engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2805 of 6020

Engine Mechanical – V6 Page 6A1–28

Page 6A1–28

Pipe Joint Compound

• Pipe joint compound is a pliable sealer that does not comp letely harden. This type of sealer is used where two non-

rigid parts (such as pressed steel and ma chined surfaces) are assembled together.

• Do not use pipe joint compound in areas where extreme temperatures are expected. These areas include the

exhaust manifold, head gasket, or other surfaces where gasket eliminator is specified.

• Follow all safety recommendations and di rections that are on the container.

• To remove the sealant or the gasket mate rial, refer to Replacing Engine Gaskets.

• Apply the pipe joint compound to a clean surface. Use a bead size or quantity as specified in the procedure. Run

the bead to the inside of any bolt holes. Do not allow the s ealer to enter any blind threaded holes as it may prevent

the bolt from clamping correctly or caus e component damage when the bolt is tightened.

• Apply a continuous bead of pipe joint compound to one seali ng surface. Sealing surfaces to be resealed must be

clean and dry.

• Tighten the bolts to the correct torque specification. Do not over-tighten.

Separating Parts

CAUTION

Many internal engine components will

develop specific wear patterns on their

friction surfaces. When disassembling the

engine, internal components must be

separated, marked and organised in a way to

ensure reinstallation in their original location

and position.

Separate, mark, or organise the following components:

• Piston and the piston pin.

• Piston to the specific cylinder bore.

• Piston rings to the specific piston.

• Connecting rod to the crankshaft journal.

• Connecting rod to the bearing cap.

• Crankshaft main and connecting rod bearings.

• Camshaft and rocker arms.

• Rocker arms and stationary hydraulic lash adjusters to cylinder head location.

• Valve to the valve guide.

• Valve spring and shim to the cylinder head location.

• Engine block main bearing cap location and direction.

• Oil pump drive and driven gears.

Tools and Equipment

Special tools are listed and illustrated throughout this Section with a complete listing at the end, refer to 7 Special Tools.

These tools (or their equivalents) are specially designed to quickly and safely accomplish the operations for which they

are intended. The use of these special tools will also minimise possible damage to engine components. Some precision

measuring tools are required for inspec tion of certain critical components. A commercially available torque wrench and

torque angle wrench, Tool No. EN-7115 are required for the correct tightening of various fasteners.

To correctly service the engine assembly, the following items should be readily available:

• Approved eye protection and safety gloves.

• A clean, well-lit, work area.

• A suitable parts cleaning tank.

• A compressed air supply.

• Trays or storage containers to keep parts and fasteners organised.

• An adequate set of hand tools.

• Approved engine repair stand.

• An approved engine lifting device that will adequatel y support the weight of the components.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2806 of 6020

