CIRCUIT DIAGRAM ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2181 of 6020

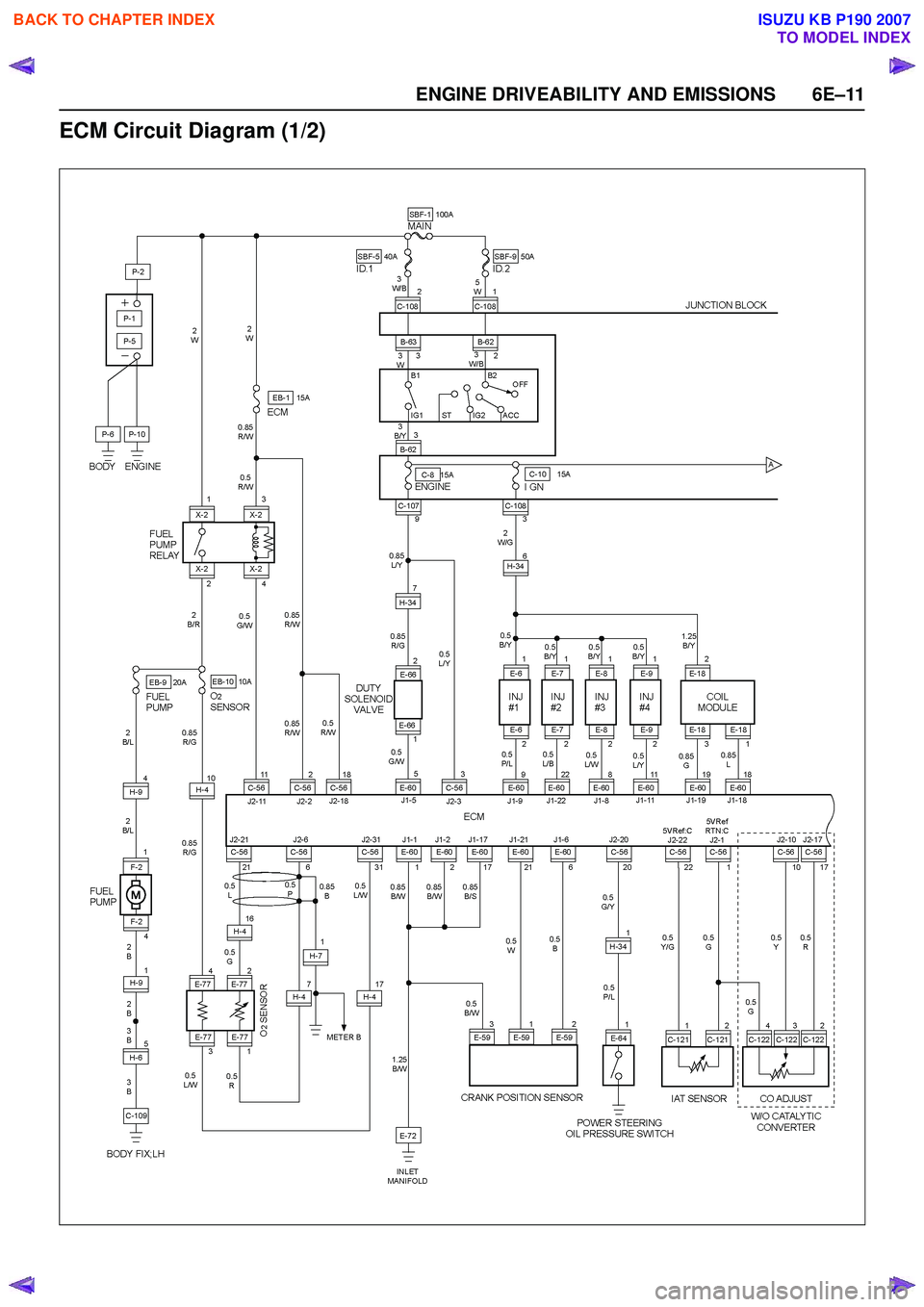

ENGINE DRIVEABILITY AND EMISSIONS 6E–11

ECM Circuit Diagram (1/2)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2182 of 6020

6E–12 ENGINE DRIVEABILITY AND EMISSIONS

ECM Circuit Diagram (2/2)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2230 of 6020

6E–60 ENGINE DRIVEABILITY AND EMISSIONS

A/C CLUTCH DIAGNOSIS

A/C Clutch Circuit Operation

A 12-volt signal is supplied to the A/C request input of

the ECM when the A/C is selected through the A/C

control switch.

The A/C compressor clutch relay is controlled through

the ECM. This allows the ECM to modify the idle air

control position prior to the A/C clutch engagement for

better idle quality. If the engine operating conditions are

within their specified calibrated acceptable ranges, the

ECM will enable the A/C compressor relay. This is done

by providing a ground path for the A/C relay coil within

the ECM. When the A/C compressor relay is enabled,

battery voltage is supplied to the compressor relay is

enabled, battery voltage is supplied to the compressor

clutch coil.

The ECM will enable the A/C compressor clutch

whenever the engine is running and the A/C has been

requested. The ECM will not enable the A/C

compressor clutch if any of the following conditions are

met:

• The engine speed is greater than 6000 RPM.

• The ECT is greater than 122°C (251°F).

• The throttle is more than 95% open.

A/C Clutch Circuit Purpose

The A/C compressor operation is controlled by the

engine control module (ECM) for the following reasons:

• It improves idle quality during compressor clutch engagement.

