sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1127 of 6020

Engine Control System (4JH1) 6E-93

DTC P0115 (Symptom Code 2) (Flash Code 14)

Circuit Description

The engine coolant temperature (ECT) sensor is

installed to the thermostat housing. The ECT sensor is

a variable resistor. The ECT sensor has a signal circuit

and a low reference circuit. The ECT sensor measures

the temperature of the engine coolant. The engine

control module (ECM) supplies 5 volts to the ECT signal

circuit and a ground for the ECT low reference circuit.

W hen the ECT sensor is cold, the sensor resistance is

high. W hen the engine coolant temperature increases,

the sensor resistance decreases. W ith high senso

r

resistance, the ECM detects a high voltage on the ECT

signal circuit. W ith lower sensor resistance, the ECM

detects a lower voltage on the ECT signal circuit. If the

ECM detects an excessively low ECT signal voltage,

this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the ECT sensor signal

voltage is less than 0.3 volts for 3 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses an ECT substitution of fuel

temperature for engine control.

•

The ECM uses an ECT substitution of 60 °C

(120 °F) for injection timing control.

• The ECM uses an ECT substitution -15 °C (5 °F) fo

r

glow control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

•

After starting the engine, the ECT should rise

steadily to about 80°C – 85°C (176°F – 185°F)

then stabilize when the thermostat opens.

• Use the Temperature vs. Resistance table to test

the ECT sensor at various temperature levels to

evaluate the possibility of a skewed sensor.

A

skewed sensor could result in poor driveabilit

y

concerns.

DTC P0115 (Symptom Code 2) (Flash Code 14)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Observe the Engine Coolant Temperature (ECT) parameter with the scan tool.

Is the ECT parameter more than the specified value? 135°C (275°F)

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the ECT sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Observe the Coolant Temperature parameter with the scan tool.

Is the ECT parameter less than the specified value? -35°C (-31°F)

Go to Step 5 Go to Step 4

4 1. Test the signal circuit between the engine control module (ECM) (pin 89 of C-57 connector) and

the ECT sensor (pin 1 of E-41 connector) for the

following conditions: • A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 8 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1128 of 6020

6E-94 Engine Control System (4JH1)

Step Action Value(s) Yes No

5 Replace the ECT sensor. Refer to Engine Coolant

Temperature Sensor Replacement in this section.

Did you complete the replacement?

Go to Step 8

6 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect connections on the ECT sensor circuits at the harness connector of the ECM (pins 89

and 93 of C-57 connector) for corrosion.

4. Repair or clean the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 8 Go to Step 7

7 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 8

8 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 2 Go to Step 9

9 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1129 of 6020

Engine Control System (4JH1) 6E-95

DTC P0180 (Symptom Code B) (Flash Code 15)

Circuit Description

The fuel temperature (FT) sensor is internal to the fuel

injection pump control unit (PCU). It detects fuel

temperature in the fuel injection pump. The engine

control module (ECM) and PCU communicates with

each other over the controller area network (CAN) link.

If the PCU internal FT sensor output is an excessivel

y

high or low, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The PCU internal FT sensor output is lower than -

40°C (-40°F) for 3 seconds or higher than 150°C

(302°F) for 3 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

•

The ECM uses a default FT substitution for engine

control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• FT sensor is internal to the PCU and it is part o

f

the fuel injection pump assembly.

DTC P0180 (Symptom Code B) (Flash Code 15)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Step 4

3 Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section. (Fuel temperature (FT) sensor is internal to

the fuel injection pump control unit (PCU) and it is

part of the fuel injection pump assembly.)

Did you complete the replacement?

Go to Step 4

4 1. Clear the DTCs with the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 5

5 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1130 of 6020

6E-96 Engine Control System (4JH1)

DTC P0215 (Symptom Code A) (Flash Code 52)

Circuit Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The fuel injection solenoid valve is installed to the fuel

injection pump rear side. The fuel injection event is

determined by this solenoid ON/OFF command. The

fuel injection solenoid valve cuts the fuel when the

engine shutoff (ESO) solenoid valve is commanded

shutoff from the PCU. (The fuel injection solenoid valve

and engine shutoff (ESO) solenoid valve is same part. It

calls ESO solenoid valve when fuel is shutoff.) W hen

the ignition switch is turned OFF or commanded from

fail-safe action, the ESO solenoid valve is commanded

shutoff to stop the engine running. If the ECM detects

that the engine is continuously run after the ignition

switch is OFF, this DTC will set.

