ECO mode ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 68 of 6020

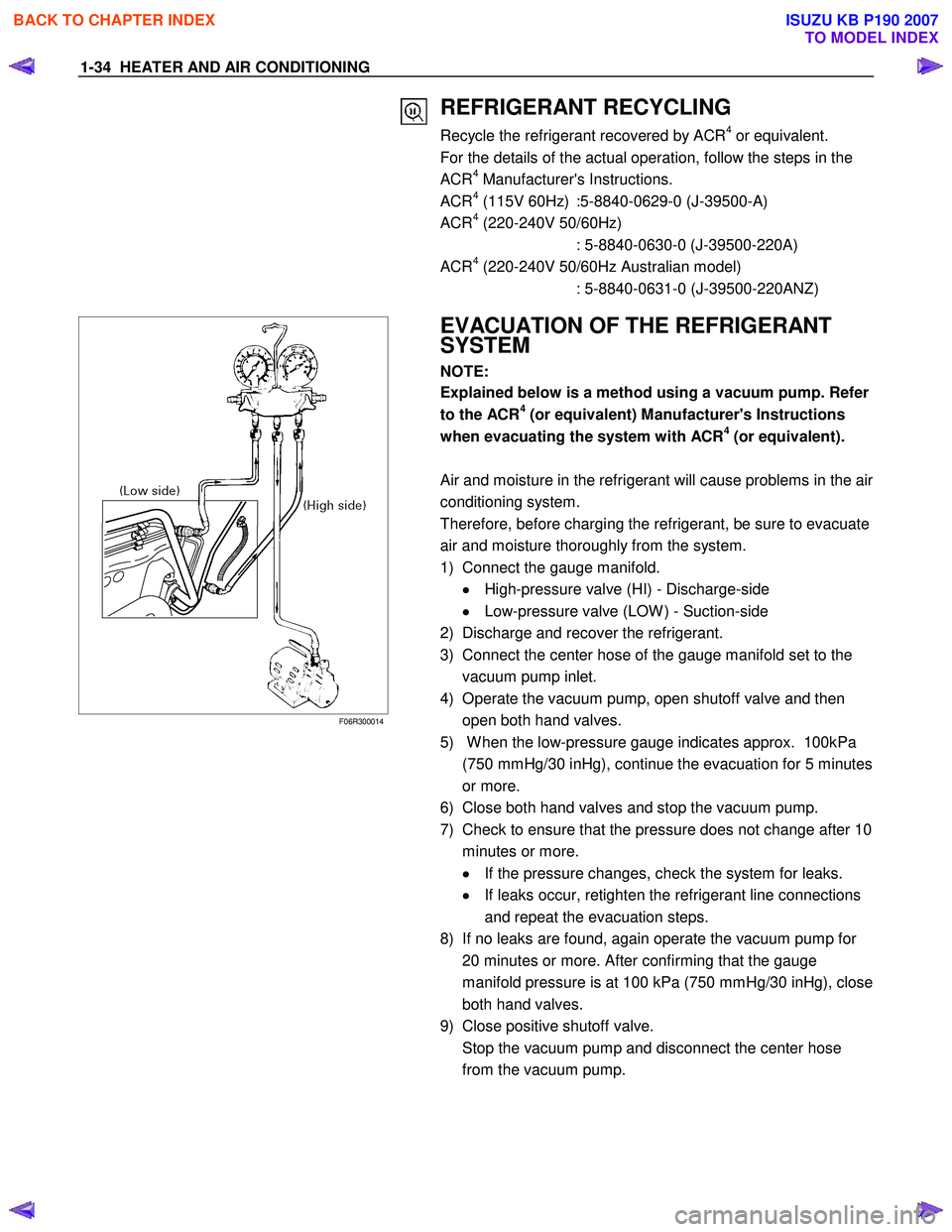

1-34 HEATER AND AIR CONDITIONING

REFRIGERANT RECYCLING

Recycle the refrigerant recovered by ACR4 or equivalent.

For the details of the actual operation, follow the steps in the

ACR

4 Manufacturer's Instructions.

ACR4 (115V 60Hz) :5-8840-0629-0 (J-39500-A)

ACR4 (220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

F06R300014

EVACUATION OF THE REFRIGERANT

SYSTEM

NOTE:

Explained below is a method using a vacuum pump. Refer

to the ACR

4 (or equivalent) Manufacturer's Instructions

when evacuating the system with ACR4 (or equivalent).

Air and moisture in the refrigerant will cause problems in the air

conditioning system.

Therefore, before charging the refrigerant, be sure to evacuate

air and moisture thoroughly from the system.

1) Connect the gauge manifold. •

••

•

High-pressure valve (HI) - Discharge-side

•

••

•

Low-pressure valve (LOW ) - Suction-side

2) Discharge and recover the refrigerant.

3) Connect the center hose of the gauge manifold set to the vacuum pump inlet.

4) Operate the vacuum pump, open shutoff valve and then open both hand valves.

5) W hen the low-pressure gauge indicates approx. 100kPa (750 mmHg/30 inHg), continue the evacuation for 5 minutes

or more.

6) Close both hand valves and stop the vacuum pump.

7) Check to ensure that the pressure does not change after 10

minutes or more. •

••

•

If the pressure changes, check the system for leaks.

•

••

•

If leaks occur, retighten the refrigerant line connections

and repeat the evacuation steps.

8) If no leaks are found, again operate the vacuum pump for 20 minutes or more. After confirming that the gauge

manifold pressure is at 100 kPa (750 mmHg/30 inHg), close

both hand valves.

9) Close positive shutoff valve.