• It improves wide open throttle (WOT) performance.

• It provides A/C compressor protection from operation with incorrect refrigerant pressures.

The A/C electrical system consists of the following

components:

• The A/C control switch.

• The A/C refrigerant pressure switches.

• The A/C compressor clutch.

• The A/C compressor clutch relay.

•The ECM.

A/C Request Signal

This signal tells the ECM when the A/C mode is

selected at the A/C control switch. The ECM uses this

input to adjust the idle speed before turning on the A/C

clutch. The A/C compressor will be inoperative if this

signal is not available to the ECM.

Refer to A/C Clutch Circuit Diagnosis for A/C wiring

diagrams and diagnosis for the A/C electrical system.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2233 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–63

3. Check Bulletins and Troubleshooting Hints

NOTE: As estimated 30 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You should have enough information gained from

preliminary checks to accurately search for a bulletin

and other related service information. Some service

manual sections provide troubleshooting hints that

match symptoms with specific complaints.

What resources you should use

You should use the following resources for assistance in

checking for bulletins and troubleshooting hints:

• Printed bulletins

• Access ISUZU Bulletin Web site.

• Videotapes

• Service manual

4. Perform Service Manual Diagnostic Checks

What you should do

The “System Checks” in most service manual sections

and in most cells of section 8A (electrical) provide you

with:

• A systematic approach to narrowing down the possible causes of a system fault

• Direction to specific diagnostic procedures in the service manual

• Assistance to identify what systems work correctly

What resources you should use

Whenever possible, you should use the following

resources to perform service manual checks:

• Service manual

• Technical equipment (for viewing DTCs and analyzing data)

• Digital multimeter and circuit testing tools

• Other tools as needed

5a and 5b. Perform Service Manual Diagnostic Procedures

NOTE: An estimated 40 percent of successful vehicle

repairs are diagnosed with these steps!

What you should do

When directed by service manual diagnostic checks,

you must then carefully and accurately perform the

steps of diagnostic procedures to locate the fault related to the customer complaint.

What resources you should use

Whenever appropriate, you should use the following

resources to perform service manual diagnostic

procedures:

• Service manual

• Technical equipment (for analyzing diagnostic data)

• Digital multimeter and circuit testing tools

• Essential and special tools

5c. Technician Self Diagnoses

When there is no DTC stored and no matching

symptom for the condition identified in the service

manual, you must begin with a thorough understanding

of how the system(s) operates. Efficient use of the

service manual combined with you experience and a

good process of elimination will result in accurate

diagnosis of the condition.

What you should do

Step 1: Identify and understand the suspect

circuit(s)

Having completed steps 1 through 4 of the Strategy

Based Diagnostics chart, you should have enough

information to identify the system(s) or sub-system(s)

involved. Using the service manual, you should

determine and investigate the following circuit

characteristics:

• Electrical: – How is the circuit powered (power distributioncharts and/or fuse block details)?

– How is the circuit grounded (ground distribution charts)?

– How is the circuit controlled or sensed (theory of operation):

– If it is a switched circuit, is it normally open or normally closed?

– Is the power switched or is the ground switched?

– Is it a variable resistance circuit (ECT sensor or TP sensor, for example)?

– Is it a signal generating device (MAF sensor of VSS, for example)?

– Does it rely on some mechanical/vacuum device to operate?

•Physical:

– Where are the circuit components (componentlocators and wire harness routing diagrams):

– Are there areas where wires could be chafed or pinched (brackets or frames)?

– Are there areas subjected to extreme temperatures?

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2402 of 6020

6E–232 ENGINE DRIVEABILITY AND EMISSIONS

SYMPTOM DIAGNOSIS

PRELIMINARY CHECKS

Before using this section, perform the “On-Board

Diagnostic (OBD) System Check” and verify all of the

following items:

• The engine control module (ECM) and malfunction indicator lamp (MIL = Check Engine Lamp) are

operating correctly.

• There are no Diagnostic Trouble Code(s) stored.

• Tech 2 data is within normal operating range. Refer to Typical Scan Data Values.

• Verify the customer complaint and locate the correct symptom in the table of contents. Perform the

procedure included in the symptom chart.

VISUAL/PHYSICAL CHECK

Several of the symptom procedures call for a careful

visual/physical check. This can lead to correcting a

problem without further checks and can save valuable

time. This check should include the following items:

• ECM grounds for cleanliness, tightness and proper location.

• Vacuum hoses for splits, kinks, and proper connection, shown on the “Emission Control System

Schematics”. Check thoroughly for any type of leak or

restriction.

• Air intake ducts for collapsed or damaged areas.

• Air leaks at throttle body mounting area, manifold absolute pressure (MAP) sensor and intake manifold

sealing surfaces.

• Ignition wires for cracking, harness, and carbon tracking.

• Wiring for proper connections, pinches and cuts.

INTERMITTENT

Important: An intermittent problem may or may not turn

on the malfunction indicator lamp (MIL) or store a

Diagnostic Trouble Code. Do NOT use the Diagnostic

Trouble Code (DTC) charts for intermittent problems.

The fault must be present to locate the problem.

Most intermittent problems are cased by faulty electrical

connections or wiring. Perform a careful visual/physical

check for the following conditions.

• Poor mating of the connector halves or a terminal not fully seated in the connector (backed out).

• Improperly formed or damaged terminal.

• All connector terminals in the problem circuit should be carefully checked for proper contact tension.

• Poor terminal-to-wire connection. This requires removing the terminal form the connector body to

check.

