sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1193 of 6020

Engine Control System (4JH1) 6E-159

Step Action Value(s) Yes No

3 1. Turn OFF the ignition.

2. Disconnect the VSS harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the VSS

(pins 1, 2 and 3 of E-44 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 4

4 1. Turn OFF the ignition. 2. Disconnect the engine control module (ECM) harness connector.

3. Inspect for an intermittent and for a poor connection on VSS circuit at the harness

connector of the ECM (pin 68 of C-56 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 5

5 1. Remove the VSS. Refer to Vehicle Speed Sensor (VSS) Replacement in this section.

2. Visually inspect the VSS for the following conditions: • Physical damage

• Being loose

• Improper installation

3. The following conditions may cause this DTC to set: • Electromagnetic interference in the VSS

circuits

4. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 6

6 Replace the VSS. Refer to Vehicle Speed Sensor (VSS) Replacement in this section.

Did you complete the replacement?

Go to Step 7

7 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Drive the vehicle.

5. Observe the Vehicle Speed parameter with the scan tool.

Does the Vehicle Speed parameter indicate correct

vehicle speed?

Go to Step 8 Go to Step 2

8 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1194 of 6020

6E-160 Engine Control System (4JH1)

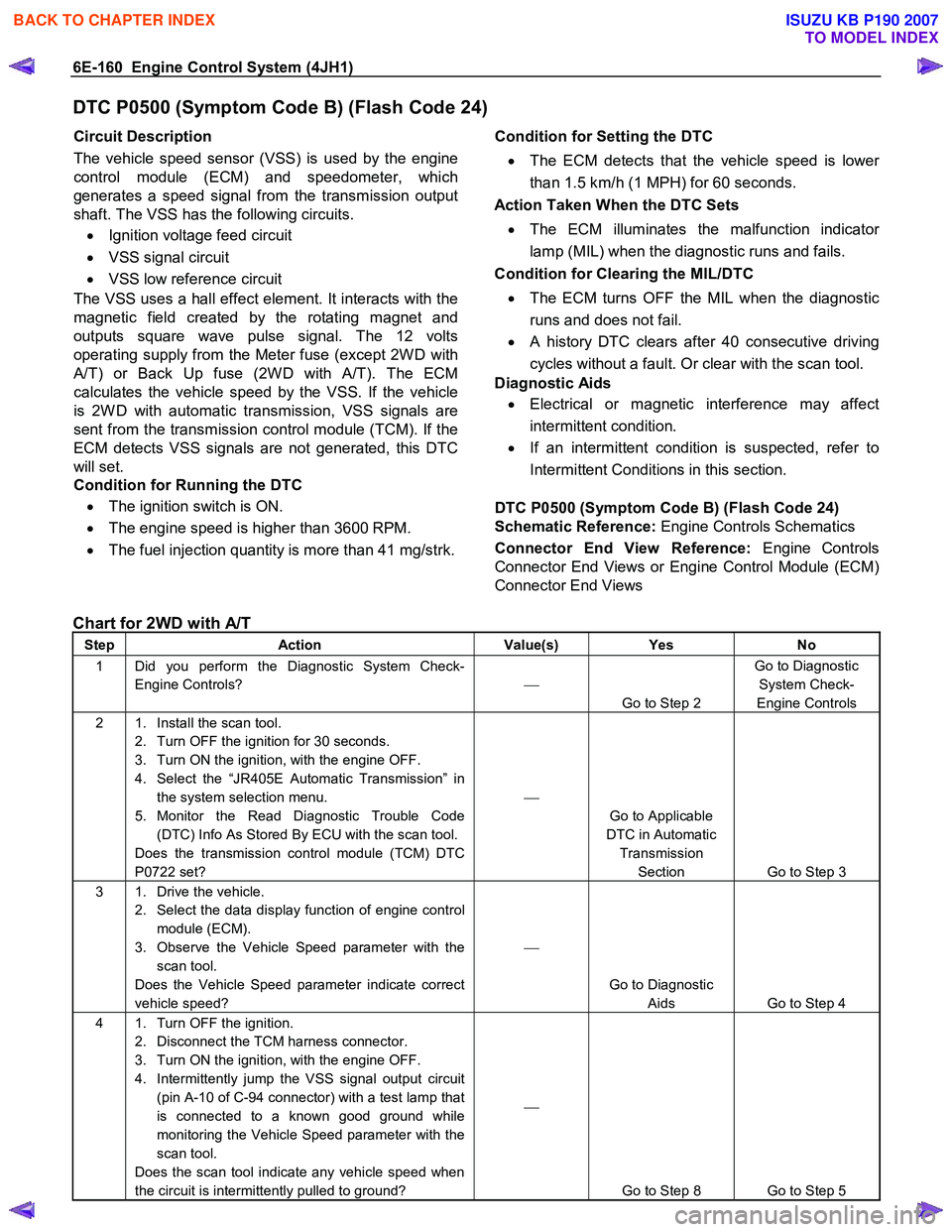

DTC P0500 (Symptom Code B) (Flash Code 24)

