fuel type ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2005 of 6020

ENGINE DIAGNOSIS (C24SE) 6-5

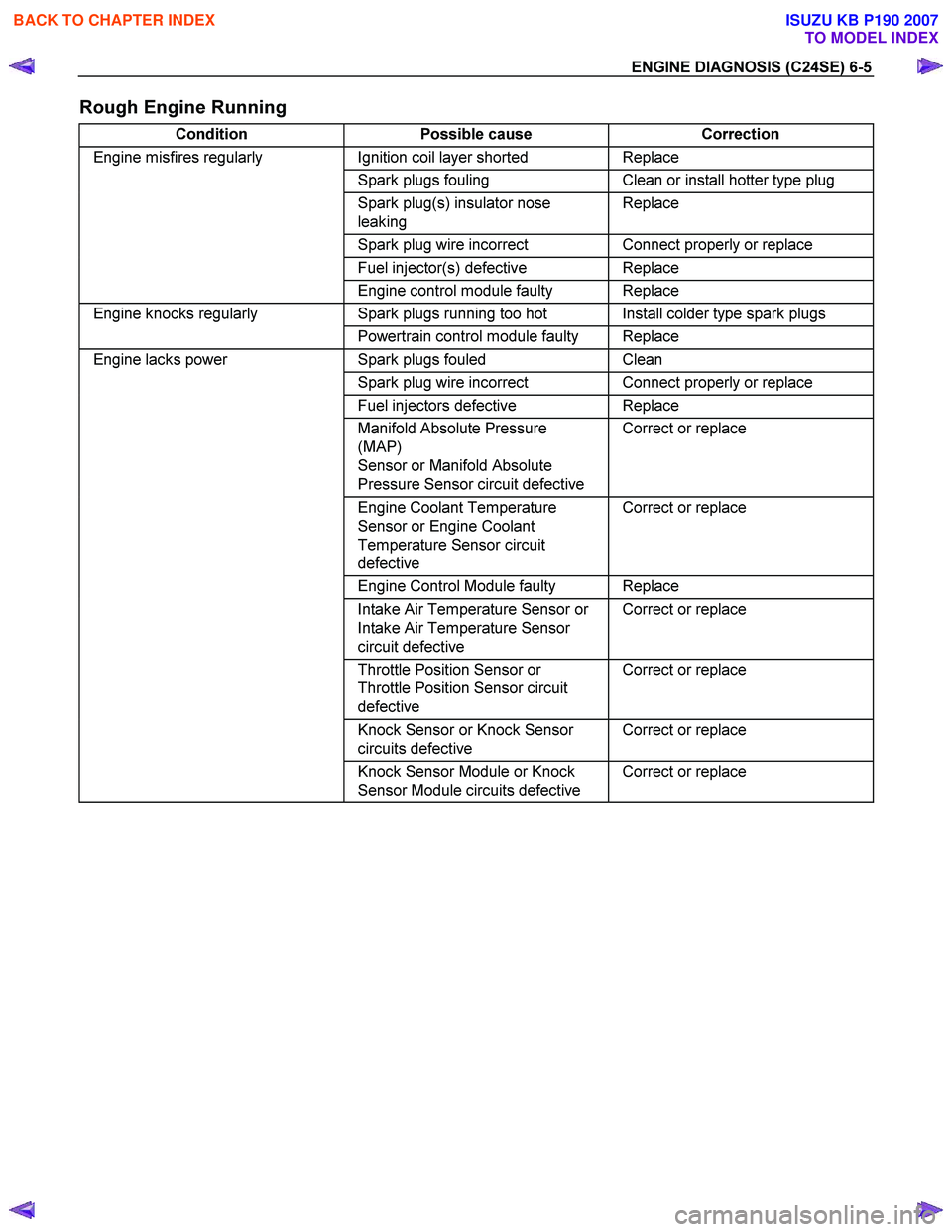

Rough Engine Running

Condition Possible cause Correction

Engine misfires regularly Ignition coil layer shorted Replace

Spark plugs fouling Clean or install hotter type plug

Spark plug(s) insulator nose

leaking Replace

Spark plug wire incorrect Connect properly or replace

Fuel injector(s) defective Replace

Engine control module faulty Replace

Engine knocks regularly Spark plugs running too hot Install colder type spark plugs

Powertrain control module faulty Replace

Engine lacks power Spark plugs fouled Clean

Spark plug wire incorrect Connect properly or replace

Fuel injectors defective Replace

Manifold Absolute Pressure

(MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defective Correct or replace

Engine Coolant Temperature

Sensor or Engine Coolant

Temperature Sensor circuit

defective Correct or replace

Engine Control Module faulty Replace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor

