lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2066 of 6020

6A-52 ENGINE MECHANICAL (C24SE)

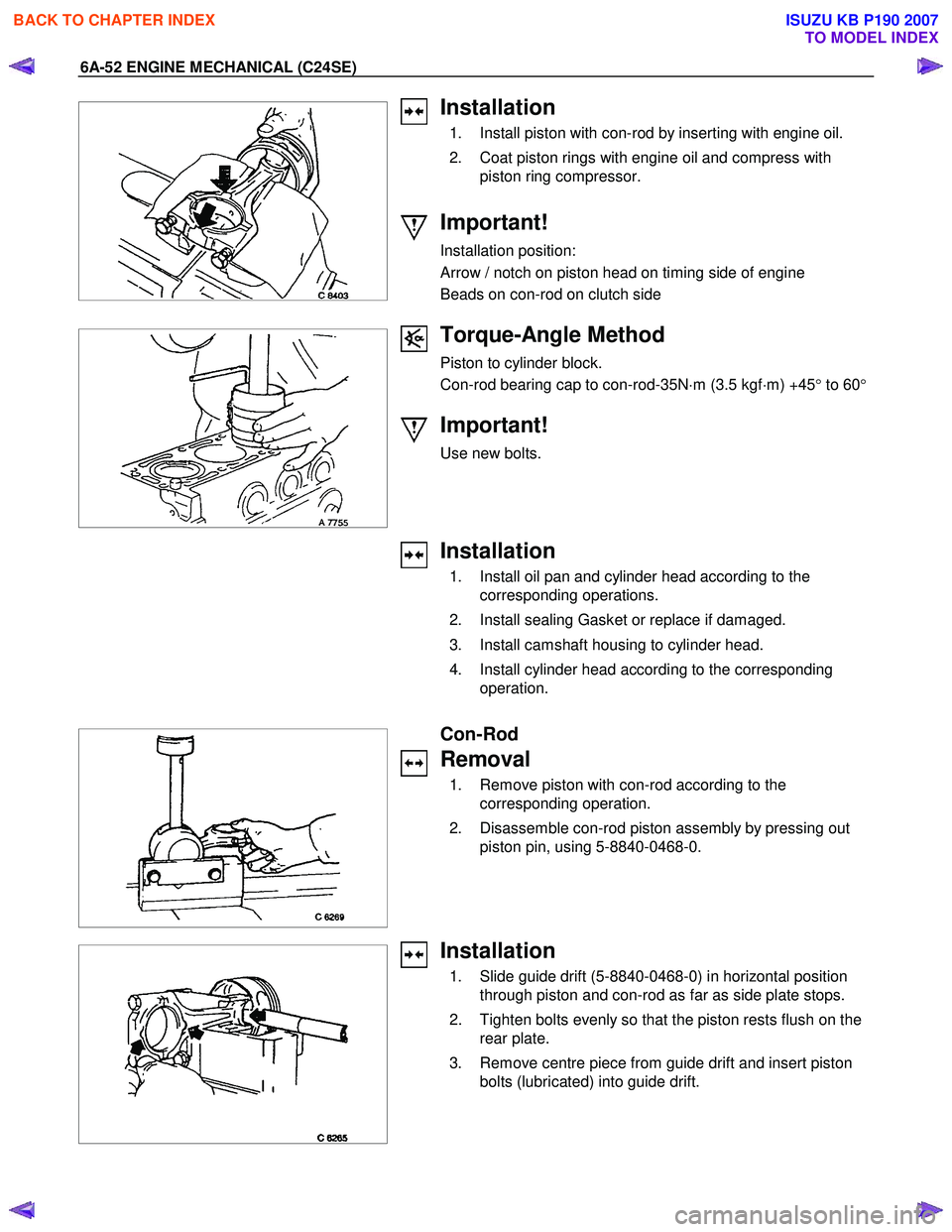

Installation

1. Install piston with con-rod by inserting with engine oil.

2. Coat piston rings with engine oil and compress with piston ring compressor.

Important!

Installation position:

Arrow / notch on piston head on timing side of engine

Beads on con-rod on clutch side

Torque-Angle Method

Piston to cylinder block.

Con-rod bearing cap to con-rod-35N ⋅m (3.5 kgf ⋅m) +45 ° to 60 °

Important!

Use new bolts.

