fuel type ISUZU KB P190 2007 Workshop Owners Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1884 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-267

DTC P2127 or P2128 (Flash Code 122)

Circuit Description

The accelerator pedal position (APP) sensor is

mounted on the accelerator pedal control assembly.

The sensor is made up of three individual sensors

within one housing. The ECM uses the APP sensors to

determine the amount of acceleration or deceleration

that is desired. The APP sensor 2 has the following

circuits.

• 5 volts reference circuit

• Low reference circuit

• APP sensor 2 signal circuit

The APP sensor 2 provides a signal to the ECM on the

signal circuit, which is relative to the position changes

of the accelerator pedal angle. If the ECM detects an

excessively low or high signal voltage, DTC P2127 or

P2128 will set.

Condition for Running the DTC • DTCs P0652 and P0653 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the APP sensor 2 signal voltage is less than 0.15 volts. (DTC P2127)

• The ECM detects that the APP sensor 2 signal voltage is more than 4.85 volts. (DTC P2128) Action Taken When the DTC Sets

• The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• APP sensor 2 may have an intermittent open somewhere in the pedal range.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2127

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0652 also set? —

Go to DTC P0652 Go to Step 3

3 Fully depress and release the accelerator pedal

while observing the Accelerator Pedal Position

(APP) Sensor 2 parameter with a scan tool.

Does the scan tool indicate less than the specified

value during depressing or releasing the pedal? 0.2 volts

Go to Step 4 Go to Diagnostic

Aids

4 1. Turn OFF the ignition.

2. Disconnect the APP sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

Is the APP Sensor 2 parameter more than the

specified value? 4.7 volts

Go to Step 5 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1888 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-271

DTC P2132 or P2133 (Flash Code 123)

Circuit Description

The accelerator pedal position (APP) sensor is

mounted on the accelerator pedal control assembly.

The sensor is made up of three individual sensors

within one housing. The ECM uses the APP sensors to

determine the amount of acceleration or deceleration

that is desired. The APP sensor 3 has the following

circuits.

• 5 volts reference circuit

• Low reference circuit

• APP sensor 3 signal circuit

The APP sensor 3 provides a signal to the ECM on the

signal circuit, which is relative to the position changes

of the accelerator pedal angle. If the ECM detects an

excessively low or high signal voltage, DTC P2132 or

P2133 will set.

Condition for Running the DTC • DTCs P0698 and P0699 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the APP sensor 3 signal voltage is less than 1.2 volts. (DTC P2132)

• The ECM detects that the APP sensor 3 signal voltage is more than 4.85 volts. (DTC P2133)

Action Taken When the DTC Sets

DTC P2132 • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

DTC P2133

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

Condition for Clearing the DTC

DTC P2132 • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

DTC P2133

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• APP sensor 3 may have an intermittent open somewhere in the pedal range.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2132

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0698 also set? —

Go to DTC P0698 Go to Step 3

3 Fully depress and release the accelerator pedal

while observing the Accelerator Pedal Position

(APP) Sensor 3 parameter with a scan tool.

Does the scan tool indicate less than the specified

value during depressing or releasing the pedal? 1.2 volts

Go to Step 4 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1893 of 6020

6E-276 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P2138, P2139 or P2140 (Flash Code 124, 125 or 126)

Circuit Description

The accelerator pedal position (APP) sensor is

mounted on the accelerator pedal control assembly.

The sensor is made up of three individual sensors

within one housing. The APP sensor 1, APP sensor 2

and APP sensor 3 are potentiometer type sensors,

each with the following circuits.