• Ignition coils shorted to ground and arcing at ignition wires or plugs. • MIL (Check Engine Lamp) wire to ECM shorted to

ground.

• Poor ECM grounds. Refer to the ECM wiring diagrams.

Road test the vehicle with a Digital Multimeter

connected to a suspected circuit. An abnormal voltage

when the malfunction occurs is a good indication that

there is a fault in the circuit being monitored.

Using Tech 2 to help detect intermittent conditions. The

Tech 2 has several features that can be used to located

an intermittent condition.

An intermittent MIL (Check Engine Lamp) with no stored

Diagnostic Trouble Code may be caused by the

following:

• Ignition coil shorted to ground and arcing at ignition wires or plugs.

• MIL (Check Engine Lamp) wire to ECM short to ground.

• Poor ECM grounds. Refer to the ECM wiring diagrams.

Check for improper installation of electrical options such

as light, cellular phones, etc. Check all wires from ECM

to the ignition control module for poor connections.

Check for an open diode across the A/C compressor

clutch and check for other open diodes (refer to wiring

diagrams in Electrical Diagnosis).

If problem has not been found, refer to ECM connector

symptom tables.

• Check the “Broadcast Code” of the ECM, and compare it with the latest Isuzu service bulletins and/

or Isuzu EEPROM reprogramming equipment to

determine if an update to the ECM’s reprogrammable

memory has been released.

To check the “Broadcast Code”, connect the Tech 2,

then look for “ID info.” then select “Broadcast Code”.

This should display a 4 character code, such as “XBYA”

(example only).

This identifies the contents of the reprogrammable

software and calibration contained in the ECM.

If the “Broadcast Code” is not the most current

available, it is advisable to reprogram the ECM’s

EEPROM memory, which may either help identify a

hard-to find problem or may fix the problem.

The Service Programming System (SPS) will not allow

incorrect software programming or incorrect calibration

changes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2418 of 6020

6E–248 ENGINE DRIVEABILITY AND EMISSIONS

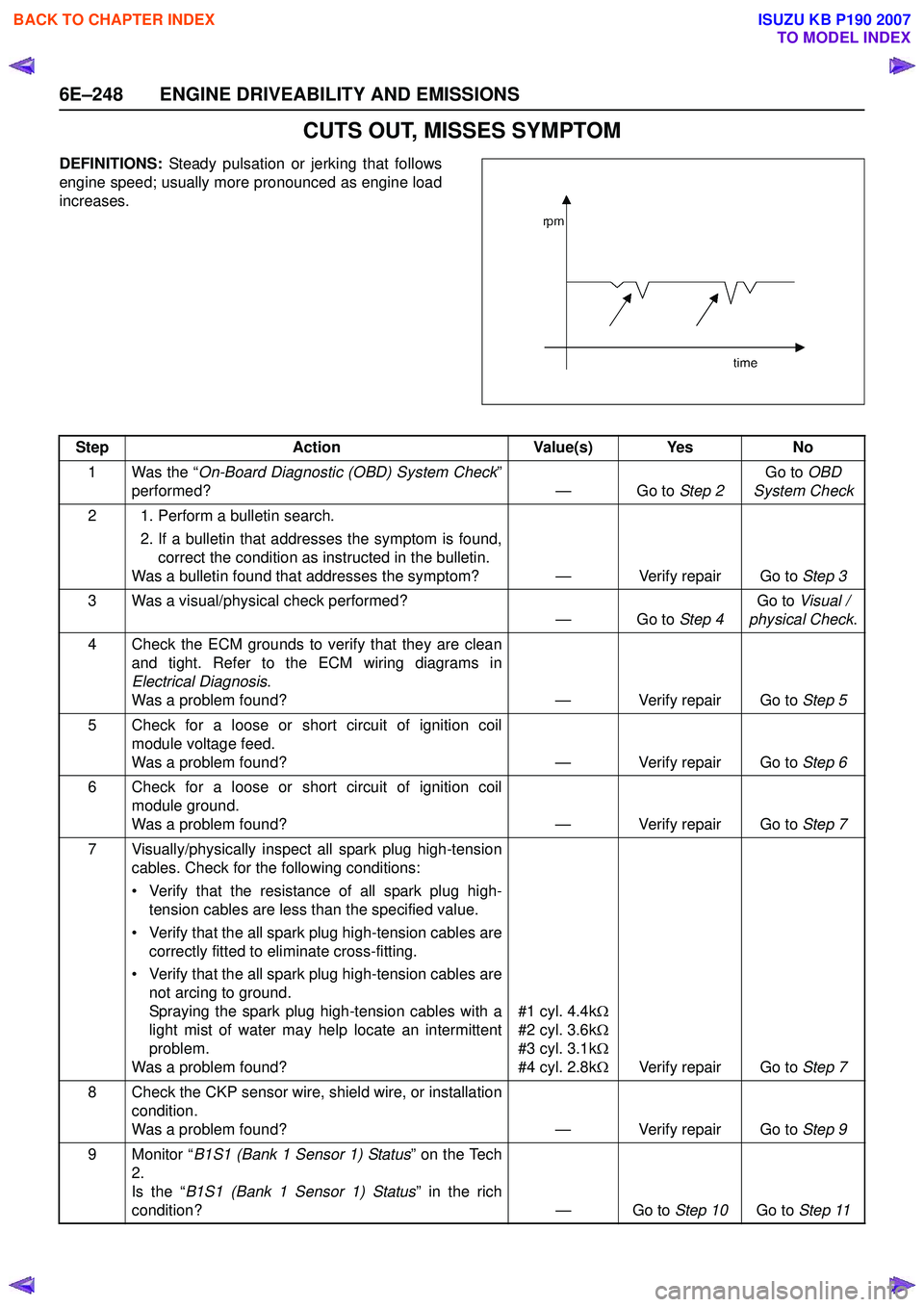

CUTS OUT, MISSES SYMPTOM

DEFINITIONS: Steady pulsation or jerking that follows

engine speed; usually more pronounced as engine load

increases.