Stop the vacuum pump and disconnect the center hose from the vacuum pump.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 69 of 6020

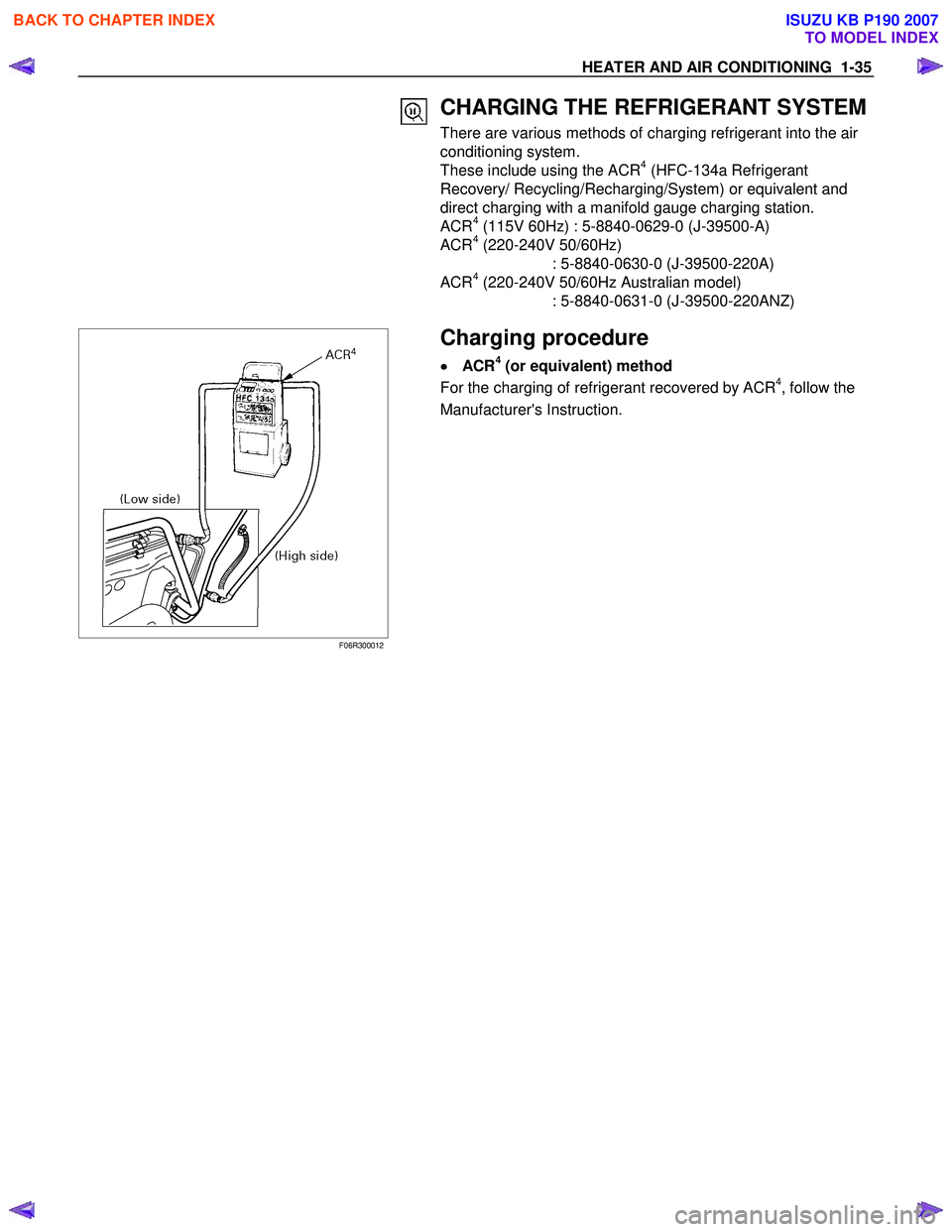

HEATER AND AIR CONDITIONING 1-35

CHARGING THE REFRIGERANT SYSTEM

There are various methods of charging refrigerant into the air

conditioning system.

These include using the ACR

4 (HFC-134a Refrigerant

Recovery/ Recycling/Recharging/System) or equivalent and

direct charging with a manifold gauge charging station.

ACR

4 (115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4 (220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

F06R300012

Charging procedure

•

••

•

ACR4 (or equivalent) method

For the charging of refrigerant recovered by ACR4, follow the

Manufacturer's Instruction.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 71 of 6020

HEATER AND AIR CONDITIONING 1-37

refrigerant container.

1) Make sure the evacuation process is correctly completed.

2) Connect the center-hose of the manifold gauge to the refrigerant container. •

••

•

Turn the charge valve handle counterclockwise to purge

to the charging line and purge any air exiting in the

center-hose of the manifold gauge.

3) Open the low-pressure hand valve and charge the refrigerant about 200 g (0.44 lbs.). •

••

•

Make sure the high-pressure hand valve is closed.

•

••

•

Avoid charging the refrigerant by turning the refrigerant

container upside down.

4) Close the low-pressure hand valve of the manifold gauge. •

••

•

Check to ensure that the degree of pressure does not

change.

5) Check the refrigerant leaks by using a HFC-134a leak detector. •

••

•

If a leak occurs, repair the leak connection, and start all

over again from the first step of evacuation.

6) If no leaks are found, open the low-pressure hand valve of the manifold gauge. Then continue charging refrigerant to

the system. •

••

•

W hen charging the system becomes difficult:

(1) Run the engine at Idling and close the all vehicle doors.

(2) A/C switch is "ON".

(3) Set the fan control knob (fan switch) to its highest position.

(4) Set air source selector lever to “RECIRC”

WARNING

BE ABSOLUTELY SURE NOT TO OPEN THE HIGH-

PRESSURE HAND VALVE. SHOULD THE HIGH-

PRESSURE HAND VALVE BE OPENED, THE HIGH-

PRESSURE REFRIGERANT GAS WOULD FLOW

BACKWARD, AND THIS MAY CAUSE THE REFRIGERANT

CONTAINER TO BURST.

