ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3741 of 6020

Powertrain Interface Module – V6 Page 6E1–80

F2: Snapshot Options

In this test mode, Tech 2 captures data before and after a snapshot triggering event that may or may not set a DTC.

Trigger Type : Manual Trigger

F0: Manual Trigger

Trigger Point : Centre

F4: Beginning

F5: Centre

F6: End

F3: Miscellaneous Tests

F0: Warnings

F1: Status Indicators

F2: Gauge Control Tests

F4: Additional Functions

W hen this selection is made from the Tech 2 screen, an additional choice is provided:

F0: Read PIM Information

F5: Program

W ithin this selection, there are two programming selections available:

F0: Program Variant Configuration

F1: Program VIN

F6: Security

F0: Immobiliser Link To ECM/PIM

F1: Reset PIM

F2: Security Information

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3742 of 6020

Powertrain Interface Module – V6 Page 6E1–81

13.3 Powertrain Interface Module Data List

Diagnostic Data Display

Tech 2 Display Units Displayed Switch On Switch Off

AC Switch On/Off On Off

Cruise Cancel Switch Active/Inactive Active Inactive

Cruise Resume Switch Active/Inactive Active Inactive

Cruise Set Switch Active/Inactive Active Inactive

Cruise Main Switch Active/Inactive Active Inactive

Cruise Control Set Lamp On/Off On Off

Cruise Control On Lamp On/Off On Off

Power Drive Switch On/Off On Off

Power Drive Lamp On/Off On Off

3rd Start Switch On/Off On Off

3rd Start Lamp On/Off On Off

4W D Low Gear Active/Inactive Active Inactive

G-Sensor V 2.43 2.43

G-Sensor Pa 0.027 0.027

Engine Speed RPM 152 1093

Coolant temperature Input °C 35 25

Coolant Temperature % 70 70

Fuel Level Input % 26 26

Fuel Level % 43 43

Alternator Lamp On/Off On Off

Oil Pressure Lamp On/Off On Off

SVS Lamp (Service Vehicle soon) On/Off On Off

Check transmission MIL On/Off On Off

Transmission Oil Temperature Lamp On/Off On Off

LED [ - P - ] On/Off On Off

LED [ - R - ] On/Off On Off

LED [ - N - ] On/Off On Off

LED [ - D - ] On/Off On Off

LED [ - 3 - ] On/Off On Off

LED [ - 2 - ] On/Off On Off

LED [ - 1 - ] On/Off On Off

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3743 of 6020

Powertrain Interface Module – V6 Page 6E1–82

13.4 Miscellaneous Tests

F0: Warnings

F0: Alternator

This test checks the alternator warning lamp turns On and Off when selected on Tech 2.

F1: Oil Pressure Telltale Test

This test checks the Oil Pressure warning lamp turns On and Off when selected on Tech 2.

F2: Service Vehicle Soon Lamp Test

This test checks the Service Vehicle Soon warning lamp turns On and Off when selected on Tech 2.

F3: AT Oil Temperature Lamp

This test checks the Oil Temperature warning lamp turns On and Off when selected on Tech 2.

F4: AT Telltale Test

This test checks the Automatic Transmission warning lamp turns On and Off when selected on Tech 2.

F1: Status Indicators

F0: Cruise Control On Lamp

This test checks the Cruise Control On status lamp turns On and Off when selected on Tech 2.

F1: Cruise Control Set Lamp

This test checks the Cruise Control Set status lamp turns On and Off when selected on Tech 2.

F2: PRNDL Lamps

This test checks the all the Automatic Transmission status lamps turn On and Off when selected on Tech 2.

F3: Power Drive Lamp

This test checks the Power Drive status lamp turns On and Off when selected on Tech 2.

F2: Gauge Control Tests

F0: Tachometer

This test checks the operation of the Tachometer by driving the pointer in 1000 rpm steps to 6000 rpm when

selected on Tech 2.