Condition for Running the DTC

• The ignition switch is OFF.

• The engine speed is lower than 1500 RPM.

• The vehicle speed is lower than 1.5 km/h (1 MPH).

Condition for Setting the DTC

•

After the condition for running this DTC for 2

seconds, the engine speed is higher than 200

RPM when the ESO solenoid valve is commanded

shutoff from the CPU. This indicates the PCU

reacts to the command from the ECM but ESO

solenoid valve does not react to the command

from the PCU and fuel cannot shutoff.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) at next ignition cycle.

• The ECM cuts fuel injection.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• Fuel injection solenoid valve is internal to the fuel

injection pump assembly.

• PCU is part of the fuel injection pump assembly.

DTC P0215 (Symptom Code A) (Flash Code 52)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

5. Turn OFF the engine.

Does the DTC fail this ignition before the engine

control module (ECM) turned OFF?

Go to Step 3 Go to Step 4

3 Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section.

Did you complete the replacement?

Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1132 of 6020

6E-98 Engine Control System (4JH1)

DTC P0215 (Symptom Code B) (Flash Code 52)

Circuit Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The fuel injection solenoid valve is installed to the fuel

injection pump rear side. The fuel injection event is

determined by this solenoid ON/OFF command. The

fuel injection solenoid valve cuts the fuel when the

engine shutoff (ESO) solenoid valve is commanded

shutoff from the PCU. (The fuel injection solenoid valve

and engine shutoff (ESO) solenoid valve is same part. It

calls ESO solenoid valve when fuel is shutoff.) W hen

the ignition switch is turned OFF or commanded from

fail-safe action, the ESO solenoid valve is commanded

shutoff to stop the engine running. If the PCU detects

that the ESO solenoid valve control circuit voltage level

from the ECM to PCU is high, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The PCU detects high voltage condition on the

ESO solenoid valve control circuit for longer than 1

second when the ECM does not command shutoff.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• Fuel injection solenoid valve is internal to the fuel

injection pump assembly.

• PCU is part of the fuel injection pump assembly.

• If this DTC is present, engine will not start.

DTC P0215 (Symptom Code B) (Flash Code 52)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine. If the engine does not start, crank over the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the fuel injection pump control unit (PCU) harness connector.

3. Connect a test lamp between the engine shutoff (ESO) solenoid valve control signal circuit (pin 5

of E-6 connector) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 5 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1134 of 6020

6E-100 Engine Control System (4JH1)

DTC P0215 (Symptom Code C) (Flash Code 52)

Circuit Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The fuel injection solenoid valve is installed to the fuel

injection pump rear side. The fuel injection event is

determined by this solenoid ON/OFF command. The

fuel injection solenoid valve cuts the fuel when the

engine shutoff (ESO) solenoid valve is commanded

shutoff from the PCU. (The fuel injection solenoid valve

and engine shutoff (ESO) solenoid valve is same part. It

calls ESO solenoid valve when fuel is shutoff.) W hen

the ignition switch is turned OFF or commanded from

fail-safe action, the ESO solenoid valve is commanded

shutoff to stop the engine running. If the ECM detects

that the engine is continuously run after the ignition

switch is OFF, this DTC will set.

Condition for Running the DTC

• The ignition switch is OFF.

• The engine speed is lower than 1500 RPM.

• The vehicle speed is lower than 1.5 km/h (1 MPH).

Condition for Setting the DTC

• The engine speed is higher than 200 RPM within 2

seconds after the condition for running the DTC

are met. This indicates the PCU does not react to

the command from the ECM and fuel cannot

shutoff.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM cuts fuel injection.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• Fuel injection solenoid valve is internal to the fuel

injection pump assembly.