circuit defective Correct or replace

Throttle Position Sensor or

Throttle Position Sensor circuit

defective Correct or replace

Knock Sensor or Knock Sensor

circuits defective Correct or replace

Knock Sensor Module or Knock

Sensor Module circuits defective Correct or replace

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2025 of 6020

ENGINE MECHANICAL (C24SE) 6A-11

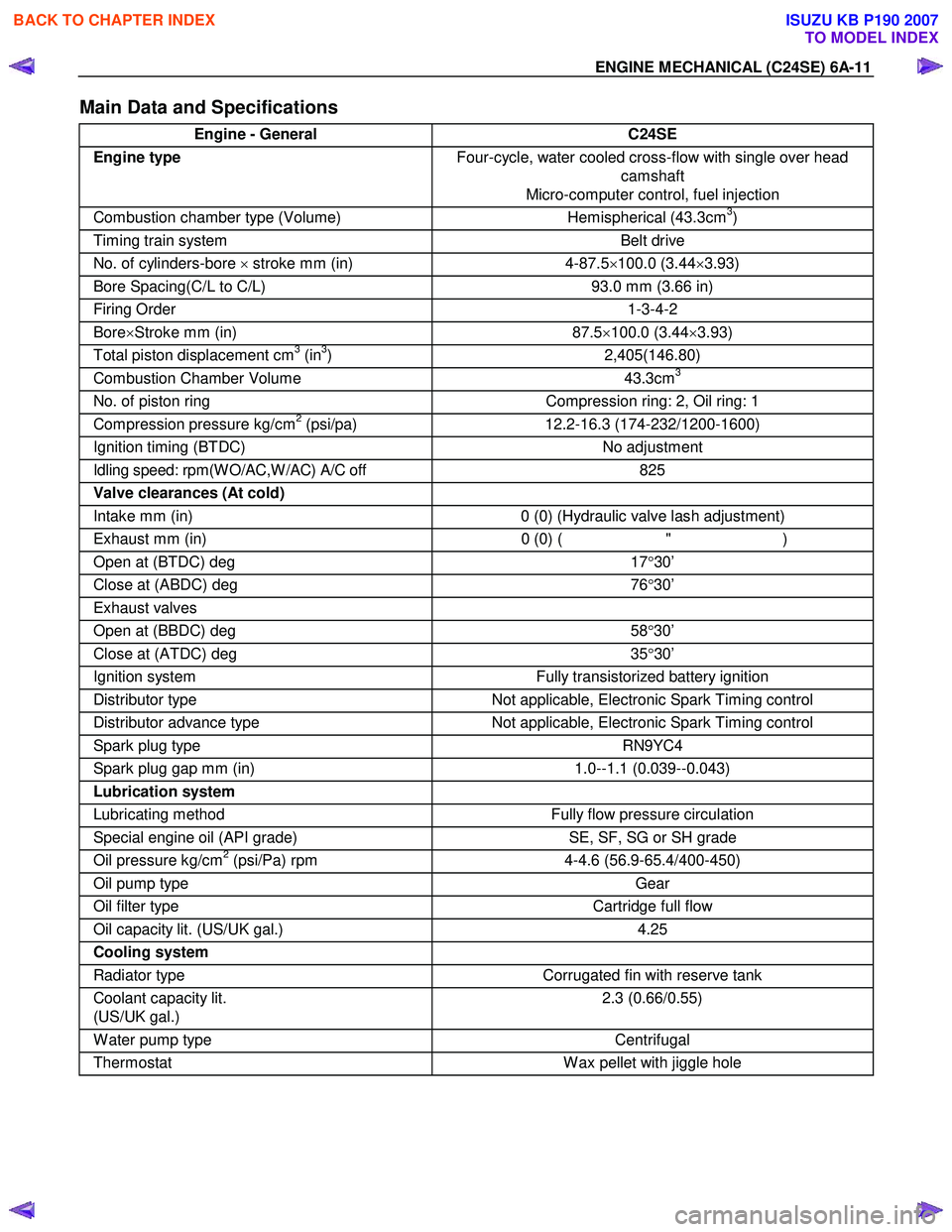

Main Data and Specifications

Engine - General C24SE

Engine type Four-cycle, water cooled cross-flow with single over head

camshaft

Micro-computer control, fuel injection

Combustion chamber type (Volume) Hemispherical (43.3cm3)

Timing train system Belt drive

No. of cylinders-bore × stroke mm (in) 4-87.5 ×100.0 (3.44 ×3.93)

Bore Spacing(C/L to C/L) 93.0 mm (3.66 in)

Firing Order 1-3-4-2

Bore×Stroke mm (in) 87.5 ×100.0 (3.44 ×3.93)

Total piston displacement cm3 (in3) 2,405(146.80)

Combustion Chamber Volume 43.3cm3

No. of piston ring Compression ring: 2, Oil ring: 1

Compression pressure kg/cm2 (psi/pa) 12.2-16.3 (174-232/1200-1600)

Ignition timing (BTDC) No adjustment

Idling speed: rpm(W O/AC,W /AC) A/C off 825

Valve clearances (At cold)

Intake mm (in) 0 (0) (Hydraulic valve lash adjustment)

Exhaust mm (in) 0 (0) ( " )

Open at (BTDC) deg 17°30’

Close at (ABDC) deg 76°30’

Exhaust valves

Open at (BBDC) deg 58°30’

Close at (ATDC) deg 35°30’

Ignition system Fully transistorized battery ignition

Distributor type Not applicable, Electronic Spark Timing control

Distributor advance type Not applicable, Electronic Spark Timing control

Spark plug type RN9YC4

Spark plug gap mm (in) 1.0--1.1 (0.039--0.043)

Lubrication system

Lubricating method Fully flow pressure circulation

Special engine oil (API grade) SE, SF, SG or SH grade

Oil pressure kg/cm2 (psi/Pa) rpm 4-4.6 (56.9-65.4/400-450)

Oil pump type Gear

Oil filter type Cartridge full flow

Oil capacity lit. (US/UK gal.) 4.25

Cooling system

Radiator type Corrugated fin with reserve tank

Coolant capacity lit.

