4WD ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3021 of 6020

Engine Mechanical – V6 Page 6A1–244

Page 6A1–244

28 Remove the centre exhaust pipe (1), refer to

Section 6F Exhaust System - V6 .

Figure 6A1 – 417

29 Disconnect the two post-catalytic converter oxygen sensor wiring harness connectors, 1 each bank.

Figure 6A1 – 418

30 Disconnect the two pre-catalytic converter oxygen sensor wiring harness connectors, 1 each bank.

31 Remove the front exhaust flange nuts, three each bank.

32 Remove the front left-hand exhaust pipe from the rubber mount.

33 Remove the front exhaust pipes from the vehicle, for further information, refer to Section 6F Exhaust

System - V6 .

Figure 6A1 – 419

34 Remove the transfer case from t he vehicle (4WD Only), refer to Section 7D Transfer Case and Adaptor Housing .

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3766 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–6

2 General information

The hydra-matic 4L60E automatic transmission is fitted to vehicles with HFV6 engine. The mechanical and internal

electrical operation of the transmission unit is controlled by the transmission control module (TCM) for HFV6 engine.

• For information on the mechanical operation of the transmission, refer to General Motors Powertrain Group

Electronically Controlled Automatic Transmission Technician's Guide.

• For further information on the TCM, refer to 3.1 Transmission Control Module.

2.1 Transmission Control Module – HFV6

Vehicles fitted with a V6 engine and the 4L60E transmission have a new control module and data bus architecture from

previous models. This is due to the introduction of the new V6 engine. Mechanically, the transmission has not changed.

V6 equipped vehicles are now fitted with T42 – Delphi with GMPT software, transmission control module (TCM) to

control all transmission operations. For further information on the TCM and its operation, refer to 3 Transmission Control

Module Operation Overview.

2.2 Transmission Identification

The 4L60E automatic transmission application and identification can be determined from the stamping at the rear of the

transmission , in the location (7) as shown in Figure 7C1 – 1.

Identification is as follows:

(1) model year,

• (6 = 2006).

(2) Broad Cast Code Identifier,

• HHD = RWD – 3.6 litre HFV6

• HLD = 4WD – 3.6 litre HFV6

(D = model 4L60E).

(3) Manufacturer Source Code,

• (4 = Ramos).

(4) Julian date (day of the year).

(5) Shift Build,

• 'A','B','J' = First shift,

• 'C','H','W' = Second shift.

(6) Individual transmission serial number.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3915 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–2

Remove ................................................................................................................................................................. 22

Reinstall ................................................................................................................................................................ 24

3.10 Adaptor Housing, 4WD ........................................................................................................................................ 24

Remove and Reinstall .......................................................................................................................................... 24

3.11 Shift Solenoid Locations ..................................................................................................................................... 25

Location and Identification .................................................................................................... ............................. 25

3.12 1 – 2 Accumulator Assembly ..................................................................................................... ......................... 25

Remove ................................................................................................................................................................. 25

Clean and Inspect ................................................................................................................................................ 26

Reinstall ................................................................................................................................................................ 26

3.13 Control Valve Body Harness ..................................................................................................... .......................... 26

Remove ................................................................................................................................................................. 26

Reinstall ................................................................................................................................................................ 28

3.14 Control Valve Body .............................................................................................................................................. 30

Remove ................................................................................................................................................................. 30

Reinstall ................................................................................................................................................................ 31

3.15 Spacer Plate, Check Balls, Filter Screens and 3 – 4 Accumulator ................................................................ .. 35

Remove ................................................................................................................................................................. 35

Clean and Inspect ................................................................................................................................................ 36

Reinstall ................................................................................................................................................................ 37

3.16 Filler Tube and Breather Hose .................................................................................................. .......................... 39

Remove ................................................................................................................................................................. 39

Reinstall ................................................................................................................................................................ 40

3.17 Transmission Cooler Line/Hose Assemblies ....................................................................................... ............. 41

Remove ................................................................................................................................................................. 41

Reinstall ................................................................................................................................................................ 42

3.18 Transmission Assembly...................................................................................................................................... 43

Remove ................................................................................................................................................................. 43

Reinstall ................................................................................................................................................................ 46

3.19 Transmission Control Module ............................................................................................................................ 47

Remove ................................................................................................................................................................. 47

Reinstall ................................................................................................................................................................ 48

TCM Programming Procedure ...................................................................................................... ...................... 48

4 Specifications .......................................................................................................................................50

5 Torque Wrench Specifications................................................................................................... .........51

6 Special Tools ........................................................................................................................................52

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3931 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–18

Ensure the four wheels are off the ground

before performing the starting test.

