ECO mode ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 269 of 6020

3B-8 POWER-ASSISTED STEERING SYSTEM

6. Fully close the shutoff valve. Record the highest

pressures.

・ If the pressure recorded is within 9800-10300 kPa

(100-105 kg/cm

2/1422-1493psi), the pump is

functioning within its specifications.

・ If the pressure recorded is higher than 10300 kPa

(105 kg/cm

2/1493psi), the valve in the pump is

defective.

・ If the pressure recorded is lower than 9800 kPa

(100 kg/cm

2/1422psi), the valve or the rotating

assembly in the pump is defective.

7. If the pump pressures are within specifications, leave the valve open and turn (or have someone

else turn) the steering wheel fully in both directions.

Record the highest pressures and compare with the

maximum pump pressure recorded in step 6. If this

pressure cannot be built up at either side of the

power steering unit, the power steering unit is

leaking internally and must be replaced.

8. Shut the engine off, remove the testing gauge.

9. Reconnect the pressure hose, check the fluid level and make the needed repairs.

10. If the problem still exists, the steering and front suspension must be thoroughly examined.

Maintenance

The hydraulic system should be kept clean, the fluid

level in the reservoir should be checked at regula

r

intervals and fluid added when required. Refer to

Recommended Fluids and Lubricants in General

Information section for the type of fluid to be used and

the intervals for filling.

If the system contains some dirt, flush it as described in

this section. If it is exceptionally dirty, the pump must be

completely disassembled before further usage. (The

steering unit cannot be disassembled.)

All tubes, hoses, and fittings should be inspected for

leakage at regular intervals. Fittings must be tight. Make

sure the clips, clamps and supporting tubes and hoses

are in place and properly secured.

Power steering hoses and lines must not be twisted,

kinked or tightly bent. Air in the system will cause

spongy action and noisy operation. W hen a hose is

disconnected or when fluid is lost, for any reason, the

system must be bled after refilling. Refer to Bleeding the

Power Steering System in this section.

・ Inspect gear for looseness or damage.

・ Inspect hoses to insure they are not touching an

y

other parts of the vehicle.

・ Inspect fluid level and fill to the proper level.

Fluid Level

1. Run the engine until the power steering fluid

reaches normal operating temperature, about 55 °

C (130 °F), then shut the engine off.

2. Check the level of fluid in the reservoir.

3. If the fluid level is low, add power steering fluid as

specified in General Information to the proper level

and install the receiver cap.

4. W hen checking the fluid level after the steering system has been serviced, air must be bled from

the system. Refer to Bleeding the Power Steering

System in this section.

Bleeding the Power Steering System

W hen a power steering pump or unit has been installed,

or an oil line has been disconnected, the air that has

entered the system must be bled out before the vehicle

is operated. If air is allowed to remain in the powe

r

steering fluid system, noisy and unsatisfactory operation

of the system may result.

Bleeding Procedure

W hen bleeding the system, and any time fluid is added

to the power steering system, be sure to use only powe

r

steering fluid as specified in General Information.

1. Fill the pump fluid reservoir to the proper level and let the fluid settle for at least two minutes.

2. Start the engine and let it run for a few seconds. Do not turn the steering wheel. Then turn the engine

off.

3. Add fluid if necessary.

4. Repeat the above procedure until the fluid level remains constant after running the engine.

5. Raise and support the front end of the vehicle so that the wheels are off the ground.

6. Start the engine. Slowly turn the steering wheel right and left, lightly contacting the wheel stops.

7. Add power steering fluid if necessary.

8. Lower the vehicle, set the steering wheel at the straight forward position after turning it to its full

steer positions 2 or 3 times, and stop the engine.

9. Check the fluid level and refill as required.

10. If the fluid is extremely foamy, allow the vehicle to settle for a few minutes, then repeat the above

procedure.

Flushing the Power Steering System

1. Raise and support the front end of the vehicle off

the ground until the wheels are free to turn.

2. Remove the fluid return line at the pump inlet connector and plug the connector port on the pump.

Direct the line toward a large container to catch the

draining fluid.

3. W hile running the engine at idle, fill the reservoi

r

with new power steering fluid. Turn the steering

wheel in both directions. Do not contact or hold the

steering wheel to the wheel stops. This will cause

the pump to go to pressure relief mode, which ma

y

cause a sudden fluid overflow at the reservoir.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 280 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-19

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of solvent).

Be careful not to expose the oil seal of shaft

assembly to solvent.

2. Remove the bolt, suction pipe and O-ring.

3. Remove the connector, O-ring, relief valve and spring.

4. Remove the bolt, rear housing and O-ring.

5. Remove the snap ring.

6. Remove the shaft assembly.

7. Remove the oil seal.

CAUTION: When removing the oil seal, be careful

not to damage the housing.