• 5 volts reference circuit

• Low reference circuit

• Signal circuit

The APP sensor provides a signal to the ECM on the

signal circuits, which is relative to the position changes

of the accelerator pedal angle. The APP sensor 1

signal voltage is low at rest and increases as the pedal

is depressed. The APP sensor 2 and APP sensor 3

signal voltage is high at rest and decreases as the

pedal is depressed. If the ECM detects that each APP

sensor signal voltage is out of the correlation, DTC

P2138, P2139 or P2140 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The APP sensor 1 signal voltage is between 0.15 to 4.85 volt. (DTC P2138 or P2139)

• The APP sensor 2 signal voltage is between 0.15 to 4.85 volt. (DTC P2138 or P2140)

• The APP sensor 3 signal voltage is between 1.20 to 4.85 volt. (DTC P2139 or P2140)

Condition for Setting the DTC • The ECM detects that the APP sensor 1 and 2 are more than 40% out of range of each other. (DTC

P2138) • The ECM detects that the APP sensor 1 and 3 are

more than 40% out of range of each other. (DTC

P2139)

• The ECM detects that the APP sensor 2 and 3 are more than 40% out of range of each other. (DTC

P2140)

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification)

• The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2138

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0642, P0643, P0652, P0653, P0698,

P0699, P2132 or P2133 also set? —

Go to Applicable DTC Go to Step 3

3 Fully depress and release the accelerator pedal

while observing the DTC Information with a scan

tool.

Does the DTC fail this ignition? —

Go to Step 4 Go to Diagnostic

Aids

4 Is DTC P2140 also set? —Go to Step 6 Go to Step 5

5 Is DTC P2139 also set? —Go to Step 7 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1899 of 6020

6E-282 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P2146, P2147 or P2148 (Flash Code 158)

Circuit Description

The ECM calculates the optimum fuel injection ON time

using data sent from various engine sensors. The

common 1 fuel injector charge voltage circuit is a high-

voltage supply which drives fuel injectors for cylinder #1

and #4 in conjunction with the ECM grounding the fuel

injector solenoid control circuit. If the common 1 fuel

injector charge voltage circuit is shorted to cylinder #1

or #4 fuel injector solenoid control circuit, shorted to

ground or shorted voltage circuit DTC P2146, P2147 or

P2148 will set. If the cylinder #1 and #4 fuel injector

solenoid control circuit is shorted each other, shorted to

ground or shorted voltage circuit DTC P2146, P2147 or

P2148 will also set.

Condition for Running the DTC • DTCs P0201, P0204, P2147 and P2148 are not set. (DTC P2146)

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC • The ECM detects that the common 1 fuel injector charge voltage circuit is shored to cylinder #1 or #4

fuel injector solenoid control circuit, or cylinder #1

and #4 fuel injector solenoid control circuit is

shorted each other. (DTC P2146) • The ECM detects that the common 1 fuel injector

charge voltage circuit, cylinder #1 or #4 fuel

injector solenoid control circuit is shorted to

ground. (DTC P2147)

• The ECM detects that the common 1 fuel injector charge voltage circuit, cylinder #1 or #4 fuel

injector solenoid control circuit is shorted to

voltage circuit. (DTC P2148)

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2146

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Accelerate the engine and keep the accelerator pedal at any position.

5. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1903 of 6020

6E-286 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P2149, P2150 or P2151 (Flash Code 159)

Circuit Description

The ECM calculates the optimum fuel injection ON time

using data sent from various engine sensors. The

common 2 fuel injector charge voltage circuit is a high-

voltage supply which drives fuel injectors for cylinder #2

and #3 in conjunction with the ECM grounding the fuel

injector solenoid control circuit. If the common 2 fuel

injector charge voltage circuit is shorted to cylinder #2

or #3 fuel injector solenoid control circuit, shorted to

ground or shorted voltage circuit DTC P2149, P2150 or

P2151 will set. If the cylinder #2 and #3 fuel injector

solenoid control circuit is shorted each other, shorted to

ground or shorted voltage circuit DTC P2149, P2150 or

P2151 will also set.

Condition for Running the DTC • DTCs P0202, P0203, P2150 and P2151 are not set. (DTC P2149)

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC • The ECM detects that the common 2 fuel injector charge voltage circuit is shored to cylinder #2 or #3

fuel injector solenoid control circuit, or cylinder #2

and #3 fuel injector solenoid control circuit is

shorted each other. (DTC P2149). • The ECM detects that the common 2 fuel injector

charge voltage circuit, or cylinder #2 or #3 fuel

injector solenoid control circuit is shorted to

ground. (DTC P2150)

• The ECM detects that the common 2 fuel injector charge voltage circuit, or cylinder #2 or #3 fuel

injector solenoid control circuit is shorted to

voltage circuit. (DTC P2151)

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2149

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Accelerate the engine and keep the accelerator pedal at any position.

5. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1907 of 6020

6E-290 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P2227 (Flash Code 71)

Circuit Description

The barometric pressure (BARO) sensor is located on

the intake manifold. The BARO sensor is a transducer

that varies voltage according to changes the barometric

pressure. Within the ECM, the diagnostic compares the

BARO sensor input to the boost pressure sensor input.

If the ECM detects that the inputs are not within a

specified amount of each other, this DTC will set.

Condition for Running the DTC • DTCs P0101, P0102, P0103, P0107, P0108, P0116, P0117, P0118, P0122, P0123, P0500,

P0501, P0638, P0652, P0653, P0698, P0699,

P2100, P2101, P2103, P2228 and P2229 are not

set.

AND following conditions are met for longer than 3

seconds.

• The ignition switch is ON.

• The engine coolant temperature is more than 5 °C

(41 °F).

• The engine speed is less than 800 RPM.

• The fuel injection quantity is less than a predetermined value.

• The accelerator pedal is not depressed.

• The vehicle is not running.

• The engine run time is longer than 5 seconds. Condition for Setting the DTC

• The ECM detects that the differential pressure between the barometric pressure and the boost

pressure is more than 10 kPa (1.5 psi) for 10

seconds.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2227

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0107, P0108, P2228 or P2229 also set? —

Go to Applicable DTC Go to Step 3

3 1. Turn ON the ignition, with the engine OFF.

2. Compare the Boost Pressure parameter to the Barometric Pressure (BARO) parameter with

a scan tool.

Are both parameter within the range specified of

each other? 10 kPa (1.5

psi)

Go to Diagnostic Aids Go to Step 4

4 Determine the outside barometric pressure from

your location specified in the altitude vs barometric

pressure table. Refer to Altitude vs Barometric

Pressure.

Is the BARO parameter on the scan tool close to

the outside barometric pressure? —

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1910 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-293

DTC P2228 or P2229 (Flash Code 71)

Circuit Description

The barometric pressure (BARO) sensor is located on

the intake manifold. The BARO sensor is a transducer

that varies voltage according to changes the barometric

pressure. The sensor has the following circuits.

• 5 volts reference circuit.

• Low reference circuit.

• BARO sensor signal circuit.

The BARO sensor provides a signal to the ECM on the

signal circuit, which is relative to the pressure changes

of the barometric pressure. The ECM should detect a

low signal voltage at a low barometric pressure, such

as high altitude place. The ECM should detect high

signal voltage at a high barometric pressure. The ECM

uses this voltage signal to calibrate the fuel injection

quantity and injection timing for altitude compensation.

If the ECM detects an excessively low or high signal

voltage, DTC P2228 or P2229 will set.

Condition for Running the DTC • DTCs P0652 and P0653 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the BARO sensor signal voltage is less than 0.1 volts for 3 seconds. (DTC

P2228) • The ECM detects that the BARO sensor signal

voltage is less than 4.3 volts for 3 seconds. (DTC

P2229)

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM uses a BARO substitution of default value.

• The ECM limits fuel injection quantity.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2228

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0652 also set? —

Go to DTC P0652 Go to Step 3

3 Observe the Barometric Pressure (BARO) Sensor

parameter with a scan tool.

Is the BARO Sensor parameter less than the

specified value? 0.1 volts

Go to Step 4 Go to Diagnostic

Aids

4 1. Turn OFF the ignition.

2. Disconnect the BARO sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 3 of E-40) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 5 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1930 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-313

181. Inspect for an intermittent, poor connections

and corrosion at the harness connector of the

fuel pump resistor (pins 1 and 2 of C-57).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 25

—

191. Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the fuel pump (pins 1 and 4 of F-

2).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 25 Go to Step 24

20 Replace the fuel pump relay.

Did you complete the replacement? —

Go to Step 25

—

211. Make sure the fuel amount in the fuel tank.

Refill adequate fuel as necessary.