Installation

1. Install oil pan and cylinder head according to the corresponding operations.

2. Install sealing Gasket or replace if damaged.

3. Install camshaft housing to cylinder head.

4. Install cylinder head according to the corresponding operation.

Con-Rod

Removal

1. Remove piston with con-rod according to the corresponding operation.

2. Disassemble con-rod piston assembly by pressing out piston pin, using 5-8840-0468-0.

Installation

1. Slide guide drift (5-8840-0468-0) in horizontal position through piston and con-rod as far as side plate stops.

2. Tighten bolts evenly so that the piston rests flush on the rear plate.

3. Remove centre piece from guide drift and insert piston bolts (lubricated) into guide drift.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2069 of 6020

ENGINE MECHANICAL (C24SE) 6A-55

OPERATIONS ON REMOVED ENGINE

Crankshaft

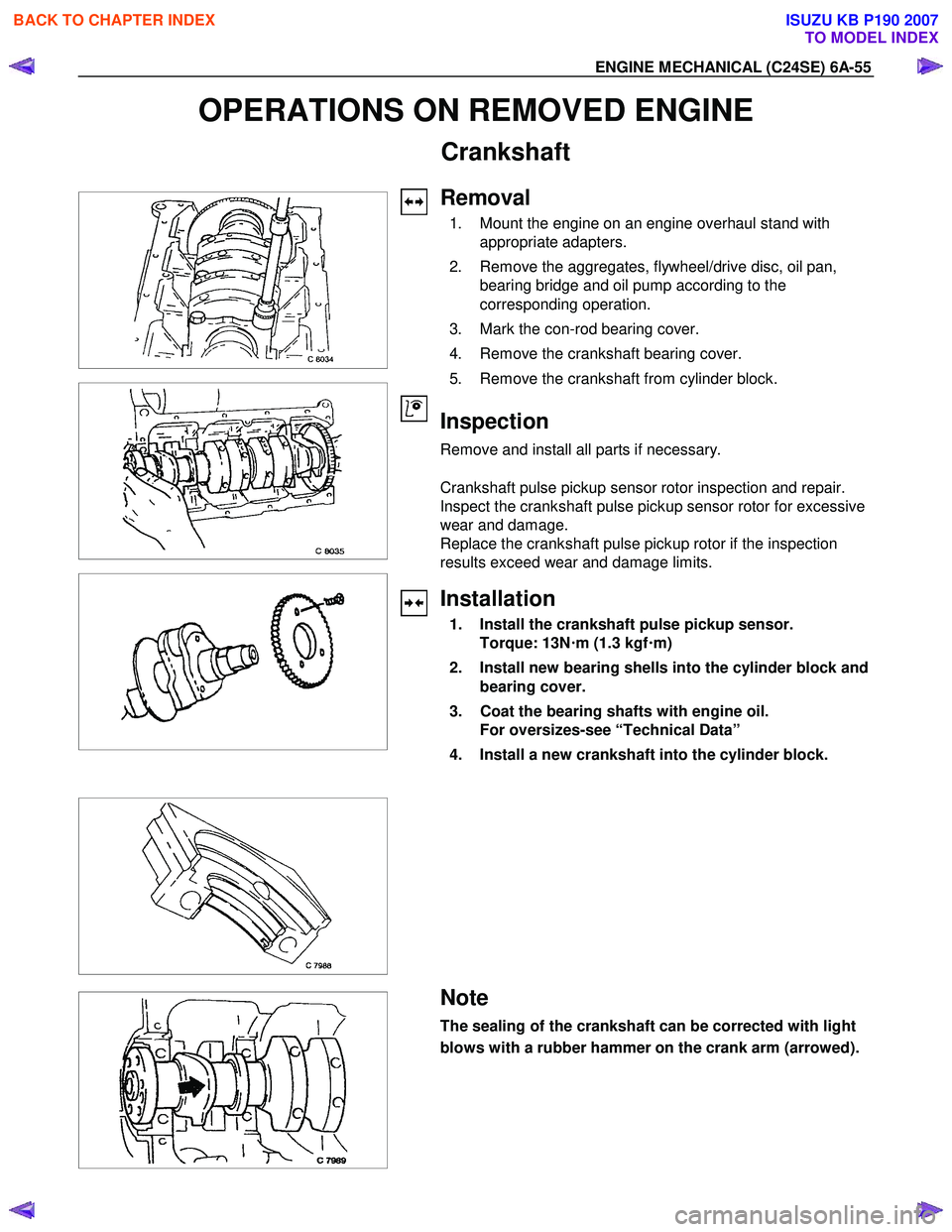

Removal

1. Mount the engine on an engine overhaul stand with appropriate adapters.

2. Remove the aggregates, flywheel/drive disc, oil pan, bearing bridge and oil pump according to the

corresponding operation.

3. Mark the con-rod bearing cover.

4. Remove the crankshaft bearing cover.

5. Remove the crankshaft from cylinder block.

Inspection

Remove and install all parts if necessary.

Crankshaft pulse pickup sensor rotor inspection and repair.

Inspect the crankshaft pulse pickup sensor rotor for excessive

wear and damage.