8. Remove the pump cartridge assembly from the front housing.

9. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

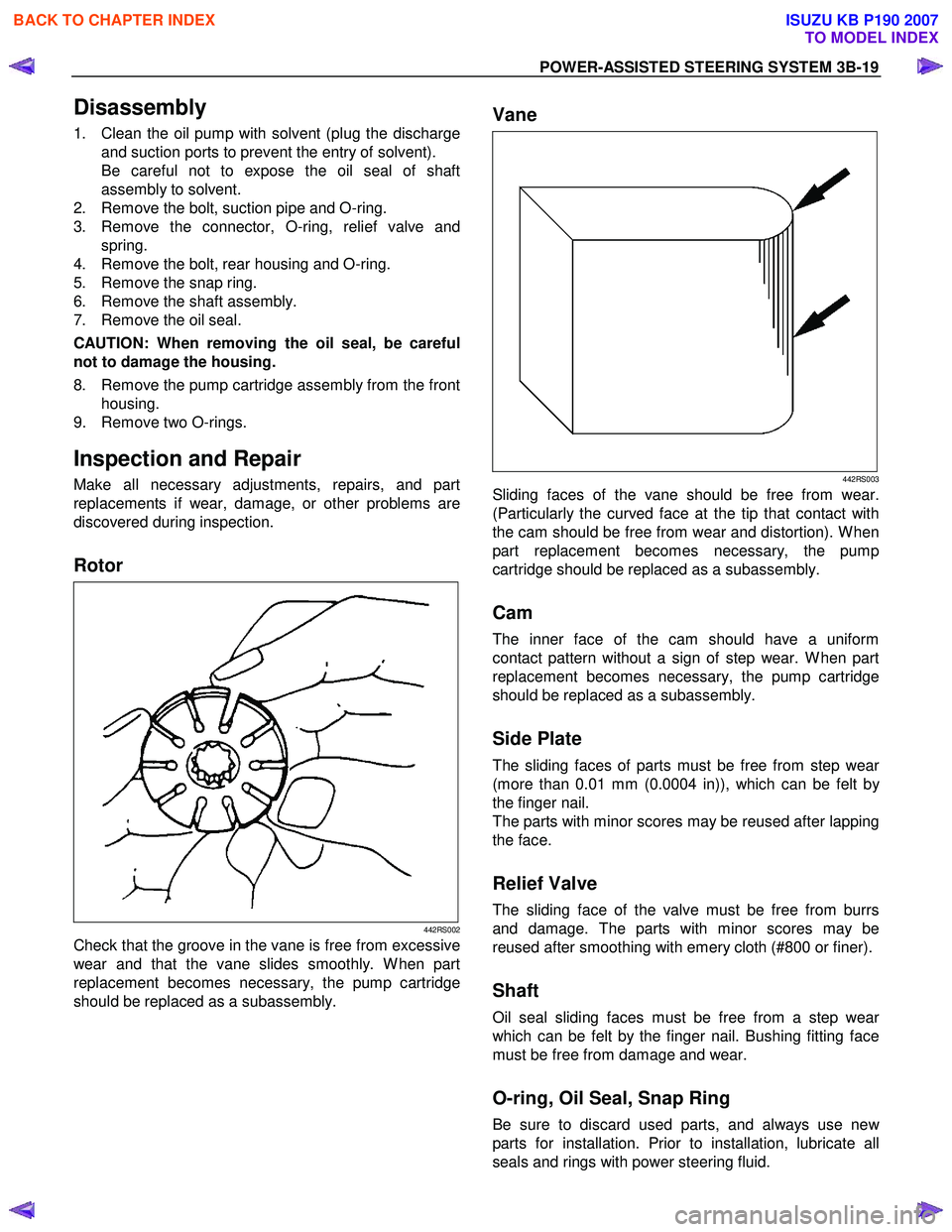

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Vane

442RS003

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip that contact with

the cam should be free from wear and distortion). W hen

part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the cam should have a uniform

contact pattern without a sign of step wear. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm (0.0004 in)), which can be felt b

y

the finger nail.

The parts with minor scores may be reused after lapping

the face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. The parts with minor scores may be

reused after smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear

which can be felt by the finger nail. Bushing fitting face

must be free from damage and wear.

O-ring, Oil Seal, Snap Ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 285 of 6020

3B-24 POWER-ASSISTED STEERING SYSTEM

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of solvent).

Be careful not to expose the oil seal of the shaft assembly to solvent.