Step Action Value(s) Yes No

1 Was the “ On-Board Diagnostic (OBD) System Check ”

performed? — Go to Step 2Go to

OBD

System Check

2 1. Perform a bulletin search. 2. If a bulletin that addresses the symptom is found,correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom? — Verify repair Go to Step 3

3 Was a visual/physical check performed? —Go to Step 4Go to

Visual /

physical Check .

4 Check the ECM grounds to verify that they are clean and tight. Refer to the ECM wiring diagrams in

Electrical Diagnosis .

Was a problem found? — Verify repair Go to Step 5

5 Check for a loose or short circuit of ignition coil module voltage feed.

Was a problem found? — Verify repair Go to Step 6

6 Check for a loose or short circuit of ignition coil module ground.

Was a problem found? — Verify repair Go to Step 7

7 Visually/physically inspect all spark plug high-tension cables. Check for the following conditions:

• Verify that the resistance of all spark plug high- tension cables are less than the specified value.

• Verify that the all spark plug high-tension cables are correctly fitted to eliminate cross-fitting.

• Verify that the all spark plug high-tension cables are not arcing to ground.

Spraying the spark plug high-tension cables with a

light mist of water may help locate an intermittent

problem.

Was a problem found? #1 cyl. 4.4k

Ω

#2 cyl. 3.6k Ω

#3 cyl. 3.1k Ω

#4 cyl. 2.8k ΩVerify repair Go to Step 7

8 Check the CKP sensor wire, shield wire, or installation condition.

Was a problem found? — Verify repair Go to Step 9

9 Monitor “ B1S1 (Bank 1 Sensor 1) Status ” on the Tech

2.

