4WD ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4244 of 6020

CONSTRUCTION AND FUNCTION 7A1-5

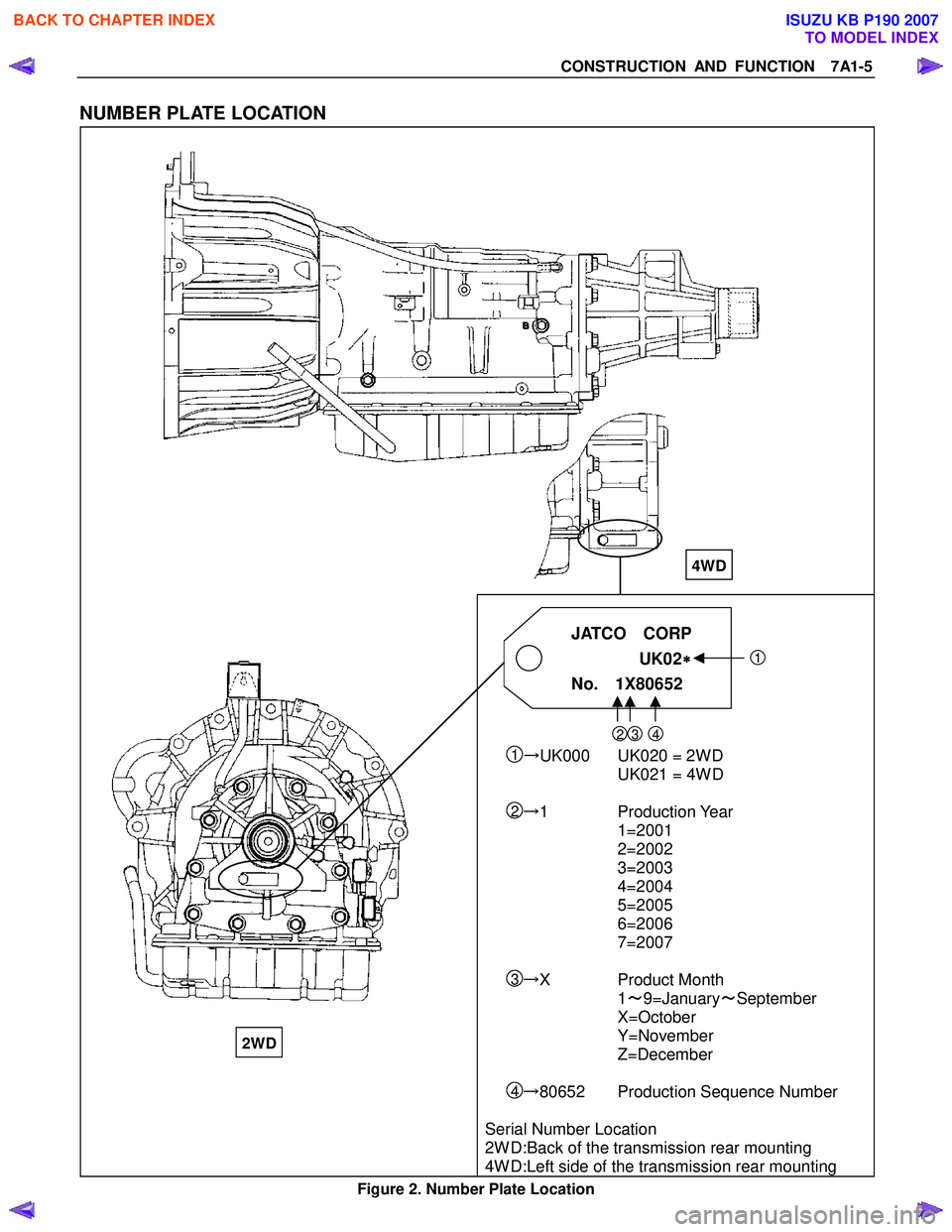

NUMBER PLATE LOCATION

JATCO CORP

UK02

∗

∗∗

∗

1

No. 1X80652

23 4 1→ UK000 UK020 = 2WD

UK021 = 4WD

2→ 1 Production Year

1=2001

2=2002

3=2003

4=2004

5=2005

6=2006

7=2007

3→ X Product Month

1 ~9=January ~September

X=October

Y=November

Z=December

4→ 80652 Production Sequence Number

Serial Number Location

2WD:Back of the transmission rear mounting

4WD:Left side of the transmission rear mounting

Figure 2. Number Plate Location

4WD

2WD

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4245 of 6020

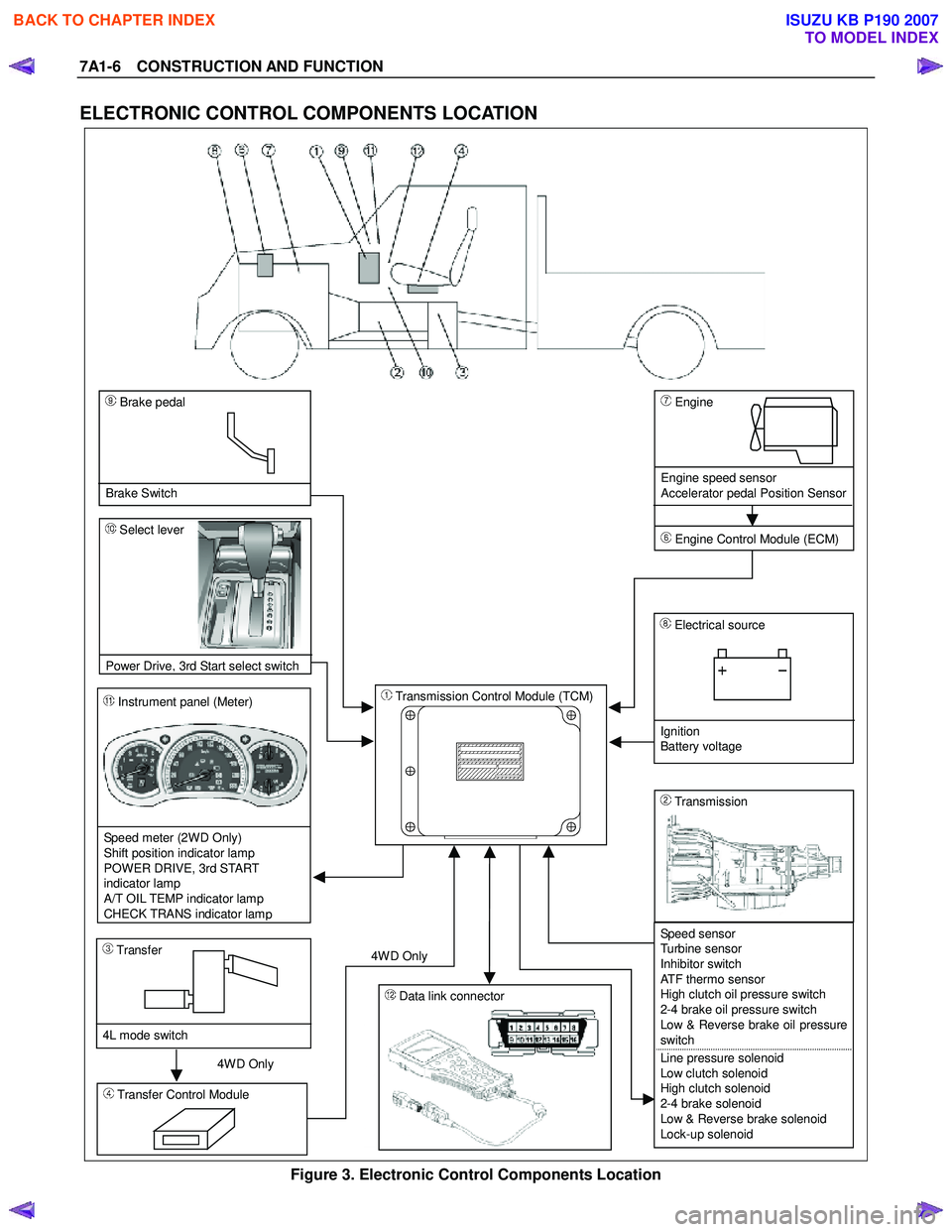

7A1-6 CONSTRUCTION AND FUNCTION

ELECTRONIC CONTROL COMPONENTS LOCATION

4WD Only 4W D Only

Instrument panel (Meter)

Speed meter (2WD Only)

Shift position indicator lamp

POWER DRIVE, 3rd START

indicator lamp