F1: Temperature Gauge

This test checks the operation of the Temperature gauge by driving the pointer to the Cold, Mid and High

positions when selected on Tech 2.

F2: Fuel Gauge

This test checks the operation of the Fuel gauge by driving the pointer from zero in 20% increments to full when selected on Tech 2.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3744 of 6020

Powertrain Interface Module – V6 Page 6E1–83

13.5 Security

F0: Immobiliser Link To ECM/PIM

Should the ECM, PIM or ICU be replaced, the modules must be security linked to each other. If this linking

procedure is not performed, the vehicle will not crank nor run. For additional information relating to Tech 2

and the linking procedure, refer to 11A – Immobiliser.

NOTE

After an ECU reset, the ignition switch must be

turned Off for at least 10 seconds and then

turned On for at least one minute, before

attempting communication between Tech 2 and

the ECU.

Preconditions: TIS approval (TIS 2000 Security Access) must be obtained, the four digit security number

entered into Tech 2 and the theft deterrent system disarmed. Then the ignition must be turned ‘On’, using a

programmed remote coded key.

F1: Reset PIM

This function erases the security link between the Engine Control Module (ECM) and the Powertrain Interface Modules (PIM). If this procedure is performed, the engine will not crank nor run. A ICU Link to ECM/PIM

procedure will need to be performed. For additional information relating to the ICU Link to ECM/PIM

procedure, refer to 11A – Immobiliser.

NOTE

After an ECU reset, the ignition switch must be

turned Off for at least 10 seconds and then

turned On for at least one minute, before

attempting communication between Tech 2 and

the ECU.

Preconditions: The four digit security code must be entered into Tech 2 and the ignition switched ‘On’ with a

programmed remote coded key.

F2: Security Information

The security code is required when performing certain PIM, ICU and ECM programming functions. W hen Tech 2 requests the security code to be entered, and an incorrect code is entered, the PIM will go into a

security wait time stage. This wait time stage will prevent any further attempts to enter the security code until

the wait time has elapsed.

Should a second incorrect security code be entered after the initial wait time has elapsed, the PIM will go into a second wait time stage. The wait time will increase each time an incorrect code is entered. W hen the

correct code is entered the wait time will reset back to its original value of 10 seconds.

NOTE

The ignition switch must be in the ON position

with the battery connected during the wait time

period.

The wait time stages are as follows: • Stage 1 = 10 seconds.

• Stage 2 = 10 seconds.

• Stage 3 = 10 minutes.

• Stage 4 = 20 minutes.

• Stage 5 = 40 minutes.

• Stage 5 = 80 minutes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3745 of 6020

Powertrain Interface Module – V6 Page 6E1–84

Tech 2 PIM Security Information Data List

The Tech 2 PIM Security Information Data List displays the PIM's current security status.

To view the data list:

1 Connect Tech 2 to the data link connector (DLC) and turn the ignition switch on.

2 On Tech 2 select: Body / Powertrain Interface Module / Security / Security Information .

NOTE

The Tech 2 PIM Security Information Data List

typical display values are obtained from a

correctly operating vehicle under the following

conditions:

• ignition switched on,

• engine not running, and

• vehicle is stationary.

Tech 2 Parameter Units Displayed Typical Display Values

Security Code Programmed Yes / No Yes

Security W ait Time Inactive / Active Inactive

Security W ait Time Inactive / 0:00:00 Inactive

Security Code Reset Counter 0 0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3746 of 6020

Powertrain Interface Module – V6 Page 6E1–85

14 Specifications

Powertrain Interface Module Bus Cut-off Resistor.................................... 120 Ω

Engine Control Module Bus Cut-off Resistor ............................................ 120 Ω

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3747 of 6020

Powertrain Interface Module – V6 Page 6E1–86

15 Torque Wrench Specifications

Powertrain Interface Module Attaching Screw ............................. 8.0 – 12.0 Nm