(US/UK gal.) 2.3 (0.66/0.55)

W ater pump type

Centrifugal

Thermostat W ax pellet with jiggle hole

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2026 of 6020

6A-12 ENGINE MECHANICAL (C24SE)

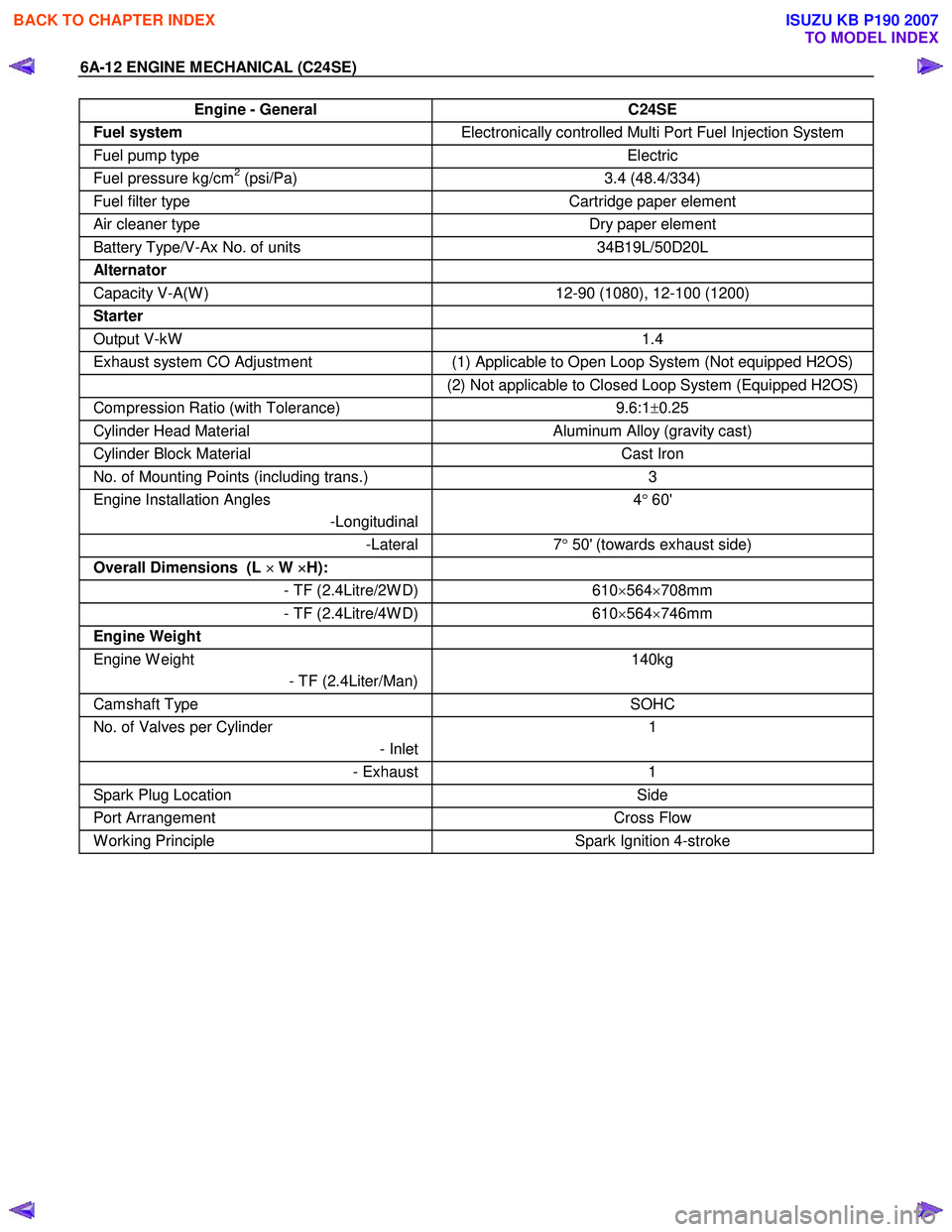

Engine - General C24SE

Fuel system Electronically controlled Multi Port Fuel Injection System

Fuel pump type Electric

Fuel pressure kg/cm2 (psi/Pa) 3.4 (48.4/334)

Fuel filter type Cartridge paper element

Air cleaner type Dry paper element

Battery Type/V-Ax No. of units 34B19L/50D20L

Alternator

Capacity V-A(W ) 12-90 (1080), 12-100 (1200)

Starter

Output V-kW 1.4

Exhaust system CO Adjustment (1) Applicable to Open Loop System (Not equipped H2OS)

(2) Not applicable to Closed Loop System (Equipped H2OS)

Compression Ratio (with Tolerance) 9.6:1±0.25

Cylinder Head Material Aluminum Alloy (gravity cast)

Cylinder Block Material Cast Iron

No. of Mounting Points (including trans.) 3

Engine Installation Angles

-Longitudinal 4

° 60'

-Lateral 7° 50' (towards exhaust side)

Overall Dimensions (L ×

××

×

W ×

××

×

H):