Circuit Description

The vehicle speed sensor (VSS) is used by the engine

control module (ECM) and speedometer, which

generates a speed signal from the transmission output

shaft. The VSS has the following circuits.

• Ignition voltage feed circuit

• VSS signal circuit

• VSS low reference circuit

The VSS uses a hall effect element. It interacts with the

magnetic field created by the rotating magnet and

outputs square wave pulse signal. The 12 volts

operating supply from the Meter fuse (except 2W D with

A/T) or Back Up fuse (2W D with A/T). The ECM

calculates the vehicle speed by the VSS. If the vehicle

is 2W D with automatic transmission, VSS signals are

sent from the transmission control module (TCM). If the

ECM detects VSS signals are not generated, this DTC

will set.

Condition for Running the DTC

• The ignition switch is ON.

• The engine speed is higher than 3600 RPM.

• The fuel injection quantity is more than 41 mg/strk.

Condition for Setting the DTC

• The ECM detects that the vehicle speed is lowe

r

than 1.5 km/h (1 MPH) for 60 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• Electrical or magnetic interference may affect

intermittent condition.

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P0500 (Symptom Code B) (Flash Code 24)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Chart for 2WD with A/T

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Select the “JR405E Automatic Transmission” in the system selection menu.

5. Monitor the Read Diagnostic Trouble Code (DTC) Info As Stored By ECU with the scan tool.

Does the transmission control module (TCM) DTC

P0722 set?

Go to Applicable

DTC in Automatic Transmission Section Go to Step 3

3 1. Drive the vehicle. 2. Select the data display function of engine control module (ECM).

3. Observe the Vehicle Speed parameter with the scan tool.

Does the Vehicle Speed parameter indicate correct

vehicle speed?

Go to Diagnostic Aids Go to Step 4

4 1. Turn OFF the ignition. 2. Disconnect the TCM harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Intermittently jump the VSS signal output circuit (pin A-10 of C-94 connector) with a test lamp that

is connected to a known good ground while

monitoring the Vehicle Speed parameter with the

scan tool.

Does the scan tool indicate any vehicle speed when

the circuit is intermittently pulled to ground?

