engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3155 of 6020

Engine Cooling – V6 Engine Page 6B1–20

COOLANT CONCENTRATION

Litres Of Coolant To Be Added

Concentration Reading % Automatic Transmission Manual Transmission

0 4.95 5.15

5 4.46 4.62

10 3.96 4.12

15 3.47 3.61

20 2.97 3.08

25 2.48 2.57

30 1.98 2.01

35 1.48 1.54

40 0.99 1.05

45 0.50 0.52

50 0 0

NOTE

If the reading is not clear, then properly clean

and dry the measuring surface, then conduct

another test. Also ensure that there is

sufficient fluid on the measuring prism.

9 If the reading shows that the concentration level of the coolant is inadequate, refer to the Coolant

Concentration table to determine the amount of

coolant that needs to be added to the coolant

recovery reservoir.

10 Start and run the engine until normal operating temperature is reached, to allow the added coolant

to be distributed throughout the engine cooling

system.

Figure 6B1 – 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3156 of 6020

Engine Cooling – V6 Engine Page 6B1–21

Calibrating the Tester

The coolant tester calibration is checked at manufacture. If however, the calibration check detailed in Step 1 of this

method shows that the instrument is not reading correctly, then conduct the following recalibration procedure:

1 Remove the sealant covering the adjustment screw on the underneath of the tester.

2 W ith a distilled water sample on the measuring surface, carefully adjust the screw until a zero reading is obtained.

NOTE

DO NOT completely remove the screw.