A/T OIL TEMP indicator lamp

CHECK TRANS indicator lam

p

Brake pedal

Brake Switch

Transmission Control Module (TCM)

Electrical source

Ignition

Battery voltage

Speed sensor

Turbine sensor

Inhibitor switch

ATF thermo sensor

High clutch oil pressure switch

2-4 brake oil pressure switch

Low & Reverse brake oil pressure

switch

Line pressure solenoid

Low clutch solenoid

High clutch solenoid

2-4 brake solenoid

Low & Reverse brake solenoid

Lock-up solenoid

Transmission

Transfer Control Module

Transfer

4L mode switch

Engine

Engine speed sensor

Accelerator pedal Position Sensor

Engine Control Module (ECM)

Data link connector

Select lever

Power Drive

, 3rd Start select switch

Figure 3. Electronic Control Components Location

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4301 of 6020

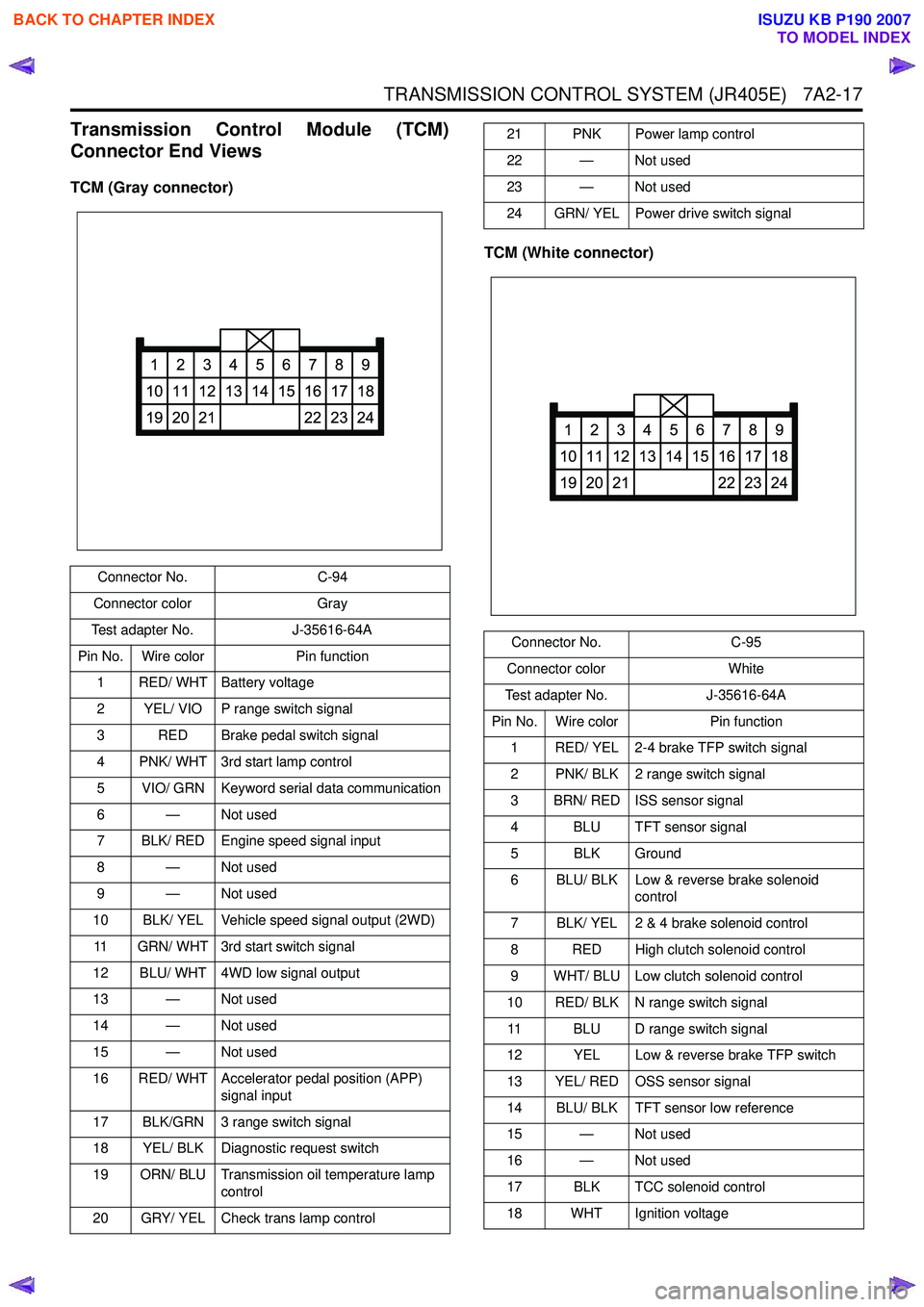

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-17

Transmission Control Module (TCM)