Replace the crankshaft pulse pickup rotor if the inspection

results exceed wear and damage limits.

Installation

1. Install the crankshaft pulse pickup sensor. Torque: 13N !

!!

!

m (1.3 kgf !

!!

!

m)

2. Install new bearing shells into the cylinder block and bearing cover.

3. Coat the bearing shafts with engine oil. For oversizes-see “Technical Data”

4. Install a new crankshaft into the cylinder block.

Note

The sealing of the crankshaft can be corrected with light

blows with a rubber hammer on the crank arm (arrowed).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2070 of 6020

6A-56 ENGINE MECHANICAL (C24SE)

5. Apply a bead of sealant (TB-1207C or equivalent) in the grooves of both bearing shells.

Important!

After installation of bearing cover, press in sealing compound

again from above, until compound emerges at the joints.

Torque - Angle Method

Bearing cover to cylinder block - 50 N ⋅m (5.1 kgf ⋅m) +40 ° to

50 °

Con-rod bearing cover to con-rod - 35 N ⋅m (3.5 kgf ⋅m) +45 ° to

60 °.

Use new bolts.

6. Install oil pump, oil pan, bearing bridge rear crankshaft

sealing, flywheel/drive plate, and aggregates according to

the corresponding operations.

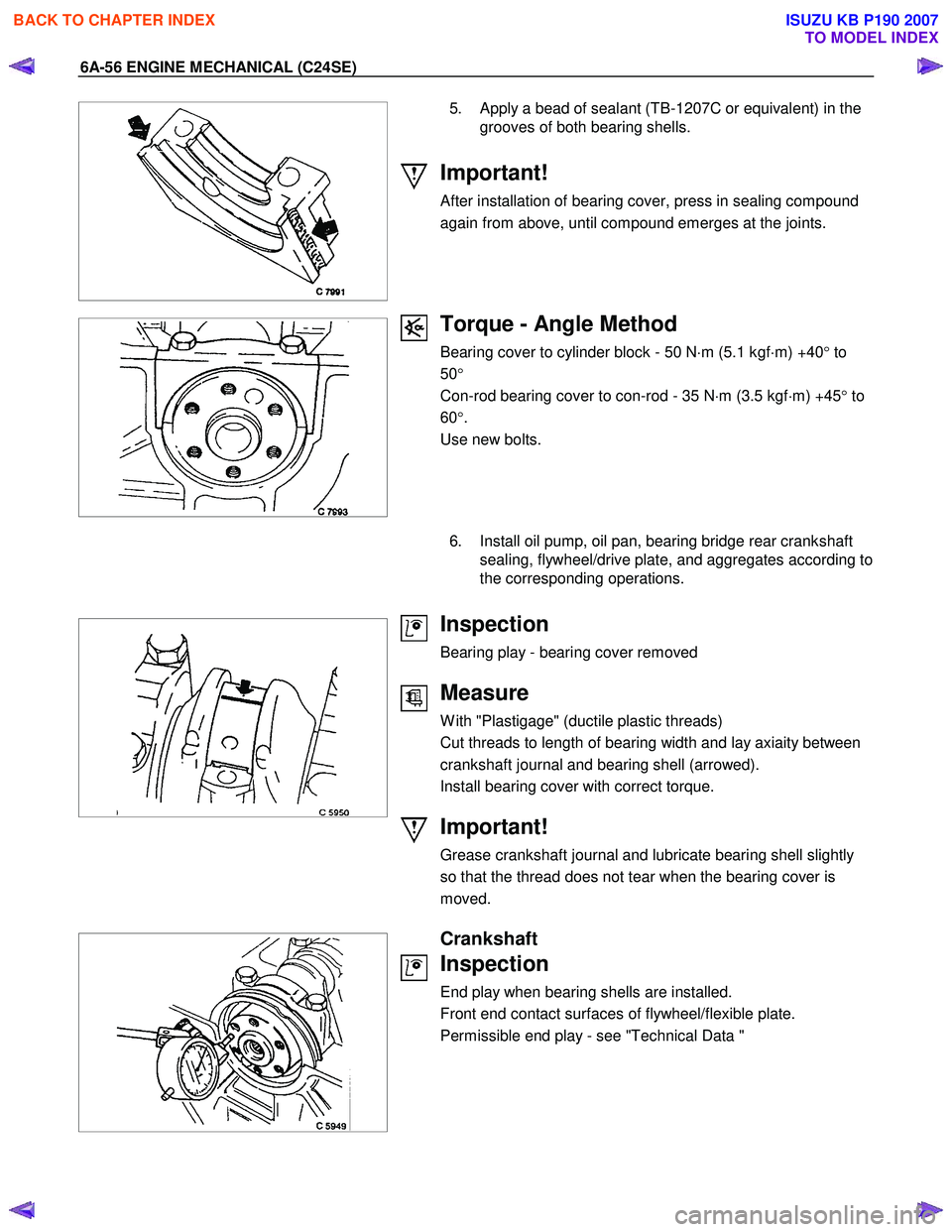

Inspection

Bearing play - bearing cover removed

Measure

W ith "Plastigage" (ductile plastic threads)

Cut threads to length of bearing width and lay axiaity between

crankshaft journal and bearing shell (arrowed).