- TF (2.4Litre/2W D)610×564 ×708mm

- TF (2.4Litre/4W D) 610×564 ×746mm

Engine Weight

Engine W eight

- TF (2.4Liter/Man) 140kg

Camshaft Type

SOHC

No. of Valves per Cylinder

- Inlet1

- Exhaust

1

Spark Plug Location Side

Port Arrangement Cross Flow

W orking Principle Spark Ignition 4-stroke

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2029 of 6020

ENGINE MECHANICAL (C24SE) 6A-15

Engine Specification Matrix for destination

04 HEO FOR TF MODEL:

VEHICLE MODEL TFR/S 2.4L

Major Description

AUSTRALIA, CHILE,

GULF, NEW

ZEALAND, SAUDI ARABIA, SOUTH AFRICA COLOMBIA, COSTA

RICA, EQUADOR, GUATEMALA BOLIVIA, GENERAL

EXPORT, PERU, VENEZUELA

VEHICLE TYPE 4× 2 4x4 4 ×2 4 ×4 4 ×2

VEHICLE IDENT. CODE TX TY TX TY TX

ENGINE TYPE C24SE ← ←

FUEL CONTROL SYSYTEM CLOSE LOOP CLOSED LOOP OPEN LOOP

COMPRESSION RATIO 9.6:1 ← ←

FUEL OCTANE(ROD) 91RON 85RON 80RON

FUEL TYPE UN-LEADED UN-LEADED LEADED

HO2 YES YES YES NO

EVAP CANISTER YES YES YES YES

PURGE CONTROL

SOLENOID YES

YES YES YES

CHECK & RELIEF VALVE YES YES YES YES

ECM YES YES YES YES

EXHAUST SYSTEM

FRONT PIPE

SILENCER

TW C YES YES YES NO

CO ADJUSTMENT NO NO NO YES

Refer to 6A-77 Refer to 6A-77 Refer to 6A-77

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2124 of 6020

6C-6 ENGINE FUEL (C24SE)

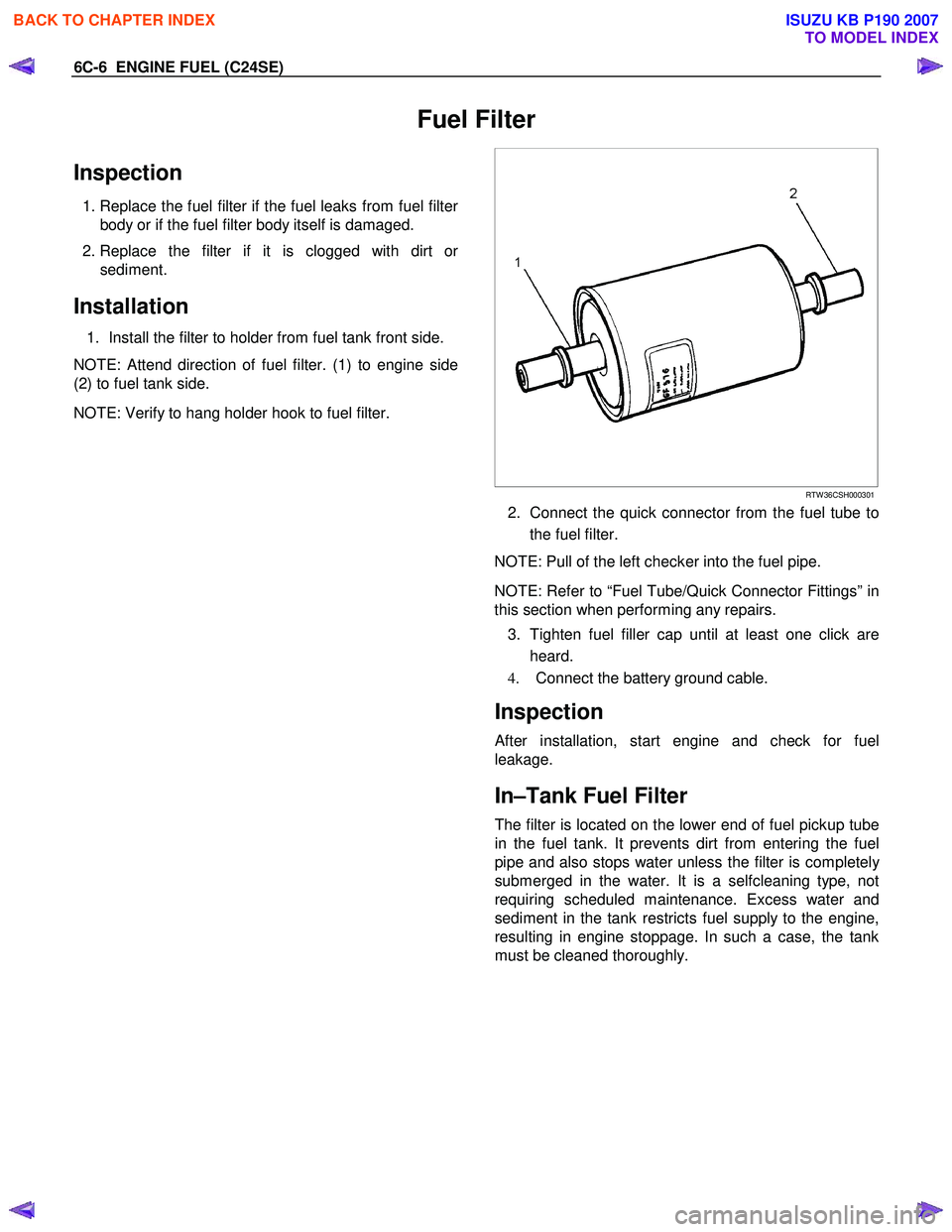

Fuel Filter

Inspection

1. Replace the fuel filter if the fuel leaks from fuel filter

body or if the fuel filter body itself is damaged.