Connector End Views

TCM (Gray connector)

TCM (White connector)

Connector No.C-94

Connector color Gray

Test adapter No. J-35616-64A

Pin No. Wire color Pin function

1 RED/ WHT Battery voltage

2 YEL/ VIO P range switch signal

3 RED Brake pedal switch signal

4 PNK/ WHT 3rd start lamp control

5 VIO/ GRN Keyword serial data communication

6 — Not used

7 BLK/ RED Engine speed signal input

8 — Not used

9 — Not used

10 BLK/ YEL Vehicle speed signal output (2WD)

11 GRN/ WHT 3rd start switch signal

12 BLU/ WHT 4WD low signal output

13 — Not used

14 — Not used

15 — Not used

16 RED/ WHT Accelerator pedal position (APP) signal input

17 BLK/GRN 3 range switch signal

18 YEL/ BLK Diagnostic request switch

19 ORN/ BLU Transmission oil temperature lamp control

20 GRY/ YEL Check trans lamp control

1

10

19

2

11

20

3

12

21

4

13

5

14

6

15

7

16

22

8

17

23

9

18

24

21 PNK Power lamp control

22 — Not used

23 — Not used

24 GRN/ YEL Power drive switch signal

Connector No. C-95

Connector color White

Test adapter No. J-35616-64A

Pin No. Wire color Pin function

1 RED/ YEL 2-4 brake TFP switch signal

2 PNK/ BLK 2 range switch signal

3 BRN/ RED ISS sensor signal

4 BLU TFT sensor signal

5 BLK Ground

6 BLU/ BLK Low & reverse brake solenoid control

7 BLK/ YEL 2 & 4 brake solenoid control

8 RED High clutch solenoid control

9 WHT/ BLU Low clutch solenoid control

10 RED/ BLK N range switch signal 11 BLU D range switch signal

12 YEL Low & reverse brake TFP switch

13 YEL/ RED OSS sensor signal

14 BLU/ BLK TFT sensor low reference

15 — Not used

16 — Not used

17 BLK TCC solenoid control

18 WHT Ignition voltage

1

10

19

2

11

20

3

12

21

4

13

5

14

6

15

7

16

22

8

17

23

9

18

24

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4310 of 6020

7A2-26 TRANSMISSION CONTROL SYSTEM (JR405E)

Low & Reverse Brake Pressure Switch

This parameter displays the input state of the low &

reverse brake transmission fluid pressure (TFP) switch

to the TCM. When the low & reverse brake fluid

pressure is generated, the scan tool displays On.

2-4 Brake Solenoid Command

This parameter displays the 2-4 brake solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the 2-4 brake is controlled to engage (fluid

pressure is applied to the 2-4 brake hydraulic circuits).

The scan tool will display higher percentage when the

2-4 brake is controlled to disengage (fluid pressure is

drained from the 2-4 brake hydraulic circuits).

2-4 Brake Pressure Switch

This parameter displays the input state of the 2-4 brake

transmission fluid pressure (TFP) switch to the TCM.

When the 2-4 brake fluid pressure is generated, the

scan tool displays On.

High Clutch Solenoid Command

This parameter displays the high clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the high clutch is controlled to engage (fluid

pressure is applied to the high clutch hydraulic circuits).

The scan tool will display higher percentage when the

high clutch is controlled to disengage (fluid pressure is

drained from the high clutch hydraulic circuits).

High Clutch Pressure Switch

This parameter displays the input state of the high

clutch transmission fluid pressure (TFP) switch to the

TCM. When the high clutch fluid pressure is generated,

the scan tool displays On.

Low Clutch Solenoid Command

This parameter displays the low clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the low clutch is controlled to engage (fluid

pressure is applied to the low clutch hydraulic circuits).

The scan tool will display higher percentage when the

low clutch is controlled to disengage (fluid pressure is

drained from the low clutch hydraulic circuits).

TCC Solenoid (Torque Converter Clutch)

This parameter displays the torque converter clutch

(TCC) control duty ratio based on the command from

the TCM. The scan tool will display a lower percentage

when the TCC is controlled to disengage (fluid

pressure is drained from the TCC release hydraulic

circuits). The scan tool will display higher percentage

when the TCC is controlled to engage (fluid pressure is

applied to the TCC apply hydraulic circuits). Transmission Fluid Temperature

This parameter displays the temperature of the

automatic transmission fluid (ATF) temperature as

calculated by the TCM using the signal from the

transmission fluid temperature (TFT) sensor. The scan

tool will display a low temperature when the signal

voltage is high, and a high temperature when the signal

voltage is low.

Transmission Oil Temperature Lamp

This parameter displays the commanded state of the

transmission oil temperature lamp control circuit. The

lamp should be On when the scan tool indicates

command On.

TCM Status Temp. (Temperature Transmission

Control Module)

This parameter displays the commanded state of the

high temperature mode shift map. On indicates the

transmission fluid temperature is high and the high

temperature mode is selected to prevent an

overheating.

4 Wheel Drive Low

This parameter displays the input state of the 4WD low

gear signal from the transfer case control module

(TCCM). When the 4L mode is selected, the scan tool

displays On.

TCM Status Transfer (Transmission Control

Module)

This parameter displays the commanded state of the

shift map that is based on the transfer case position.

