CONDENSER ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 35 of 6020

HEATER AND AIR CONDITIONING 1-1

SECTION 1

HEATER AND AIR CONDITIONING

TABLE OF CONTENTS

PAGE

General Description ........................................................................................................ 1- 3

Main Data and Specifications ......................................................................................... 1- 21

Special Parts Fixing Nuts and Bolts .............................................................................. 1- 23

On-Vehicle Service .......................................................................................................... 1- 30

Precautions For Replacement or repair of air conditioning parts .......................... 1- 30

Condenser...................................................................................................................... .. 1- 40

Removal and Installation (4JH1-TC, 4JJ1-TC Standard Output)............................. 1- 40

Removal and Installation (4JJ1-TC High Output, 4JK1-TC High Output, 4JA1-T) ........................................ 1- 41

Removal and Installation (C24SE) ............................................................................. 1- 42

Condenser Fan Motor ..................................................................................................... 1- 43 Removal and Installation............................................................................................ 1- 43

Receiver/drier ................................................................................................................. . 1- 44

Removal and Installation............................................................................................ 1- 44

Compressor ..................................................................................................................... 1- 45

Removal and Installation (4JA1-T, 4JH1-TC) ............................................................ 1- 45

Removal and Installation (4JJ1-TC Standard Output, 4JJ1-TC High Output, 4JK1-TC High Output) ......... 1- 47

Removal and Installation (C24SE) ............................................................................. 1- 49

Disassembly ................................................................................................................ 1- 55

Reassembly ................................................................................................................. 1- 57

Heater Unit .................................................................................................................... ... 1- 59

Removal and Installation............................................................................................ 1- 59

Disassembly and Reassembly................................................................................... 1- 61

Vent Unit (Without Heater) ............................................................................................. 1- 62 Removal and Installation............................................................................................ 1- 62

Disassembly and Reassembly................................................................................... 1- 64