2. Check the fuel system connections between the fuel tank and the fuel supply pump for

tightness and all fuel hoses for cuts, kinks,

cracks and for the use of proper clamps.

Repair or replace as necessary.

3. Turn OFF the ignition.

4. Disconnect the fuel hose that connects to the fuel filter inlet side. In order to measure the

discharged fuel amount, put the hose into a

bottle or a container with a scale. (The inlet of

a bottle or a container must be larger than the

diameter of hose.)

5. Turn ON the ignition for 20 seconds, with the engine OFF.

6. Turn OFF the ignition for 10 seconds.

7. Perform 5 and 6 three times. The accumulated fuel of three ignition cycles must be more than

300cc. (Normal amount is more than 100cc

per one ignition cycle.)

Is enough amount of fuel discharged? —

System OK Go to Step 22

22 1. Remove the fuel pump from the fuel tank.

Refer to Fuel Gauge Unit in the Fuel System

section.

2. Inspect the fuel pump for any type of restriction or damage on the fuel pipes.

3. Repair or replace as necessary.

Did you find and correct the condition? —

Go to Step 25 Go to Step 24

23 Replace the fuel pump resistor.

Did you complete the replacement? —

Go to Step 25

—

24Replace the fuel pump. Refer to Fuel Gauge Unit in

the Fuel System section.

Did you complete the replacement? —

Go to Step 25

—

25Reconnect all previously disconnected

components, fuse, relay or harness connector(s).