Vertical Acceleration Sensor attaching nut ............................... 12.0 – 16.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3748 of 6020

Powertrain Interface Module – V6 Page 6E1–87

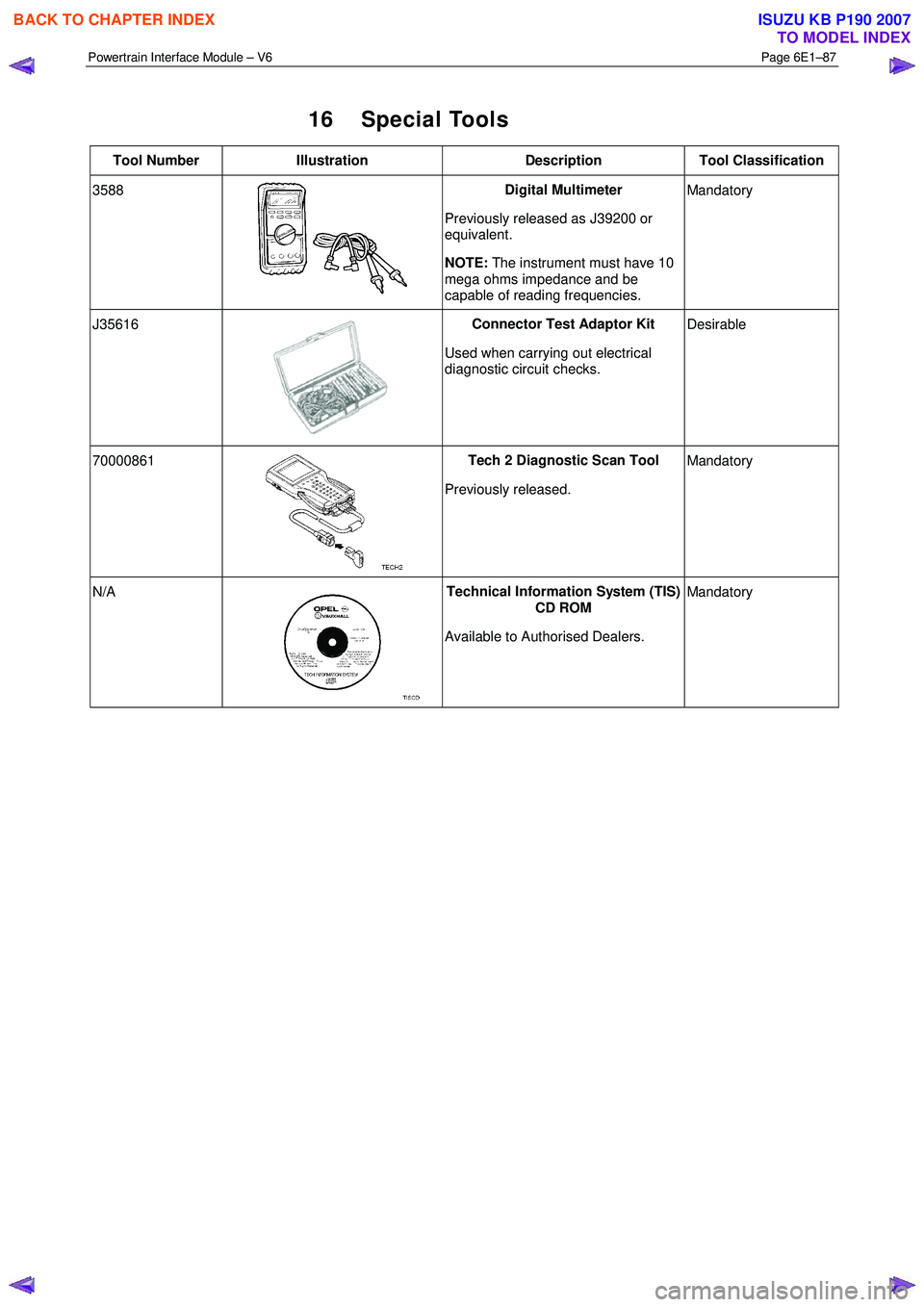

16 Special Tools

Tool Number Illustration Description Tool Classification

3588

Digital Multimeter

Previously released as J39200 or

equivalent.