2. Remove the bolt, suction pipe and O-ring.

3. Remove the nut and bracket.

4. Remove the nut, washer and joint.

5. Remove the connector, O-ring, relief valve and spring.

6. Remove the bolt, rear housing and O-ring.

7. Remove the pump cartridge assembly and the side plate from the shaft. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

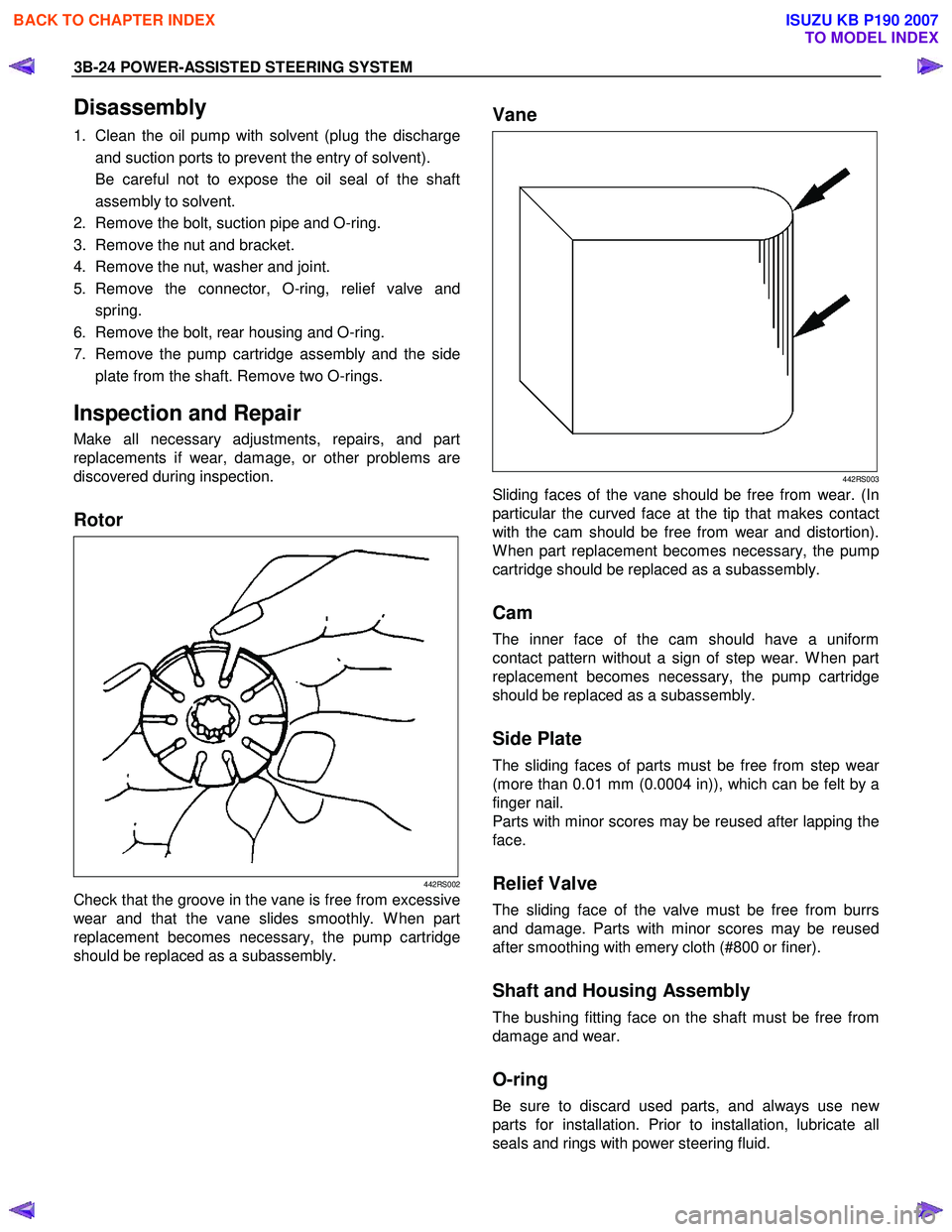

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Vane

442RS003

Sliding faces of the vane should be free from wear. (In

particular the curved face at the tip that makes contact

with the cam should be free from wear and distortion).

W hen part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the cam should have a uniform

contact pattern without a sign of step wear. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm (0.0004 in)), which can be felt by a

finger nail.

Parts with minor scores may be reused after lapping the

face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. Parts with minor scores may be reused

after smoothing with emery cloth (#800 or finer).

Shaft and Housing Assembly

The bushing fitting face on the shaft must be free from

damage and wear.