Is the “ B1S1 (Bank 1 Sensor 1) Status ” in the rich

condition? — Go to Step 10Go to Step 11

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3279 of 6020

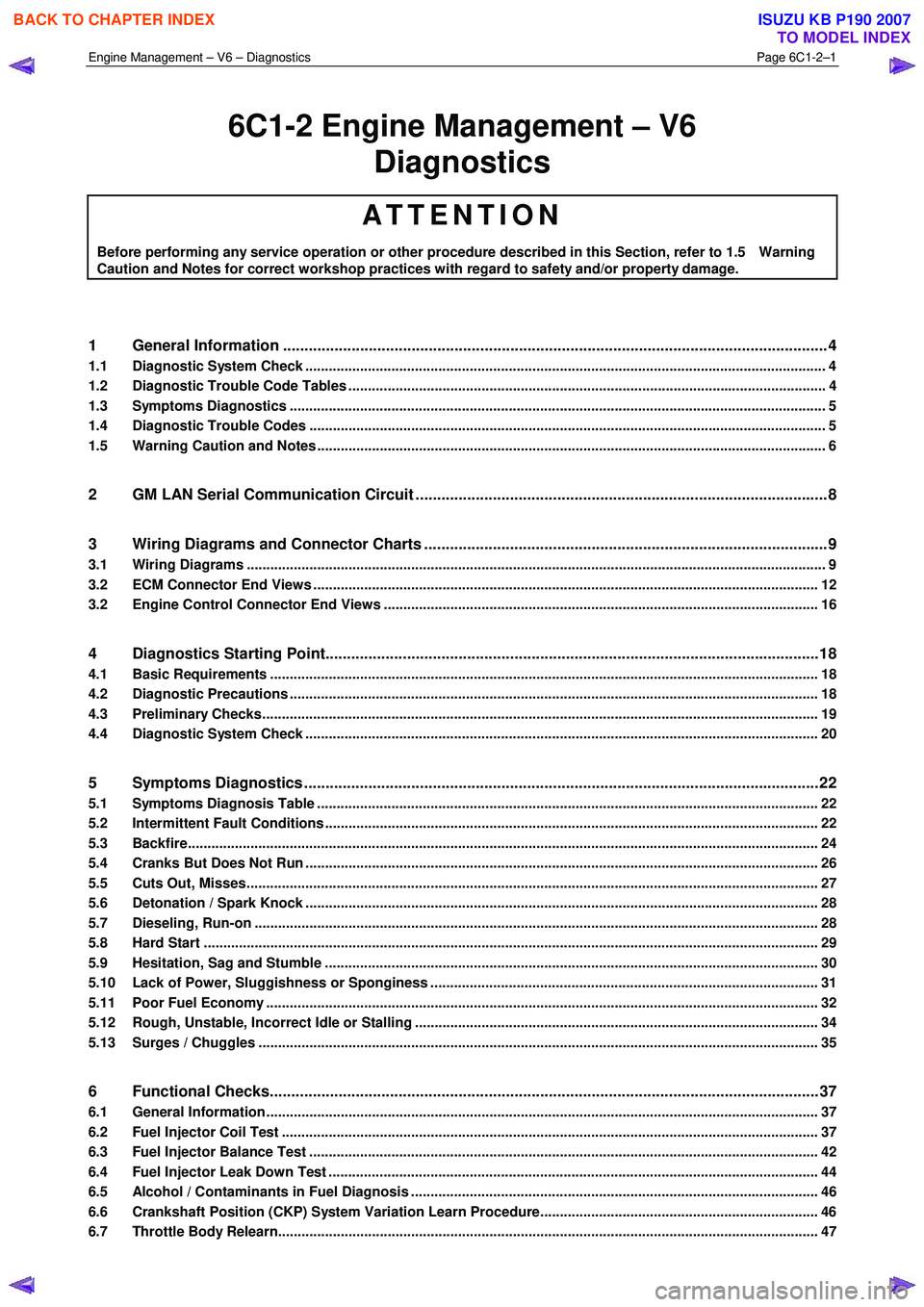

Engine Management – V6 – Diagnostics Page 6C1-2–1

6C1-2 Engine Management – V6

Diagnostics

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 1.5 Warning

Caution and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ............................................................................................................ ...................4

1.1 Diagnostic System Check ..................................................................................................................................... 4

1.2 Diagnostic Trouble Code Tables ................................................................................................. ......................... 4

1.3 Symptoms Diagnostics ......................................................................................................................................... 5

1.4 Diagnostic Trouble Codes .................................................................................................................................... 5

1.5 Warning Caution and Notes .................................................................................................................................. 6

2 GM LAN Serial Communication Circuit ............................................................................................ ....8

3 Wiring Diagrams and Connector Charts ........................................................................................... ...9

3.1 Wiring Diagrams .................................................................................................................................................... 9

3.2 ECM Connector End Views ................................................................................................................................. 12

3.2 Engine Control Connector End Views ............................................................................................. .................. 16

4 Diagnostics Starting Point...................................................................................................................18

4.1 Basic Requirements ............................................................................................................................................ 18

4.2 Diagnostic Precautions ......................................................................................................... .............................. 18

4.3 Preliminary Checks.............................................................................................................................................. 19

4.4 Diagnostic System Check ........................................................................................................ ........................... 20

5 Symptoms Diagnostics ........................................................................................................................22

5.1 Symptoms Diagnosis Table ....................................................................................................... ......................... 22

5.2 Intermittent Fault Conditions .............................................................................................................................. 22

5.3 Backfire................................................................................................................................................................. 24

5.4 Cranks But Does Not Run ........................................................................................................ ........................... 26

5.5 Cuts Out, Misses.................................................................................................................................................. 27

5.6 Detonation / Spark Knock ....................................................................................................... ............................ 28

5.7 Dieseling, Run-on ................................................................................................................................................ 28

5.8 Hard Start ............................................................................................................................................................. 29

5.9 Hesitation, Sag and Stumble .................................................................................................... .......................... 30

5.10 Lack of Power, Sluggishness or Sponginess ...................................................................................... ............. 31

5.11 Poor Fuel Economy ............................................................................................................................................. 32

5.12 Rough, Unstable, Incorrect Idle or Stalling .................................................................................... ................... 34

5.13 Surges / Chuggles ............................................................................................................................................... 35

6 Functional Checks................................................................................................................................37

6.1 General Information ............................................................................................................ ................................. 37

6.2 Fuel Injector Coil Test ......................................................................................................................................... 37

6.3 Fuel Injector Balance Test ..................................................................................................... ............................. 42

6.4 Fuel Injector Leak Down Test ................................................................................................... .......................... 44

6.5 Alcohol / Contaminants in Fuel Diagnosis ....................................................................................... ................. 46

6.6 Crankshaft Position (CKP) System Variation Learn Procedure..................................................................... .. 46

6.7 Throttle Body Relearn.......................................................................................................................................... 47

