ECT sensor at various temperature levels to

evaluate the possibility of a skewed sensor. A

skewed sensor could result in poor driveability

concerns.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0117

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Observe the Engine Coolant Temperature (ECT) Sensor parameter with a scan tool.

Is the ECT Sensor parameter less than the

specified value? 0.1 volts

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the ECT sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

Is the ECT Sensor parameter more than the

specified value? 4.7 volts

Go to Step 5 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1730 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-113

Circuit/ System Testing DTC P0118

41. Test the signal circuit between the ECM (pin

27 of E-90) and the ECT sensor (pin 1 of E-

41) for the following conditions:

• A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 6

5 Replace the ECT sensor. Refer to ECT Sensor

Replacement.

Did you complete the replacement? —

Go to Step 8

—

61. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect connections at the harness connector of the ECM (pins 26 and 27 of E-90) for

corrosion.

4. Repair or clean the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 8 Go to Step 7

7 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 8

—

81. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 9

9 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Observe the Engine Coolant Temperature (ECT) Sensor parameter with a scan tool.

Is the ECT Sensor parameter more than the

specified value? 4.7 volts

Go to Step 3 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1731 of 6020

6E-114 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

31. Turn OFF the ignition.

2. Disconnect the ECT sensor harness connector.

3. Connect a DMM between the signal circuit (pin 1 of E-41) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 5.3 volts

Go to Step 4 Go to Step 5

4 Important:

The ECT sensor may be damaged if

the sensor signal circuit is shorted to a voltage

source.

1. Test the signal circuit between the ECM (pin 27 of E-90) and the ECT sensor (pin 1 of E-

41) for a short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 13

5 Connect a 3-amp fused jumper wire between the

signal circuit and the low reference circuit (pins 1

and 2 of E-41).

Is the Engine Coolant Temperature Sensor

parameter less than the specified value? 0.1 volts

Go to Step 9 Go to Step 6

6 Connect a 3-amp fused jumper wire between the

signal circuit (pin 1 of E-41) and a known good

ground.

Is the Engine Coolant Temperature Sensor

parameter less than the specified value? 0.1 volts

Go to Step 8 Go to Step 7

7 1. Test the signal circuit between the ECM (pin

27 of E-90) and the ECT sensor (pin 1 of E-

41) for an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 11

8 1. Test the low reference circuit between the

ECM (pin 26 of E-90) and the ECT sensor (pin

2 of E-41) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 11

9 1. Test the signal circuit between the ECM (pin

27 of E-90) and the ECT sensor (pin 1 of E-

41) for a short to any 5 volts reference circuit.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 10

10 1. Inspect for an intermittent and for poor

connections at the harness connector of the

ECT sensor (pins 1 and 2 of E-41).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 12

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1737 of 6020

6E-120 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0182 or P0183 (Flash Code 211)

Circuit Description

The fuel temperature (FT) sensor is installed to the fuel

supply pump. The FT sensor is a variable resistor and it

measures the temperature of the fuel entering the fuel

supply pump. The sensor has a signal circuit and a low

reference circuit. The ECM supplies 5 volts to the

signal circuit and a ground for the low reference circuit.

When the FT sensor is cold, the sensor resistance is

high. When the fuel temperature increases, the sensor

resistance decreases. With high sensor resistance, the

ECM detects a high voltage on the signal circuit. With

lower sensor resistance, the ECM detects a lower

voltage on the signal circuit. If the ECM detects an

excessively low or high signal voltage, DTC P0182 or

P0183 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine run time is longer than 3 minutes. (DTC P0183)

Condition for Setting the DTC • The ECM detects that the FT sensor signal voltage is less than 0.1 volts for 3 seconds. (DTC P0182)

• The ECM detects that the FT sensor signal voltage is more than 4.75 volts for 3 seconds. (DTC

P0183) Action Taken When the DTC Sets

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM uses a FT substitution of default value.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • Before starting a cold engine, FT sensor and engine coolant temperature (ECT) sensor

temperature should be relatively close to each

other.

• If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Use the Temperature vs. Resistance table to test the FT sensor at various temperature levels to

evaluate the possibility of a skewed sensor. A

skewed sensor could result in poor driveability

concerns.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0182

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Observe the Fuel Temperature (FT) Sensor parameter with a scan tool.

Is the FT Sensor parameter less than the specified

value? 0.1 volts

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the FT sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

Is the FT Sensor parameter more than the

specified value? 4.7 volts

Go to Step 5 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1752 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-135

DTC P0217 (Flash Code 542)

Circuit Description

The engine coolant temperature (ECT) sensor is

installed to the thermostat housing. The ECT sensor is

a variable resistor and it measures the temperature of

the engine coolant. If the ECM detects an excessive

high coolant temperature, this DTC will set.

Condition for Running the DTC • DTCs P0116, P0117 and P0118 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC • The ECM detects that the engine coolant temperature is more than 110 °C (230 °F) for 5

seconds.

Action Taken When the DTC Sets • The ECM will not illuminate the MIL or SVS lamp. Refer to DTC Type Definitions for Action Taken

When the DTC Sets - Type D. Condition for Clearing the DTC

• Refer to DTC Type Definitions for Condition for Clearing the DTC - Type D.

Diagnostic Aids • After starting the engine, the ECT should rise steadily to about 80 to 85 °C (176 to 185 °F) then

stabilize when the thermostat opens.

• Use the Temperature vs. Resistance table to test the ECT sensor at various temperature levels to

evaluate the possibility of a skewed sensor. A

skewed sensor could result in poor driveability

concerns.

• The Total Engine Coolant Overtemperature Events parameter on scan tool indicates number of

overheat events.