4 W ith the ignition switched to the ON position, check if the engine can only be started in the Park and Neutral shift selector positions and ensure the back-up lamps illuminate when Reverse is selected. A further minor adjustment

may be required to achieve this state.

NOTE

To gain access to the rear attaching screw (11) it

will be necessary to remove the connector.

5 After the switch has been adjusted, tighten the rear attaching screw (11) to the correct torque specification. Neutral start and back-up lamp switch

attaching screw torque specification .................. 25.0 Nm

6 Reinstall the connector and the CPA securing pin.

7 Remove the switch front attaching screw (1).

8 Install the heat shield (3) and tighten the attaching screws (1 and 2) to the correct torque specification.

Heat shield front attaching screw

torque specification ............................................ 25.0 Nm

Heat shield rear attaching screw torque specification ..............................................9.0 Nm

9 Lower the vehicle to the ground and re-check the operation of the neutral start and back-up lamp switch. The vehicle must start only with the shift selector in the Park or Neutral positions and the back-up lamps should only

illuminate when Reverse is selected.

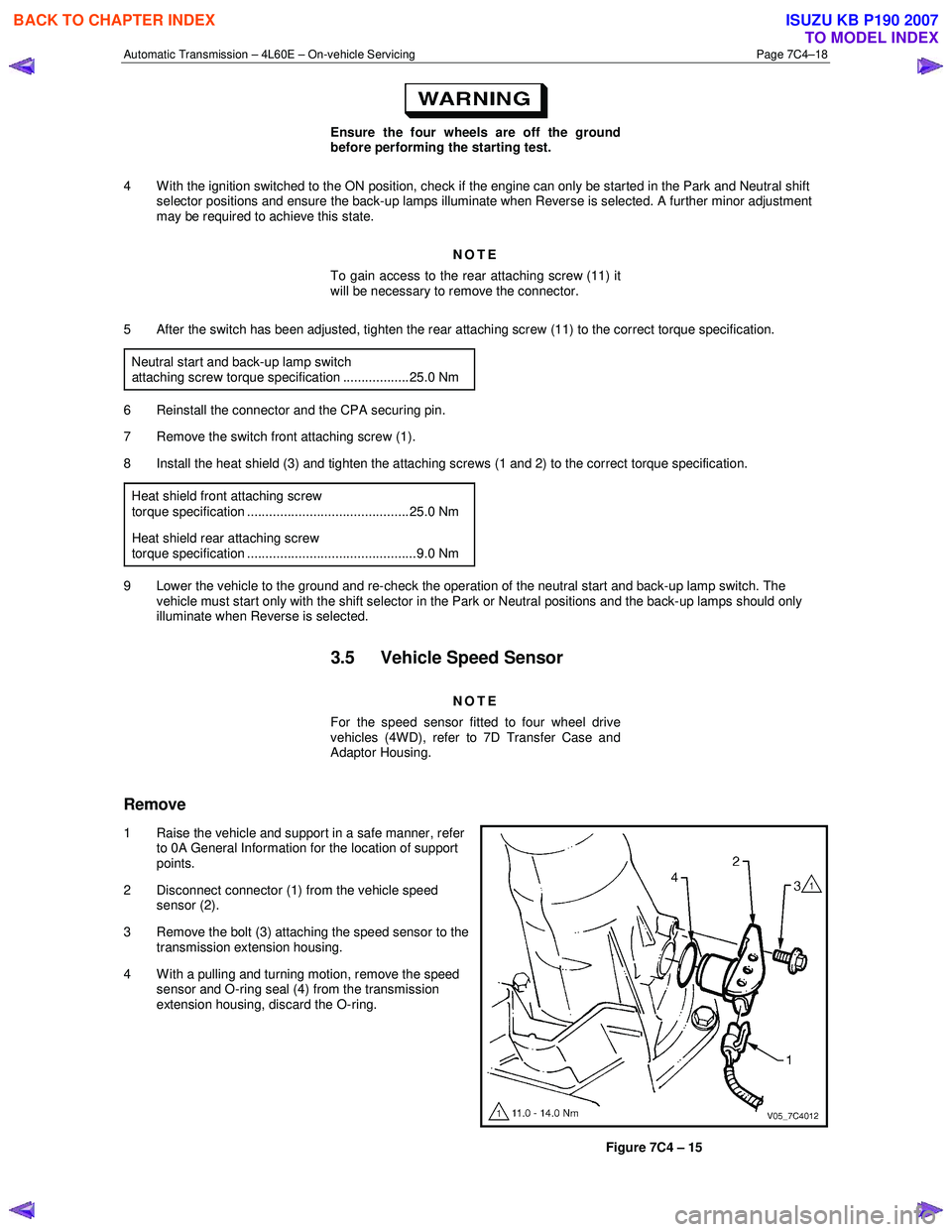

3.5 Vehicle Speed Sensor

NOTE

For the speed sensor fitted to four wheel drive

vehicles (4WD), refer to 7D Transfer Case and

Adaptor Housing.

Remove

1 Raise the vehicle and support in a safe manner, refer

to 0A General Information for the location of support

points.

2 Disconnect connector (1) from the vehicle speed sensor (2).

3 Remove the bolt (3) attaching the speed sensor to the transmission extension housing.

4 With a pulling and turning motion, remove the speed sensor and O-ring seal (4) from the transmission

extension housing, discard the O-ring.

Figure 7C4 – 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3937 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–24