Install bearing cover with correct torque.

Important!

Grease crankshaft journal and lubricate bearing shell slightly

so that the thread does not tear when the bearing cover is

moved.

Crankshaft

Inspection

End play when bearing shells are installed.

Front end contact surfaces of flywheel/flexible plate.

Permissible end play - see "Technical Data "

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2072 of 6020

6A-58 ENGINE MECHANICAL (C24SE)

Clean

Plastigage from journals.

Lightly coat journals and bearings with engine oil.

Installation

Install bearing cap and shell using new bolts.

Torque - Angle Method

Main bearing cap bolt - 60 N ⋅m (6.1 kgf ⋅m) +40 ° to 50 °.

Con-rod bearing cap bolts - 35 N ⋅m (3.9 kgf ⋅m) +45 °.

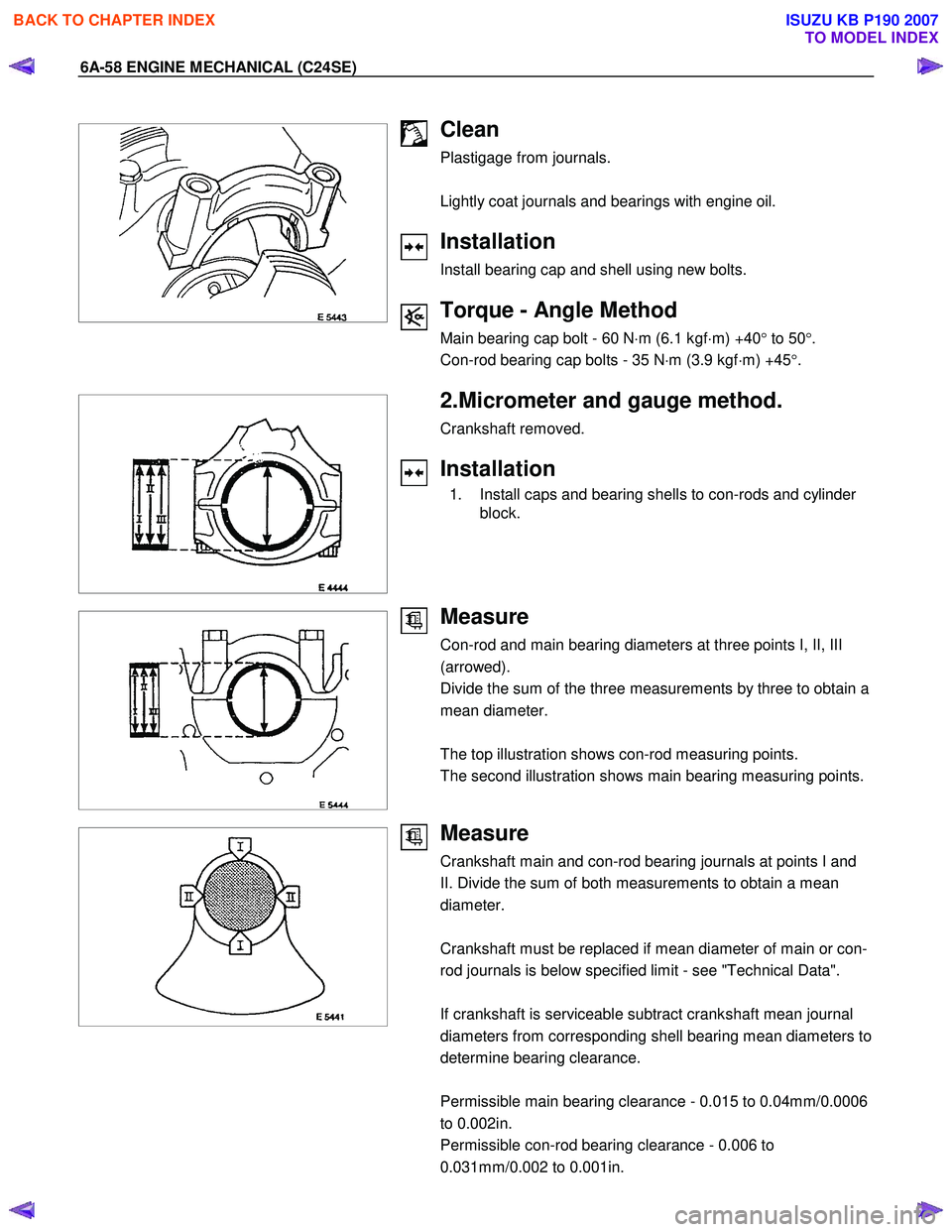

2.Micrometer and gauge method.