NOTE: The instrument must have 10

mega ohms impedance and be

capable of reading frequencies. Mandatory

J35616

Connector Test Adaptor Kit

Used when carrying out electrical

diagnostic circuit checks.

Desirable

70000861

Tech 2 Diagnostic Scan Tool

Previously released. Mandatory

N/A

Technical Information System (TIS)

CD ROM

Available to Authorised Dealers. Mandatory

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3749 of 6020

Exhaust System – V6 Page 6F – 1

6F

Exhaust System – V6

ATTENTION

Before performing any service operations or other procedure described in this Section, refer to

1.3 WARNING, CAUTION and NOTES for correct workshop practices with regard to safety and / or

property damage.

1 General Information ............................................................................................................ ...................2

1.1 Emission Reductions ............................................................................................................................................ 2

Euro 3 Emissions Standards ................................................................................................................................ 3

1.2 General Description ............................................................................................................ ................................... 4

Service Notes ......................................................................................................................................................... 5

1.3 WARNING, CAUTION and NOTES..................................................................................................... .................... 5

1.1 Definition of WARNING, CAUTION and NOTE Statements......................................................................... .. 5

W ARNING defined ............................................................................................................................................. 5

CAUTION defined .............................................................................................................................................. 5

NOTE defined .................................................................................................................................................... 6

2 Front and Centre Exhaust Pipe .................................................................................................. ...........7

Removal .................................................................................................................................................................. 7

Reinstallation ......................................................................................................................................................... 8

3 Silencer and Rear Exhaust Pipe............................................................................................................9

Removal .................................................................................................................................................................. 9

Reinstallation ......................................................................................................................................................... 9

4 Torque Wrench Specifications............................................................................................................10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3750 of 6020

Exhaust System – V6 Page 6F – 2

1 General Information

Information contained within this section describes the general exhaust system.

1.1 Emission Reductions

Through developments in various vehicle emissions reduction systems, significant reductions in emissions have been

achieved. The developments have been primarily concerned with refinements in engine calibration and the optimisation

of exhaust system catalytic converter configurations.