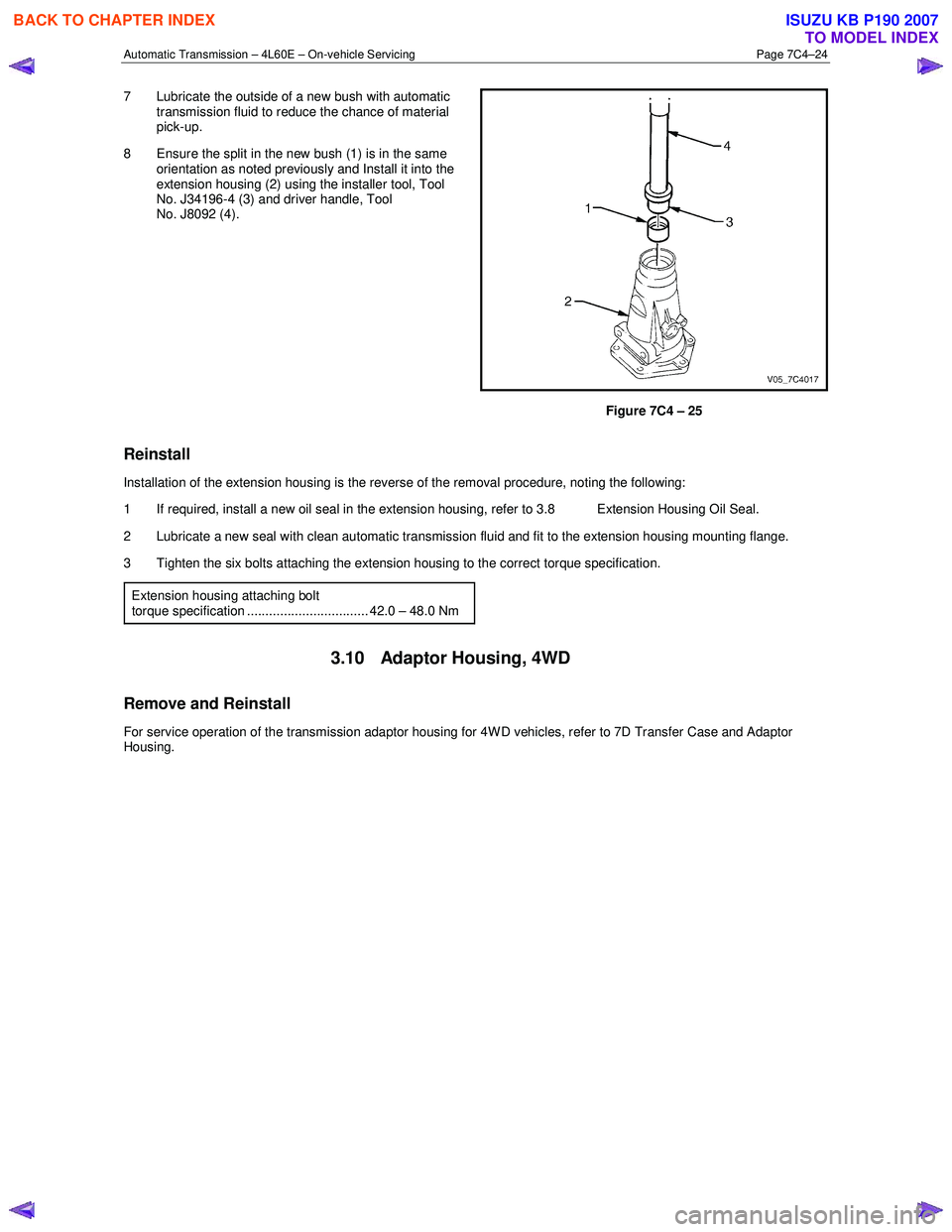

7 Lubricate the outside of a new bush with automatic

transmission fluid to reduce the chance of material

pick-up.

8 Ensure the split in the new bush (1) is in the same orientation as noted previously and Install it into the

extension housing (2) using the installer tool, Tool

No. J34196-4 (3) and driver handle, Tool

No. J8092 (4).

Figure 7C4 – 25

Reinstall

Installation of the extension housing is the reverse of the removal procedure, noting the following:

1 If required, install a new oil seal in the extension housing, refer to 3.8 Extension Housing Oil Seal.

2 Lubricate a new seal with clean automatic transmission fluid and fit to the extension housing mounting flange.

3 Tighten the six bolts attaching the extension housing to the correct torque specification.

Extension housing attaching bolt

torque specification ................................. 42.0 – 48.0 Nm

3.10 Adaptor Housing, 4WD

Remove and Reinstall

For service operation of the transmission adaptor housing for 4W D vehicles, refer to 7D Transfer Case and Adaptor

Housing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3956 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–43

If the verifier disc does not clip into place, the

quick-connect fitting is not engaged, rectify

as required.

10 As a security check, push and clip each verification disc into place over the quick-connect fittings. If difficulty is experienced, repeat the installation process until the verification disc can be clipped into place over the radiator

quick-connect fitting.

11 Snap the outlet cooler line (4) in the clip (5) of the radiator fan shroud.

12 Ensure the routeing of the cooler lines is correct and there is no fouling of the lines.

13 Tighten the screw attaching the cooler lines bracket to the correct torque specifications.

Transmission cooler lines bracket

attaching screw torque specification .................. 23.0 Nm

14 If required, top up the transmission fluid level (cold).