Did you complete the action? —

Go to Step 3

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1945 of 6020

6E-328 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

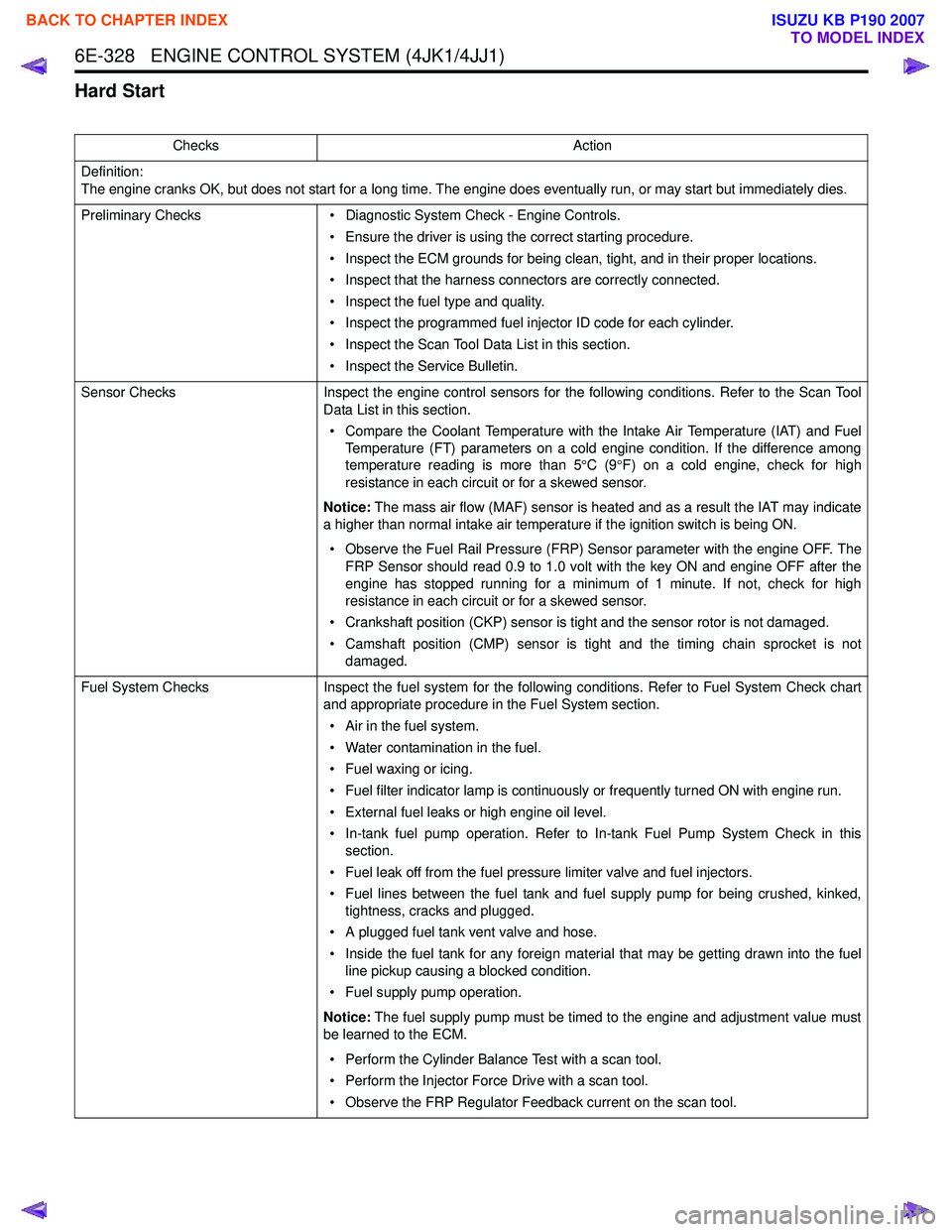

Hard Start

ChecksAction

Definition:

The engine cranks OK, but does not start for a long time. The engine does eventually run, or may start but immediately dies.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Ensure the driver is using the correct starting procedure.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Inspect that the harness connectors are correctly connected.

• Inspect the fuel type and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Crankshaft position (CKP) sensor is tight and the sensor rotor is not damaged.

• Camshaft position (CMP) sensor is tight and the timing chain sprocket is not damaged.

Fuel System Checks Inspect the fuel system for the following conditions. Refer to Fuel System Check chart

and appropriate procedure in the Fuel System section.

• Air in the fuel system.

• Water contamination in the fuel.

• Fuel waxing or icing.

• Fuel filter indicator lamp is continuously or frequently turned ON with engine run.

• External fuel leaks or high engine oil level.

• In-tank fuel pump operation. Refer to In-tank Fuel Pump System Check in this section.

• Fuel leak off from the fuel pressure limiter valve and fuel injectors.

• Fuel lines between the fuel tank and fuel supply pump for being crushed, kinked, tightness, cracks and plugged.

• A plugged fuel tank vent valve and hose.

• Inside the fuel tank for any foreign material that may be getting drawn into the fuel line pickup causing a blocked condition.

• Fuel supply pump operation.

Notice: The fuel supply pump must be timed to the engine and adjustment value must

be learned to the ECM.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the FRP Regulator Feedback current on the scan tool.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1947 of 6020