Crankshaft removed.

Installation

1. Install caps and bearing shells to con-rods and cylinder block.

Measure

Con-rod and main bearing diameters at three points I, II, III

(arrowed).

Divide the sum of the three measurements by three to obtain a

mean diameter.

The top illustration shows con-rod measuring points.

The second illustration shows main bearing measuring points.

Measure

Crankshaft main and con-rod bearing journals at points I and

II. Divide the sum of both measurements to obtain a mean

diameter.

Crankshaft must be replaced if mean diameter of main or con-

rod journals is below specified limit - see "Technical Data".

If crankshaft is serviceable subtract crankshaft mean journal

diameters from corresponding shell bearing mean diameters to

determine bearing clearance.

Permissible main bearing clearance - 0.015 to 0.04mm/0.0006

to 0.002in.

Permissible con-rod bearing clearance - 0.006 to

0.031mm/0.002 to 0.001in.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2073 of 6020

ENGINE MECHANICAL (C24SE) 6A-59

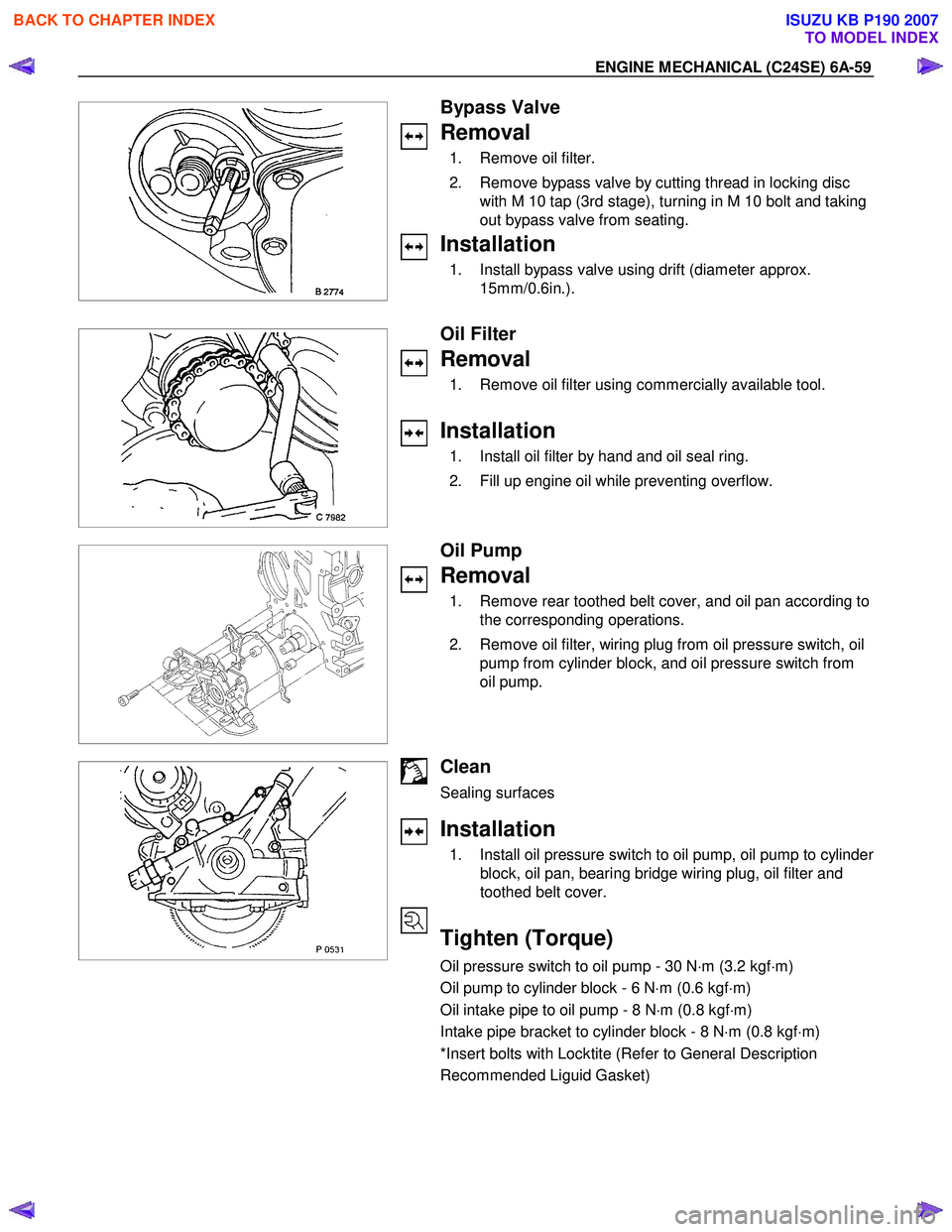

Bypass Valve

Removal

1. Remove oil filter.

2. Remove bypass valve by cutting thread in locking disc with M 10 tap (3rd stage), turning in M 10 bolt and taking

out bypass valve from seating.

Installation

1. Install bypass valve using drift (diameter approx. 15mm/0.6in.).

Oil Filter

Removal

1. Remove oil filter using commercially available tool.

Installation

1. Install oil filter by hand and oil seal ring.

2. Fill up engine oil while preventing overflow.

Oil Pump

Removal

1. Remove rear toothed belt cover, and oil pan according to the corresponding operations.

2. Remove oil filter, wiring plug from oil pressure switch, oil pump from cylinder block, and oil pressure switch from

oil pump.

Clean

Sealing surfaces

Installation

1. Install oil pressure switch to oil pump, oil pump to cylinder

block, oil pan, bearing bridge wiring plug, oil filter and

toothed belt cover.

Tighten (Torque)

Oil pressure switch to oil pump - 30 N ⋅m (3.2 kgf ⋅m)

Oil pump to cylinder block - 6 N ⋅m (0.6 kgf ⋅m)

Oil intake pipe to oil pump - 8 N ⋅m (0.8 kgf ⋅m)

Intake pipe bracket to cylinder block - 8 N ⋅m (0.8 kgf ⋅m)

*Insert bolts with Locktite (Refer to General Description

Recommended Liguid Gasket)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2079 of 6020