15 Start the engine and check for any fluid leak at the fittings. If a leak is found, stop the engine and rectify the leak.

16 Check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

3.18 Transmission Assembly

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery, before disconnecting the battery.

1 Disconnect the battery ground lead.

2 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

3 Remove the heat shield from the neutral start and back-up lamp switch, gently prise the selector cable from the transmission external manual shaft linkage and remove the selector cable from the bracket, refer to

3.3 Selector Cable Assembly.

4 Disconnect the harness connectors from the following:

a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on four wheel drive vehicles (4W D), refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

NOTE

If the battery is connected, avoid turning the

ignition switch to the ON position, as the transfer

case control module (TTCM) must first be

removed (memory to be cleared as Check 4W D

Indicator will light).

5 Remove the following components: a Front and centre exhaust assemblies, refer to 6F Exhaust System.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3957 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–44

b Starter motor, refer to 6D1-2 Starting System.

b Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

6 On 4WD vehicle, disconnect the harness two clips from the upper side of the transfer case.

7 From within the starter motor access hole, remove the three bolts (2) attaching the torque converter to the flexplate and discard, refer to Figure 7C4 – 62.

8 Remove the transmission support, refer to 3.7 Transmission Support and Mount.

9 Disconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

Before lowering the transmission take care of

the following:

• Do not strain the harness and connector

as the connector pins could be

permanently damaged.

• Ensure the inlet manifold does not hit the

firewall.