O-ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 312 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-51

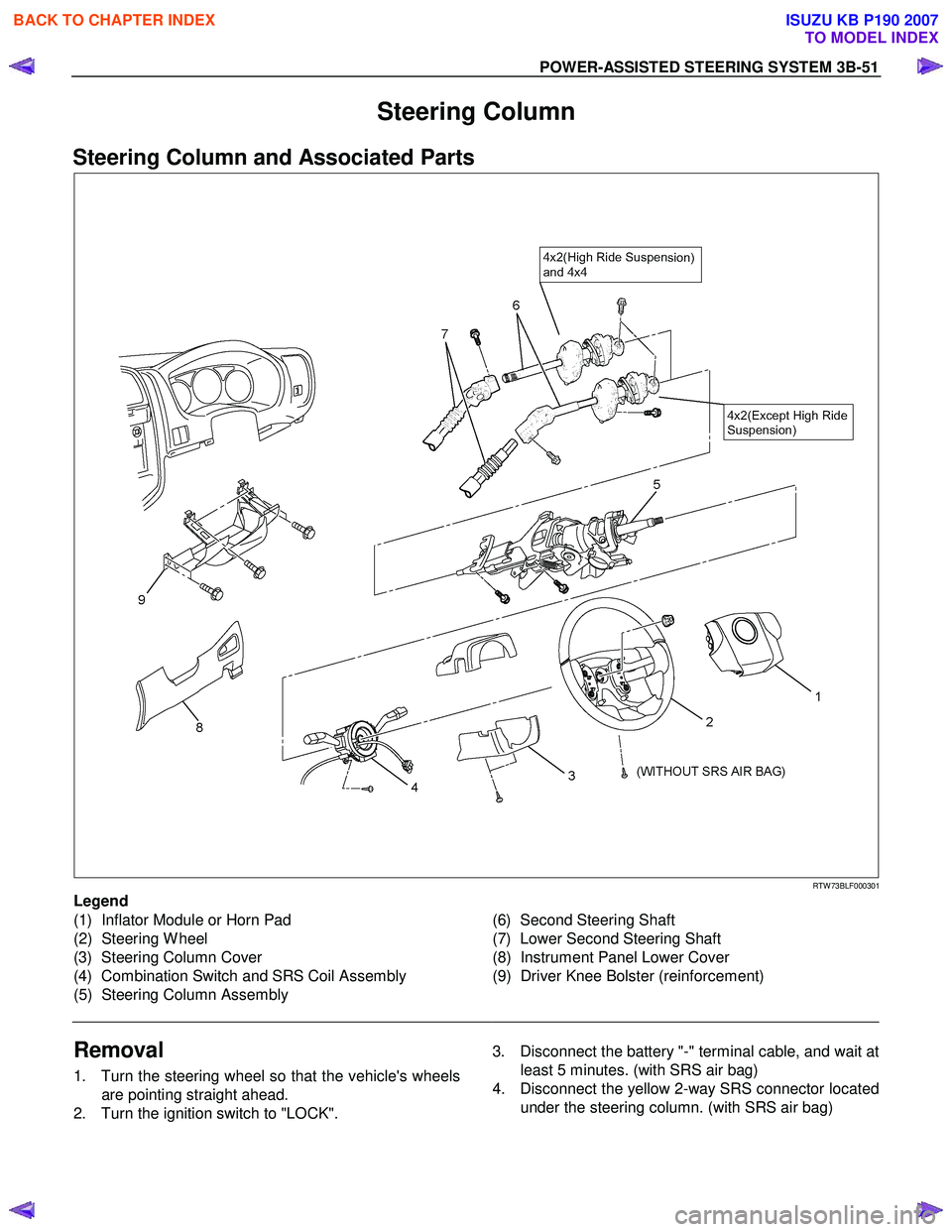

Steering Column

Steering Column and Associated Parts

RTW 73BLF000301

Legend

(1) Inflator Module or Horn Pad

(2) Steering W heel

(3) Steering Column Cover

(4) Combination Switch and SRS Coil Assembly

(5) Steering Column Assembly

(6) Second Steering Shaft

(7) Lower Second Steering Shaft

(8) Instrument Panel Lower Cover

(9) Driver Knee Bolster (reinforcement)

Removal

1. Turn the steering wheel so that the vehicle's wheels are pointing straight ahead.

2. Turn the ignition switch to "LOCK".

3. Disconnect the battery "-" terminal cable, and wait at

least 5 minutes. (with SRS air bag)

4. Disconnect the yellow 2-way SRS connector located under the steering column. (with SRS air bag)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 315 of 6020