• PCU is part of the fuel injection pump assembly.

DTC P0215 (Symptom Code C) (Flash Code 52)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

5. Turn OFF the engine.

Does the DTC fail this ignition before the engine

control module (ECM) turns OFF?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the fuel injection pump control unit (PCU) harness connector.

3. Connect a test lamp between the engine shutoff (ESO) solenoid valve control signal circuit (pin 5

of E-6 connector) and battery voltage.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 5 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1136 of 6020

6E-102 Engine Control System (4JH1)

DTC P0215 (Symptom Code D) (Flash Code 52)

Circuit Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The ECM monitors CAN operational status by expecting

a constant flow of messages from the PCU. If the ECM

detects that the internal CAN controller does not Bus

OFF when the ignition switch is OFF, this DTC will set.

Condition for Running the DTC

• The ignition switch is OFF.

Condition for Setting the DTC

• The ECM detects internal CAN controller does not

Bus OFF mode.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• CAN controller is internal to the ECM.

DTC P0215 (Symptom Code D) (Flash Code 52)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

5. Turn OFF the engine.

Does the DTC fail this ignition before the engine

control module (ECM) turns OFF?

Go to Step 3 Go to Step 4

3 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 4

4 1. Clear the DTCs with the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the DTC Information with the scan tool.

5. Turn OFF the engine.

Does the DTC fail this ignition before the ECM turns

OFF?