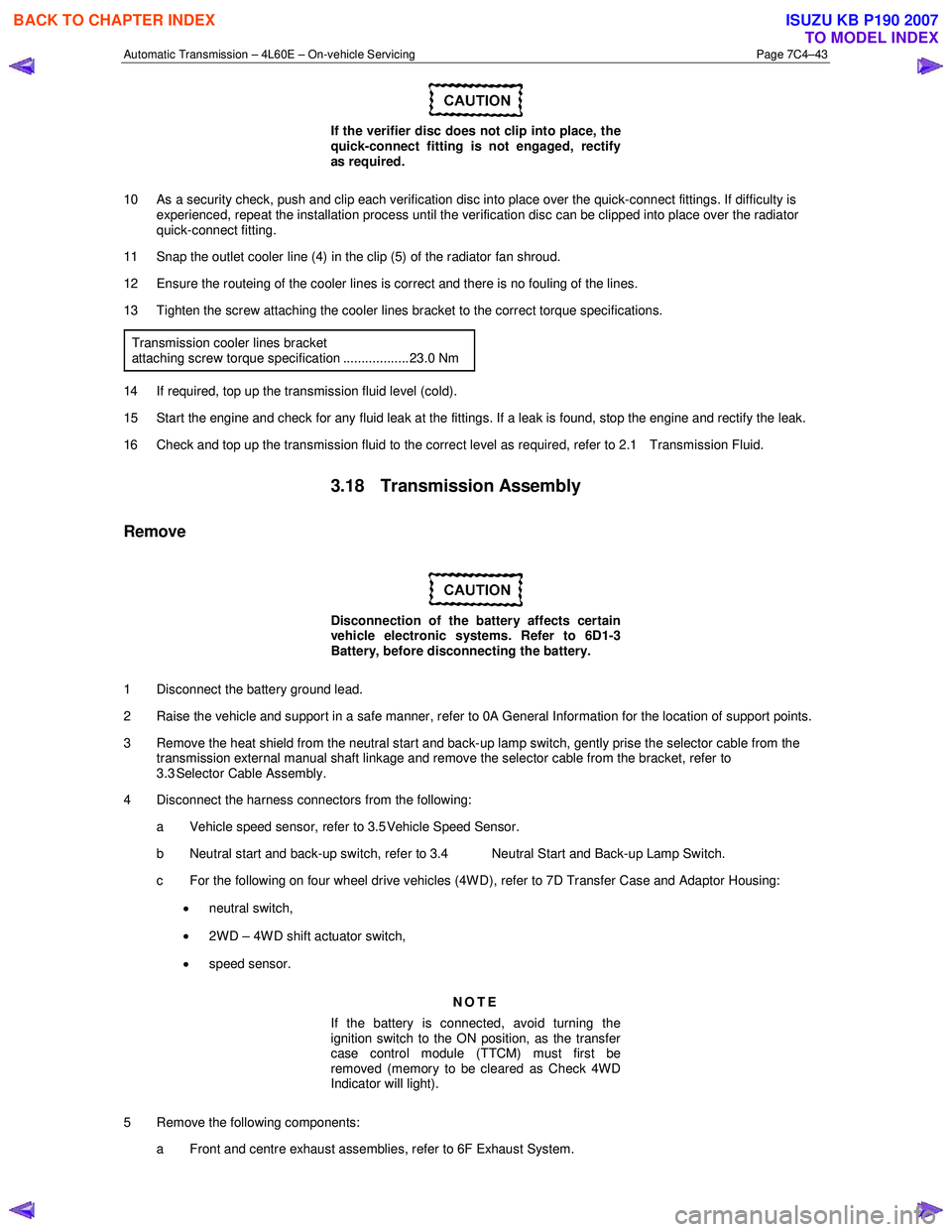

10 Carefully lower the transmission to provide enough clearance to disconnect the harness connector (1).

Do not wiggle the connector from side to side

during removal as the connector pins could

be permanently damaged.

11 Disconnect the harness connector from the transmission as follows:

a Roll back the dust boot to access the connector.

b Squeeze the widest side of the connector (A) inward and pull it directly upward.

Figure 7C4 – 61

12 Remove the screws attaching the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and W iring Harnesses.

13 Place a suitable sized drip tray underneath the transmission.

14 Remove the transmission cooler lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

15 Disconnect the breather hose from the top of the transmission case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3959 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–46

Reinstall

1 If required on 4W D vehicle, reinstall the transfer case, refer to 7D Transfer Case and Adaptor Housing.

2 Ensure the transmission and the engine mating surfaces are clean and free of burrs.

3 Lubricate the torque converter spigot (7) with a small amount of high temperature wheel bearing grease, refer to Figure 7C4 – 62.

4 Install a new filler tube seal into the transmission case.

Support the transmission while installing the

attaching bolts to avoid damage to the torque

converter and flexplate. Do not have the

transmission hanging.