6E-330 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

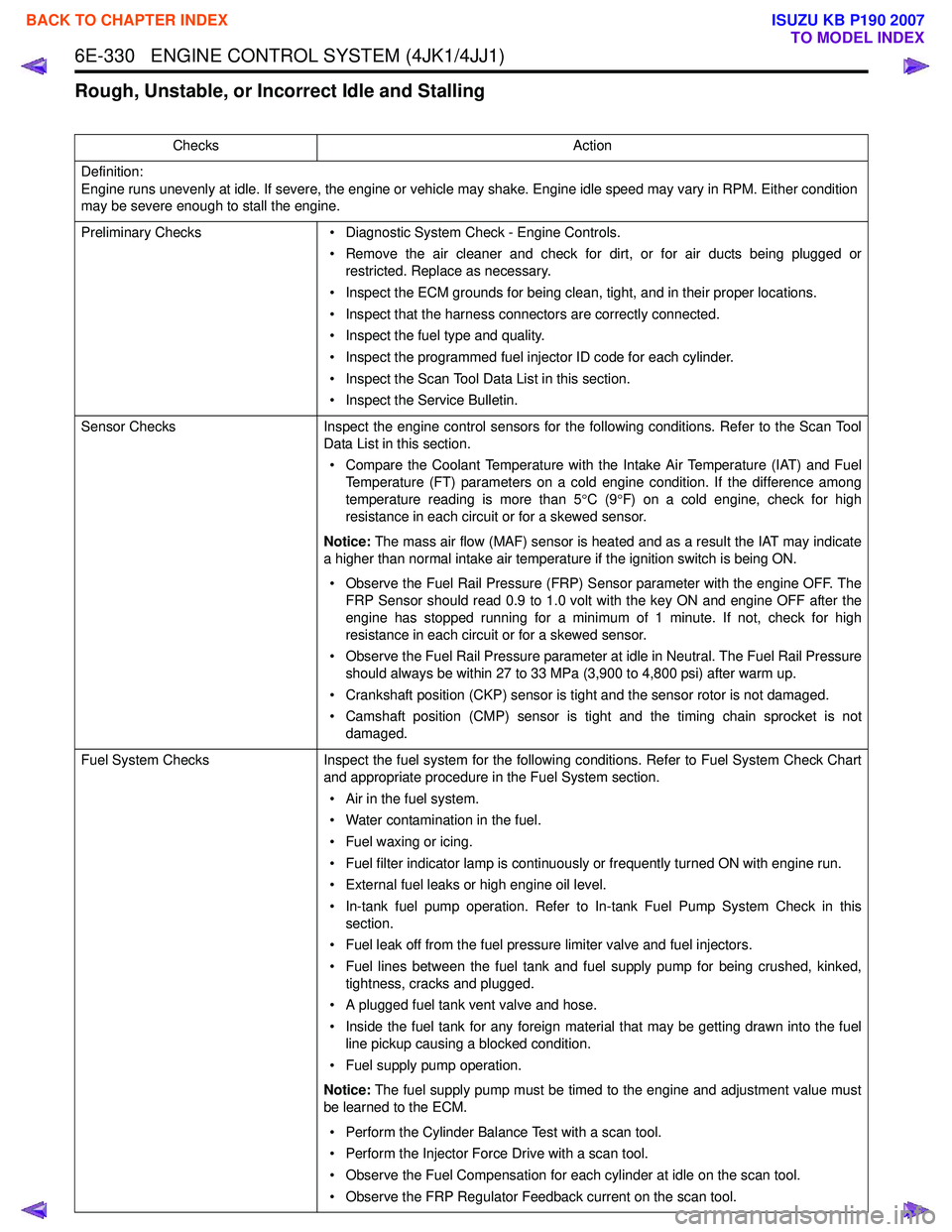

Rough, Unstable, or Incorrect Idle and Stalling

ChecksAction

Definition:

Engine runs unevenly at idle. If severe, the engine or vehicle may shake. Engine idle speed may vary in RPM. Either condition

may be severe enough to stall the engine.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or restricted. Replace as necessary.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Inspect that the harness connectors are correctly connected.

• Inspect the fuel type and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure parameter at idle in Neutral. The Fuel Rail Pressure should always be within 27 to 33 MPa (3,900 to 4,800 psi) after warm up.

• Crankshaft position (CKP) sensor is tight and the sensor rotor is not damaged.

• Camshaft position (CMP) sensor is tight and the timing chain sprocket is not damaged.

Fuel System Checks Inspect the fuel system for the following conditions. Refer to Fuel System Check Chart

and appropriate procedure in the Fuel System section.

• Air in the fuel system.

• Water contamination in the fuel.

• Fuel waxing or icing.

• Fuel filter indicator lamp is continuously or frequently turned ON with engine run.

• External fuel leaks or high engine oil level.

• In-tank fuel pump operation. Refer to In-tank Fuel Pump System Check in this section.

• Fuel leak off from the fuel pressure limiter valve and fuel injectors.

• Fuel lines between the fuel tank and fuel supply pump for being crushed, kinked, tightness, cracks and plugged.

• A plugged fuel tank vent valve and hose.

• Inside the fuel tank for any foreign material that may be getting drawn into the fuel line pickup causing a blocked condition.

• Fuel supply pump operation.

Notice: The fuel supply pump must be timed to the engine and adjustment value must

be learned to the ECM.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

• Observe the FRP Regulator Feedback current on the scan tool.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007