3B-54 POWER-ASSISTED STEERING SYSTEM

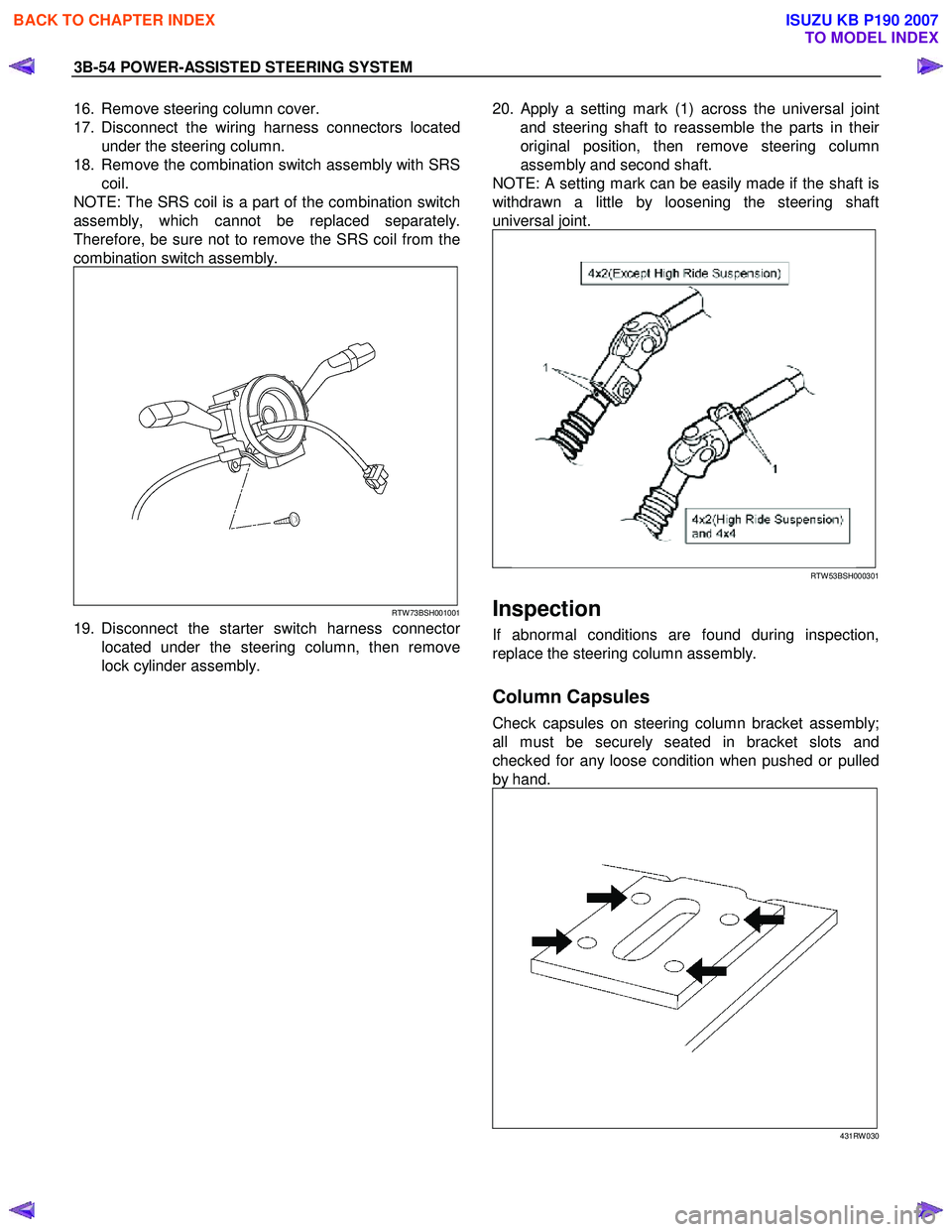

16. Remove steering column cover.

17. Disconnect the wiring harness connectors located under the steering column.

18. Remove the combination switch assembly with SRS coil.

NOTE: The SRS coil is a part of the combination switch

assembly, which cannot be replaced separately.

Therefore, be sure not to remove the SRS coil from the

combination switch assembly.

RTW 73BSH001001

19. Disconnect the starter switch harness connector

located under the steering column, then remove

lock cylinder assembly.