TO MODEL INDEX

BACK TO MAIN INDEX

ISUZU KB P190 2007

Page 37 of 6020

HEATER AND AIR CONDITIONING 1-3

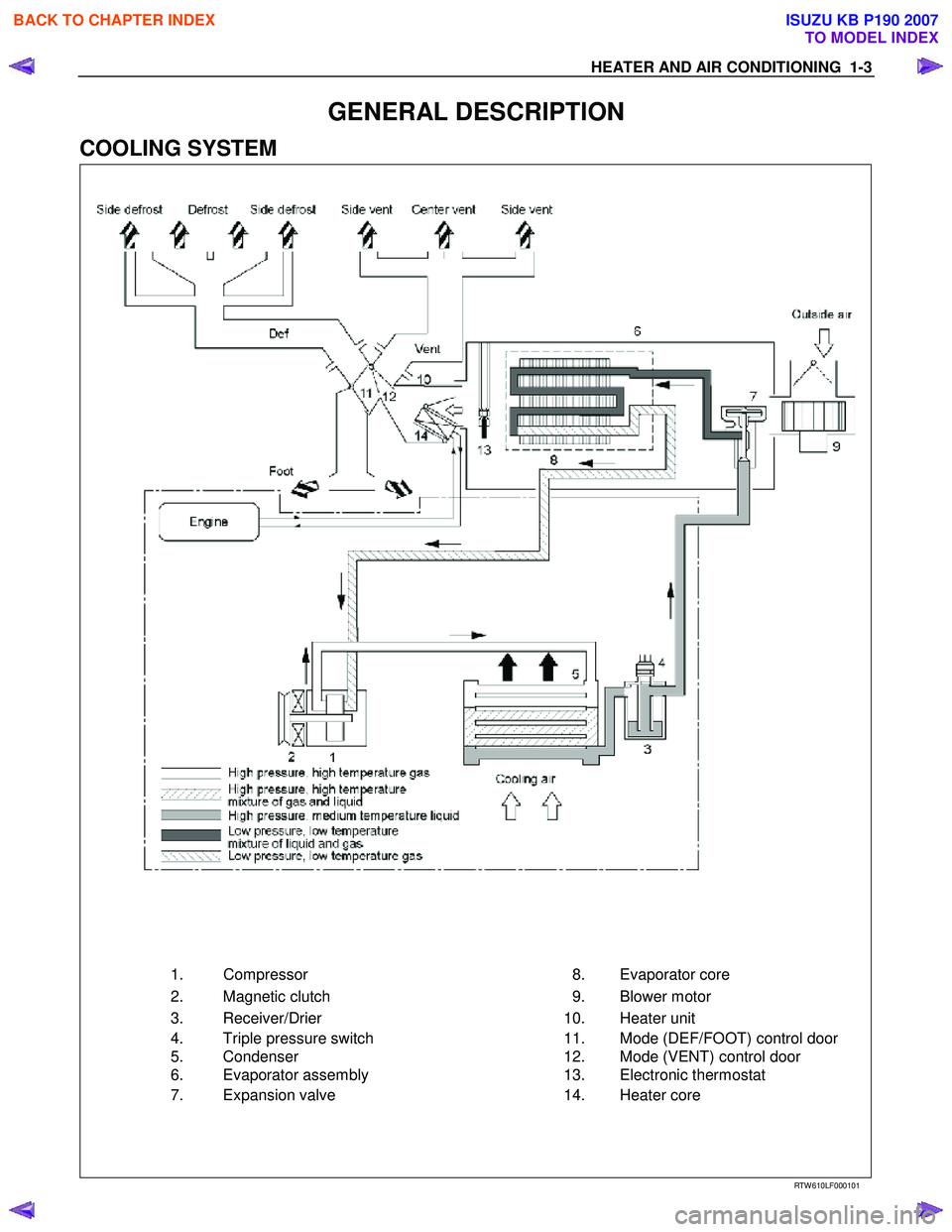

GENERAL DESCRIPTION

COOLING SYSTEM

1.

Compressor 8.

Evaporator core

2.

Magnetic clutch 9.

Blower motor

3.

Receiver/Drier 10.

Heater unit

4.

Triple pressure switch 11.

Mode (DEF/FOOT) control door

5.

Condenser 12.

Mode (VENT) control door

6.

Evaporator assembly 13.

Electronic thermostat

7.

Expansion valve 14.