7) W hen the refrigerant container is emptied, use the following procedure to replace it with a new refrigerant container.

(1) Close the low-pressure hand valve.

(2) Raise the needle upward and remove the charge valve.

(3) Reinstall the charge valve to the new refrigerant container.

(4) Purge any air existing in the center hose of the manifold gauge.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 73 of 6020

HEATER AND AIR CONDITIONING 1-39

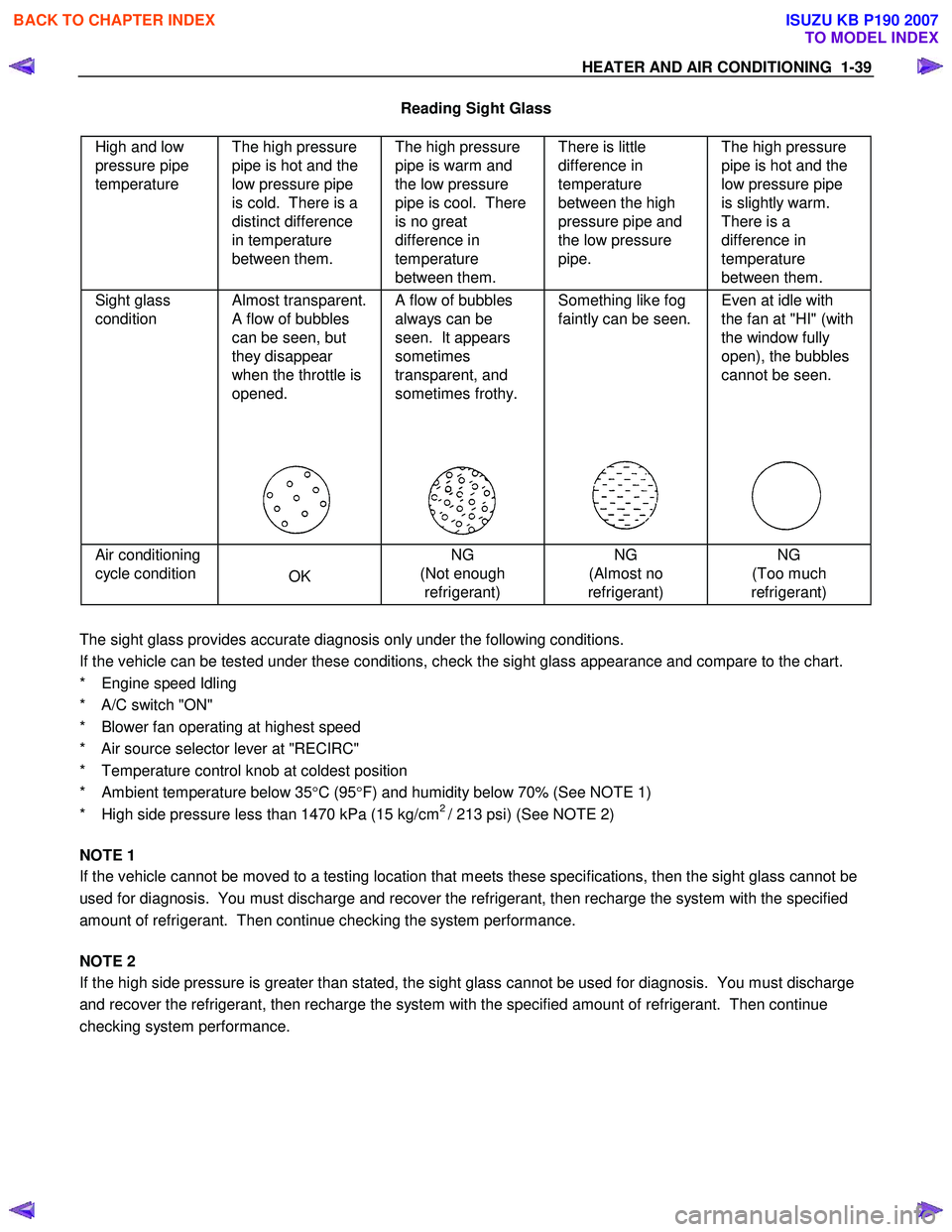

Reading Sight Glass

High and low

pressure pipe

temperature The high pressure

pipe is hot and the

low pressure pipe

is cold. There is a

distinct difference

in temperature

between them. The high pressure

pipe is warm and

the low pressure

pipe is cool. There

is no great

difference in

temperature

between them. There is little

difference in

temperature

between the high

pressure pipe and

the low pressure

pipe. The high pressure

pipe is hot and the

low pressure pipe

is slightly warm.

There is a

difference in

temperature

between them.

Sight glass

condition Almost transparent.

A flow of bubbles

can be seen, but

they disappear

when the throttle is

opened.

A flow of bubbles

always can be

seen. It appears

sometimes

transparent, and

sometimes frothy.

Something like fog

faintly can be seen.

Even at idle with

the fan at "HI" (with

the window fully

open), the bubbles

cannot be seen.

Air conditioning

cycle condition

OK NG

(Not enough refrigerant) NG

(Almost no

refrigerant) NG

(Too much

refrigerant)

The sight glass provides accurate diagnosis only under the following conditions.

If the vehicle can be tested under these conditions, check the sight glass appearance and compare to the chart.

* Engine speed Idling

* A/C switch "ON"

* Blower fan operating at highest speed

* Air source selector lever at "RECIRC"

* Temperature control knob at coldest position

* Ambient temperature below 35 °C (95 °F) and humidity below 70% (See NOTE 1)

* High side pressure less than 1470 kPa (15 kg/cm

2 / 213 psi) (See NOTE 2)

NOTE 1

If the vehicle cannot be moved to a testing location that meets these specifications, then the sight glass cannot be

used for diagnosis. You must discharge and recover the refrigerant, then recharge the system with the specified

amount of refrigerant. Then continue checking the system performance.