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3282 of 6020

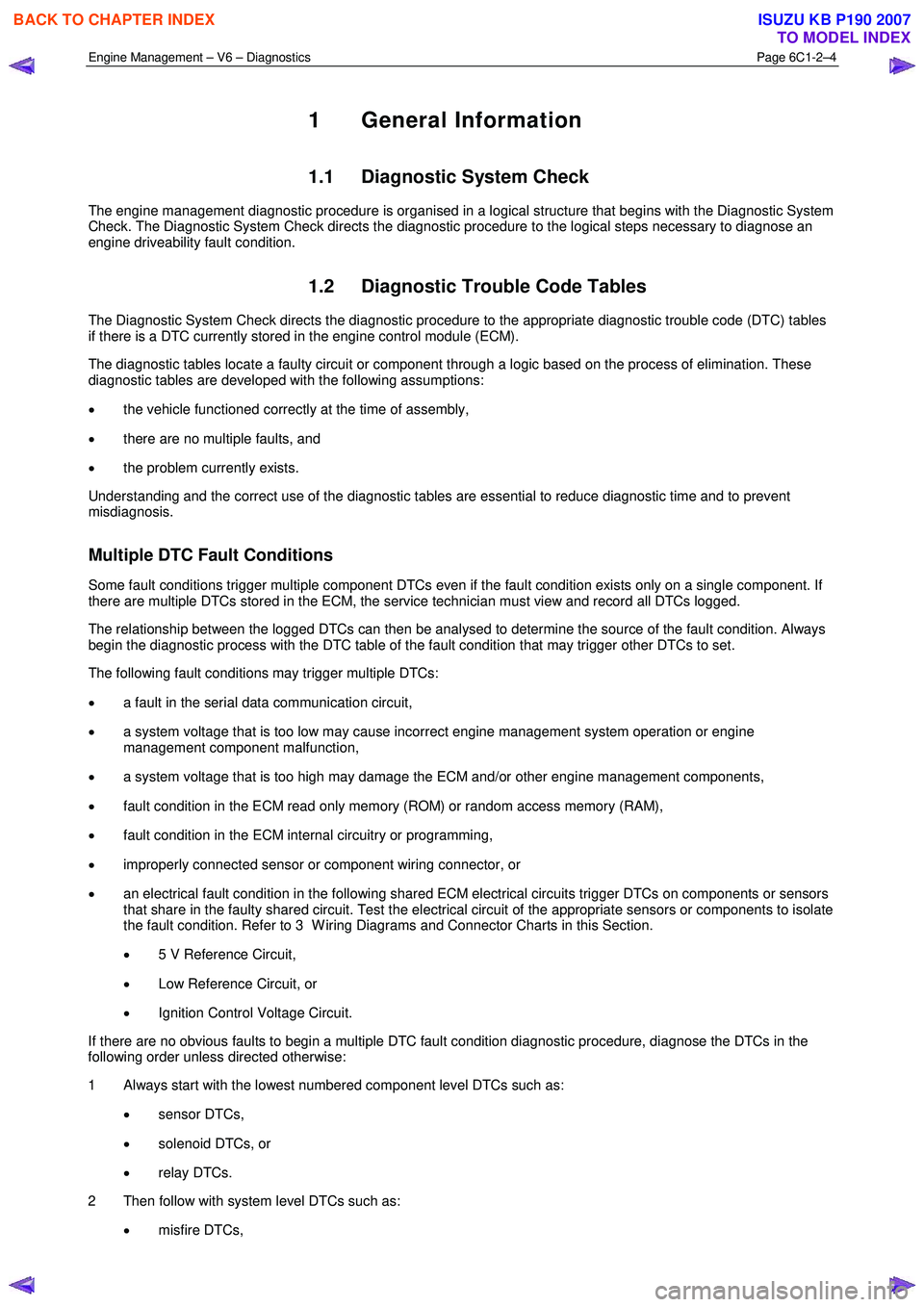

Engine Management – V6 – Diagnostics Page 6C1-2–4

1 General Information

1.1 Diagnostic System Check

The engine management diagnostic procedure is organised in a logical structure that begins with the Diagnostic System

Check. The Diagnostic System Check directs the diagnostic procedure to the logical steps necessary to diagnose an

engine driveability fault condition.

1.2 Diagnostic Trouble Code Tables

The Diagnostic System Check directs the diagnostic procedure to the appropriate diagnostic trouble code (DTC) tables

if there is a DTC currently stored in the engine control module (ECM).

The diagnostic tables locate a faulty circuit or component through a logic based on the process of elimination. These

diagnostic tables are developed with the following assumptions:

• the vehicle functioned correctly at the time of assembly,

• there are no multiple faults, and

• the problem currently exists.

Understanding and the correct use of the diagnostic tables are essential to reduce diagnostic time and to prevent

misdiagnosis.

Multiple DTC Fault Conditions

Some fault conditions trigger multiple component DTCs even if the fault condition exists only on a single component. If

there are multiple DTCs stored in the ECM, the service technician must view and record all DTCs logged.

The relationship between the logged DTCs can then be analysed to determine the source of the fault condition. Always

begin the diagnostic process with the DTC table of the fault condition that may trigger other DTCs to set.

The following fault conditions may trigger multiple DTCs:

• a fault in the serial data communication circuit,

• a system voltage that is too low may cause incorrect engine management system operation or engine

management component malfunction,

• a system voltage that is too high may damage the ECM and/or other engine management components,

• fault condition in the ECM read only memory (ROM) or random access memory (RAM),

• fault condition in the ECM internal circuitry or programming,

• improperly connected sensor or component wiring connector, or

• an electrical fault condition in the following shared ECM electrical circuits trigger DTCs on components or sensors

that share in the faulty shared circuit. Test the electrical circuit of the appropriate sensors or components to isolate

the fault condition. Refer to 3 W iring Diagrams and Connector Charts in this Section.

• 5 V Reference Circuit,

• Low Reference Circuit, or

• Ignition Control Voltage Circuit.

If there are no obvious faults to begin a multiple DTC fault condition diagnostic procedure, diagnose the DTCs in the

following order unless directed otherwise:

1 Always start with the lowest numbered component level DTCs such as:

• sensor DTCs,

• solenoid DTCs, or

• relay DTCs.