High indicates the high mode (2H or 4H) is inputted

from the transfer case control module (TCCM). Low

indicates the low mode (4L) is inputted from the TCCM.

TCM Status Down Slope (Transmission Control

Module)

This parameter displays the commanded state of the

down slope mode shift map. On indicates the down

slope mode is selected under certain driving conditions.

TCM Status Up Slope (Transmission Control

Module)

This parameter displays the commanded state of the

up slope mode shift map. On indicates the up slope

mode is selected under certin driving conditions.

3rd Start Switch

This parameter displays the input state of the 3rd start

switch to the TCM. When the switch is pressed, the

scan tool displays On.

3rd Start Lamp

This parameter displays the commanded state of the

3rd start lamp control circuit. The lamp should be On

when the scan tool indicates command On.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4418 of 6020

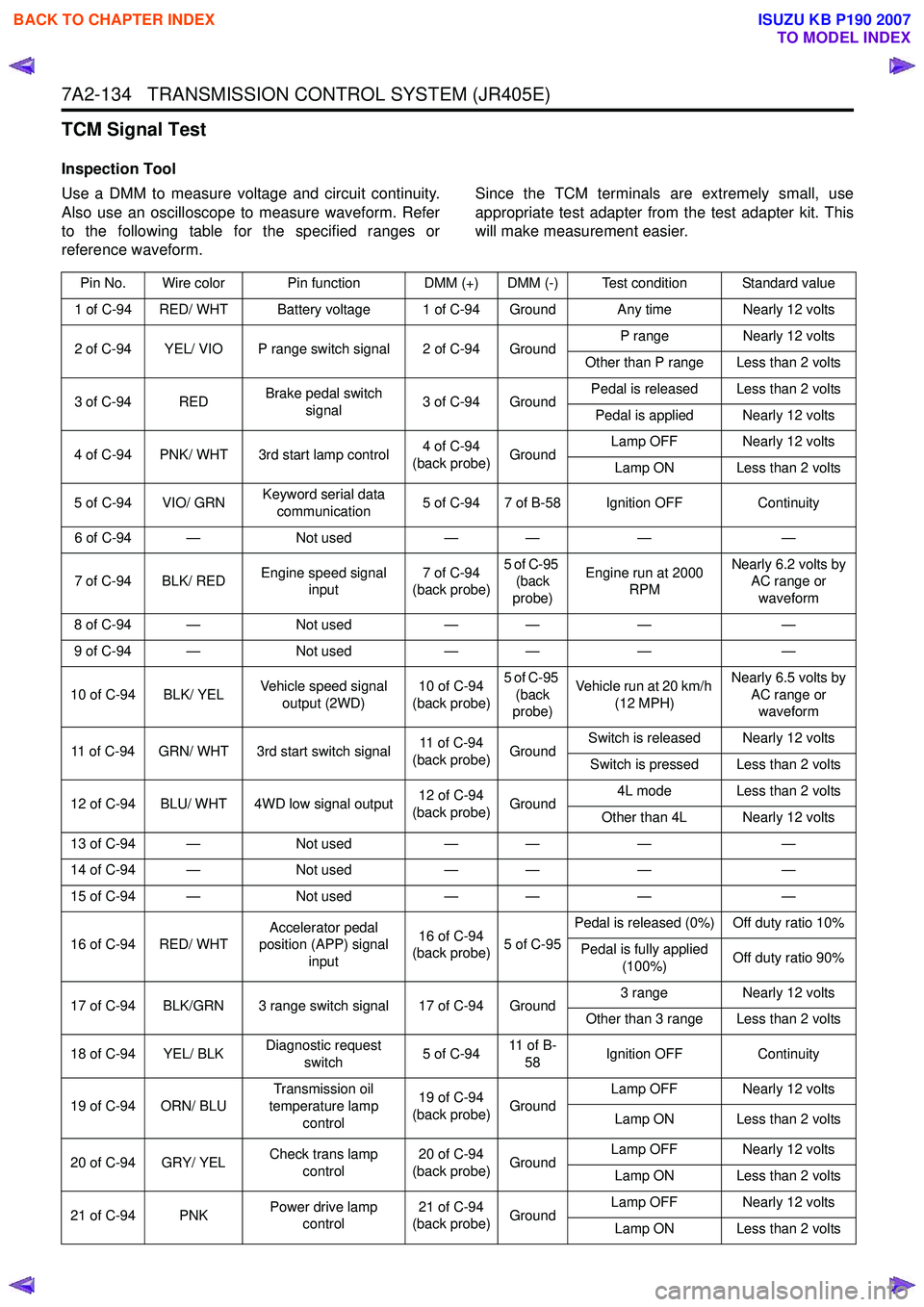

7A2-134 TRANSMISSION CONTROL SYSTEM (JR405E)

TCM Signal Test

Inspection Tool

Use a DMM to measure voltage and circuit continuity.

Also use an oscilloscope to measure waveform. Refer

to the following table for the specified ranges or

reference waveform. Since the TCM terminals are extremely small, use

appropriate test adapter from the test adapter kit. This

will make measurement easier.