NOTE 2

If the high side pressure is greater than stated, the sight glass cannot be used for diagnosis. You must discharge

and recover the refrigerant, then recharge the system with the specified amount of refrigerant. Then continue

checking system performance.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 87 of 6020

HEATER AND AIR CONDITIONING 1-53

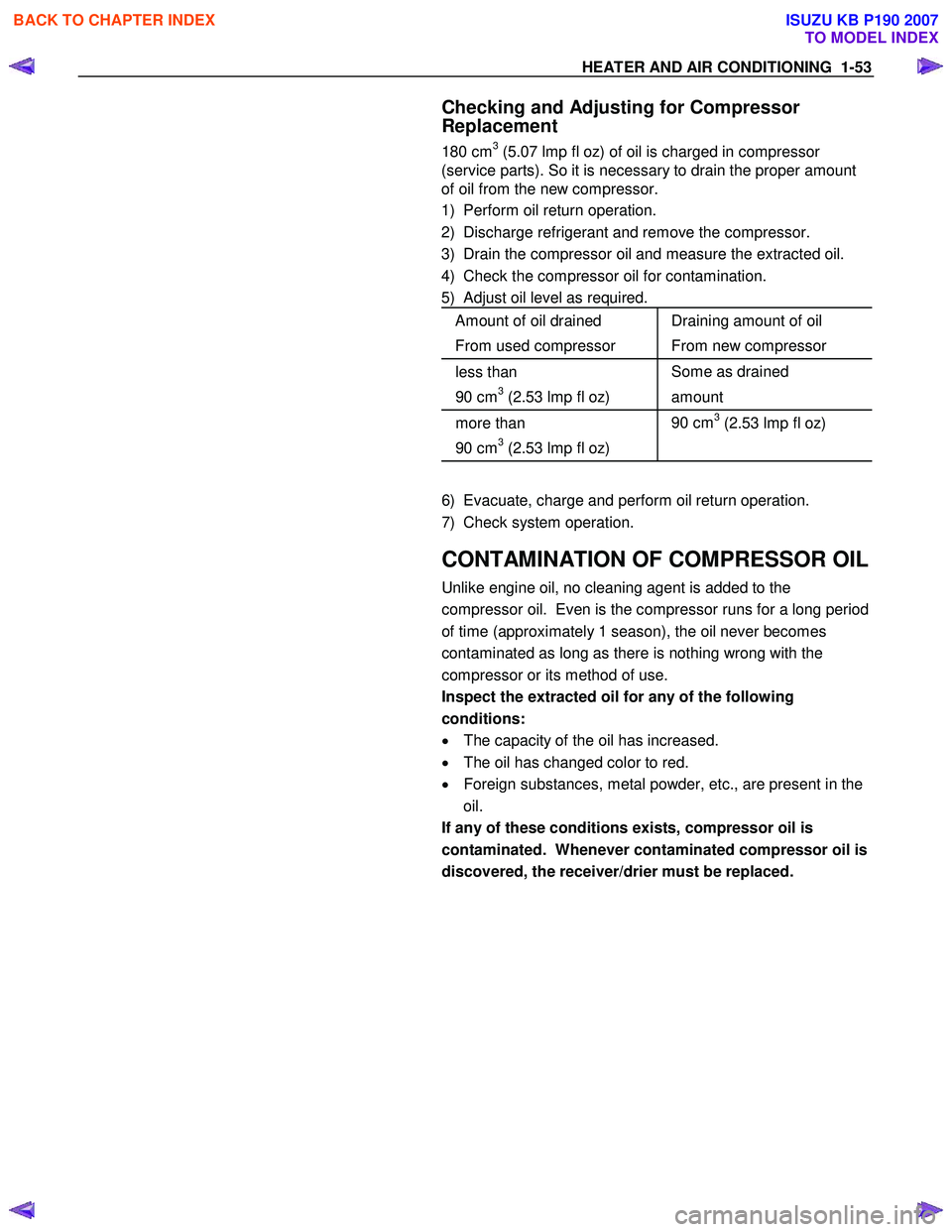

Checking and Adjusting for Compressor

Replacement

180 cm3 (5.07 lmp fl oz) of oil is charged in compressor

(service parts). So it is necessary to drain the proper amount

of oil from the new compressor.

1) Perform oil return operation.

2) Discharge refrigerant and remove the compressor.

3) Drain the compressor oil and measure the extracted oil.

4) Check the compressor oil for contamination.

5) Adjust oil level as required.

Amount of oil drained

From used compressor Draining amount of oil

From new compressor

less than

90 cm

3 (2.53 lmp fl oz) Some as drained

amount

more than

90 cm

3 (2.53 lmp fl oz) 90 cm

3 (2.53 lmp fl oz)

6) Evacuate, charge and perform oil return operation.

7) Check system operation.

CONTAMINATION OF COMPRESSOR OIL

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even is the compressor runs for a long period

of time (approximately 1 season), the oil never becomes

contaminated as long as there is nothing wrong with the

compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

• The capacity of the oil has increased.

• The oil has changed color to red.

• Foreign substances, metal powder, etc., are present in the

oil.