Heater core

RTW 610LF000101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 55 of 6020

HEATER AND AIR CONDITIONING 1-21

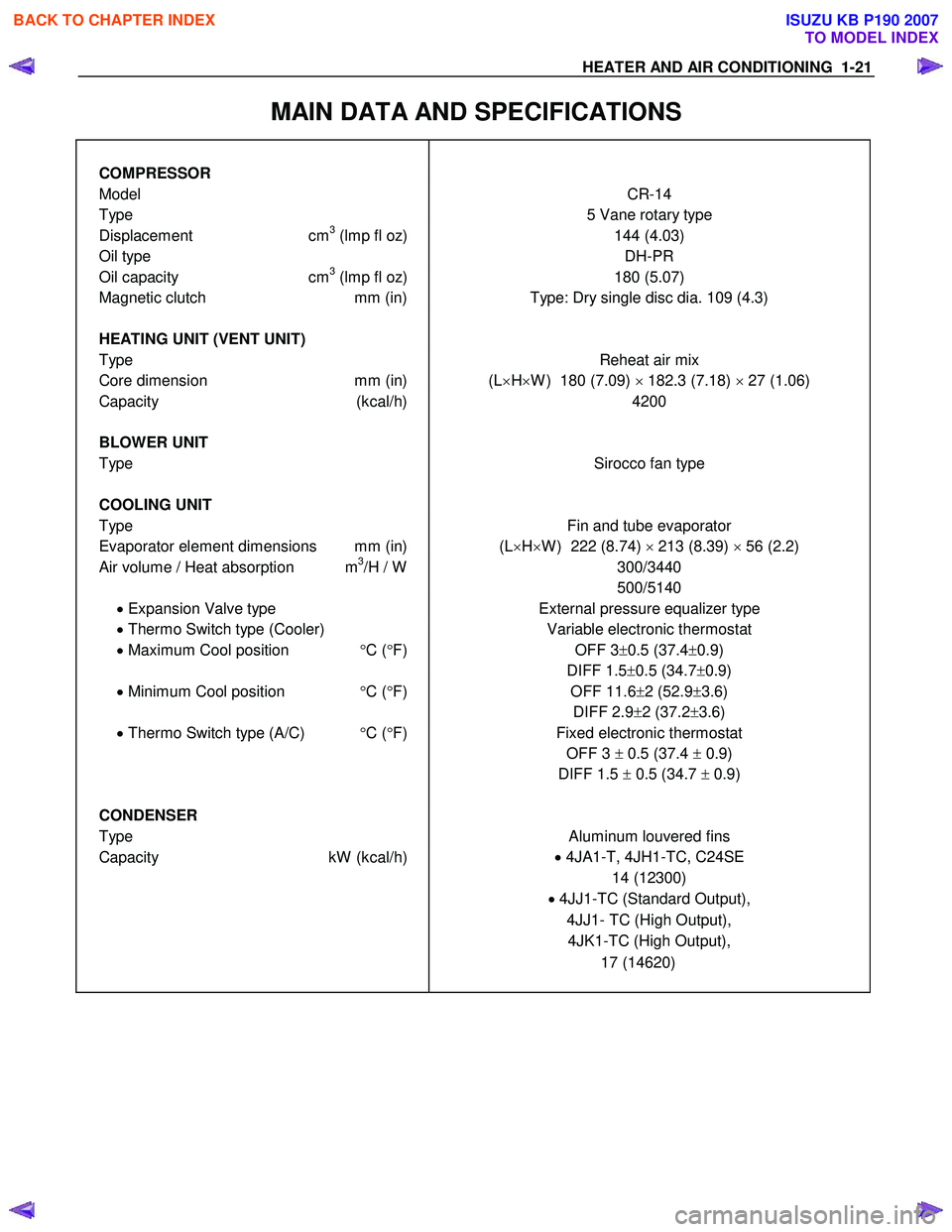

MAIN DATA AND SPECIFICATIONS

COMPRESSOR

Model CR-14

Type 5 Vane rotary type

Displacement cm3 (lmp fl oz) 144 (4.03)

Oil type DH-PR

Oil capacity cm3 (lmp fl oz) 180 (5.07)

Magnetic clutch mm (in) Type: Dry single disc dia. 109 (4.3)

HEATING UNIT (VENT UNIT)

Type Reheat air mix

Core dimension mm (in) (L×H ×W ) 180 (7.09) × 182.3 (7.18) × 27 (1.06)

Capacity (kcal/h) 4200

BLOWER UNIT

Type Sirocco fan type

COOLING UNIT

Type Fin and tube evaporator

Evaporator element dimensions mm (in) (L×H ×W ) 222 (8.74) × 213 (8.39) × 56 (2.2)

Air volume / Heat absorption m3/H / W

300/3440

500/5140

• Expansion Valve type External pressure equalizer type

• Thermo Switch type (Cooler) Variable electronic thermostat

• Maximum Cool position °C ( °F) OFF 3± 0.5 (37.4 ±0.9)

DIFF 1.5 ±0.5 (34.7 ±0.9)

• Minimum Cool position °C ( °F)

OFF 11.6

±2 (52.9 ±3.6)

DIFF 2.9 ±2 (37.2 ±3.6)

• Thermo Switch type (A/C) °C ( °F) Fixed electronic thermostat

OFF 3 ± 0.5 (37.4 ± 0.9)

DIFF 1.5 ± 0.5 (34.7 ± 0.9)

CONDENSER

Type Aluminum louvered fins

Capacity kW (kcal/h) •

4JA1-T, 4JH1-TC, C24SE

14 (12300)