Go to Step 8 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1197 of 6020

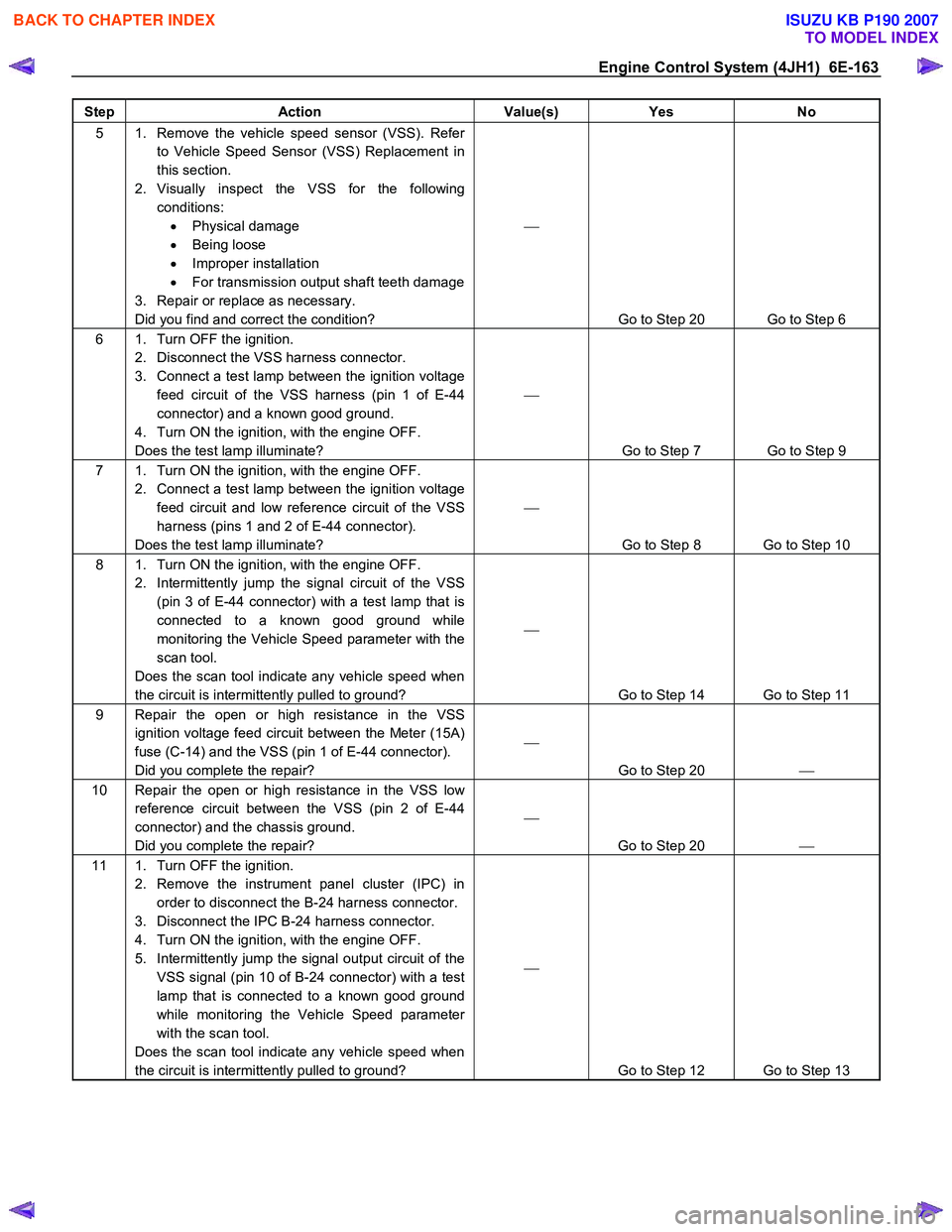

Engine Control System (4JH1) 6E-163

Step Action Value(s) Yes No

5 1. Remove the vehicle speed sensor (VSS). Refer

to Vehicle Speed Sensor (VSS) Replacement in

this section.

2. Visually inspect the VSS for the following conditions: • Physical damage

• Being loose

• Improper installation

• For transmission output shaft teeth damage

3. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 20 Go to Step 6

6 1. Turn OFF the ignition. 2. Disconnect the VSS harness connector.

3. Connect a test lamp between the ignition voltage feed circuit of the VSS harness (pin 1 of E-44

connector) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 7 Go to Step 9

7 1. Turn ON the ignition, with the engine OFF. 2. Connect a test lamp between the ignition voltage feed circuit and low reference circuit of the VSS

harness (pins 1 and 2 of E-44 connector).

Does the test lamp illuminate?

Go to Step 8 Go to Step 10

8 1. Turn ON the ignition, with the engine OFF. 2. Intermittently jump the signal circuit of the VSS (pin 3 of E-44 connector) with a test lamp that is

connected to a known good ground while

monitoring the Vehicle Speed parameter with the

scan tool.

Does the scan tool indicate any vehicle speed when

the circuit is intermittently pulled to ground?

Go to Step 14 Go to Step 11

9 Repair the open or high resistance in the VSS ignition voltage feed circuit between the Meter (15A)

fuse (C-14) and the VSS (pin 1 of E-44 connector).

Did you complete the repair?

Go to Step 20

10 Repair the open or high resistance in the VSS low

reference circuit between the VSS (pin 2 of E-44

connector) and the chassis ground.

Did you complete the repair?

Go to Step 20

11 1. Turn OFF the ignition.

2. Remove the instrument panel cluster (IPC) in order to disconnect the B-24 harness connector.

3. Disconnect the IPC B-24 harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Intermittently jump the signal output circuit of the VSS signal (pin 10 of B-24 connector) with a test

lamp that is connected to a known good ground

while monitoring the Vehicle Speed parameter

with the scan tool.

Does the scan tool indicate any vehicle speed when

the circuit is intermittently pulled to ground?