Pin No. Wire color Pin function DMM (+) DMM (-) Test condition Standard value

1 of C-94 RED/ WHT Battery voltage 1 of C-94 Ground Any time Nearly 12 volts

2 of C-94 YEL/ VIO P range switch signal 2 of C-94 Ground P range

Nearly 12 volts

Other than P range Less than 2 volts

3 of C-94 RED Brake pedal switch

signal 3 of C-94 Ground Pedal is released Less than 2 volts

Pedal is applied Nearly 12 volts

4 of C-94 PNK/ WHT 3rd start lamp control 4 of C-94

(back probe) Ground Lamp OFF Nearly 12 volts

Lamp ON Less than 2 volts

5 of C-94 VIO/ GRN Keyword serial data

communication 5 of C-94 7 of B-58 Ignition OFF

Continuity

6 of C-94 — Not used— — ——

7 of C-94 BLK/ RED Engine speed signal

input 7 of C-94

(back probe) 5 of C-95

(back

probe) Engine run at 2000

RPM Nearly 6.2 volts by

AC range or

waveform

8 of C-94 — Not used— — ——

9 of C-94 — Not used— — ——

10 of C-94 BLK/ YEL Vehicle speed signal

output (2WD) 10 of C-94

(back probe) 5 of C-95

(back

probe) Vehicle run at 20 km/h

(12 MPH) Nearly 6.5 volts by

AC range or waveform

11 of C-94 GRN/ WHT 3rd start switch signal 11 of C-94

(back probe) GroundSwitch is released Nearly 12 volts

Switch is pressed Less than 2 volts

12 of C-94 BLU/ WHT 4WD low signal output 12 of C-94

(back probe) Ground 4L mode Less than 2 volts

Other than 4L Nearly 12 volts

13 of C-94 — Not used— — ——

14 of C-94 — Not used— — ——

15 of C-94 — Not used— — ——

16 of C-94 RED/ WHT Accelerator pedal

position (APP) signal

input 16 of C-94

(back probe) 5 of C-95Pedal is released (0%) Off duty ratio 10%

Pedal is fully applied (100%) Off duty ratio 90%

17 of C-94 BLK/GRN 3 range switch signal 17 of C-94 Ground 3 range

Nearly 12 volts

Other than 3 range Less than 2 volts

18 of C-94 YEL/ BLK Diagnostic request

switch 5 of C-9411 o f B -

58 Ignition OFF

Continuity

19 of C-94 ORN/ BLU Transmission oil

temperature lamp control 19 of C-94

(back probe) Ground Lamp OFF Nearly 12 volts

Lamp ON Less than 2 volts

20 of C-94 GRY/ YEL Check trans lamp

control 20 of C-94

(back probe) Ground Lamp OFF Nearly 12 volts

Lamp ON Less than 2 volts

21 of C-94 PNK Power drive lamp

control 21 of C-94

(back probe) Ground Lamp OFF Nearly 12 volts

Lamp ON Less than 2 volts

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4427 of 6020

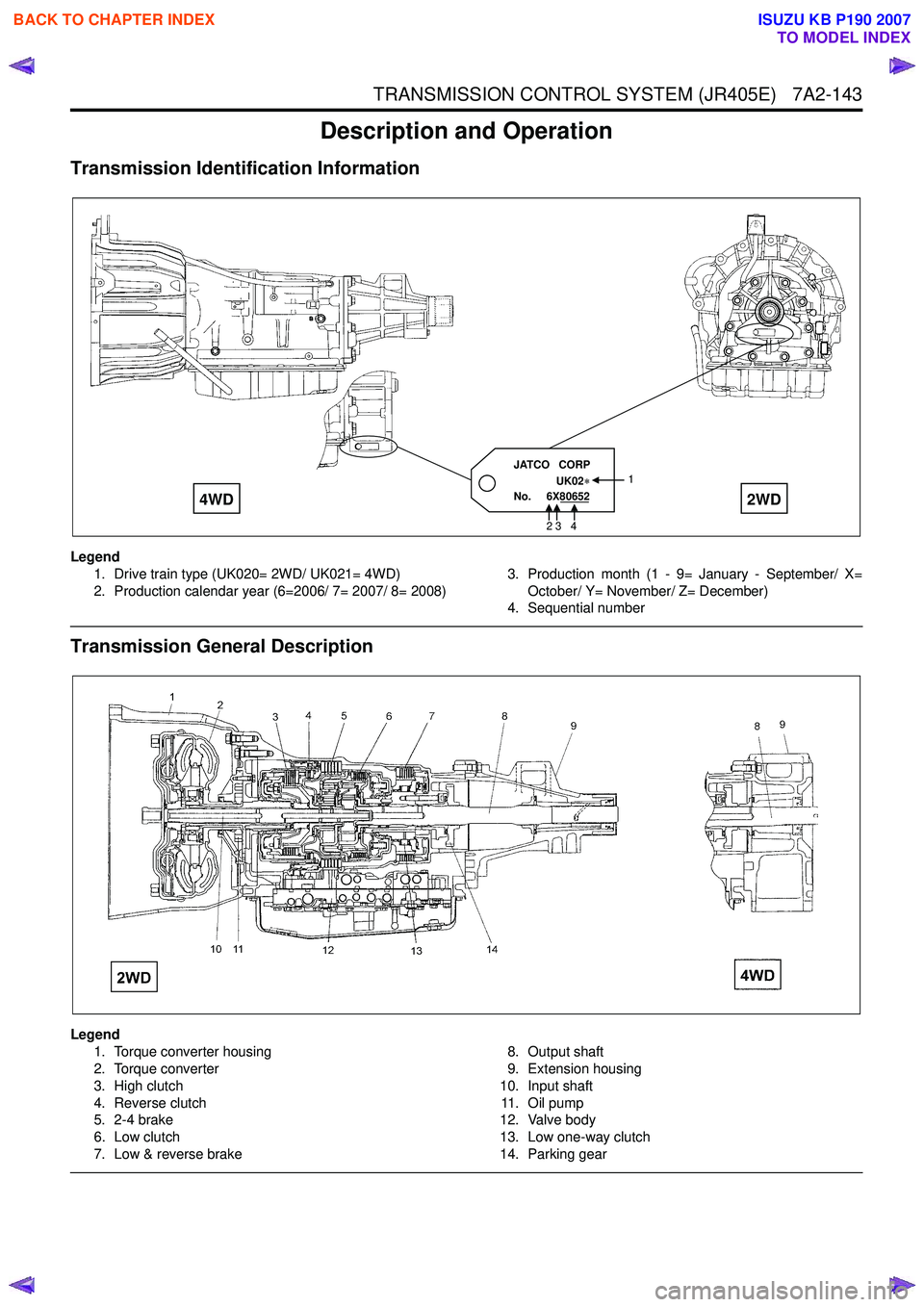

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-143

Description and Operation

Transmission Identification Information

Legend1. Drive train type (UK020= 2WD/ UK021= 4WD)

2. Production calendar year (6=2006/ 7= 2007/ 8= 2008) 3. Production month (1 - 9= January - September/ X=

October/ Y= November/ Z= December)