• 4JJ1-TC (Standard Output),

4JJ1- TC (High Output), 4JK1-TC (High Output),

17 (14620)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 74 of 6020

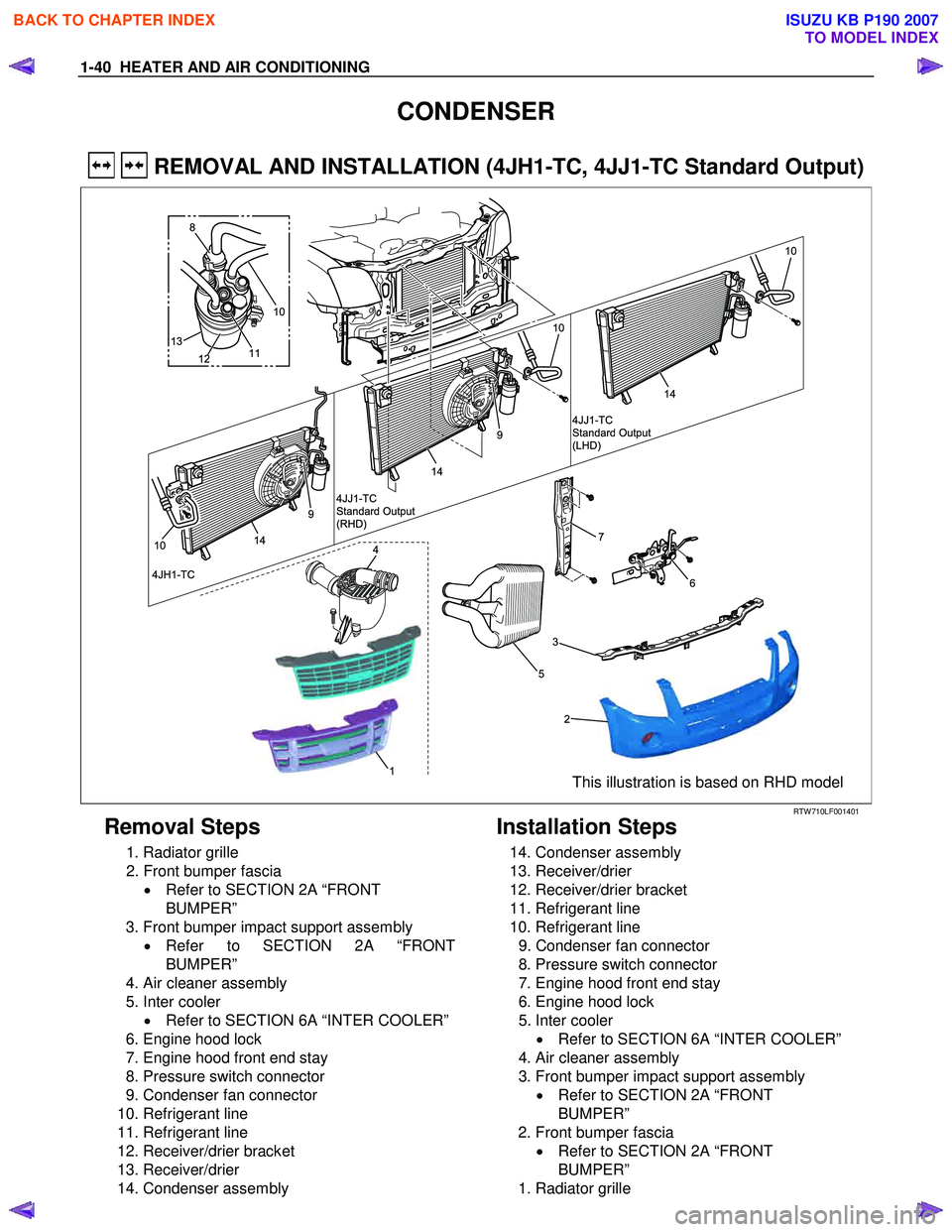

1-40 HEATER AND AIR CONDITIONING

CONDENSER

REMOVAL AND INSTALLATION (4JH1-TC, 4JJ1-TC Standard Output)