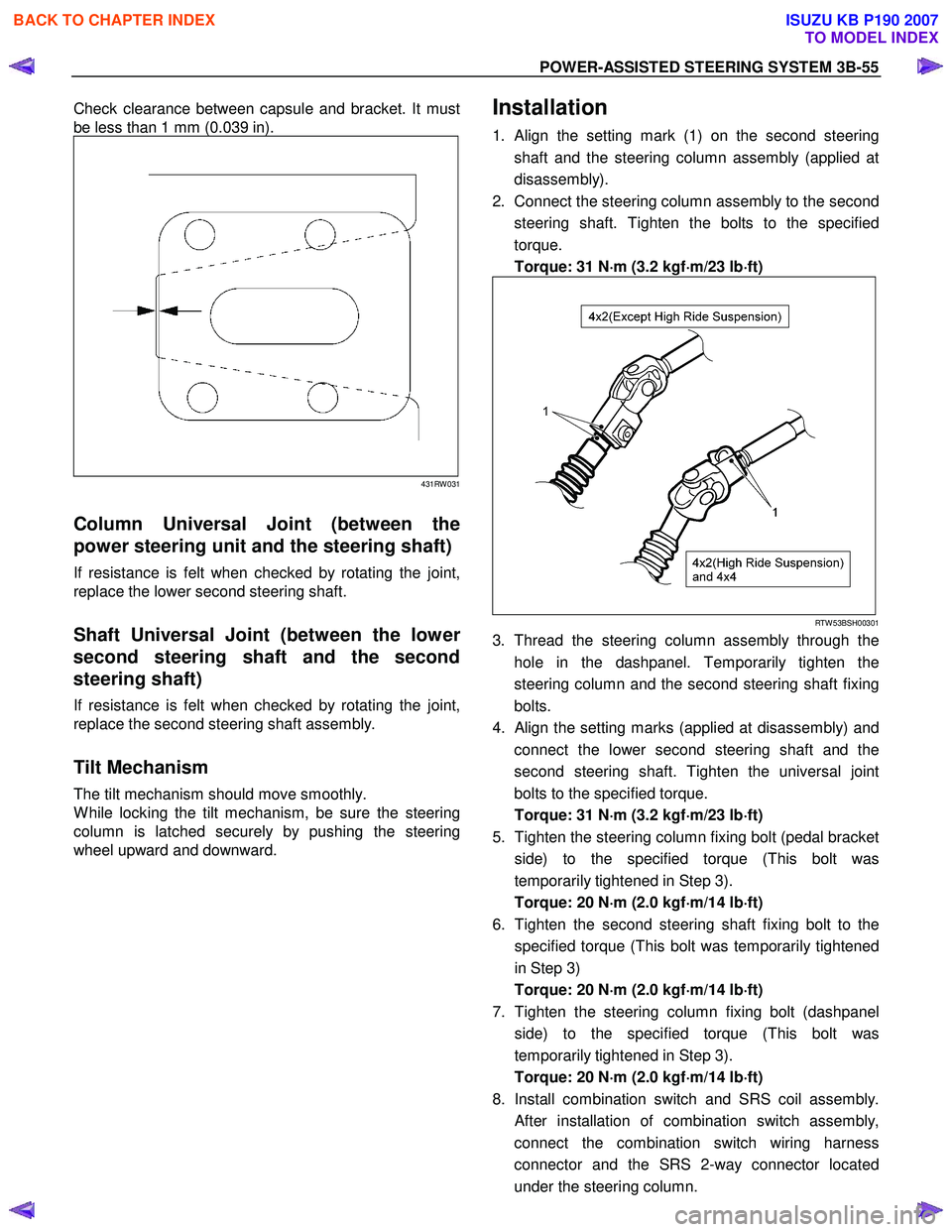

20.

Apply a setting mark (1) across the universal joint

and steering shaft to reassemble the parts in thei

r

original position, then remove steering column

assembly and second shaft.

NOTE: A setting mark can be easily made if the shaft is

withdrawn a little by loosening the steering shaft

universal joint.

RTW 53BSH000301

Inspection

If abnormal conditions are found during inspection,

replace the steering column assembly.

Column Capsules

Check capsules on steering column bracket assembly;

all must be securely seated in bracket slots and

checked for any loose condition when pushed or pulled

by hand.

431RW 030

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 316 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-55

Check clearance between capsule and bracket. It must

be less than 1 mm (0.039 in).

431RW 031

Column Universal Joint (between the

power steering unit and the steering shaft)

If resistance is felt when checked by rotating the joint,

replace the lower second steering shaft.

Shaft Universal Joint (between the lower

second steering shaft and the second

steering shaft)

If resistance is felt when checked by rotating the joint,

replace the second steering shaft assembly.

Tilt Mechanism

The tilt mechanism should move smoothly.

W hile locking the tilt mechanism, be sure the steering

column is latched securely by pushing the steering

wheel upward and downward.

Installation

1. Align the setting mark (1) on the second steering

shaft and the steering column assembly (applied at

disassembly).

2. Connect the steering column assembly to the second steering shaft. Tighten the bolts to the specified

torque.

Torque: 31 N ⋅

⋅⋅

⋅

m (3.2 kgf ⋅

⋅⋅

⋅

m/23 lb ⋅

⋅⋅

⋅

ft)

RTW 53BSH00301

3. Thread the steering column assembly through the

hole in the dashpanel. Temporarily tighten the

steering column and the second steering shaft fixing

bolts.