2 Then follow with system level DTCs such as:

• misfire DTCs,

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3326 of 6020

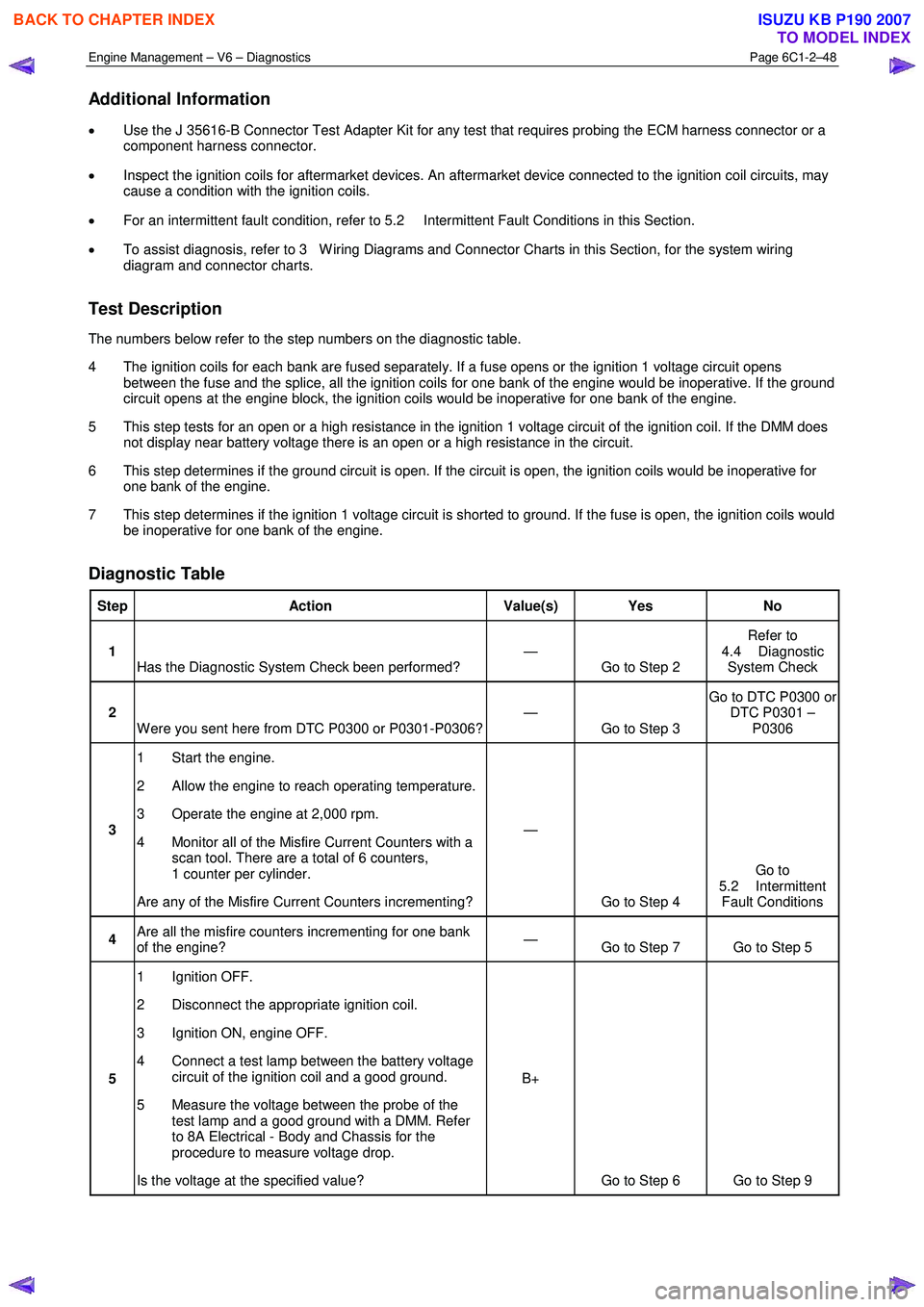

Engine Management – V6 – Diagnostics Page 6C1-2–48

Additional Information

• Use the J 35616-B Connector Test Adapter Kit for any test that requires probing the ECM harness connector or a

component harness connector.

• Inspect the ignition coils for aftermarket devices. An aftermarket device connected to the ignition coil circuits, may

cause a condition with the ignition coils.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

4 The ignition coils for each bank are fused separately. If a fuse opens or the ignition 1 voltage circuit opens between the fuse and the splice, all the ignition coils for one bank of the engine would be inoperative. If the ground

circuit opens at the engine block, the ignition coils would be inoperative for one bank of the engine.

5 This step tests for an open or a high resistance in the ignition 1 voltage circuit of the ignition coil. If the DMM does not display near battery voltage there is an open or a high resistance in the circuit.

6 This step determines if the ground circuit is open. If the circuit is open, the ignition coils would be inoperative for one bank of the engine.

7 This step determines if the ignition 1 voltage circuit is shorted to ground. If the fuse is open, the ignition coils would be inoperative for one bank of the engine.

Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been performed? —

Go to Step 2 Refer to

4.4 Diagnostic System Check

2 W ere you sent here from DTC P0300 or P0301-P0306? —

Go to Step 3 Go to DTC P0300 or

DTC P0301 – P0306

3 1 Start the engine.

2 Allow the engine to reach operating temperature.

3 Operate the engine at 2,000 rpm.

4 Monitor all of the Misfire Current Counters with a scan tool. There are a total of 6 counters,

1 counter per cylinder.

Are any of the Misfire Current Counters incrementing? —

Go to Step 4 Go to

5.2 Intermittent Fault Conditions

4 Are all the misfire counters incrementing for one bank

of the engine? —

Go to Step 7 Go to Step 5

5 1 Ignition OFF.

2 Disconnect the appropriate ignition coil.

3 Ignition ON, engine OFF.

4 Connect a test lamp between the battery voltage circuit of the ignition coil and a good ground.

5 Measure the voltage between the probe of the test lamp and a good ground with a DMM. Refer

to 8A Electrical - Body and Chassis for the

procedure to measure voltage drop.