5 Bring the transmission up to the engine, inserting the filler tube and ensuring the locating dowels completely enter the torque converter housing.

6 Reconnect the breather hose to the top of the transmission case.

NOTE

The bolts attaching the torque converter housing

are facing forward except for the bolt in position ℑ

which is facing rearward.

7 With the transmission supported, install the bolt (1), nine places, attaching the torque converter housing to the engine and tighten to the correct torque specification following the sequence shown in

within Figure 7C4 – 62.

Torque converter housing attaching

bolt torque specification .......................... 52.0 – 66.0 Nm

8 Remove the access hole cover plate from the lower surface of the housing and push the torque converter forward to meet the flexplate, then hand start three new bolts (2) before tightening to the correct torque specification.

Reinstall the access hole cover plate.

Torque converter to flexplate attaching

bolt torque specification .......................... 60.0 – 70.0 Nm

9 Reinstall the bolt (3) and torque converter cover (4) on the transmission right-hand side and the bolt (5) and torque converter cover (6) on the transmission left-hand side, tighten the bolts to the correct torque specification.

Torque converter cover attaching

bolt torque specification .......................... 12.0 – 16.0 Nm

10 Reinstall the transmission fluid lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

Prior to connecting the harness connector to

the transmission, check that all pins and

seals are in sound condition and the dust

boot is not torn or damaged.

11 Reconnect the transmission harness connector to the transmission as follows: a Push straight down on the connector body until a click is heard.

b Reinstall the dust boot ensuring it is correctly located.

12 Attach the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and Wiring Harnesses.

13 On 4WD vehicle, connect the harness two clips from the upper side of the transfer case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3960 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–47

14 Reconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

15 Reinstall the following components:

a Starter motor, refer to 6D1-2 Starting System.

b Transmission support, refer to 3.7 Transmission Support and Mount.

c Front and centre exhaust assemblies, refer to 6F Exhaust System.

d Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

16 Reconnect the harness connectors to the following: a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on 4W D vehicles, refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

17 Reinstall the selector cable to the transmission external manual shaft linkage, secure the selector cable to the bracket and attach the heat shield to the neutral start and back-up lamp switch, refer to 3.3 Selector Cable

Assembly.

18 Perform a reverse flush of the cooler lines and a flow rate test, refer to 2.2 Reverse Flush and Flow Rate, if either of the following applies:

• the transmission fluid is contaminated,

• the transmission has been replaced,

• the torque converter has been replaced, or

• the transmission oil pump has been replaced.

19 Lower the vehicle to the ground.

20 If required, top up the transmission fluid level (cold).

21 Reconnect the battery ground lead.

22 Start the engine and check for any fluid leaking at the fittings. If a leak is found, stop the engine and rectify the leak.

23 Road test until the transmission has reached operating temperature. Re-check the fluid level and for any fluid leaks, refer to 2.1 Transmission Fluid.

3.19 Transmission Control Module

Remove

1 Ensure the ignition switch is in the OFF position.

2 Disconnect the connector (1) from the transmission control module (TCM) (2) as follows, refer to Figure 7C4 – 63: a remove the securing pin (3),

b press the locking tab and swing the lever (4) to free the connector,

c remove the connector.

3 Remove the four bolts (5) and nuts (6), then the TCM from the mounting bracket (7).

4 If required, remove the two nuts (8) and the mounting bracket from the firewall.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4242 of 6020