4. Sequential number

Transmission General Description

Legend

1. Torque converter housing

2. Torque converter

3. High clutch

4. Reverse clutch

5. 2-4 brake

6. Low clutch

7. Low & reverse brake 8. Output shaft

9. Extension housing

10. Input shaft 11 . O i l p u m p

12. Valve body

13. Low one-way clutch

14. Parking gear

JATCO CORP

UK02

No. 6X80652 1

2 3 4

4WD

2WD

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4437 of 6020

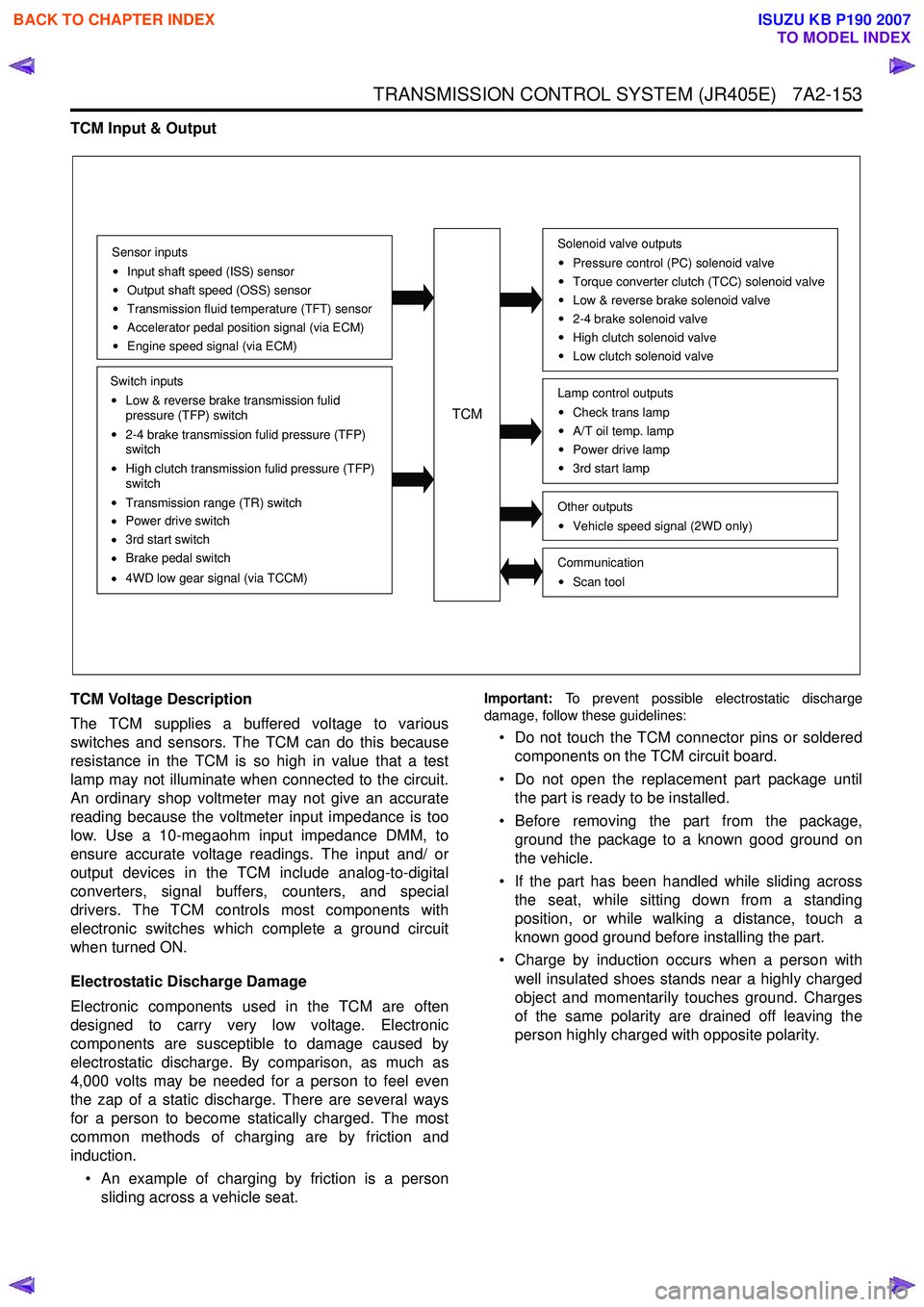

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-153

TCM Input & Output

TCM Voltage Description

The TCM supplies a buffered voltage to various

switches and sensors. The TCM can do this because

resistance in the TCM is so high in value that a test

lamp may not illuminate when connected to the circuit.

An ordinary shop voltmeter may not give an accurate

reading because the voltmeter input impedance is too

low. Use a 10-megaohm input impedance DMM, to

ensure accurate voltage readings. The input and/ or

output devices in the TCM include analog-to-digital

converters, signal buffers, counters, and special

drivers. The TCM controls most components with

electronic switches which complete a ground circuit

when turned ON.

Electrostatic Discharge Damage

Electronic components used in the TCM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. By comparison, as much as

4,000 volts may be needed for a person to feel even

the zap of a static discharge. There are several ways

for a person to become statically charged. The most

common methods of charging are by friction and

induction.

• An example of charging by friction is a person sliding across a vehicle seat.

Important: To prevent possible electrostatic discharge

damage, follow these guidelines:

• Do not touch the TCM connector pins or soldered components on the TCM circuit board.

• Do not open the replacement part package until the part is ready to be installed.

• Before removing the part from the package, ground the package to a known good ground on

the vehicle.

• If the part has been handled while sliding across the seat, while sitting down from a standing

position, or while walking a distance, touch a

known good ground before installing the part.

• Charge by induction occurs when a person with well insulated shoes stands near a highly charged

object and momentarily touches ground. Charges

of the same polarity are drained off leaving the

person highly charged with opposite polarity.