Is the voltage at the specified value? B+

Go to Step 6 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

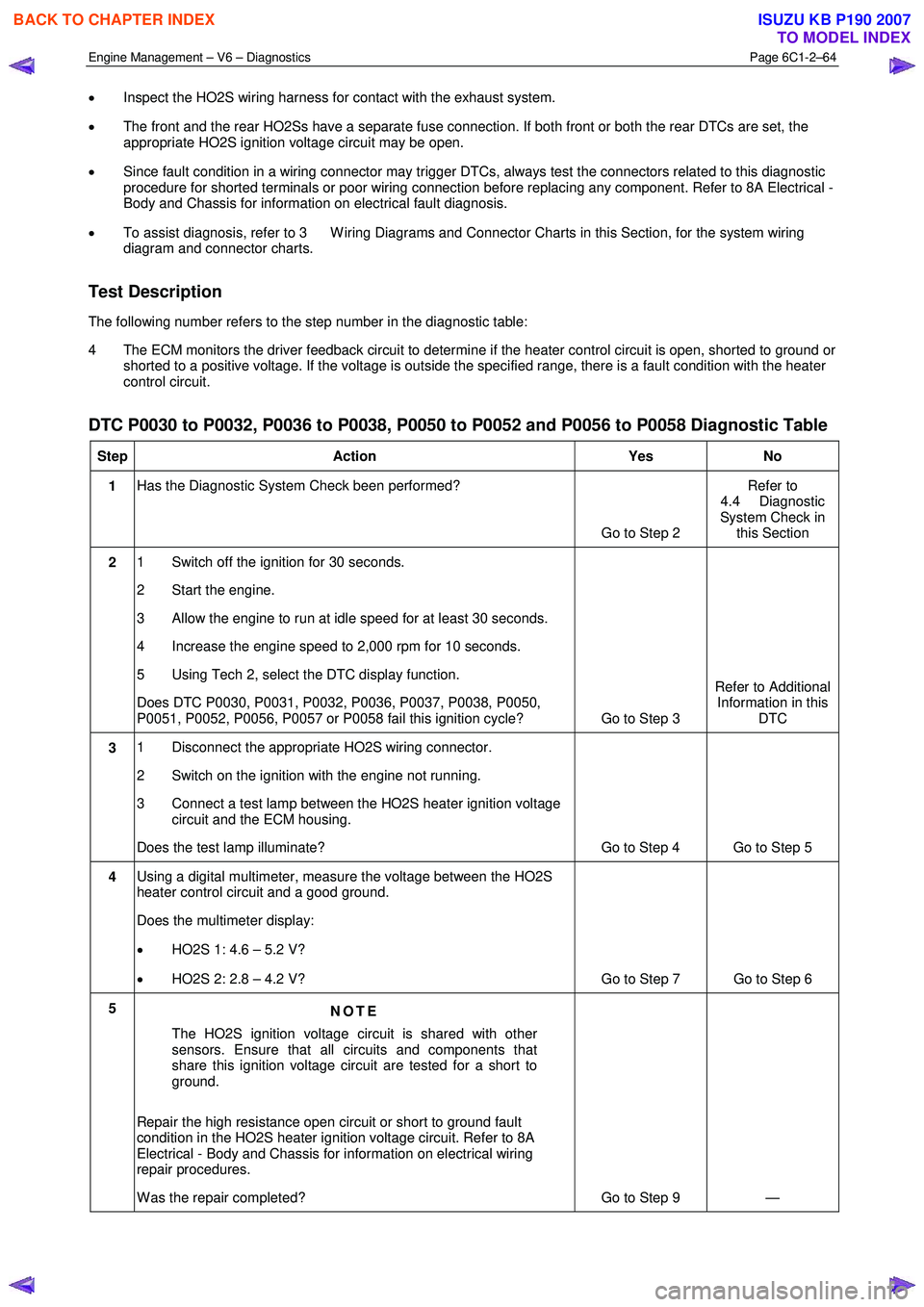

Page 3342 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–64

• Inspect the HO2S wiring harness for contact with the exhaust system.

• The front and the rear HO2Ss have a separate fuse connection. If both front or both the rear DTCs are set, the

appropriate HO2S ignition voltage circuit may be open.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step number in the diagnostic table:

4 The ECM monitors the driver feedback circuit to determine if the heater control circuit is open, shorted to ground or shorted to a positive voltage. If the voltage is outside the specified range, there is a fault condition with the heater

control circuit.

DTC P0030 to P0032, P0036 to P0038, P0050 to P0052 and P0056 to P0058 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Start the engine.

3 Allow the engine to run at idle speed for at least 30 seconds.

4 Increase the engine speed to 2,000 rpm for 10 seconds.

5 Using Tech 2, select the DTC display function.

Does DTC P0030, P0031, P0032, P0036, P0037, P0038, P0050,

P0051, P0052, P0056, P0057 or P0058 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Disconnect the appropriate HO2S wiring connector.

2 Switch on the ignition with the engine not running.

3 Connect a test lamp between the HO2S heater ignition voltage circuit and the ECM housing.

Does the test lamp illuminate? Go to Step 4 Go to Step 5

4 Using a digital multimeter, measure the voltage between the HO2S

heater control circuit and a good ground.

Does the multimeter display:

• HO2S 1: 4.6 – 5.2 V?

• HO2S 2: 2.8 – 4.2 V? Go to Step 7 Go to Step 6

5

NOTE

The HO2S ignition voltage circuit is shared with other

sensors. Ensure that all circuits and components that

share this ignition voltage circuit are tested for a short to

ground.

Repair the high resistance open circuit or short to ground fault

condition in the HO2S heater ignition voltage circuit. Refer to 8A

Electrical - Body and Chassis for information on electrical wiring

repair procedures.

W as the repair completed? Go to Step 9 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007