2. Replace the filter if it is clogged with dirt o

r

sediment.

Installation

1. Install the filter to holder from fuel tank front side.

NOTE: Attend direction of fuel filter. (1) to engine side

(2) to fuel tank side.

NOTE: Verify to hang holder hook to fuel filter.

RTW 36CSH000301

2. Connect the quick connector from the fuel tube to

the fuel filter.

NOTE: Pull of the left checker into the fuel pipe.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in

this section when performing any repairs.

3. Tighten fuel filler cap until at least one click are heard.

4. Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel

leakage.

In–Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube

in the fuel tank. It prevents dirt from entering the fuel

pipe and also stops water unless the filter is completel

y

submerged in the water. It is a selfcleaning type, not

requiring scheduled maintenance. Excess water and

sediment in the tank restricts fuel supply to the engine,

resulting in engine stoppage. In such a case, the tank

must be cleaned thoroughly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2134 of 6020

6C-16 ENGINE FUEL (C24SE)

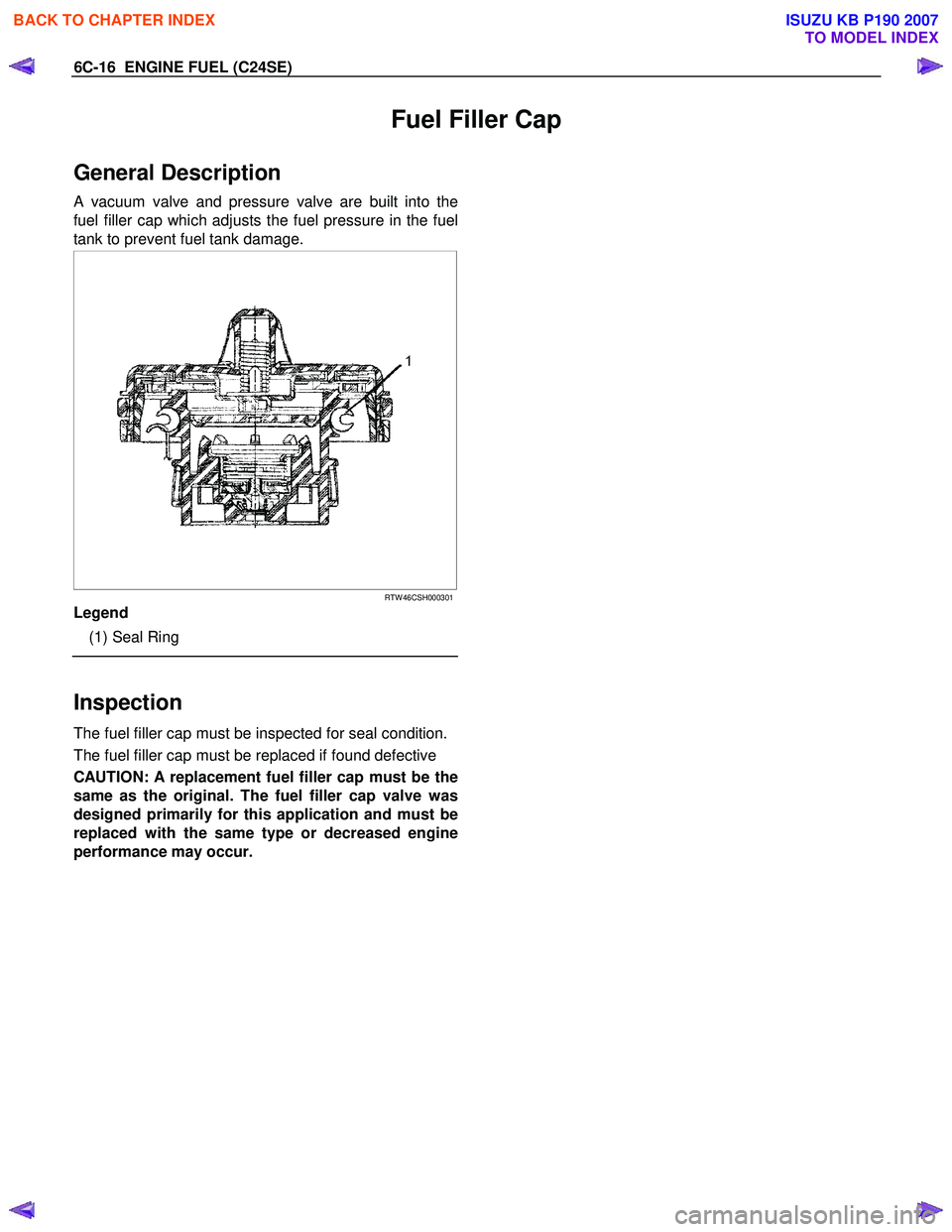

Fuel Filler Cap

General Description

A vacuum valve and pressure valve are built into the

fuel filler cap which adjusts the fuel pressure in the fuel

tank to prevent fuel tank damage.