Notice: • This DTC is caused by an engine overheat condition (e.g. low engine coolant level). Since this

DTC does not illuminate any lamps, clear the DTC

and ensure there are no signs of engine damage.

Excessive engine overheat may damage internal

engine components.

Circuit/ System Testing DTC P0217

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0117 also set? —

Go to DTC P0117 Go to Step 3

3 1. Test the engine cooling system for the

following condition. Refer to diagnosis of the

engine cooling system section for testing.

• Engine coolant level

• Engine coolant leakage

• Cooling fan belt slippage

• Cooling fan clutch working

• Thermostat working

• Water pump working

• Radiator clogging

2. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 4

4 Start the engine and wait until engine is fully warm

upped while observing the Coolant Temperature

parameter with a scan tool.

Does the scan tool indicate more than the specified

value? 11 0

°C (230 °F)

Go to Step 6 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1753 of 6020

6E-136 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

5Ask the driver if overheat is caused by low engine

coolant level, etc.

If engine overheat has experienced, the engine

must be inspected and repaired as necessary.

Did you complete the action? —

Go to Step 7

—

61. Test the engine coolant temperature (ECT)

sensor at various temperature levels to

evaluate the possibility of a skewed sensor.

2. Replace the ECT sensor as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Diagnostic

Aids

7 1. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and wait until engine is fully warm upped while observing the Coolant

Temperature parameter with a scan tool.

Does the scan tool indicate more than the specified

value? 11 0

°C (230 °F)

Go to Step 2 Go to Step 8

8 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1775 of 6020

6E-158 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0380 (Flash Code 66)

Circuit Description

The ECM controls the glow relay which supplies power

to the glow plugs based on engine coolant

temperature. In the after glow phase, the glow indicator

light is not illuminated but glow plugs remain active for

a certain period. If the ECM detects an open circuit or

short circuit on the relay control circuit, this DTC will

set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The ECM detects a low voltage condition on the glow relay control circuit for longer than 3 second

when the relay is commanded OFF.

• The ECM detects a high voltage condition on the glow relay control circuit for longer than 3 second

when the relay is commanded ON.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Test Description

The numbers below refers to the step number on the

Circuit/ System Testing.

2. Listen for an audible click when the glow relay

operates. Command both the ON and OFF states.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0380

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Perform the Glow Relay Control with a scan tool.

3. Command the relay ON and OFF.

Does the glow relay click with each command? —

Go to Step 3 Go to Step 4

3 1. Turn OFF the ignition for 30 seconds.

2. Disconnect the engine coolant temperature (ECT) sensor harness connector in order to

gain glow ON time long enough.

3. Turn ON the ignition for 30 seconds while observing the DTC Information with a scan

tool.

Does the DTC P0380 fail this ignition? —

Go to Step 11 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1778 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-161

DTC P0401 (Flash Code 93)

Circuit Description

The ECM controls the EGR valve opening based on the

engine running condition and by controlling the EGR

solenoid. The EGR valve position is detected by the

position sensor, and relayed to the ECM. When the

proper enabling conditions are met, the ECM will open

the EGR valve while monitoring the mass air flow

(MAF) signal. An expected MAF difference should be

detected between the closed and open positions. If the

ECM detects the MAF difference less than expected,

this DTC will set. This DTC will only run once per

ignition cycle within the enabling conditions.

Condition for Running the DTC • DTCs P0101, P0102, P0103, P0112, P0113, P0116, P0117, P0118, P0122, P0123, P0403,

P0404, P0405, P0406, P0500, P0501, P0652,

P0653, P0698, P0699, P2100, P2101, P2102,

P2103, P2227, P2228 and P2229 are not set.

• The battery voltage is between 10 to 16 volts.

• The ignition switch is ON. Condition for Setting the DTC

• The ECM detects that the MAF amount is not within the calculated range during the EGR flow

test. This indicates insufficient amount of EGR

flow.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• A sticking or intermittently sticking the EGR valve may set this DTC.

Circuit/ System Testing DTC P0401

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and warm up as necessary (allow engine coolant temperature to reach at

least 60 °C [140 °F]).

4. Perform the EGR Solenoid Control with a scan tool.

5. Command the Desired EGR Position Increase or Decrease while observing the Mass Air

Flow (MAF) Sensor parameter with a scan

tool.

Does the MAF Sensor parameter decrease by at

least 0.5 volts when the Desired EGR Position is

commanded from 0 to 90%? —

Go to Diagnostic Aids Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1779 of 6020

6E-162 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

31. Inspect the following conditions:

• An EGR valve gasket that is missing ordamaged

• A sticking EGR valve

• EGR gas leakage from any of the EGR passages between the exhaust manifold

and intake manifold

• Restricted or collapsed EGR passage between the exhaust manifold and the

EGR valve

• Any type of restriction in the exhaust system

• Restricted air cleaner element, restricted or collapsed air tubing between the air

cleaner and the intake manifold

• Any air induction leak

• Any water intrusion in the induction system

• Any contamination or objects that block the MAF sensor inlet

• Skewed or slow MAF sensor

• A ventilation duct that is connected to the exhaust tail pipe. Retest without the duct

if connected.

2. Repair or replace as necessary

Did you find and correct the condition? —

Go to Step 5 Go to Step 4

4 Replace the EGR valve. Refer to EGR Valve

Replacement.

Did you complete the replacement? —

Go to Step 5

—

51. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and warm up as necessary (allow engine coolant temperature to reach at

least 60 °C [140 °F]).

5. Perform the EGR Solenoid Control with a scan tool.

6. Command the Desired EGR Position Increase or Decrease while observing the MAF Sensor

parameter with a scan tool.

Does the MAF parameter decrease by at least 0.5

volts when the Desired EGR Position is

commanded from 0 to 90%? —

Go to Step 6 Go to Step 3

6 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007