13

12

8

10

11

14

10

9

6

7

5

2

3

1

41410

4JH1-TC 4JJ1-TC

Standard Output

(RHD)

14

10

4JJ1-TC

Standard Output

(LHD)

9

This illustration is based on RHD model

RTW 710LF001401

Removal Steps

1. Radiator grille

2. Front bumper fascia • Refer to SECTION 2A “FRONT

BUMPER”

3. Front bumper impact support assembly • Refer to SECTION 2A “FRONT

BUMPER”

4. Air cleaner assembly

5. Inter cooler • Refer to SECTION 6A “INTER COOLER”

6. Engine hood lock

7. Engine hood front end stay

8. Pressure switch connector

9. Condenser fan connector

10. Refrigerant line

11. Refrigerant line

12. Receiver/drier bracket

13. Receiver/drier

14. Condenser assembly

Installation Steps

14. Condenser assembly

13. Receiver/drier

12. Receiver/drier bracket

11. Refrigerant line

10. Refrigerant line

9. Condenser fan connector

8. Pressure switch connector

7. Engine hood front end stay

6. Engine hood lock

5. Inter cooler • Refer to SECTION 6A “INTER COOLER”

4. Air cleaner assembly

3. Front bumper impact support assembly • Refer to SECTION 2A “FRONT

BUMPER”

2. Front bumper fascia • Refer to SECTION 2A “FRONT

BUMPER”