3 After recalibration, reseal the screw with a small amount of silicone sealant.

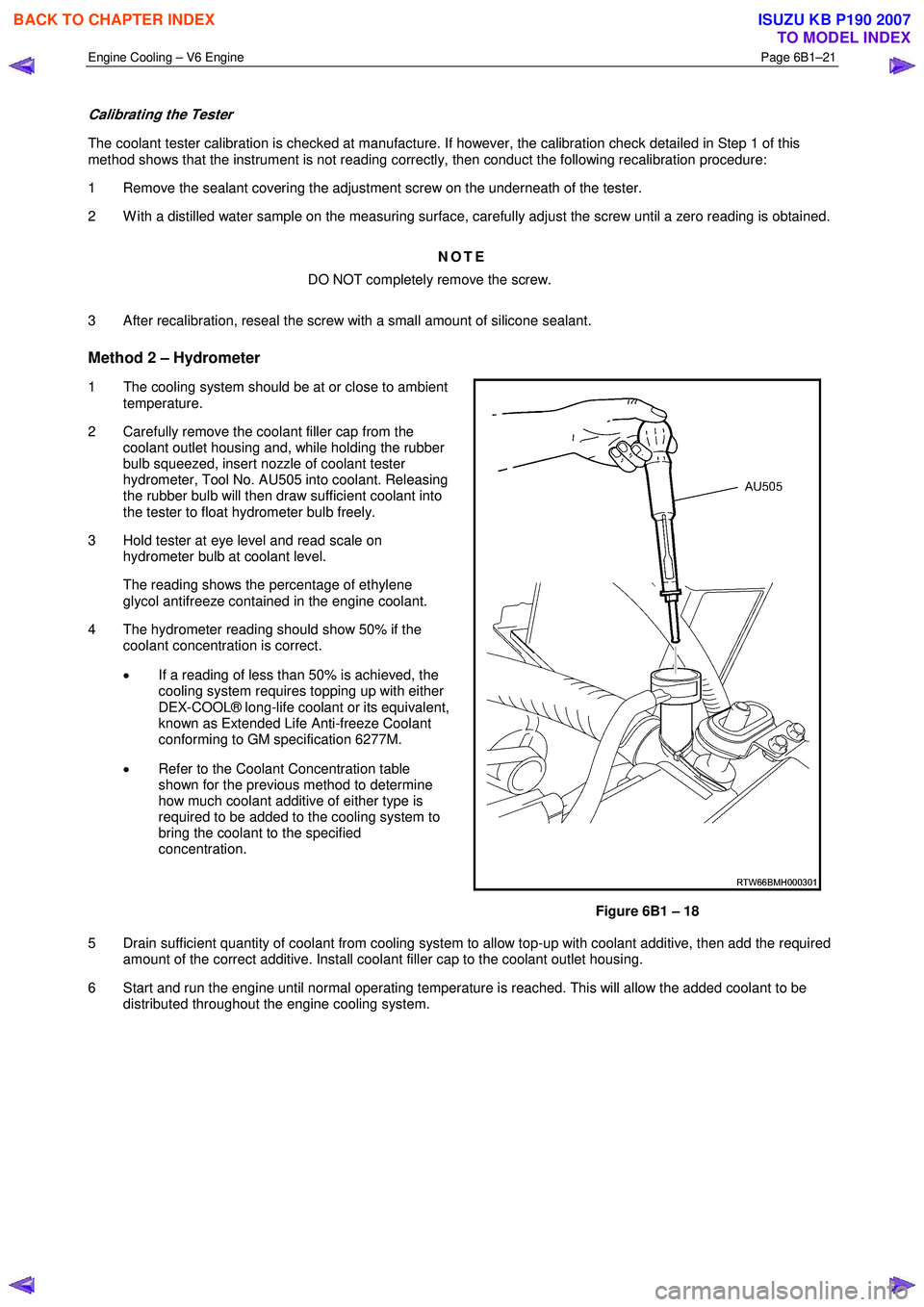

Method 2 – Hydrometer

1 The cooling system should be at or close to ambient temperature.

2 Carefully remove the coolant filler cap from the coolant outlet housing and, while holding the rubber

bulb squeezed, insert nozzle of coolant tester

hydrometer, Tool No. AU505 into coolant. Releasing

the rubber bulb will then draw sufficient coolant into

the tester to float hydrometer bulb freely.

3 Hold tester at eye level and read scale on hydrometer bulb at coolant level.

The reading shows the percentage of ethylene glycol antifreeze contained in the engine coolant.

4 The hydrometer reading should show 50% if the coolant concentration is correct.

• If a reading of less than 50% is achieved, the

cooling system requires topping up with either

DEX-COOL® long-life coolant or its equivalent,

known as Extended Life Anti-freeze Coolant

conforming to GM specification 6277M.

• Refer to the Coolant Concentration table

shown for the previous method to determine

how much coolant additive of either type is

required to be added to the cooling system to

bring the coolant to the specified

concentration.

Figure 6B1 – 18

5 Drain sufficient quantity of coolant from cooling system to allow top-up with coolant additive, then add the required amount of the correct additive. Install coolant filler cap to the coolant outlet housing.

6 Start and run the engine until normal operating temperature is reached. This will allow the added coolant to be distributed throughout the engine cooling system.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3157 of 6020

Engine Cooling – V6 Engine Page 6B1–22

3.3 Draining and Filling Cooling System

Draining

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow engine to cool to ambient temperature (less than 50 ° C), and then remove the coolant filler cap (located near

the brake booster assembly).

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 1.1

WARNING, CAUTION and NOTES, before

removing the ground lead.

2 Disconnect the battery ground lead. Refer to 6D1– 3 Battery – V6.

3 Drain the coolant from the system via the radiator drain tap on the lower RHS of the radiator below the lower hose outlet. Attach a suitable piece of rubber tubing to the tap outlet to help direct the flow of the coolant into a suitable

container (capacity at least 12 litres).

Filling

During any service operation that requires the cooling system to be partly or completely drained, the following

instructions must be followed when refilling the cooling system, to ensure that all air is bleed from system.

• Refer to 3.1 Service Notes in this Section,

for important safety items.

• Before opening the radiator bleed screw,

the cooling system must first be

completely depressurised with the engine

coolant filler cap removed.