Engine Mechanical – V6 Page 6A1–29

Page 6A1–29

Fasteners

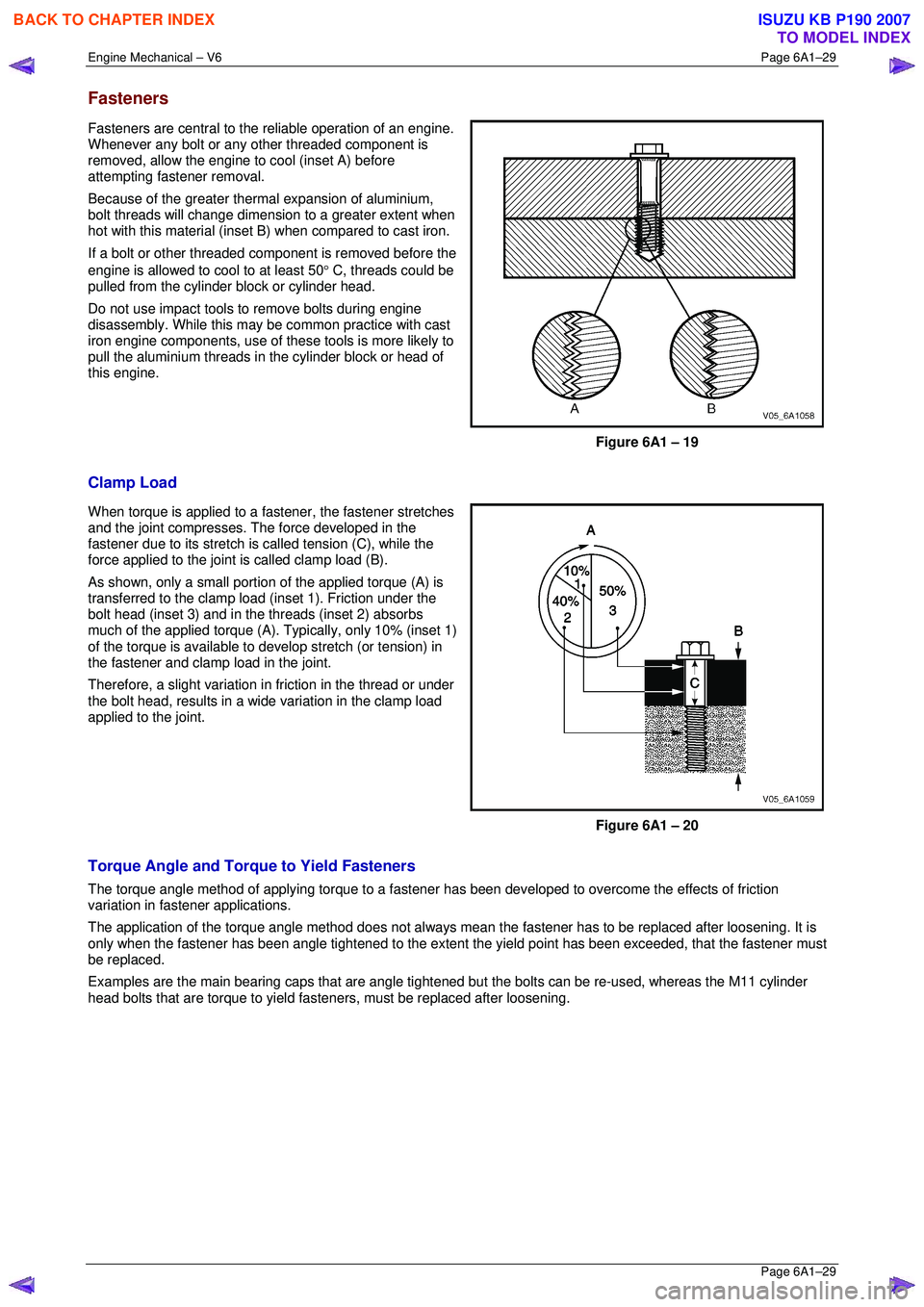

Fasteners are central to the reliable operation of an engine.

Whenever any bolt or any other threaded component is

removed, allow the engine to cool (inset A) before

attempting fastener removal.

Because of the greater the rmal expansion of aluminium,

bolt threads will change dimensi on to a greater extent when

hot with this material (inset B) when compared to cast iron.

If a bolt or other threaded com ponent is removed before the

engine is allowed to cool to at least 50 ° C, threads could be

pulled from the cylinder block or cylinder head.

Do not use impact tools to remove bolts during engine

disassembly. While this may be common practice with cast

iron engine components, use of thes e tools is more likely to

pull the aluminium threads in the cylinder block or head of

this engine.