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 75 of 6020

HEATER AND AIR CONDITIONING 1-41

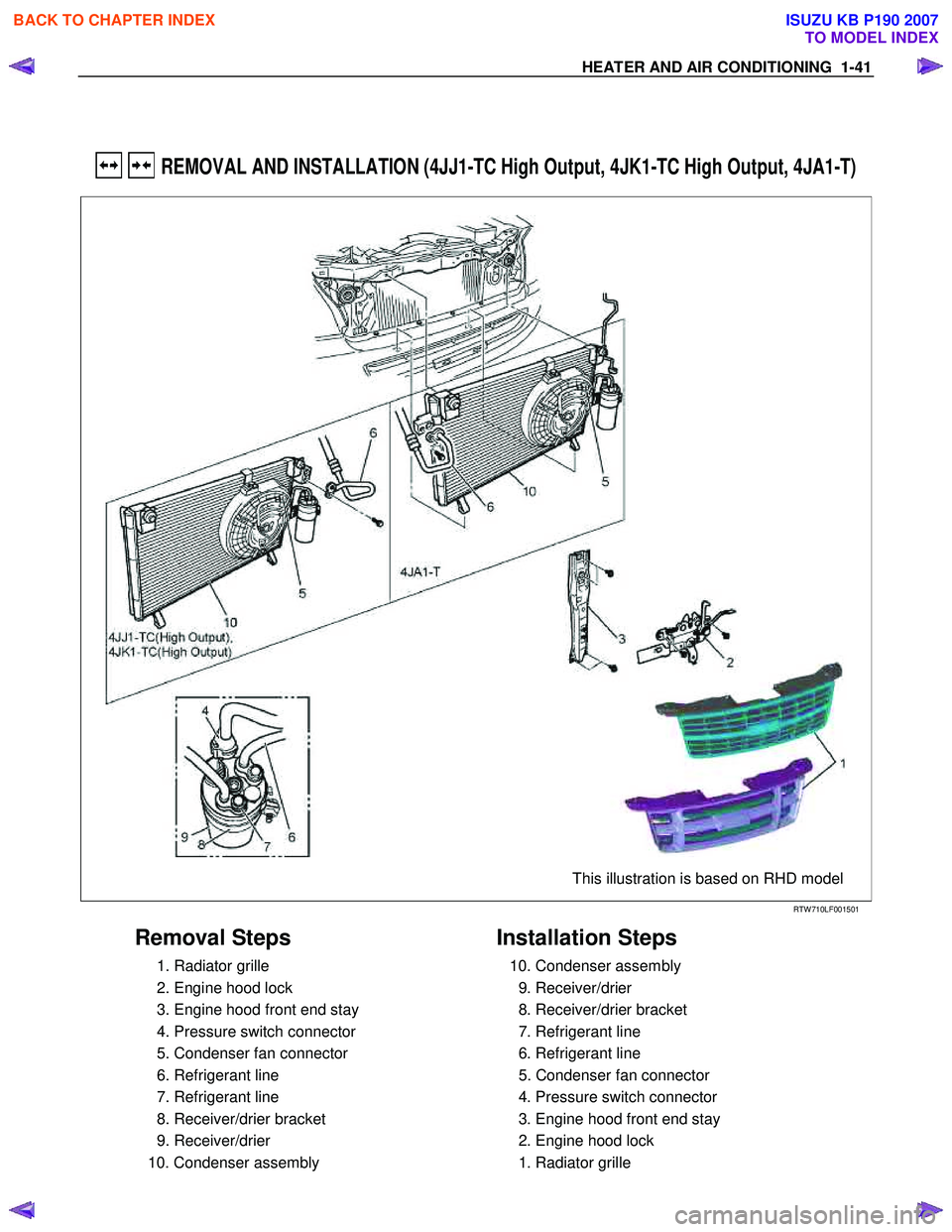

REMOVAL AND INSTALLATION (4JJ1-TC High Output, 4JK1-TC High Output, 4JA1-T)