Go to Step 12 Go to Step 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1198 of 6020

6E-164 Engine Control System (4JH1)

Step Action Value(s) Yes No

12 1. Test the VSS signal circuit between the VSS (pin

3 of E-44 connector) and the IPC (pin 9 of B-23

connector) for the following conditions: • An open circuit

• A short to ground

• A short to battery or ignition voltage

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 20 Go to Step 15

13 1. Test the VSS signal circuit between the engine control module (ECM) (pin 68 of C-56 connector)

and the IPC (pin 10 of B-23 connector) for the

following conditions: • An open circuit

• A short to ground

• A short to battery or ignition voltage

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 20 Go to Step 16

14 1. Turn OFF the ignition. 2. Disconnect the VSS harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the VSS

(pin 1, 2 and 3 of E-44 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 20 Go to Step 17

15 1. Turn OFF the ignition. 2. Disconnect the IPC B-23 harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the IPC

(pins 9 and 10 of B-23 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 20 Go to Step 18

16 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection on the VSS signal circuit at the

harness connector of the ECM (pin 68 of C-56

connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 20 Go to Step 19

17 Replace the VSS. Refer to Vehicle Speed Sensor (VSS) Replacement in this section.

Did you complete the replacement?

Go to Step 20

18 Replace the IPC (meter assembly). Refer to Meter

Replacement in electrical section.

Did you complete the replacement?

Go to Step 20

19 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 20

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1222 of 6020

6E-188 Engine Control System (4JH1)

DTC P1105 (Symptom Code 1) (Flash Code 86)

Circuit Description

The barometric pressure (BARO) sensor is installed

inside of the engine control module (ECM) and converts

the BARO into a voltage signal. The ECM uses this

voltage signal to calibrate the fuel injection quantity and

injection timing for altitude compensation. If the ECM

detects an excessively high BARO sensor signal

voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the BARO sensor signal

voltage is more than 4.4 volts for 1 second.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a BARO substitution of 1013 hPa.

Condition for Clearing the MIL/DTC • The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

DTC P1105 (Symptom Code 1) (Flash Code 86)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Step 4

3 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 4

4 1. Clear the DTCs with the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 5

5 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1223 of 6020

Engine Control System (4JH1) 6E-189

DTC P1105 (Symptom Code 2) (Flash Code 86)

Circuit Description

The barometric pressure (BARO) sensor is installed

inside of the engine control module (ECM) and converts

the BARO into a voltage signal. The ECM uses this

voltage signal to calibrate the fuel injection quantity and

injection timing for altitude compensation. If the ECM

detects an excessively low BARO sensor signal voltage,

this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the BARO sensor signal

voltage is less than 1.5 volts for 1 second.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a BARO substitution of 1013 hPa.

Condition for Clearing the MIL/DTC • The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

DTC P1105 (Symptom Code 2) (Flash Code 86)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Step 4

3 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 4

4 1. Clear the DTCs with the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 5

5 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1224 of 6020

6E-190 Engine Control System (4JH1)

DTC P1120 (Symptom Code 1) (Flash Code 21)

Circuit Description

The accelerator pedal position (APP) sensor is mounted

on the intake throttle assembly. The engine control

module (ECM) uses the APP sensors to determine the

amount of acceleration or deceleration desired by the

person driving the vehicle via the fuel injection control.

The APP sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• APP sensor signal circuit

The ECM supplies 5 volts to the APP sensor on the 5

volts reference circuit. The ECM also provides a ground

on the low reference circuit. The APP sensor provides a

signal to the ECM on the APP sensor signal circuit,

which is relative to the position changes of the

accelerator pedal angle. The ECM monitors the

APP

sensor signal for voltages outside the normal range o

f

the APP sensor. If the ECM detects an excessively high

APP sensor signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the APP sensor signal

voltage is more than 4.5 volts for 0.5 seconds.

Action Taken When the DTC Sets • The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses an engine speed substitution o

f

1400 RPM.

Condition for Clearing the MIL/DTC • The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids • If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P1120 (Symptom Code 1) (Flash Code 21)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the accelerator pedal position (APP) sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Observe the Accelerator Pedal Position (APP) parameter with the scan tool.

Does the APP parameter less than the specified

value? 1%

Go to Step 4 Go to Step 5

4 1. Turn OFF the ignition. 2. Connect a test lamp between the low reference circuit of the APP sensor harness (pin 1 of E-22

connector) and battery voltage.

3. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 11 Go to Step 8

5 1. Turn OFF the ignition. 2. Connect a DMM between the 5 volts reference circuit of the APP sensor harness (pin 3 of E-22

connector) and a known good ground.

3. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 4.5 volts

Go to Step 6 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1225 of 6020

Engine Control System (4JH1) 6E-191

Step Action Value(s) Yes No

6 Is the DMM voltage less than the specified value at

step 5? 5.5 volts

Go to Step 7 Go to Step 10

7 Important: The APP sensor may be damaged if the

sensor signal circuit is shorted to a voltage source.

1. Test the signal circuit between the engine control module (ECM) (pin 38 of C-56 connector) and

the APP sensor (pin 2 of E-22 connector) for the

following conditions: • A short to battery or ignition voltage

• A short to any 5 volts reference

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 14

8 . Test the low reference circuit between the 1ECM (pin 49 of C-56 connector) and the APP sensor

(pin 1 of E-22 connector) for an open circuit or

high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 12

9 1. Test the 5 volts reference circuit between the ECM (pin 57 of C-56 connector) and the APP

sensor (pin 3 of E-22 connector) for the following

conditions: • A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 14

10 1. Test the 5 volts reference circuit between the ECM (pin 57 of C-56 connector) and the APP

sensor (pin 3 of E-22 connector) for a short to

battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 14

11 1. Turn OFF the ignition. 2. Inspect for an intermittent and for a poor connection at the harness connector of the APP

sensor (pin 1 of E-22 connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 13

12 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection on the APP sensor circuit at the

harness connector of the ECM (pin 49 of C-56

connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 14

13 Replace APP sensor. Refer to Accelerator Pedal Position (APP) Sensor Replacement in this section.

Did you complete the replacement?

Go to Step 15

14 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1227 of 6020

Engine Control System (4JH1) 6E-193

DTC P1120 (Symptom Code 7) (Flash Code 21)

Circuit Description

The accelerator pedal position (APP) sensor is mounted

on the intake throttle assembly. The engine control

module (ECM) uses the APP sensors to determine the

amount of acceleration or deceleration desired by the

person driving the vehicle via the fuel injection control.

The APP sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• APP sensor signal circuit

The ECM provides 5 volts reference voltage through the

reference circuit to the APP sensor. The ECM monitors

the voltage on the 5 volts reference circuit. If the ECM

detects an excessively high APP sensor 5 volts

reference voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the APP sensor voltage

supply circuit is more than 5.2 volts for 0.5

seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses an engine speed substitution o

f

1400 RPM.

Condition for Clearing the MIL/DTC • The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids • If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P1120 (Symptom Code 7) (Flash Code 21)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Test the 5 volts reference circuit between 1the engine control module (ECM) (pin 57 of C-56

connector) and the accelerator pedal position

(APP) sensor (pin 3 of E-22 connector) for a

short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 5 Go to Step 4

4 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 5

5 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Turn ON the ignition, with the engine OFF.

5. Fully depress and release the accelerator pedal many times.

6. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1229 of 6020

Engine Control System (4JH1) 6E-195

DTC P1120 (Symptom Code 9) (Flash Code 21)

Circuit Description

The accelerator pedal position (APP) sensor is mounted

on the intake throttle assembly. The engine control

module (ECM) uses the APP sensors to determine the

amount of acceleration or deceleration desired by the

person driving the vehicle via the fuel injection control.

The APP sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• APP sensor signal circuit

The ECM provides 5 volts reference voltage through the

reference circuit to the APP sensor. The ECM monitors

the voltage on the 5 volts reference circuit. If the ECM

detects an excessively high APP sensor 5 volts

reference voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the APP sensor voltage

supply circuit is less than 4.6 volts for 0.5 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses an engine speed substitution o

f

1400 RPM.

Condition for Clearing the MIL/DTC • The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids • If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the APP sensor 5 volts reference circuit between

the ECM and the sensor is normal, the sensor signal

correlation DTC P1120 (Symptom Code E) will set.

DTC P1120 (Symptom Code 9) (Flash Code 21)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the accelerator pedal position (APP) sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Depress and release the accelerator pedal many times.

5. Monitor the DTC Information with the scan tool.

Does DTC P1120 (Symptom Code E) set, but not

DTC P1120 (Symptom Code 9)?

Go to Step 5 Go to Step 4

4 1. Test the 5 volts reference circuit between the engine control module (ECM) (pin 57 of C-56

connector) and the APP sensor (pin 3 of E-22

connector) for the following conditions: • A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007