Do not mix different types of anti-freeze or

corrosion inhibitors, as they may be

incompatible. Always check which coolant is

to be added to the particular vehicle being

serviced. If a different type has been used in

the cooling system (or is added accidentally),

flush the system with clean water. Refer to 3.4

Cleaning Cooling System in this Section.

NOTE

Ensure that the radiator drain tap located at the

bottom of right-hand side radiator tank is closed

before proceeding.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3158 of 6020

Engine Cooling – V6 Engine Page 6B1–23

1 W ith the engine off, remove the coolant filler cap on

the coolant outlet housing, located at the front left-

hand side of the engine.

Figure 6B1 – 19

2 If filling a completely empty cooling system for automatic transmission models, mix 5 litres of clean

water with 5 litres of the recommended coolant or

5.2 litres of each for manual transmission models.

3 Add coolant via the engine coolant filler neck on the coolant outlet housing.

NOTE

Do not replace the coolant filler cap before

starting the engine (in step 6). Leaving the filler

cap off allows the engine to warm up without

pressurising.

4 Reconnect battery ground lead. Refer to 6D1 – 3 Battery – V6.

5 Start the engine and set the HVAC controls to: • Full hot

• Low fan

Figure 6B1 – 20

6 Run the engine at approximately 2,000 rpm to warm up the engine.

7 W ait until the radiator fan switches on.

8 W hen the radiator fan has switched on, let the engine rpm drop back to idle.

9 Turn the engine off when the radiator fan switches off.

10 Top up the coolant until full.

11 Replace the coolant filler cap.

Do not loosen or remove the radiator filler cap

when the coolant temperature is high. Steam

or boiling coolant will gush out and you may

be burnt. To open the radiator filler cap, cover

the filler cap with a thick cloth when the

coolant has cooled, release the pressure by

slowly turning the filler cap, and remove the

cap.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3159 of 6020

Engine Cooling – V6 Engine Page 6B1–24

12 Open the coolant reservoir tank cap.

13 Top up the radiator coolant recovery reservoir to the MAX line.

14 Reinstall the coolant recovery reservoir cap.

NOTE

This condition only applies when the cooling

system is first being filled after a major loss of

coolant. The level of coolant in the reservoir

will then drop, once the engine is started and

normal operating temperature is reached. The

coolant level should then be maintained at the

correct level (between the MAX and MIN

Lines).

Figure 6B1 – 21

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3160 of 6020

Engine Cooling – V6 Engine Page 6B1–25

3.4 Cleaning Cooling System

NOTE

• Before carrying out reverse flushing

procedures, it is recommended that a

cleaning solution be used to loosen scale and

corrosion. Only use a Holden approved

radiator cleaner following the instructions on

the container label.

• This operation should only be carried out

when the engine and radiator are at ambient

temperature.

• When using specialised cooling system

flushing equipment, connect the equipment as

recommended by the manufacturer.

Cooling System Reverse Flush

Radiator

Refer to ‘

‘‘

‘

Environmental Issues ’

’’

’

in 3.1

Service Notes, before draining the coolant.

1 Drain the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

2 Remove the lower radiator outlet hose (1) at the coolant inlet pipe connection (2).

3 Remove the upper radiator inlet hose (3) at the coolant outlet housing connection (4).

4 Attach a lead-away hose to the open end of the upper radiator hose.

5 Attach a suitable piece of hose or adaptor between the flushing gun and the open end of the lower

radiator hose.

6 Connect and operate the flushing equipment as recommended by the manufacturer.

Apply air pressure gradually and not in

excess of 120 kPa, otherwise radiator

damage will result.

Figure 6B1 – 22

7 Continue flushing until the water from the lead-away hose runs clean and clear.

8 Install all disconnected hoses, ensuring that they are correctly positioned and securely clamped.

9 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3161 of 6020

Engine Cooling – V6 Engine Page 6B1–26

10 Pressure test the cooling system. Refer to 3.7 Pressure Testing in this Section.

Engine

Refer to ‘

‘‘

‘

Environmental Issues ’

’’

’

in 3.1

Service Notes, before draining the coolant.