If any of these conditions exists, compressor oil is

contaminated. Whenever contaminated compressor oil is

discovered, the receiver/drier must be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 123 of 6020

HEATER AND AIR CONDITIONING 1-89

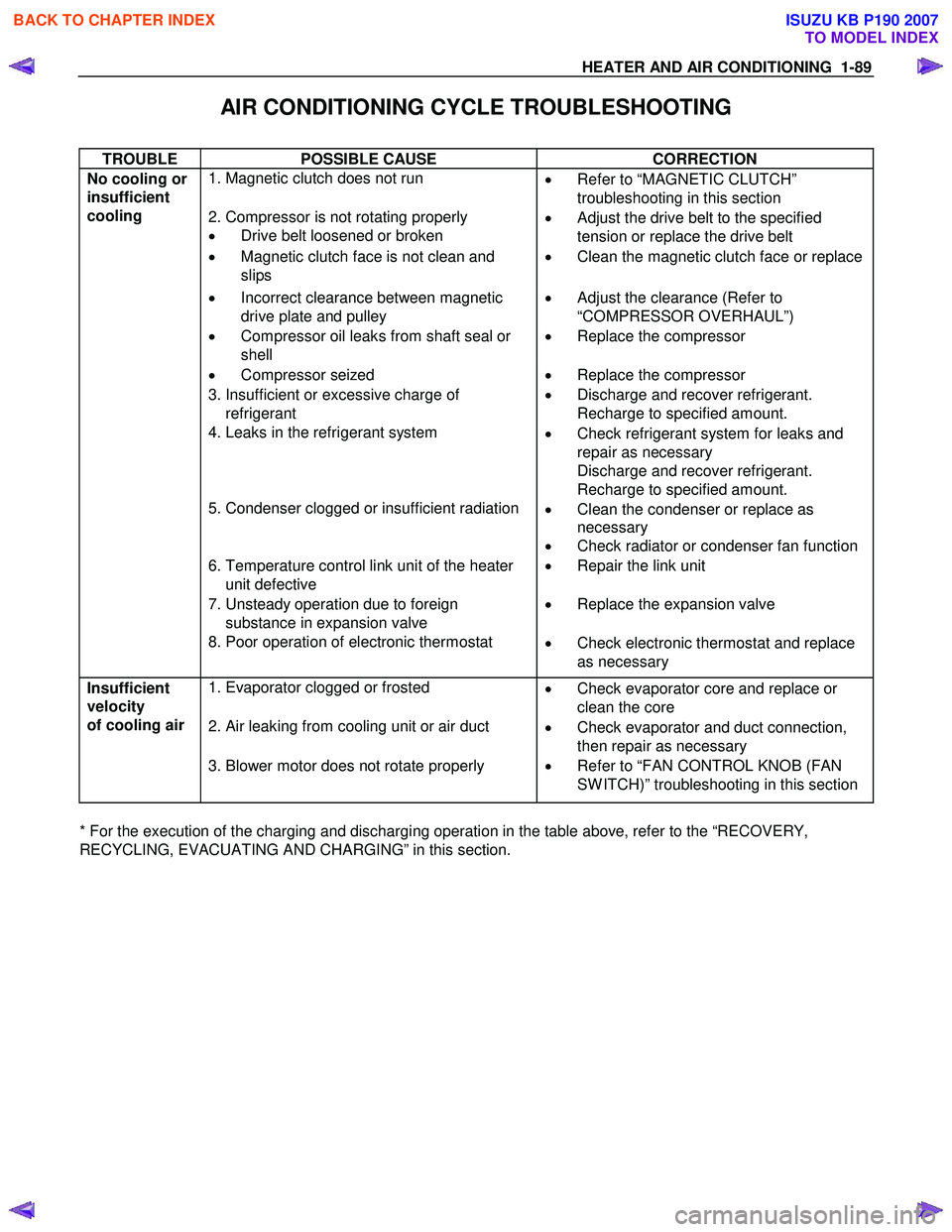

AIR CONDITIONING CYCLE TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE CORRECTION

1. Magnetic clutch does not run

•

Refer to “MAGNETIC CLUTCH”

troubleshooting in this section

2. Compressor is not rotating properly

• Drive belt loosened or broken •

Adjust the drive belt to the specified

tension or replace the drive belt

• Magnetic clutch face is not clean and

slips •

Clean the magnetic clutch face or replace

• Incorrect clearance between magnetic

drive plate and pulley •

Adjust the clearance (Refer to

“COMPRESSOR OVERHAUL”)

• Compressor oil leaks from shaft seal or

shell •

Replace the compressor

• Compressor seized • Replace the compressor

3. Insufficient or excessive charge of

refrigerant •

Discharge and recover refrigerant.

Recharge to specified amount.

4. Leaks in the refrigerant system

•

Check refrigerant system for leaks and

repair as necessary

Discharge and recover refrigerant.

Recharge to specified amount.

5. Condenser clogged or insufficient radiation

•

Clean the condenser or replace as

necessary

• Check radiator or condenser fan function

6. Temperature control link unit of the heater

unit defective •

Repair the link unit

7. Unsteady operation due to foreign

substance in expansion valve •

Replace the expansion valve

No cooling or

insufficient

cooling

8. Poor operation of electronic thermostat

•

Check electronic thermostat and replace

as necessary

1. Evaporator clogged or frosted

•

Check evaporator core and replace or

clean the core

2. Air leaking from cooling unit or air duct

•

Check evaporator and duct connection,

then repair as necessary

Insufficient

velocity

of cooling air

3. Blower motor does not rotate properly

• Refer to “FAN CONTROL KNOB (FAN

SW ITCH)” troubleshooting in this section

* For the execution of the charging and discharging operation in the table above, refer to the “RECOVERY,

RECYCLING, EVACUATING AND CHARGING” in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 125 of 6020