This illustration is based on RHD model

RTW 710LF001501

Removal Steps

1. Radiator grille

2. Engine hood lock

3. Engine hood front end stay

4. Pressure switch connector

5. Condenser fan connector

6. Refrigerant line

7. Refrigerant line

8. Receiver/drier bracket

9. Receiver/drier

10. Condenser assembly

Installation Steps

10. Condenser assembly

9. Receiver/drier

8. Receiver/drier bracket

7. Refrigerant line

6. Refrigerant line

5. Condenser fan connector

4. Pressure switch connector

3. Engine hood front end stay

2. Engine hood lock

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 76 of 6020

1-42 HEATER AND AIR CONDITIONING

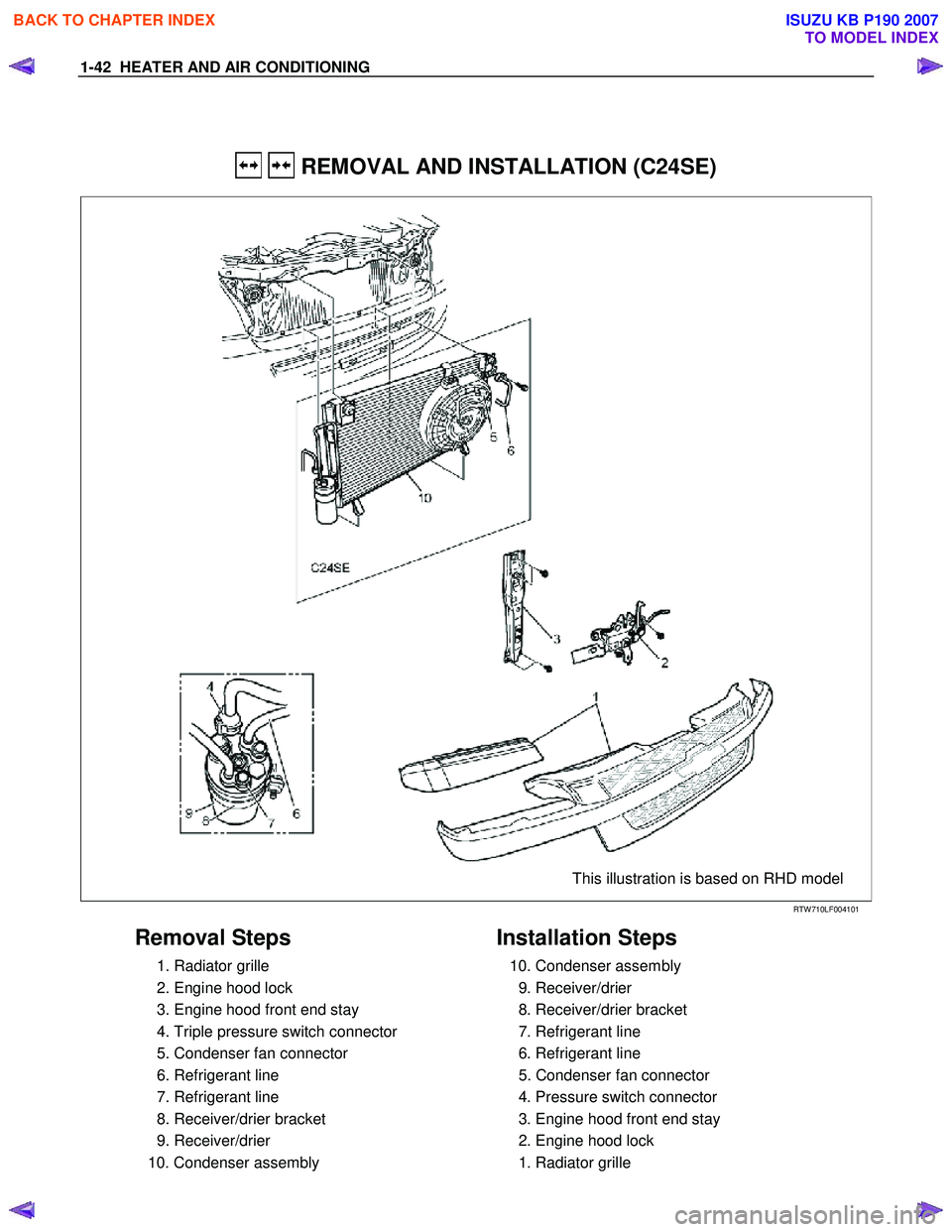

REMOVAL AND INSTALLATION (C24SE)