RTW 46CSH000301

Legend

(1) Seal Ring

Inspection

The fuel filler cap must be inspected for seal condition.

The fuel filler cap must be replaced if found defective

CAUTION: A replacement fuel filler cap must be the

same as the original. The fuel filler cap valve was

designed primarily for this application and must be

replaced with the same type or decreased engine

performance may occur.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2146 of 6020

IGNITION SYSTEM 6D2-3

Spark Plug

Removal

1. Remove spark plugs.

Inspection and Repair

The spark plug affects entire engine performance and

therefore its inspection is very important.

• Check electrode and insulator for presence of cracks, and

replace if any.

• Check electrode for wear, and replace if necessary.

• Check gasket for damage, and replace if necessary.

• Measure insulation resistance with an ohmmeter, and

replace if faulty.

• Adjust spark plug gap to 1.0 - 1.1 mm (0.027 in) - 0.8 mm

(0.031 in).

• Check fuel and electrical systems if spark plug is extremely

dirty.

• Use spark plugs having low heat value (hot type plug) if fuel

and electrical systems are normal.

• Use spark plugs having high heat value (cold type plug) i

f

insulator and electrode are extremely burned.

Sooty Spark Plugs

Much deposit of carbon or oil on the electrode and insulator of

spark plug reduces the engine performance.

Possible causes:

• Too rich mixture

• Presence of oil in combustion chamber

• Incorrectly adjusted spark plug gap

Burning Electrodes

This fault is characterized by scorched or heavily oxidized

electrode or blistered insulator nose.

Possible causes:

• Too lean mixture

• Improper heat value

Measuring Insulation Resistance

• Measure insulation resistance using a 500 volt megaohm

meter.

• Replace spark plugs if measured value is out of standard.

Insulation resistance: 50 M Ω or more

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2237 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–67

GENERAL SERVICE INFORMATION

Aftermarket Electrical and Vacuum

Equipment

Aftermarket (add-on) electrical and vacuum equipment

is defined as any equipment which connects to the

vehicle's electrical or vacuum systems that is installed

on a vehicle after it leaves the factory. No allowances

have been made in the vehicle design for this type of

equipment.

NOTE: No add-on vacuum equipment should be added

to this vehicle.

NOTE: Add-on electrical equipment must only be

connected to the vehicle's electrical system at the

battery (power and ground).

Add-on electrical equipment, even when installed to

these guidelines, may still cause the electric system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such as

portable telephones and radios. Therefore, the first step

in diagnosing any electric problem is to eliminate all

aftermarket electrical equipment from the vehicle. After

this is done, if the problem still exists, it may be

diagnosed in the normal manner.

Electrostatic Discharge Damage

Electronic components used in the ECM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4000

volts for a person to feel even the zap of a static

discharge.

There are several ways for a person to become

statically charged. The most common methods of

charging are by friction and induction.

• An example of charging by friction is a person sliding across a vehicle seat.

• Charge by induction occurs when a person with well- insulated shoes stands near a highly charged object

and momentarily touches ground. Charges of the

same polarity are drained off leaving the person

highly charged with the opposite polarity. Static

charges can cause damage, therefore it is important

to use care when handling and testing electronic

components. Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly, if commercially sold

sensor or switch is installed, it makes a wrong diagnosis

and turns on the check engine lamp.

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the check

engine lamp.

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the check

engine lamp to turn on if the vehicle is not maintained

properly. Restricted oil filters, fuel filters, and crankcase

deposits due to lack of oil changes or improper oil

viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics,

vehicle maintenance schedules must be more closely

followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any

diagnostic procedure or diagnosing the cause of an

emission test failure. This can often lead to repairing a

problem without further steps. Use the following

guidelines when performing a visual/physical

inspection:

• Inspect all vacuum hoses for punches, cuts, disconnects, and correct routing.

• Inspect hoses that are difficult to see behind other components.

• Inspect all wires in the engine compartment for proper connections, burned or chafed spots, pinched

wires, contact with sharp edges or contact with hot

exhaust manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain

when performing diagnostic procedures could result in

an incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to

effectively use this section of the Service Manual.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2241 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–71