1 Drain the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

2 Remove the upper and lower radiator hoses from the coolant outlet housing and coolant inlet pipe connections. Refer to Figure 6B1 – 22.

3 Remove the thermostat housing from the rear of the engine block. Refer to 6A1 Engine Mechanical – V6..

4 Remove the thermostat from the thermostat housing and reinstall the housing to the rear of the intake manifold. Refer to 3.8 Thermostat in this Section.

5 Remove both heater hoses (1) and (2) from their connections at the heater pipe assembly, noting

which hose was connected to which connection.

Seal the heater pipe assembly connections by

looping the heater inlet connection to the outlet

connection using a suitable piece of hose and two

hose clamps.

6 Install a lead-away hose to the coolant inlet pipe connection and a length of suitable hose between

the coolant outlet housing connection and the

flushing equipment.

7 Connect and operate the flushing equipment as recommended by the manufacturer.

Figure 6B1 – 23

8 Continue flushing until the water from the lead-away hose runs clear.

9 Remove the coolant recovery reservoir, flush it out with clean water and install. Refer to 3.9 Coolant Recovery Reservoir in this Section.

10 Install the thermostat. Refer to 3.8 Thermostat in this Section.

11 Install all disconnected hoses, ensuring that they are correctly positioned and securely clamped.

12 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

13 Pressure-test the cooling system. Refer to 3.7 Pressure Testing in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3162 of 6020

Engine Cooling – V6 Engine Page 6B1–27

Heater Hoses and Core

Refer to ‘

‘‘

‘

Environmental Issues ’

’’

’

in 3.1

Service Notes, before draining the coolant.

1 Drain the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

Always wear eye protection when working

with spring-type hose clamps. Failure to do

so may result in eye injury.

2 Remove both heater hoses (1) and (2) from their connections at the heater pipe assembly, noting

which hose was connected to which connection.

3 Direct the hose (1) that was connected to the heater pipe assembly’s front connection into a

suitable container.

4 Attach the hose (2) from the rear-most connection to the flushing gun.

5 Cycle the heater switch to ensure that the water valve is open.

Figure 6B1 – 24

6 Connect and operate the flushing equipment as recommended by the manufacturer.

Apply air pressure gradually and not in

excess of 130 kPa, otherwise heater core

damage will result.

7 Install all disconnected hoses, ensuring that they are correctly positioned and securely clamped.

8 Fill the cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

9 Pressure test the cooling system. Refer to 3.7 Pressure Testing in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3163 of 6020