ENGINE MECHANICAL (C24SE) 6A-65

ENGINE EXTERNAL PARTS

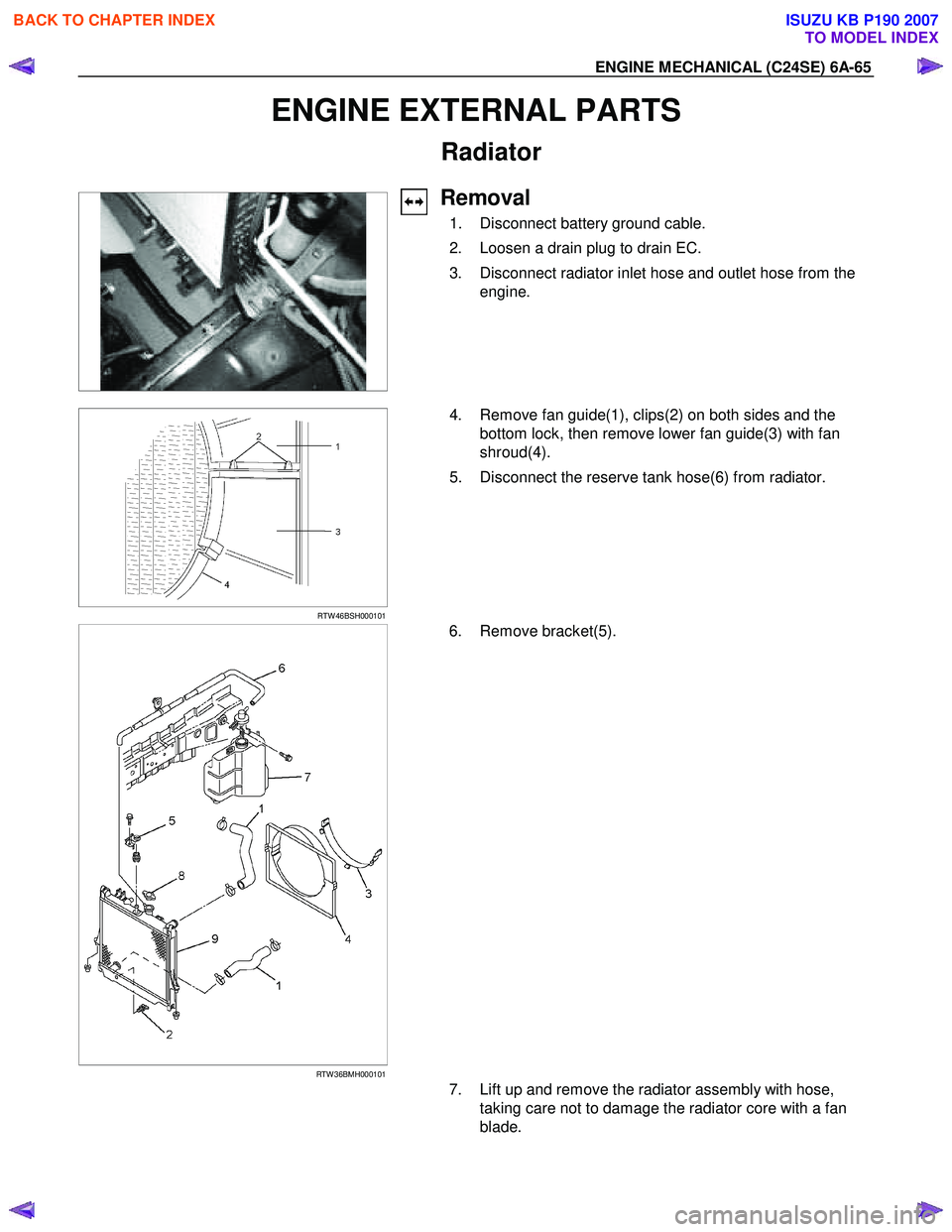

Radiator

Removal

1. Disconnect battery ground cable.

2. Loosen a drain plug to drain EC.

3. Disconnect radiator inlet hose and outlet hose from the engine.

RTW 46BSH000101

4. Remove fan guide(1), clips(2) on both sides and the

bottom lock, then remove lower fan guide(3) with fan

shroud(4).

5. Disconnect the reserve tank hose(6) from radiator.

RTW 36BMH000101

6. Remove bracket(5).

7. Lift up and remove the radiator assembly with hose,

taking care not to damage the radiator core with a fan

blade.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2080 of 6020

6A-66 ENGINE MECHANICAL (C24SE)

Installation

Follow the removal procedure in the reverse order to install the

radiator.

Thermostat

Removal

1. Remove water outlet nozzles with thermostat from thermostat housing.

2. Remove coolant hose and collect coolant.

Important!

Remove and Install thermostat only together with water outlet

nozzles.

Tighten (Torque)

W ater outlet nozzles to thermostat housing - 8 N ⋅m (0.8 kgf ⋅m)

Installation

1. Install coolant hose.

2. Fill cooling system and bleed according to the corresponding operation.

Water Pump

Removal

1. Remove lower hose band from pipe band and collect coolant.

2. Remove front toothed belt cover according to the corresponding operation.

3. Remove water pump from cylinder block after releasing tension on toothed belt.

Clean

Sealing surfaces

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2081 of 6020

ENGINE MECHANICAL (C24SE) 6A-67

Coating sealing surfaces with Silicone Grease

Installation

1. Install water pump to cylinder block with new rubber O-ring.

2. Apply tension to toothed belt according to the corresponding operation.

3. Install coolant hoses.

4. Fill cooling system and bleed according to the corresponding operation.

Alternator

Removal

1. Remove ground cable from battery.

2. Remove cable connection from alternator and V-belt.

3. Remove alternator from retaining strap and lower fastening.

Installation

1. Install alternator by tightening firmly by hand.

2. Install V-belt and apply tension according to the corresponding operation.

3. Install cable connections to alternator.

4. Install ground cable to battery.

Starter

Removeal

1. Remove cable connections from starter.

2. Remove upper bolt of transmission side.

3. Remove lower bolt of engine side.

Tighten (Torque)

Starter to cylinder block:

Engine side - 51 N ⋅m (5.2 kgf ⋅m)

Transmission side - 75 N ⋅m (7.6 kgf ⋅m)

Starter support to cylinder block - 25 N ⋅m (2.5 kgf ⋅m)

Re-connect cables.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2083 of 6020