HEATER AND AIR CONDITIONING 1-91

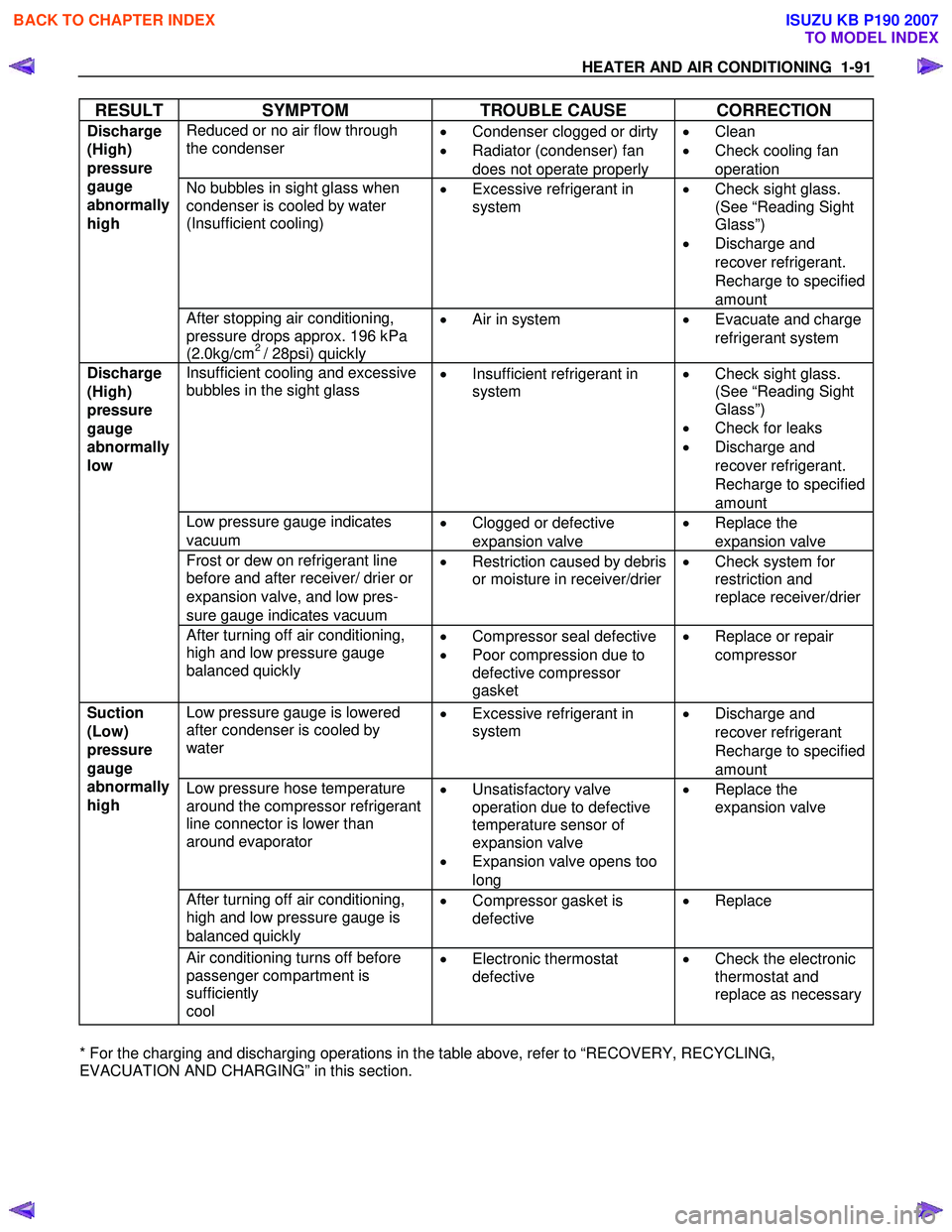

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Reduced or no air flow through

the condenser

•

Condenser clogged or dirty

• Radiator (condenser) fan

does not operate properly •

Clean

• Check cooling fan

operation

No bubbles in sight glass when

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Discharge

(High)

pressure

gauge

abnormally

high

After stopping air conditioning,

pressure drops approx. 196 kPa

(2.0kg/cm

2 / 28psi) quickly •

Air in system

•

Evacuate and charge

refrigerant system

Insufficient cooling and excessive

bubbles in the sight glass

•

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Low pressure gauge indicates

vacuum •

Clogged or defective

expansion valve •

Replace the

expansion valve

Frost or dew on refrigerant line

before and after receiver/ drier or

expansion valve, and low pres-

sure gauge indicates vacuum •

Restriction caused by debris

or moisture in receiver/drier

•

Check system for

restriction and

replace receiver/drier

Discharge

(High)

pressure

gauge

abnormally

low

After turning off air conditioning,

high and low pressure gauge

balanced quickly

•

Compressor seal defective

• Poor compression due to

defective compressor

gasket •

Replace or repair

compressor

Low pressure gauge is lowered

after condenser is cooled by

water

•

Excessive refrigerant in

system

•

Discharge and

recover refrigerant

Recharge to specified

amount

Low pressure hose temperature

around the compressor refrigerant

line connector is lower than

around evaporator

•

Unsatisfactory valve

operation due to defective

temperature sensor of

expansion valve

• Expansion valve opens too

long •

Replace the

expansion valve

After turning off air conditioning,

high and low pressure gauge is

balanced quickly •

Compressor gasket is

defective

•

Replace

Suction

(Low)

pressure

gauge

abnormally

high

Air conditioning turns off before

passenger compartment is

sufficiently

cool •

Electronic thermostat

defective

•

Check the electronic

thermostat and

replace as necessary

* For the charging and discharging operations in the table above, refer to “RECOVERY, RECYCLING,

EVACUATION AND CHARGING” in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 126 of 6020