Engine Cooling – V6 Engine Page 6B1–28

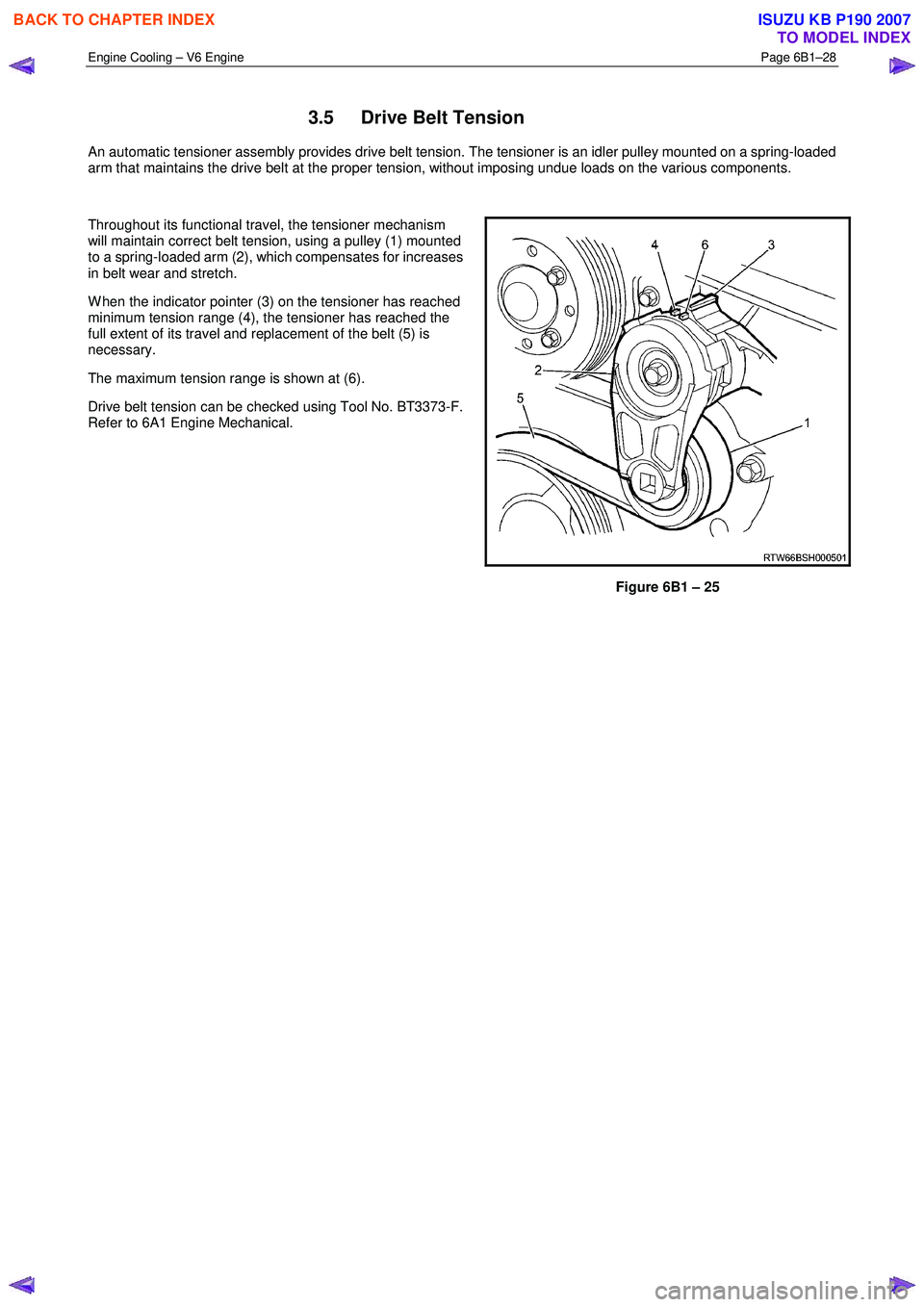

3.5 Drive Belt Tension

An automatic tensioner assembly provides drive belt tension. The tensioner is an idler pulley mounted on a spring-loaded

arm that maintains the drive belt at the proper tension, without imposing undue loads on the various components.

Throughout its functional travel, the tensioner mechanism

will maintain correct belt tension, using a pulley (1) mounted

to a spring-loaded arm (2), which compensates for increases

in belt wear and stretch.

W hen the indicator pointer (3) on the tensioner has reached

minimum tension range (4), the tensioner has reached the

full extent of its travel and replacement of the belt (5) is

necessary.

The maximum tension range is shown at (6).

Drive belt tension can be checked using Tool No. BT3373-F.

Refer to 6A1 Engine Mechanical.

Figure 6B1 – 25

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3164 of 6020

Engine Cooling – V6 Engine Page 6B1–29

Inspect

The four views in Figure 6B1 – 26 show the various stages of drive belt wear, to assist in belt replacement decisions.

NOTE

Condition of the belt ribs can be better assessed

if the belt is wrapped over the coolant pump drive

pulley.

Figure 6B1 – 26

Legend

A New Belt: No cracks or c hunks.

B Moderately Used Belt: Few cra cks, with some wear on the ribs and in the grooves. Belt replacement not required.

C Severely Used Belt: Several cracks per 30 mm. S hould be replaced before chunking occurs

D Failed Belt: Separation of rib material from backing (chunking). Belt must be replaced immediately.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007