Sensor inputs

Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Low & reverse brake transmission fulid

pressure (TFP) switch

2-4 brake transmission fulid pressure (TFP)

switch

High clutch transmission fulid pressure (TFP)

switch

Transmission range (TR) switch

Power drive switch

3rd start switch

Brake pedal switch

4WD low gear signal (via TCCM)

TCM

Solenoid valve outputs

Pressure control (PC) solenoid valve

Torque converter clutch (TCC) solenoid valve

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

Other outputsVehicle speed signal (2WD only)

CommunicationScan tool

Lamp control outputsCheck trans lamp

A/T oil temp. lamp

Power drive lamp

3rd start lamp

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4440 of 6020

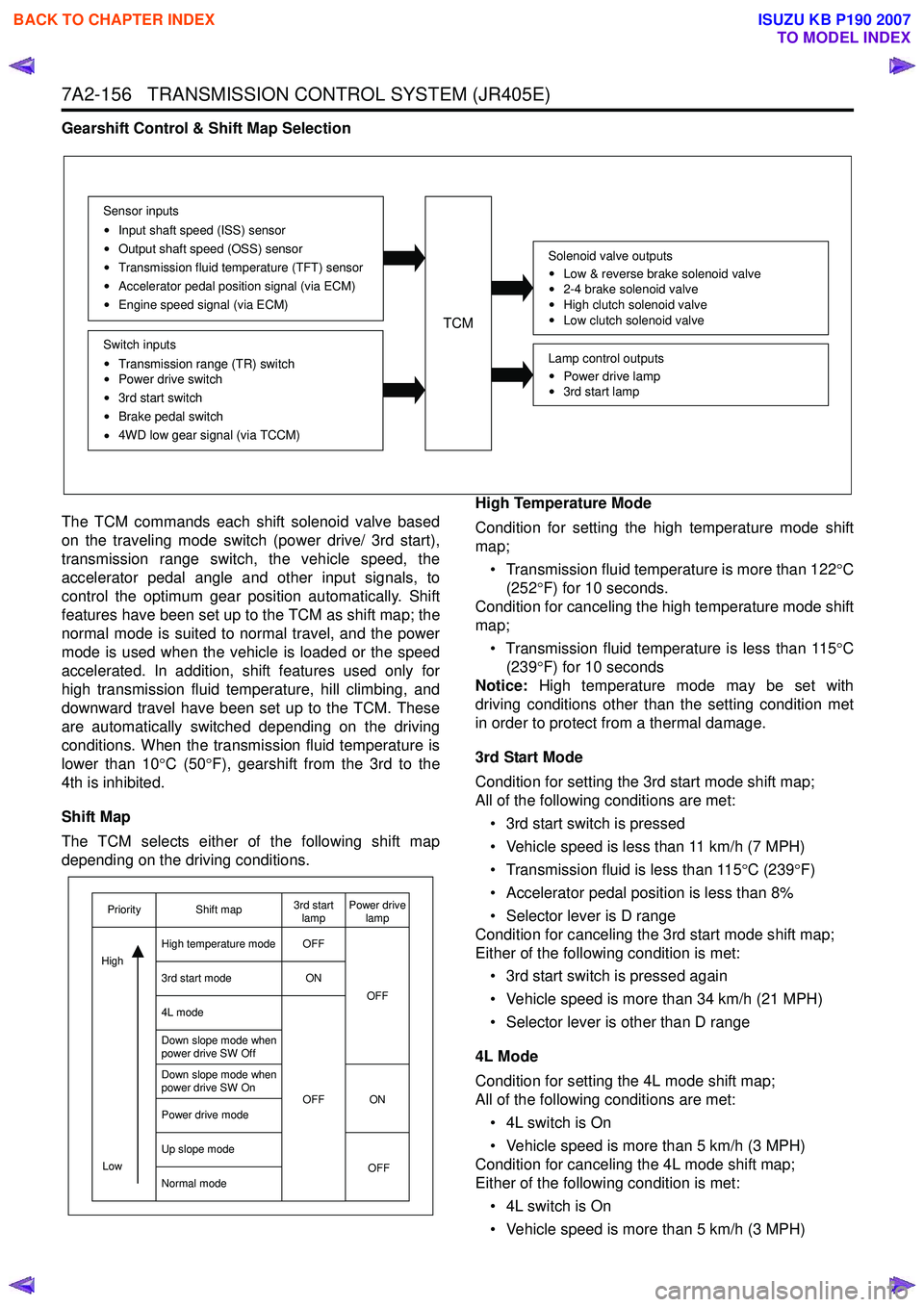

7A2-156 TRANSMISSION CONTROL SYSTEM (JR405E)

Gearshift Control & Shift Map Selection

The TCM commands each shift solenoid valve based

on the traveling mode switch (power drive/ 3rd start),

transmission range switch, the vehicle speed, the

accelerator pedal angle and other input signals, to

control the optimum gear position automatically. Shift

features have been set up to the TCM as shift map; the

normal mode is suited to normal travel, and the power

mode is used when the vehicle is loaded or the speed

accelerated. In addition, shift features used only for

high transmission fluid temperature, hill climbing, and

downward travel have been set up to the TCM. These

are automatically switched depending on the driving

conditions. When the transmission fluid temperature is

lower than 10 °C (50 °F), gearshift from the 3rd to the

4th is inhibited.

Shift Map

The TCM selects either of the following shift map

depending on the driving conditions. High Temperature Mode

Condition for setting the high temperature mode shift

map;

• Transmission fluid temperature is more than 122 °C

(252 °F) for 10 seconds.

Condition for canceling the high temperature mode shift

map;

• Transmission fluid temperature is less than 115 °C

(239 °F) for 10 seconds

Notice: High temperature mode may be set with

driving conditions other than the setting condition met

in order to protect from a thermal damage.

3rd Start Mode

Condition for setting the 3rd start mode shift map;

All of the following conditions are met:

• 3rd start switch is pressed

• Vehicle speed is less than 11 km/h (7 MPH)

• Transmission fluid is less than 115 °C (239 °F)

• Accelerator pedal position is less than 8%

• Selector lever is D range

Condition for canceling the 3rd start mode shift map;

Either of the following condition is met:

• 3rd start switch is pressed again

• Vehicle speed is more than 34 km/h (21 MPH)

• Selector lever is other than D range

4L Mode

Condition for setting the 4L mode shift map;

All of the following conditions are met:

• 4L switch is On

• Vehicle speed is more than 5 km/h (3 MPH)

Condition for canceling the 4L mode shift map;

Either of the following condition is met:

• 4L switch is On

• Vehicle speed is more than 5 km/h (3 MPH)

TCM

Sensor inputs

Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Transmission range (TR) switch

Power drive switch

3rd start switch

Brake pedal switch

4WD low gear signal (via TCCM)