Figure 6A1 – 19

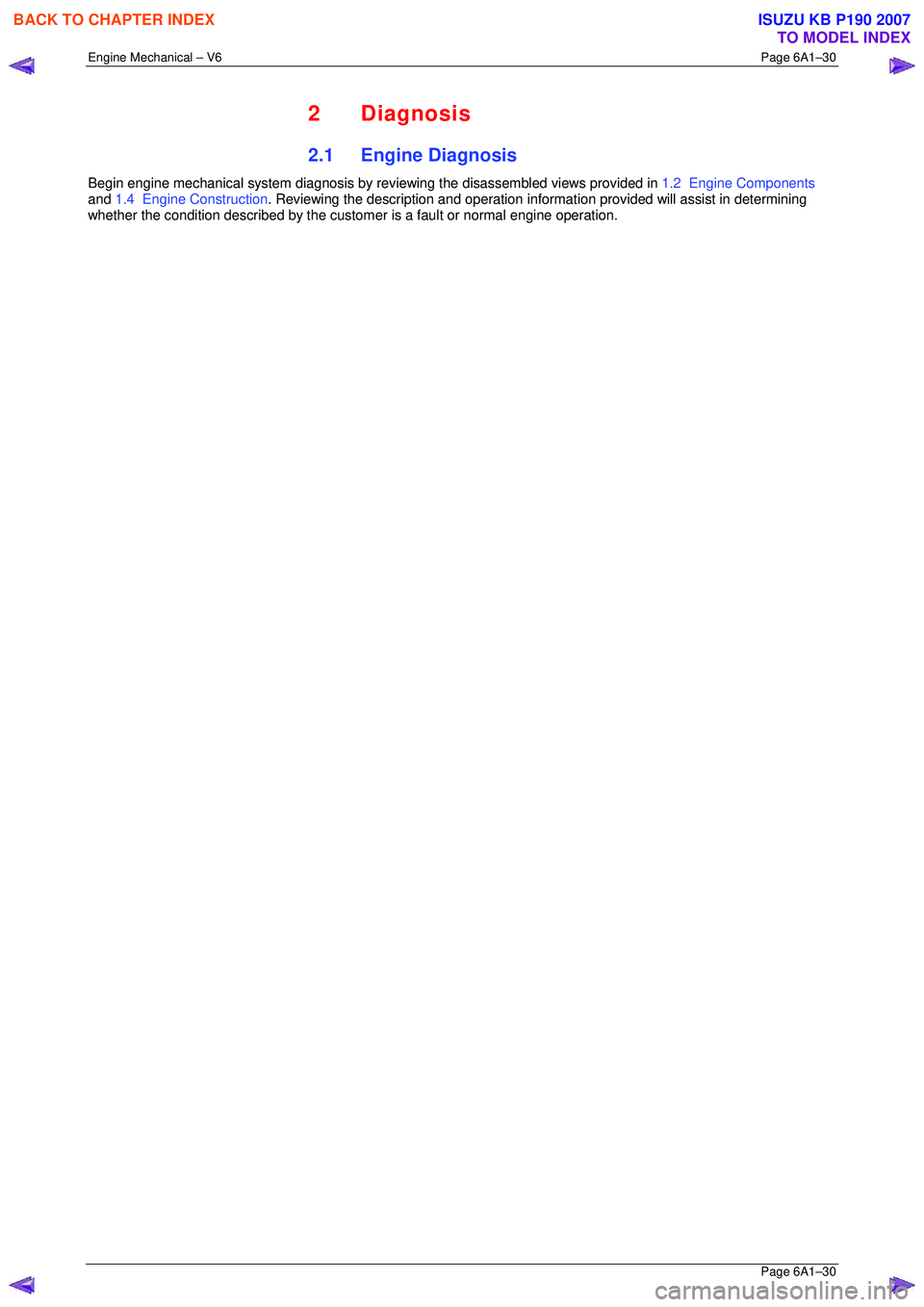

Clamp Load

When torque is applied to a fa stener, the fastener stretches

and the joint compresses. The force developed in the

fastener due to its stretch is called tension (C), while the

force applied to the joint is called clamp load (B).

As shown, only a small portion of the applied torque (A) is

transferred to the clamp load (inset 1). Friction under the

bolt head (inset 3) and in the threads (inset 2) absorbs

much of the applied torque (A). Typically, only 10% (inset 1)

of the torque is available to develop stretch (or tension) in

the fastener and clamp load in the joint.

Therefore, a slight variation in friction in the thread or under

the bolt head, results in a wide variation in the clamp load

applied to the joint.

Figure 6A1 – 20

Torque Angle and Torque to Yield Fasteners

The torque angle method of applying torque to a fastener has been developed to overcome the effects of friction

variation in fastener applications.

The application of the torque angle method does not always mean the fastener has to be replaced after loosening. It is

only when the fastener has been angle tightened to the extent the yield point has been exceeded, that the fastener must

be replaced.

Examples are the main bearing caps that are angle tightened but the bolts can be re-used, whereas the M11 cylinder

head bolts that are torque to yield fasteners, must be replaced after loosening.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2807 of 6020

Engine Mechanical – V6 Page 6A1–30

Page 6A1–30

2 Diagnosis

2.1 Engine Diagnosis

Begin engine mechanical system diagnosis by reviewing the disassembled views provided in 1.2 Engine Components

and 1.4 Engine Construction . Reviewing the description and operation info rmation provided will assist in determining

whether the condition described by the custom er is a fault or normal engine operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2808 of 6020

Engine Mechanical – V6 Page 6A1–31

Page 6A1–31

2.2 Symptoms

Strategy Based Diagnosis

1 Review the system operations to familiarise yourself with the system functions, refer to 1 General Information and

6C1-1 Engine Management General Information.

2 Perform an engine management Diagnostic System Check, refer to Section 6C1-2 Engine Management – V6 –

Diagnostics .