Go to Step 3 Go to Step 5

5 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1137 of 6020

Engine Control System (4JH1) 6E-103

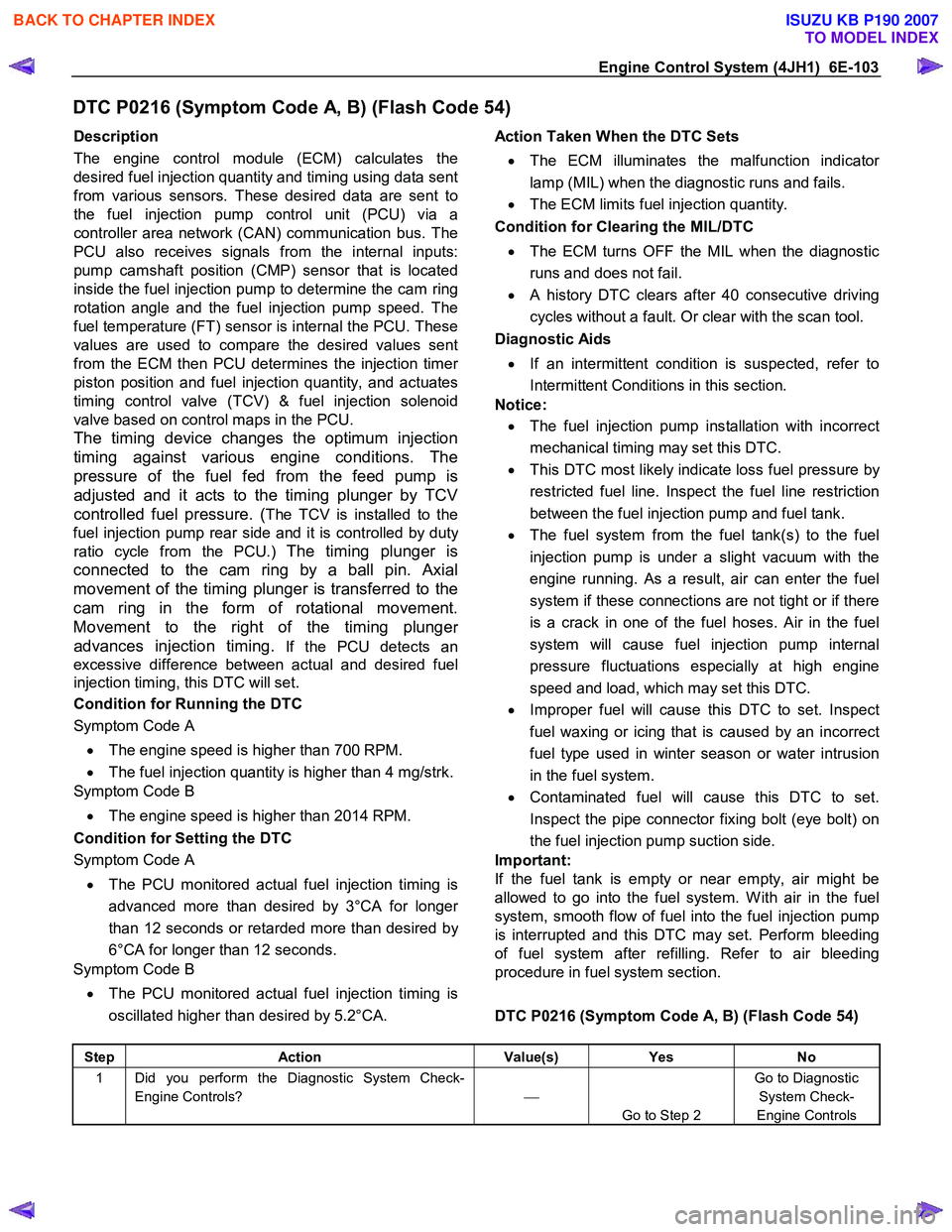

DTC P0216 (Symptom Code A, B) (Flash Code 54)

Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The timing device changes the optimum injection

timing against various engine conditions. The

pressure of the fuel fed from the feed pump is

adjusted and it acts to the timing plunger by TCV

controlled fuel pressure. (

The TCV is installed to the

fuel injection pump rear side and it is controlled by dut

y

ratio cycle from the PCU.) The timing plunger is

connected to the cam ring by a ball pin. Axial

movement of the timing plunger is transferred to the

cam ring in the form of rotational movement.

Movement to the right of the timing plunge

r

advances injection timing.

If the PCU detects an

excessive difference between actual and desired fuel

injection timing, this DTC will set.

Condition for Running the DTC

Symptom Code A

• The engine speed is higher than 700 RPM.

• The fuel injection quantity is higher than 4 mg/strk.

Symptom Code B

• The engine speed is higher than 2014 RPM.

Condition for Setting the DTC

Symptom Code A

• The PCU monitored actual fuel injection timing is

advanced more than desired by 3°CA for longe

r

than 12 seconds or retarded more than desired by

6°CA for longer than 12 seconds.

Symptom Code B

• The PCU monitored actual fuel injection timing is

oscillated higher than desired by 5.2°CA.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• The fuel injection pump installation with incorrect

mechanical timing may set this DTC.

• This DTC most likely indicate loss fuel pressure by

restricted fuel line. Inspect the fuel line restriction

between the fuel injection pump and fuel tank.

• The fuel system from the fuel tank(s) to the fuel

injection pump is under a slight vacuum with the

engine running. As a result, air can enter the fuel

system if these connections are not tight or if there

is a crack in one of the fuel hoses. Air in the fuel

system will cause fuel injection pump internal

pressure fluctuations especially at high engine

speed and load, which may set this DTC.

• Improper fuel will cause this DTC to set. Inspect

fuel waxing or icing that is caused by an incorrect

fuel type used in winter season or water intrusion

in the fuel system.

• Contaminated fuel will cause this DTC to set.

Inspect the pipe connector fixing bolt (eye bolt) on

the fuel injection pump suction side.

Important:

If the fuel tank is empty or near empty, air might be

allowed to go into the fuel system. W ith air in the fuel

system, smooth flow of fuel into the fuel injection pump

is interrupted and this DTC may set. Perform bleeding

of fuel system after refilling. Refer to air bleeding

procedure in fuel system section.