1-92 HEATER AND AIR CONDITIONING

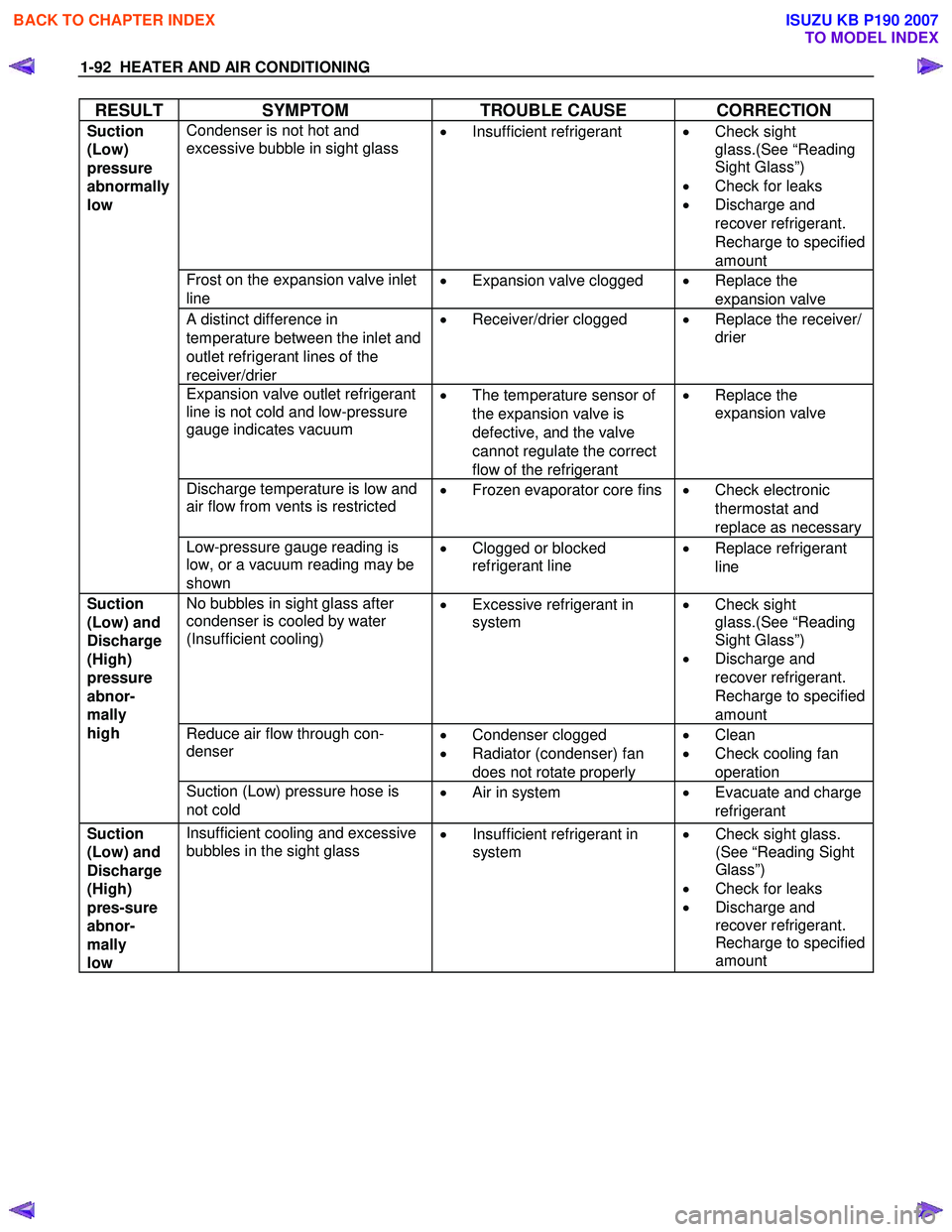

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Condenser is not hot and

excessive bubble in sight glass

•

Insufficient refrigerant

•

Check sight

glass.(See “Reading

Sight Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Frost on the expansion valve inlet

line •

Expansion valve clogged

•

Replace the

expansion valve

A distinct difference in

temperature between the inlet and

outlet refrigerant lines of the

receiver/drier •

Receiver/drier clogged

•

Replace the receiver/

drier

Expansion valve outlet refrigerant

line is not cold and low-pressure

gauge indicates vacuum

•

The temperature sensor of

the expansion valve is

defective, and the valve

cannot regulate the correct

flow of the refrigerant •

Replace the

expansion valve

Discharge temperature is low and

air flow from vents is restricted

•

Frozen evaporator core fins

•

Check electronic

thermostat and

replace as necessary

Suction

(Low)

pressure

abnormally

low

Low-pressure gauge reading is

low, or a vacuum reading may be

shown •

Clogged or blocked

refrigerant line

•

Replace refrigerant

line

No bubbles in sight glass after

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight

glass.(See “Reading

Sight Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Reduce air flow through con-

denser

•

Condenser clogged

• Radiator (condenser) fan

does not rotate properly •

Clean

• Check cooling fan

operation

Suction

(Low) and

Discharge

(High)

pressure

abnor-

mally

high

Suction (Low) pressure hose is

not cold •

Air in system • Evacuate and charge

refrigerant

Suction

(Low) and

Discharge

(High)

pres-sure

abnor-

mally

low Insufficient cooling and excessive

bubbles in the sight glass •

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 198 of 6020

SHEET METAL 2B-1

SECTION 2B

SHEET METAL

This section includes items of front end sheet metal that are attached by bolts, screws or clips and related

accessory components.

Anticorrosion materials have been applied to the interior surfaces of some metal panels to provide rust resistance.

W hen servicing these panels, areas on which this material has been disturbed, should be properly recoated with

service-type anticorrosion material.