All diagnosis on a vehicle should follow a logical process. Strategy based diagnosis is a uniform approach for repairing

all vehicle systems. The strategy based diagnostic flow chart may always be used to resolve a system problem. The

diagnostic flow chart is the place to start when repairs are required. For a detailed explanation of strategy based

diagnosis and the flow chart, refer to Section 6C1-2 Engine Management – V6 – Diagnostics .

Visual / Physical Inspection

1 Inspect the vehicle for aftermarket accessories which may adversely affect engine operation.

2 Inspect the easily accessible or visible system components for obvious signs of damage or conditions that may cause the symptom.

3 Check the engine lubrication system for the following:

• correct oil level,

• correct lubricant viscosity,

• correct oil filter application, and

• contaminated or burnt oil.

4 Confirm the exact operating conditions under whic h the fault occurs. Note factors such as:

• engine speed (r.p.m.),

• ambient temperature,

• engine temperature,

• engine warm-up time, and

• vehicle road speed.

5 Compare the engine sounds, if applic able, to a known good engine, and ensure you are not trying to diagnose a

normal operating condition.

Intermittent

For intermittent faults, test the vehicle under the same conditions the customer reported in order to confirm whether the

system is operating correctly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2809 of 6020

Engine Mechanical – V6 Page 6A1–32

Page 6A1–32

2.3 Engine Misfire without Internal Engine

Noises

Cause Correction

Abnormalities, severe cracking, bumps or missing areas in

the accessory drive belt.

Abnormalities in the accessory drive system and/or

components may cause engine speed variations that result

in a misfire diagnostic trouble code (DTC). A misfire code

may be present without an ac tual misfire condition. Replace the accessory drive belt, refer to 3.5 Accessory

Drive Belt.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs.

Worn, damaged or misaligned accessory drive components

and excessive pulley run-out may lead to a misfire DTC.

A misfire code may be present without an actual misfire

condition. Inspect the components and repair or replace as required.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs.

Loose or incorrectly fitted flexplate or crankshaft balancer

assembly.

A misfire DTC may be present without an actual misfire

condition. Repair or replace the flexplat

e or crankshaft balancer as

required, refer to 3.13 Crankshaft Balancer Assembly or

4.3 Flexplate Assembly.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Restricted exhaust system.

A severe restriction in the exhaust flow can cause

significant loss of engine performance and may set a DTC.

Possible causes of restrict ions in the exhaust system

include collapsed/dented pipes and blocked mufflers and/or

catalytic converters. Repair or replace exhaust syst

em components as required,

refer to 8B Exhaust System.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Incorrectly installed or damaged vacuum hoses. Repair or replace vacuum hoses as required.

Incorrect sealing between the intake manifold and cylinder

heads, upper intake manifold and lower intake manifold,

throttle body and intake manifold. Repair or replace the intake

manifold, throttle body gaskets,

cylinder heads, throttle body as required.

Incorrectly installed or damaged barometric

pressure(BARO) sensor and/or seal. The seal should not

be torn or damaged. Repair or replace the BARO sensor and/or seal as

required, refer to 6C1-3 Engine Management – V6 –

Service Operations.

Incorrectly installed or damaged EVAP purge solenoid

and/or O-ring seal. Repair or replace the EVAP purge solenoid and/or seal as

required, refer to 6C1-3 Engine Management – V6 –

Service Operations

Worn or loose stationary hydraulic lash adjusters (SHLA)

and/or rocker arms.

The SHLAs, rocker arms and roller bearings should be

intact and in the correct position. Replace the SHLAs and/or rocker arms as required, refer to

3.21 Stationary Hydraulic Las h Adjuster or 3.20 Rocker

Arm.

Stuck valves.

Carbon build up on the valve stem s can result in the valves

not closing correctly. Repair or replace as required, refer to 3.22 Cylinder Head

Assembly.

Excessively worn or misaligned timing chain/s. Replace the timing chain/s and components as required,

refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

Worn camshaft lobes. Replace the camshaft/s and SHLAs as required, refer to

3.19 Camshaft or 3.21 Stati onary Hydraulic Lash Adjuster.

Excessive oil pressure.

A lubrication system with ex cessive oil pressure may lead

to excessive lash adjuster pump-up and loss of

compression. 1 Perform an oil pressure tes

t, refer to 3.1 Engine Oil.