CONSTRUCTION AND FUNCTION 7A1-3

DESCRIPTION

CONSTRUCTION

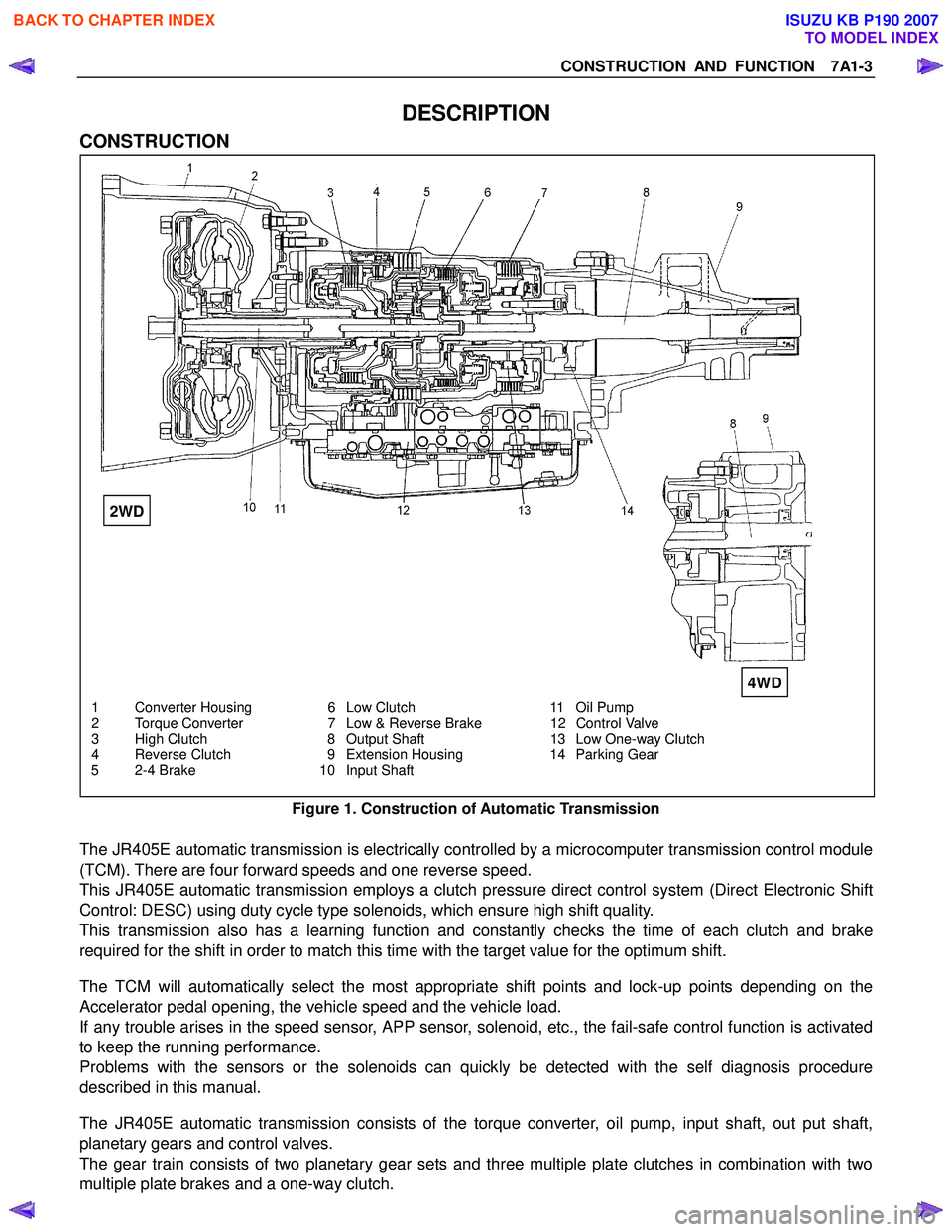

1 Converter Housing 6 Low Clutch 11 Oil Pump

2 Torque Converter 7 Low & Reverse Brake 12 Control Valve

3 High Clutch 8 Output Shaft 13 Low One-way Clutch

4 Reverse Clutch 9 Extension Housing 14 Parking Gear

5 2-4 Brake 10 Input Shaft

Figure 1. Construction of Automatic Transmission

The JR405E automatic transmission is electrically controlled by a microcomputer transmission control module

(TCM). There are four forward speeds and one reverse speed.

This JR405E automatic transmission employs a clutch pressure direct control system (Direct Electronic Shift

Control: DESC) using duty cycle type solenoids, which ensure high shift quality.

This transmission also has a learning function and constantly checks the time of each clutch and brake

required for the shift in order to match this time with the target value for the optimum shift.

The TCM will automatically select the most appropriate shift points and lock-up points depending on the

Accelerator pedal opening, the vehicle speed and the vehicle load.

If any trouble arises in the speed sensor, APP sensor, solenoid, etc., the fail-safe control function is activated

to keep the running performance.

Problems with the sensors or the solenoids can quickly be detected with the self diagnosis procedure

described in this manual.

The JR405E automatic transmission consists of the torque converter, oil pump, input shaft, out put shaft,

planetary gears and control valves.

The gear train consists of two planetary gear sets and three multiple plate clutches in combination with two

multiple plate brakes and a one-way clutch.

2WD

4WD

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007