DTC P0216 (Symptom Code A, B) (Flash Code 54)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1141 of 6020

Engine Control System (4JH1) 6E-107

DTC P0243 (Symptom Code 3) (Flash Code 64)

Circuit Description

The engine control module (ECM) controls the

turbocharger wastegate valve based on the barometric

pressure in order to reduce turbocharger spinning

speeds at high altitude area. The ECM controls the

turbocharger wastegate valve diaphragm by acting the

regulated vacuum pressure via controlling the solenoid

valve. The vacuum pressure sensor monitors the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The ECM calculates desired vacuum

pressure and it compares the calculated desired

vacuum pressure to the actual value to determine the

solenoid valve position. W hen the actual vacuum

pressure is higher than the desired value, the solenoid

valve is closed to decrease the vacuum pressure. An

expected vacuum pressure amount should be detected

while the engine running. If the ECM detects the actual

vacuum pressure amount is higher than desired

vacuum pressure amount, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The barometric pressure (BARO) is between 0

hPa and 3500 hPa.

• The intake air temperature (IAT) is between -50°C

(-58 °F) and 200°C (392°F).

• The engine coolant temperature (ECT) is between

-50°C (-58 °F) and 150°C (302°F)

Condition for Setting the DTC

• The ECM detects that the vacuum pressure is 50

hPa higher than the desired vacuum pressure for

3 seconds. This indicates excessive high vacuum

pressure.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

• Misrouted vacuum hoses will cause this DTC to

set.

Test Description

The numbers below refer to the step number on the

diagnostic table.

4. A skewed vacuum pressure sensor value (shifted to

a high pressure) can set this DTC. The Vacuum

Pressure on the scan tool should read near doubled

barometric pressure (BARO) with the key ON and

engine OFF.

5. A skewed BARO sensor value (shifted to a lowe

r

pressure) may set this DTC. The BARO on the scan

tool should read near surrounding barometric pressure.

DTC P0243 (Symptom Code 3) (Flash Code 64)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Is DTC P0105 (Symptom Code 1, 2, 7 or 9) or

P0243 (Symptom Code 4 or 8) set?

Go to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1142 of 6020

6E-108 Engine Control System (4JH1)

Step Action Value(s) Yes No

3 1. Turn OFF the ignition.

2. Inspect for the following conditions: • Vacuum hoses are damaged or kinked.

• Misrouted vacuum hoses.

• A turbocharger solenoid valve is damaged.

• A vacuum pump is damaged.

• A vacuum regulating valve is damaged.

• A turbocharger wastegate valve is

damaged.

• Contaminated, skewed or slow vacuum

pressure sensor.

3. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 4

4 1. Turn ON the ignition, with the engine OFF. 2. Observe the Vacuum Pressure Sensor and Barometric Pressure (BARO) with the scan tool.

Does the scan tool indicate that the difference

between the Vacuum Pressure Sensor and doubled

BARO is less than the specified value? 10 hPa

Go to Step 7 Go to Step 5

5 1. Observe the BARO parameter with the scan tool.2. Compare the BARO value to the range specified in the altitude vs. barometric pressure table.

Refer to Altitude vs. Barometric Pressure.

Is the BARO parameter within the range specified?

Go to Step 6 Go to Step 14

6 1. Turn OFF the ignition. 2. Disconnect the vacuum pressure sensor harness connector.

3. Inspect for an intermittent and for poor connections at the vacuum pressure sensor

harness connector (pins 1 and 3 of C-124

connector).

4. Disconnect the engine control module (ECM) harness connector.

5. Inspect for an intermittent, for poor connections and corrosion on each vacuum pressure sensor

circuit at the harness connector of the ECM (pins

82 and 85 of C-57 connector).

6. Test for high resistance on each vacuum pressure sensor circuit.

7. Test the vacuum pressure sensor signal circuit short to any other circuits.

8. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 15 Go to Step 10

7 1. Turn OFF the ignition. 2. Disconnect the vacuum hose from the turbocharger wastegate valve that is connected

to the vacuum pressure sensor and the

turbocharger solenoid valve.

3. Connect a hand-held vacuum pump (5-8840- 0279-0/J-23738-A) to the turbocharger

wastegate valve. This test is in order to verify an

airtight of the turbocharger wastegate valve

inside.

4. Start the engine and let engine idle.

Does the hand-held vacuum pump indicate any

vacuum pressure?

Go to Step 13 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007