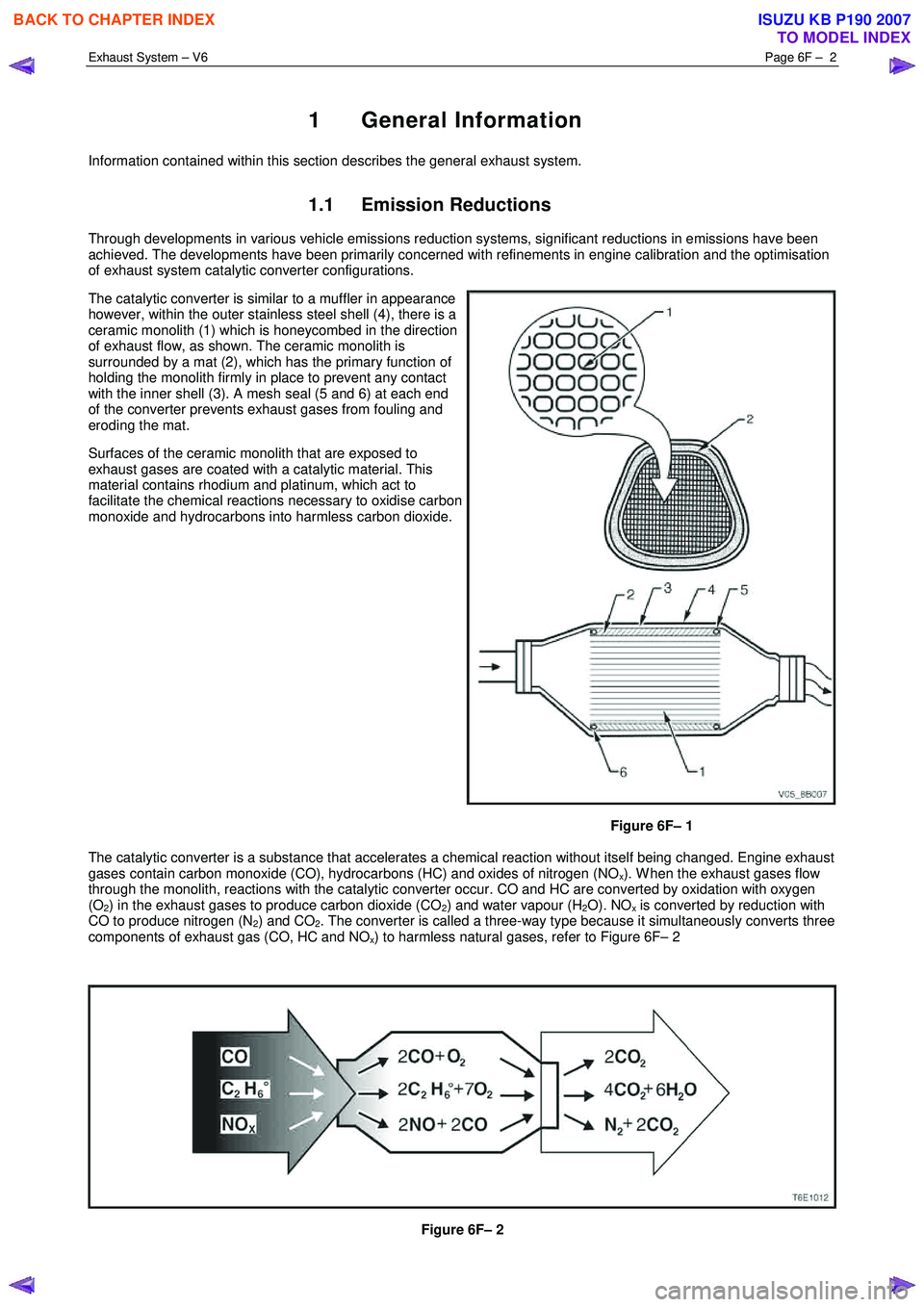

The catalytic converter is similar to a muffler in appearance

however, within the outer stainless steel shell (4), there is a

ceramic monolith (1) which is honeycombed in the direction

of exhaust flow, as shown. The ceramic monolith is

surrounded by a mat (2), which has the primary function of

holding the monolith firmly in place to prevent any contact

with the inner shell (3). A mesh seal (5 and 6) at each end

of the converter prevents exhaust gases from fouling and

eroding the mat.

Surfaces of the ceramic monolith that are exposed to

exhaust gases are coated with a catalytic material. This

material contains rhodium and platinum, which act to

facilitate the chemical reactions necessary to oxidise carbon

monoxide and hydrocarbons into harmless carbon dioxide.

Figure 6F– 1

The catalytic converter is a substance that accelerates a chemical reaction without itself being changed. Engine exhaust

gases contain carbon monoxide (CO), hydrocarbons (HC) and oxides of nitrogen (NO

x). W hen the exhaust gases flow

through the monolith, reactions with the catalytic converter occur. CO and HC are converted by oxidation with oxygen

(O

2) in the exhaust gases to produce carbon dioxide (CO2) and water vapour (H2O). NOx is converted by reduction with

CO to produce nitrogen (N

2) and CO2. The converter is called a three-way type because it simultaneously converts three

components of exhaust gas (CO, HC and NO

x) to harmless natural gases, refer to Figure 6F– 2

Figure 6F– 2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007