4.

Align the setting marks (applied at disassembly) and

connect the lower second steering shaft and the

second steering shaft. Tighten the universal joint

bolts to the specified torque.

Torque: 31 N ⋅

⋅⋅

⋅

m (3.2 kgf ⋅

⋅⋅

⋅

m/23 lb ⋅

⋅⋅

⋅

ft)

5. Tighten the steering column fixing bolt (pedal bracket side) to the specified torque (This bolt was

temporarily tightened in Step 3).

Torque: 20 N ⋅

⋅⋅

⋅

m (2.0 kgf ⋅

⋅⋅

⋅

m/14 lb ⋅

⋅⋅

⋅

ft)

6. Tighten the second steering shaft fixing bolt to the specified torque (This bolt was temporarily tightened

in Step 3)

Torque: 20 N ⋅

⋅⋅

⋅

m (2.0 kgf ⋅

⋅⋅

⋅

m/14 lb ⋅

⋅⋅

⋅

ft)

7. Tighten the steering column fixing bolt (dashpanel side) to the specified torque (This bolt was

temporarily tightened in Step 3).

Torque: 20 N ⋅

⋅⋅

⋅

m (2.0 kgf ⋅

⋅⋅

⋅

m/14 lb ⋅

⋅⋅

⋅

ft)

8. Install combination switch and SRS coil assembly.

After installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

under the steering column.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 384 of 6020