2 Repair or replace the engine oil pump as required, refer to 3.17 Oil Pump Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2810 of 6020

Engine Mechanical – V6 Page 6A1–33

Page 6A1–33

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder head and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat. 1 Inspect the spark plugs for

coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect the cylinder heads, cylinder block and/or head gaskets, refer to 3.22 Cylinder Head Assembly

and/or 4.7 Cylinder Block.

3 Repair or replace components as required.

Worn piston rings.

Oil consumption may or ma y not cause the engine to

misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of

low compression.

4 Repair or replace components as required.

A damaged crankshaft reluctor wheel.

A damaged crankshaft reluctor wheel can result in different

symptoms depending on the severity and location of the

damage.

Systems with severe relu ctor ring damage may exhibit

periodic loss of crankshaft posit ion, stop delivering a signal,

and then re-sync the crankshaft position.

Systems with slight reluctor ring damage may exhibit no

loss of crankshaft position and no misfire may occur,

however, a DTC may set. Replace the crankshaft as required, refer to 4.6 Crankshaft

and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2811 of 6020

Engine Mechanical – V6 Page 6A1–34

Page 6A1–34

2.4 Engine Misfire with Abnormal Internal

Lower Engine Noises

Cause Correction

Abnormalities, severe cracking, bumps or missing areas in

the accessory drive belt.

Abnormalities in the accessory drive system and/or

components may cause engine speed variations that result

in a misfire diagnostic trouble code (DTC). A misfire code

may be present without an ac tual misfire condition. Replace the accessory drive belt, refer to 3.5 Accessory

Drive Belt.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Worn, damaged or misaligned accessory drive components

and excessive pulley run-out may lead to a misfire DTC.

A misfire code may be present without an actual misfire

condition. Inspect the components and repair or replace as required.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Loose or Incorrectly fitted flexplate or crankshaft balancer

assembly.

A misfire code may be present without an actual misfire

condition. Repair or replace the flexplat

e or crankshaft balancer as

required, refer to 3.13 Crankshaft Balancer Assembly or

4.3 Flexplate Assembly.

Worn or broken piston rings.

Oil consumption may or may not cause an actual misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of

low compression.

4 Repair or replace components as required.

Worn crankshaft thrust bearing.

Severely worn thrust surfaces on the crankshaft and/or

thrust bearing may permit fore and aft movement of the

crankshaft and create a DTC wi thout an actual misfire

condition being present. Replace the crankshaft and/or bear

ings as required, refer to

4.6 Crankshaft and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2812 of 6020

Engine Mechanical – V6 Page 6A1–35

Page 6A1–35

2.5 Engine Misfire with Abnormal Valve

Train Noise

Cause Correction

Worn or loose stationary hydraulic lash adjusters (SHLA)

and/or valve rocker arms.

The SHLAs, rocker arm and roller bearings should be intact

and in the correct position. Replace the SHLAs and/or rocker arms as required, refer to

3.21 Stationary Hydraulic Las h Adjuster or 3.20 Rocker

Arm.

Stuck valves.

Carbon build up on the valve stem s can result in the valves

not closing correctly. Repair or replace as required, refer to 3.22 Cylinder Head

Assembly.

Excessively worn or misaligned timing chain/s. Replace the timing chain/s and components as required,

refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

Worn camshaft lobes. Replace the camshaft/s and SHLAs as required, refer to

3.19 Camshaft or 3.21 Stati onary Hydraulic Lash Adjuster.

Sticking camshaft lash adjusters.

Replace the lash adjusters as required, refer to 3.21

Stationary Hydraulic Lash Adjuster.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2813 of 6020

Engine Mechanical – V6 Page 6A1–36

Page 6A1–36

2.6 Engine Misfire with Coolant

Consumption

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder heads and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat. 1 Inspect the spark plugs for

coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect the cylinder heads, cylinder block and/or head gaskets, refer to 3.22 Cylinder Head Assembly

and/or 4.7 Cylinder Block.

3 Repair or replace components as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2814 of 6020

Engine Mechanical – V6 Page 6A1–37

Page 6A1–37

2.7 Engine Misfire with Excessive Oil

Consumption

Cause Correction

Worn valves, valve guides and/or valve stem oil seals. 1 Inspect the spark plugs for coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Repair or replace components as required, refer to 3.22 Cylinder Head Assembly.

Worn or broken piston rings.

Oil consumption may or may not cause an actual misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of

low compression.

4 Repair or replace components as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007