Solenoid valve outputs

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

Lamp control outputs

Power drive lamp

3rd start lamp

OFF

ON

OFF ON OFF

OFF

Low

Priority Shift map 3rd start

lamp Power drive

lamp

High temperature mode

3rd start mode

4L mode

Down slope mode when

power drive SW Off

Down slope mode when

power drive SW On

Power drive mode

Up slope mode

Normal mode

High

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4485 of 6020

7A4-8 UNIT REPAIR (JR405E)

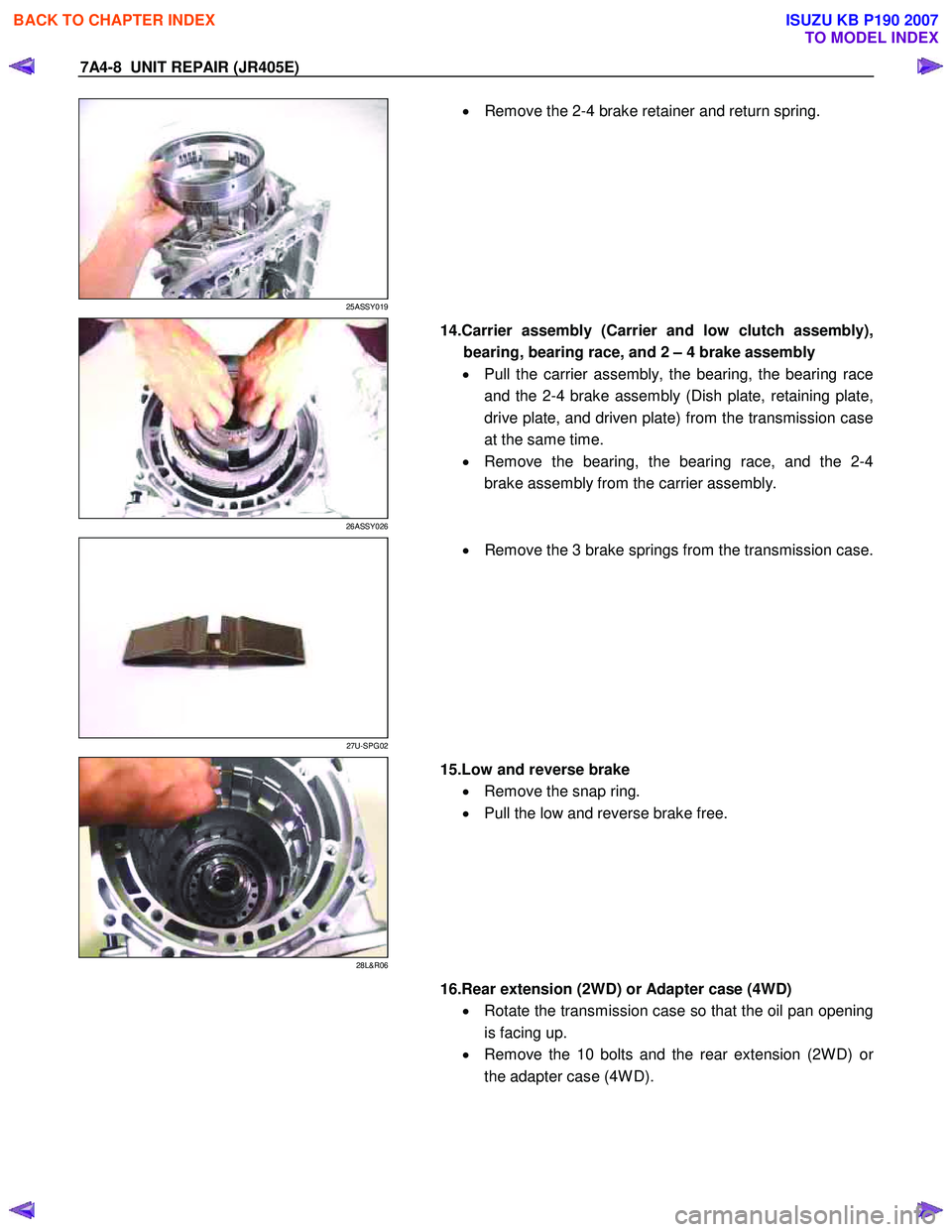

25ASSY019

•

Remove the 2-4 brake retainer and return spring.

26ASSY026

14.Carrier assembly (Carrier and low clutch assembly),

bearing, bearing race, and 2 – 4 brake assembly

• Pull the carrier assembly, the bearing, the bearing race

and the 2-4 brake assembly (Dish plate, retaining plate,

drive plate, and driven plate) from the transmission case

at the same time.

• Remove the bearing, the bearing race, and the 2-4

brake assembly from the carrier assembly.

27U-SPG02

•

Remove the 3 brake springs from the transmission case.

28L&R06

15.Low and reverse brake

• Remove the snap ring.

• Pull the low and reverse brake free.

16.Rear extension (2WD) or Adapter case (4WD)

• Rotate the transmission case so that the oil pan opening

is facing up.

• Remove the 10 bolts and the rear extension (2W D) o

r

the adapter case (4W D).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4556 of 6020

UNIT REPAIR (JR405E) 7A4-79

40ASSY091

•

Push the output shaft into place.

19.Rear extension (2WD) or adapter case (4WD)

• Use the oil seal installer to install the oil seal to the rea

r

extension (2W D) or adapter case (4W D).

Oil seal installer:

5-8840-2769-0 (2WD)

5-8840-2770-0 (4WD)

41ASSY096

•

Install the bearing (with bearing race) to the rear

extension (2W D) or adapter case (4W D).

NOTE:

•

••

•

The black side (bearing race) of the bearing must be

visible.

•

••

•

Apply Vaseline to the bearing.

249L300005

•

Apply sealing agent (TB1216B) to the rear extension

(2W D) or adapter case (4W D) contact surfaces.

249L300006

• Install the rear extension (2W D) or adapter case (4W D)

to the transmission case and tighten the 10 bolts to the

specified torque.

Torque: 53 N ⋅

⋅⋅

⋅

m (5.4 kgf ⋅

⋅⋅

⋅

m/39 Ib ⋅

⋅⋅

⋅

ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007