TABLE OF CONTENTS

PAGE

Engine Hood Assembly (A type) ...................................................................................... 2B- 2

Engine Hood Assembly (B type) ..................................................................................... 2B- 8

Engine Hood Lock (A type) .............................................................................................. 2B- 11

Engine Hood Lock (B type) .............................................................................................. 2B- 13

Front Fender Panel (A type) ............................................................................................. 2B- 15

Front Fender Panel (B type) ............................................................................................. 2B- 18

Radiator Grille (A type) ..................................................................................................... 2 B- 21

Radiator Grille (B type) .................................................................................................... 2B - 22

Rear Body...................................................................................................................... ..... 2B- 23

Body Mounting .................................................................................................................. 2B- 26

Body Dimensions .............................................................................................................. 2B - 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 268 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-7

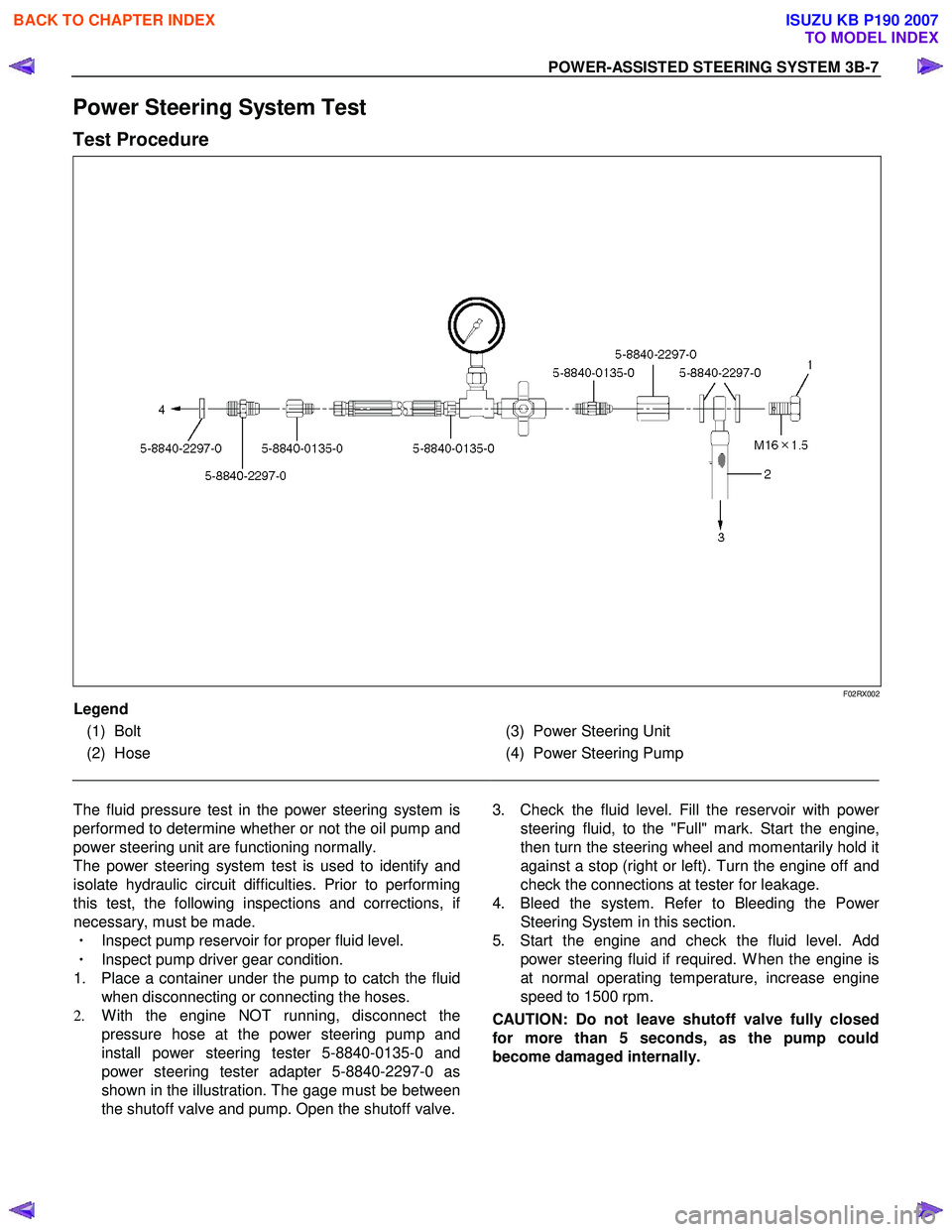

Power Steering System Test

Test Procedure

F02RX002

Legend

(1) Bolt

(2) Hose

(3) Power Steering Unit

(4) Power Steering Pump

The fluid pressure test in the power steering system is

performed to determine whether or not the oil pump and

power steering unit are functioning normally.

The power steering system test is used to identify and

isolate hydraulic circuit difficulties. Prior to performing

this test, the following inspections and corrections, i

f

necessary, must be made.

・ Inspect pump reservoir for proper fluid level.

・ Inspect pump driver gear condition.

1. Place a container under the pump to catch the fluid when disconnecting or connecting the hoses.

2. W ith the engine NOT running, disconnect the

pressure hose at the power steering pump and

install power steering tester 5-8840-0135-0 and

power steering tester adapter 5-8840-2297-0 as

shown in the illustration. The gage must be between

the shutoff valve and pump. Open the shutoff valve.

3. Check the fluid level. Fill the reservoir with powe

r

steering fluid, to the "Full" mark. Start the engine,

then turn the steering wheel and momentarily hold it

against a stop (right or left). Turn the engine off and

check the connections at tester for leakage.

4. Bleed the system. Refer to Bleeding the Powe

r

Steering System in this section.

5. Start the engine and check the fluid level. Add power steering fluid if required. W hen the engine is

at normal operating temperature, increase engine

speed to 1500 rpm.

CAUTION: Do not leave shutoff valve fully closed

for more than 5 seconds, as the pump could

become damaged internally.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007