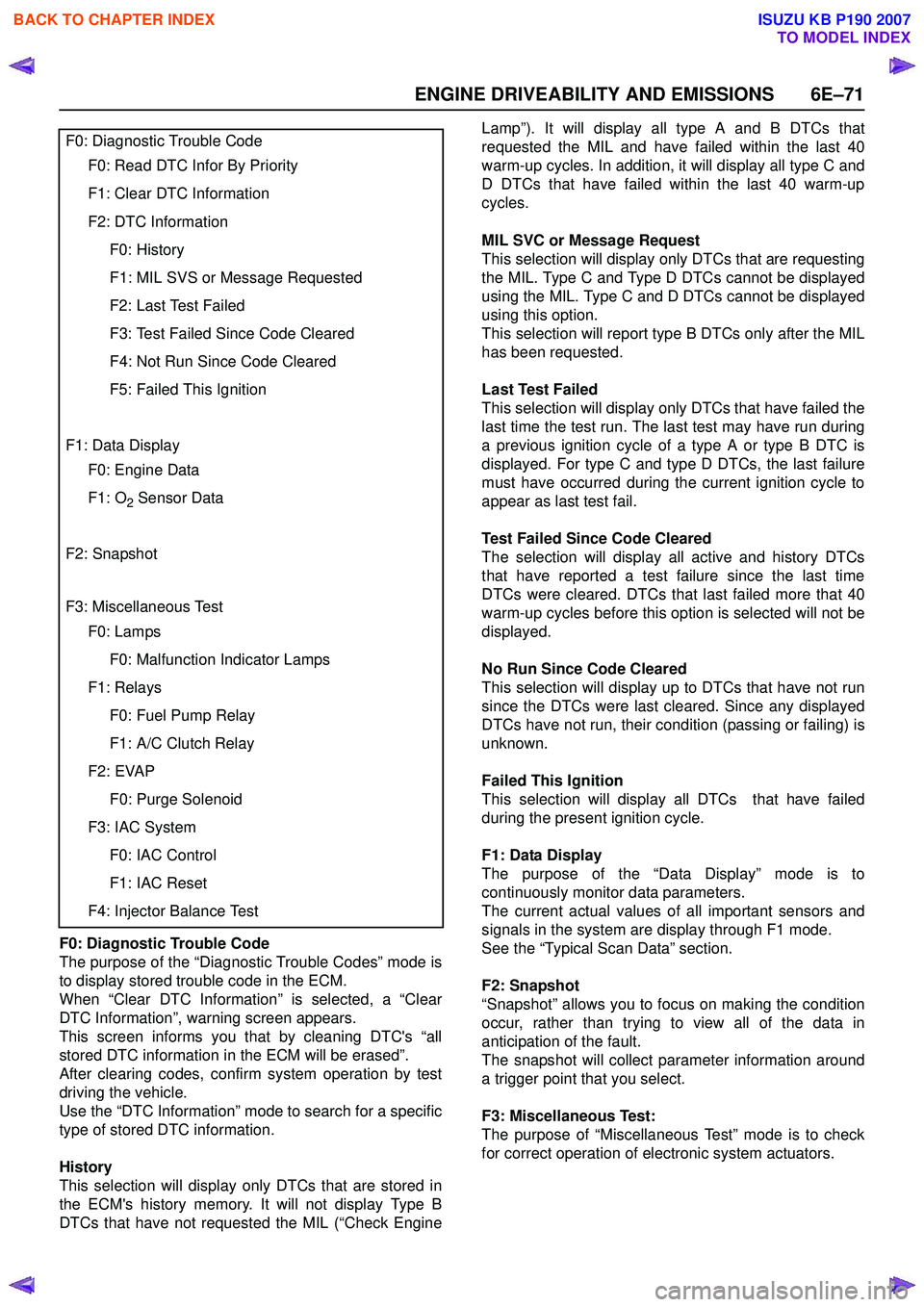

F0: Diagnostic Trouble Code

The purpose of the “Diagnostic Trouble Codes” mode is

to display stored trouble code in the ECM.

When “Clear DTC Information” is selected, a “Clear

DTC Information”, warning screen appears.

This screen informs you that by cleaning DTC's “all

stored DTC information in the ECM will be erased”.

After clearing codes, confirm system operation by test

driving the vehicle.

Use the “DTC Information” mode to search for a specific

type of stored DTC information.

History

This selection will display only DTCs that are stored in

the ECM's history memory. It will not display Type B

DTCs that have not requested the MIL (“Check Engine Lamp”). It will display all type A and B DTCs that

requested the MIL and have failed within the last 40

warm-up cycles. In addition, it will display all type C and

D DTCs that have failed within the last 40 warm-up

cycles.

MIL SVC or Message Request

This selection will display only DTCs that are requesting

the MIL. Type C and Type D DTCs cannot be displayed

using the MIL. Type C and D DTCs cannot be displayed

using this option.

This selection will report type B DTCs only after the MIL

has been requested.

Last Test Failed

This selection will display only DTCs that have failed the

last time the test run. The last test may have run during

a previous ignition cycle of a type A or type B DTC is

displayed. For type C and type D DTCs, the last failure

must have occurred during the current ignition cycle to

appear as last test fail.

Test Failed Since Code Cleared

The selection will display all active and history DTCs

that have reported a test failure since the last time

DTCs were cleared. DTCs that last failed more that 40

warm-up cycles before this option is selected will not be

displayed.

No Run Since Code Cleared

This selection will display up to DTCs that have not run

since the DTCs were last cleared. Since any displayed

DTCs have not run, their condition (passing or failing) is

unknown.

Failed This Ignition

This selection will display all DTCs that have failed

during the present ignition cycle.

F1: Data Display

The purpose of the “Data Display” mode is to

continuously monitor data parameters.

The current actual values of all important sensors and

signals in the system are display through F1 mode.

See the “Typical Scan Data” section.

F2: Snapshot

“Snapshot” allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault.

The snapshot will collect parameter information around

a trigger point that you select.

F3: Miscellaneous Test:

The purpose of “Miscellaneous Test” mode is to check

for correct operation of electronic system actuators.