ENGINE MECHANICAL (C24SE) 6A-69

RTW 66ASH000201

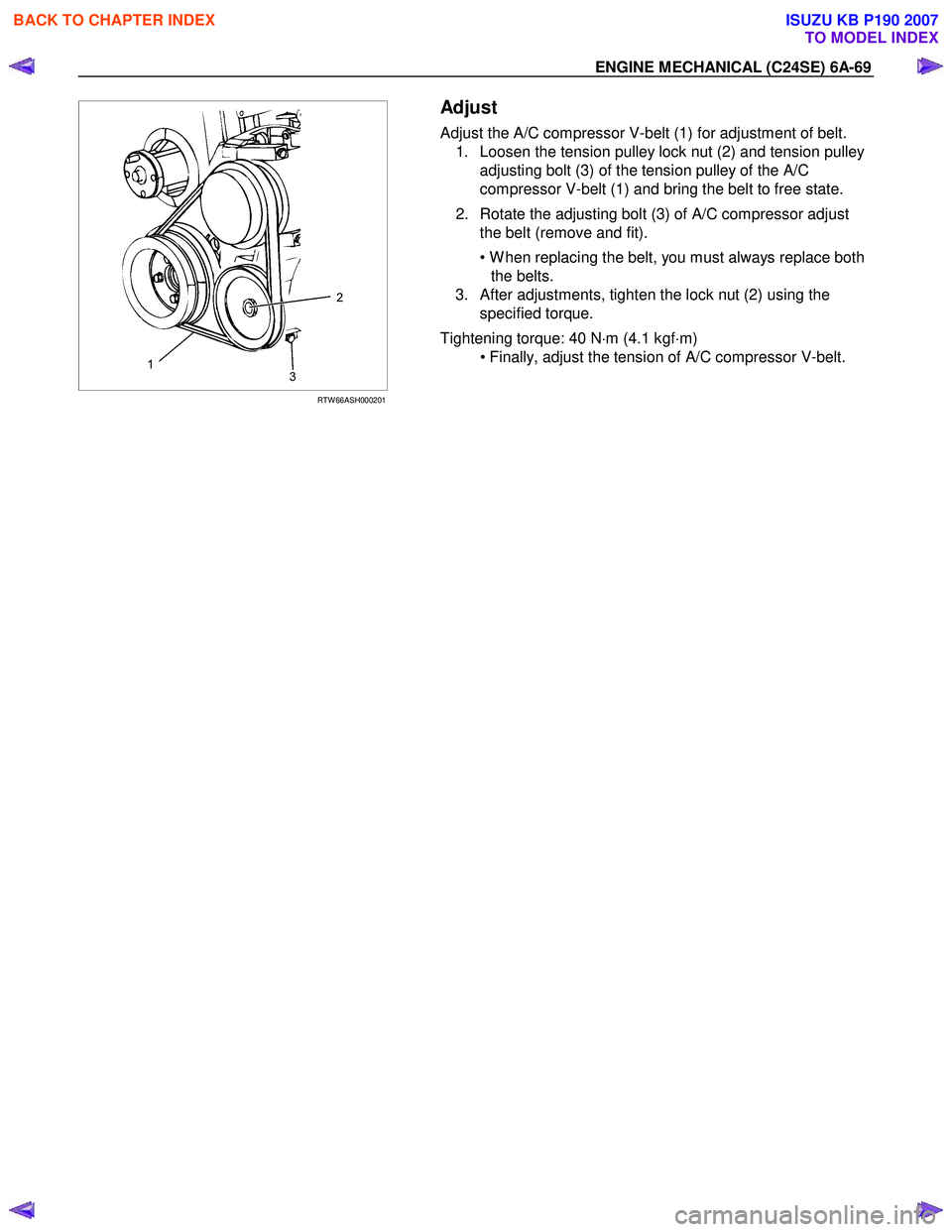

Adjust

Adjust the A/C compressor V-belt (1) for adjustment of belt.

1. Loosen the tension pulley lock nut (2) and tension pulley adjusting bolt (3) of the tension pulley of the A/C

compressor V-belt (1) and bring the belt to free state.

2. Rotate the adjusting bolt (3) of A/C compressor adjust the belt (remove and fit).

• W hen replacing the belt, you must always replace both the belts.

3. After adjustments, tighten the lock nut (2) using the specified torque.

Tightening torque: 40 N ⋅m (4.1 kgf ⋅m)

• Finally, adjust the tension of A/C compressor V-belt.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2096 of 6020

6A-82 ENGINE MECHANICAL (C24SE)

Crankshaft, Cylinder Block

Cylinder Grinding and Piston Dimensions

Size Cylinder bore dia. in mm Cylinder to Related piston dia. in mm Piston head

Crankshaft co- efficient

housing

co-efficient

over to over to

Production

(2.4L) 1 87.48

87.49 87.49

87.50 99

00 87.46

87.47 87.47

87.48 99

00

Customer service (2.4L) - 87.99 88.00 0+0.5 87.97 87.98 7+0.5

Piston diameter must be measured at the position "D".

*inclusive

Cylinder Bore

Rebore cylinder Permissible oversize to 0.5mm (see parts

microfiche)

After reboring, invalidate original crankcase

housing coefficient and drive in new oversize

coefficient

Permissible out-of-round: 0.013mm

Permissible taper: 0.013mm

Measure out-of-round in bore at 4 different

heights

Piston projection above upper edge of cylinder block 0.40mm

Piston

Type Recessed pistons

Clearance For short-blocks and cylinder blocks with complete pistons, the clearance is 0.02 to

0.04mm

For replacement (oversize), depending on

available pistons, a clearance of 0.02 to

0.04mm is permissible

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007