FRONT SUSPENSION 3C-63

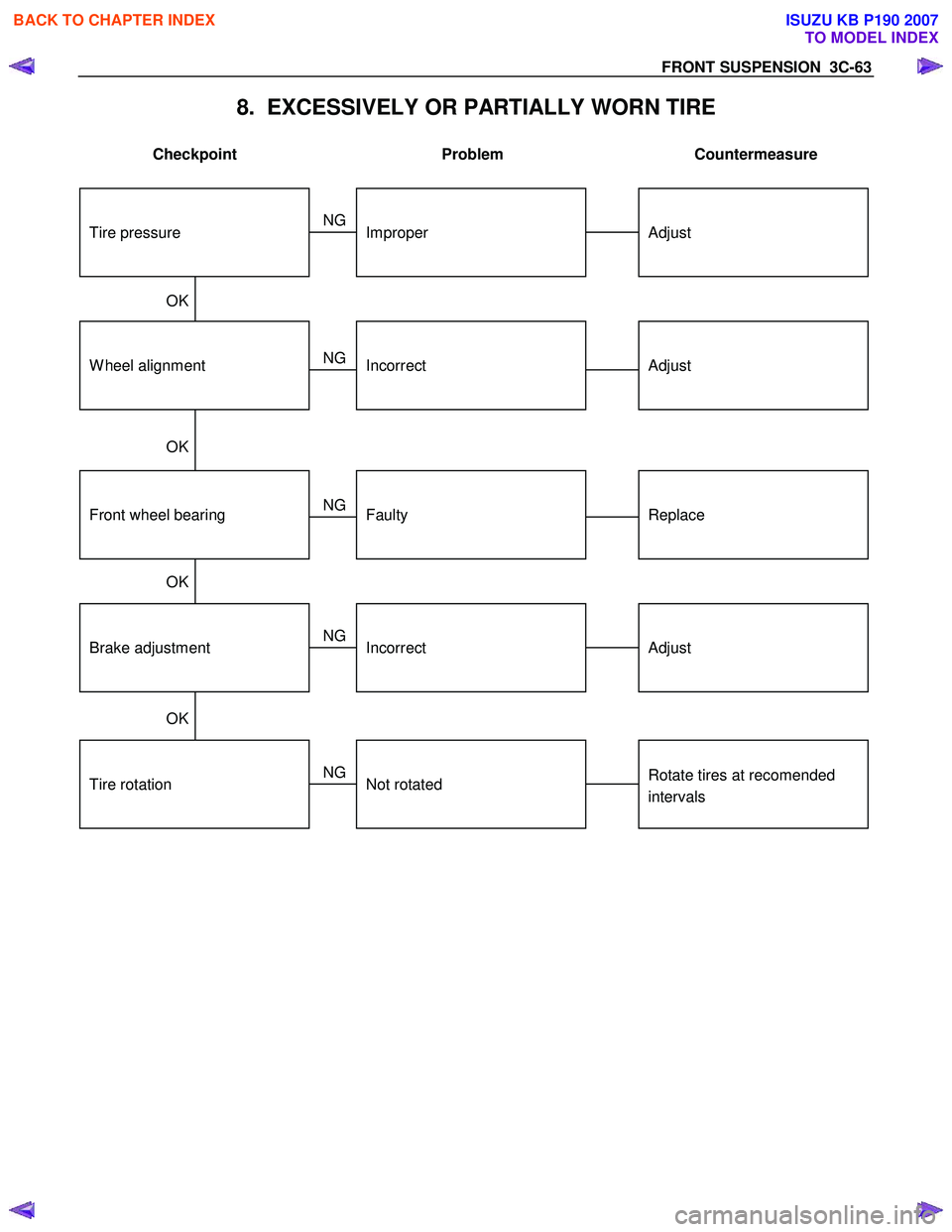

8. EXCESSIVELY OR PARTIALLY WORN TIRE

Checkpoint Problem Countermeasure

Brake adjustment

W heel alignment

Adjust

Adjust

Incorrect

Incorrect

Front wheel bearingReplace

Adjust

Faulty

Improper

OK NG

NG

NG

NG

OK

OKTire pressure

Tire rotationRotate tires at recomended

intervalsNot rotated

OK

NG

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 414 of 6020

3E-10 WHEELS AND TIRES

TROUBLESHOOTING

Typical examples of abnormal tire tread wear and major causes :

CAUTION:

Similar wear patterns can be caused by worn suspension parts, misalignment of wheels and tires, and

other suspension related problems.

Spotty wear - wear localized

on shoulder section. In

extreme cases, the tire

becomes polygonal in shape.

Tire or wheel out of

round or distorted. Hub or knuckle out

of round or distorted. Play in hub bearings

or ball joints. Rotating parts out of

balance.

Tread wear one-sided.

Rotating parts out of

balance. Tire or wheel out of

round. Hub or knuckle out

of round or distorted.

Localized tread wear.

Once spotty wear develops in

tread due to hard braking or

abrupt starting, localized wear

tends to be accelerated.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 445 of 6020

REAR AXLE 4B-1

SECTION 4B

REAR AXLE

TABLE OF CONTENTS

PAGE

Main Data and Specifications ........................................................................................... 4B- 3

Torque Specifications .............................................................................................................. 4B- 4

Recommended Liquid Gasket .......................................................................................... 4B- 6

Recommended Thread Locking Agents .......................................................................... 4B- 6

Rear Axle Assembly .......................................................................................................... 4B- 7

General Description...................................................................................................... 4B- 7

Servicing ...................................................................................................................... ...... 4B- 8

Rear Axle ...................................................................................................................... ...... 4B- 9

Disassembly .................................................................................................................. 4B - 10

Inspection and Repair .................................................................................................. 4B- 14

Reassembly ................................................................................................................... 4B - 15

Differential Assembly ..................................................................................................................... 4B- 20

Disassembly .................................................................................................................. 4B - 21

Reassembly ................................................................................................................... 4B - 24

Differential Cage Assembly .......................................................................................................... 4B- 34

Disassembly .................................................................................................................. 4B - 35

Inspection and Repair .............................................................................................................. 4B- 35

Reassembly ................................................................................................................................. 4B- 37

Limited Slip Differential (LSD) .......................................................................................... 4B- 38

Disassembly ............................................................................................................................... .4B- 39

Inspection and Repair .................................................................................................. 4B- 40

Reassembly ................................................................................................................... 4B - 42

Troubleshooting............................................................................................................ 4B- 45

Special Service Tool ................................................................................................................. 4B- 56

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 450 of 6020

4B-6 REAR AXLE

RECOMMENDED LIQUID GASKET

Type Brand Name Manufacture Remarks

RTV* Silicon Base ThreeBond 1207B

ThreeBond 1207C

ThreeBond 1215

Three Bond

Three Bond

Three Bond

For Engine Repairs

For Axle Case

Repairs, T/M

W ater Base ThreeBond 1141E Three Bond For Engine Repairs

Solvent ThreeBond 1104

BelcoBond 4

BelcoBond 401

BelcoBond 402 Three bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobic LOCTITE 515

LOCTITE 518 Loctite

Loctite All

* RTV : Room Temperature Vulcanizer

Note :

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the

vehicle.

2. Be careful to use the specified amount of liquid gasket.

Follow the manufacture's instructions at all times.

3. Be absolutely sure to remove all lubricants and

moisture from the connecting surfaces before

applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance

of greater than 0.25 mm (0.01 in). Poo

r

adhesion will result.

RECOMMENDED THREAD LOCKING AGENTS

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242

Blue 1. Completely remove all lubricant and moisture from the bolts and

the female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

LOCTITE 262

Red 2. Apply LOCTITE to the bolts.

LOCTITE 270

Green

LOCTITE 271

Red

3. Tighten the bolts to the specified torque.

4. W ait at least one hour before continuing the installation procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007