F0: Diagnostic Trouble Code

F0: Read DTC Infor By Priority

F1: Clear DTC Information

F2: DTC Information

F0: History

F1: MIL SVS or Message Requested

F2: Last Test Failed

F3: Test Failed Since Code Cleared

F4: Not Run Since Code Cleared

F5: Failed This Ignition

F1: Data Display

F0: Engine Data

F1: O2 Sensor Data

F2: Snapshot

F3: Miscellaneous Test

F0: Lamps

F0: Malfunction Indicator Lamps

F1: Relays

F0: Fuel Pump Relay

F1: A/C Clutch Relay

F2: EVAP

F0: Purge Solenoid

F3: IAC System

F0: IAC Control

F1: IAC Reset

F4: Injector Balance Test

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2285 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–11 5

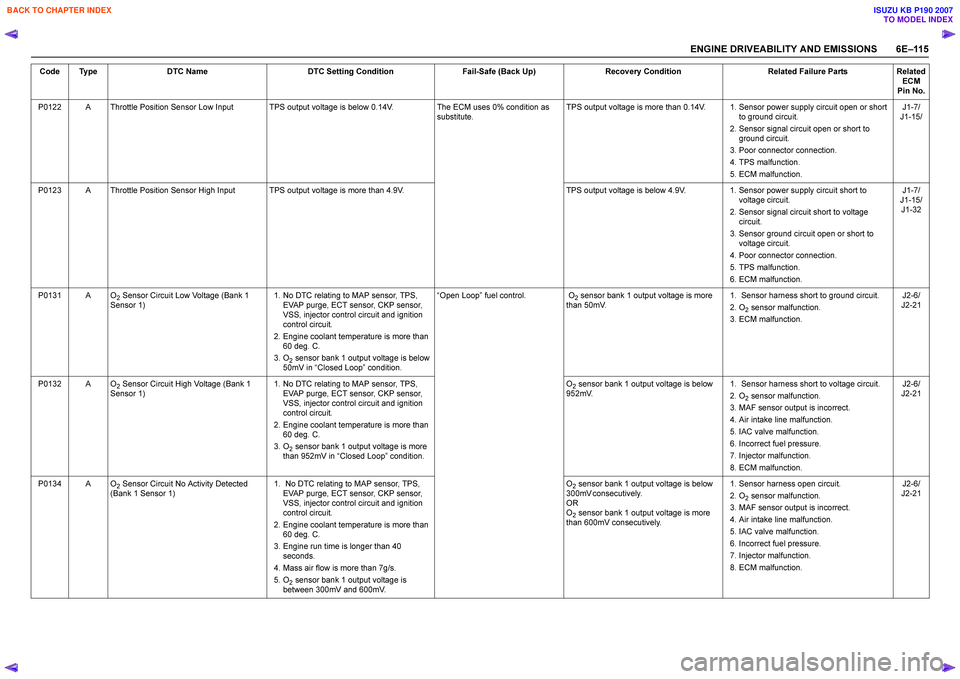

P0122 A Throttle Position Sensor Low Input TPS output voltage is below 0.14V. The ECM uses 0% condition as

substitute. TPS output voltage is more than 0.14V. 1. Sensor power supply circuit open or short

to ground circuit.

2. Sensor signal circuit open or short to ground circuit.

3. Poor connector connection.

4. TPS malfunction.

5. ECM malfunction. J1-7/

J1-15/

P0123 A Throttle Position Sensor High Input TPS output voltage is more than 4.9V. TPS output voltage is below 4.9V.1. Sensor power supply circuit short to

voltage circuit.

2. Sensor signal circuit short to voltage circuit.

3. Sensor ground circuit open or short to voltage circuit.

4. Poor connector connection.

5. TPS malfunction.

6. ECM malfunction. J1-7/

J1-15/ J1-32

P0131 A O

2 Sensor Circuit Low Voltage (Bank 1

Sensor 1) 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60 deg. C.

3. O

2 sensor bank 1 output voltage is below

50mV in “Closed Loop” condition. “Open Loop” fuel control. O

2 sensor bank 1 output voltage is more

than 50mV. 1. Sensor harness short to ground circuit.

2. O

2 sensor malfunction.

3. ECM malfunction. J2-6/

J2-21

P0132 A O

2 Sensor Circuit High Voltage (Bank 1

Sensor 1) 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60 deg. C.

3. O

2 sensor bank 1 output voltage is more

than 952mV in “Closed Loop” condition. O

2 sensor bank 1 output voltage is below

952mV. 1. Sensor harness short to voltage circuit.

2. O

2 sensor malfunction.

3. MAF sensor output is incorrect.

4. Air intake line malfunction.

5. IAC valve malfunction.

6. Incorrect fuel pressure.

7. Injector malfunction.

8. ECM malfunction. J2-6/

J2-21

P0134 A O

2 Sensor Circuit No Activity Detected

(Bank 1 Sensor 1) 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60 deg. C.

3. Engine run time is longer than 40 seconds.

4. Mass air flow is more than 7g/s.

5. O

2 sensor bank 1 output voltage is

between 300mV and 600mV. O

2 sensor bank 1 output voltage is below

3 0 0 m V c o n s e c u t i v e l y .

O R

O2 sensor bank 1 output voltage is more

than 600mV consecutively. 1. Sensor harness open circuit.

2. O

2 sensor malfunction.

3. MAF sensor output is incorrect.

4. Air intake line malfunction.

5. IAC valve malfunction.

6. Incorrect fuel pressure.

7. Injector malfunction.

8. ECM malfunction. J2-6/

J2-21

Code Type

DTC Name DTC Setting Condition Fail-Safe (Back Up)Recovery Condition Related Failure PartsRelated

ECM

Pin No.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007