This illustration is based on RHD model

RTW 710LF004101

Removal Steps

1. Radiator grille

2. Engine hood lock

3. Engine hood front end stay

4. Triple pressure switch connector

5. Condenser fan connector

6. Refrigerant line

7. Refrigerant line

8. Receiver/drier bracket

9. Receiver/drier

10. Condenser assembly

Installation Steps

10. Condenser assembly

9. Receiver/drier

8. Receiver/drier bracket

7. Refrigerant line

6. Refrigerant line

5. Condenser fan connector

4. Pressure switch connector

3. Engine hood front end stay

2. Engine hood lock

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 77 of 6020

HEATER AND AIR CONDITIONING 1-43

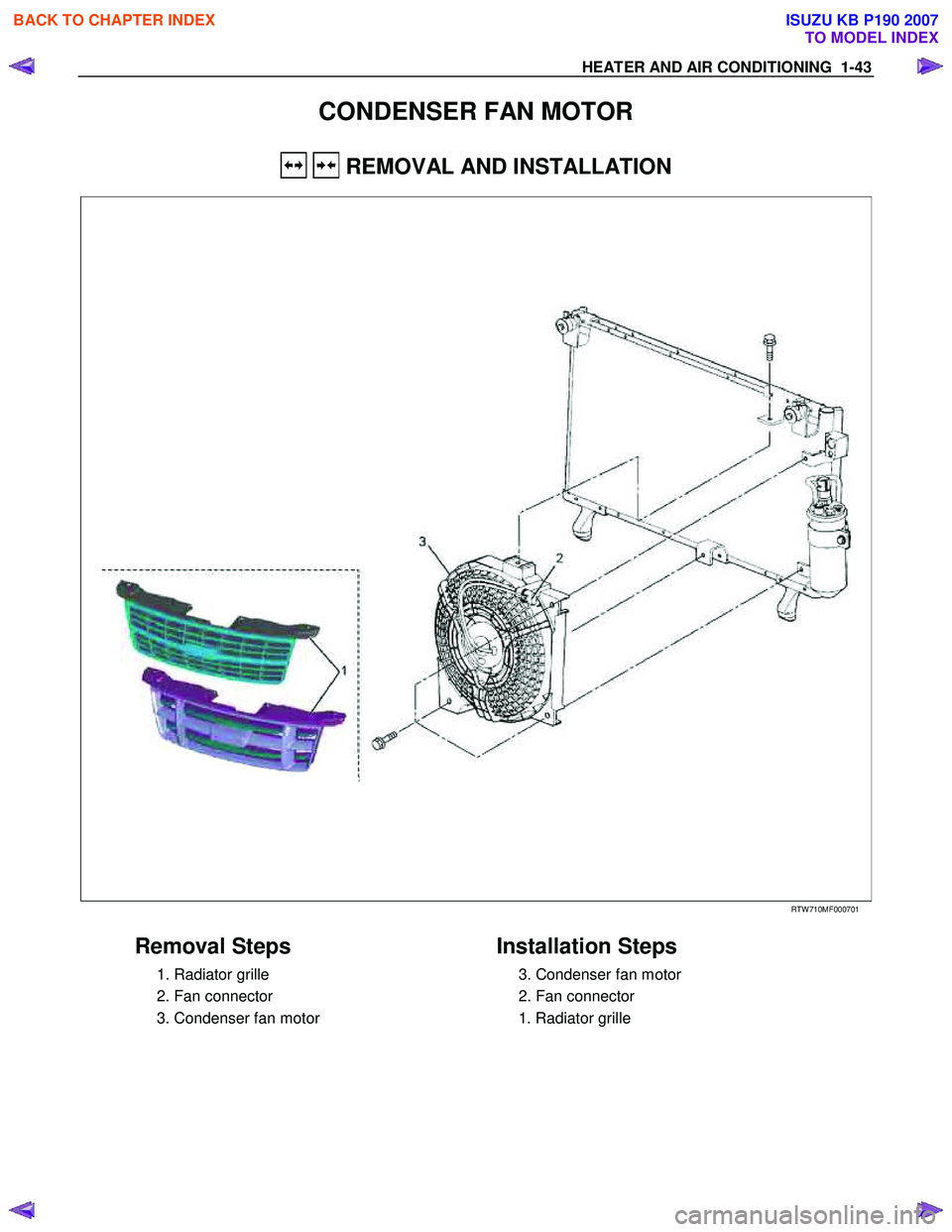

CONDENSER FAN MOTOR

REMOVAL AND INSTALLATION

RTW 710MF000701

Removal Steps

1. Radiator grille

2. Fan connector

3. Condenser fan motor

Installation Steps

3. Condenser fan motor

2. Fan connector

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 88 of 6020

1-54 HEATER AND AIR CONDITIONING

OIL RETURN OPERATION

There is close affinity between the oil and the refrigerant.

During normal operation, part of the oil recirculates with the

refrigerant in the system.

W hen checking the amount of oil in the system, or replacing

any component of the system, the compressor must be run in

advance for oil return operation. The procedure is as follows:

1) Open the all doors and engine hood.

2) Start the engine and A/C switch is "ON" and Set the fan control knob at its highest position.

3) Run the compressor for more than 20 minutes between 800 and 1,000 rpm in order to operate the system.

4) Stop the engine.

REPLACEMENT OF COMPONENT PARTS

W hen replacing system component parts, supply the following

amount of oil to the component parts to be installed.

Component parts to be installed Amount of oil

Evaporator 50 cm3 (1.41 lmp fl oz)

Condenser 30 cm3 (0.84 lmp fl oz)

Receiver/drier 30 cm3 (0.84 lmp fl oz)

Refrigerant line (One piece) 10 cm3 (0.28 lmp fl oz)

Refrigeration oil must be replenished if more than two parts

are removed at the same time. After installing these

components, check compressor oil.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 123 of 6020

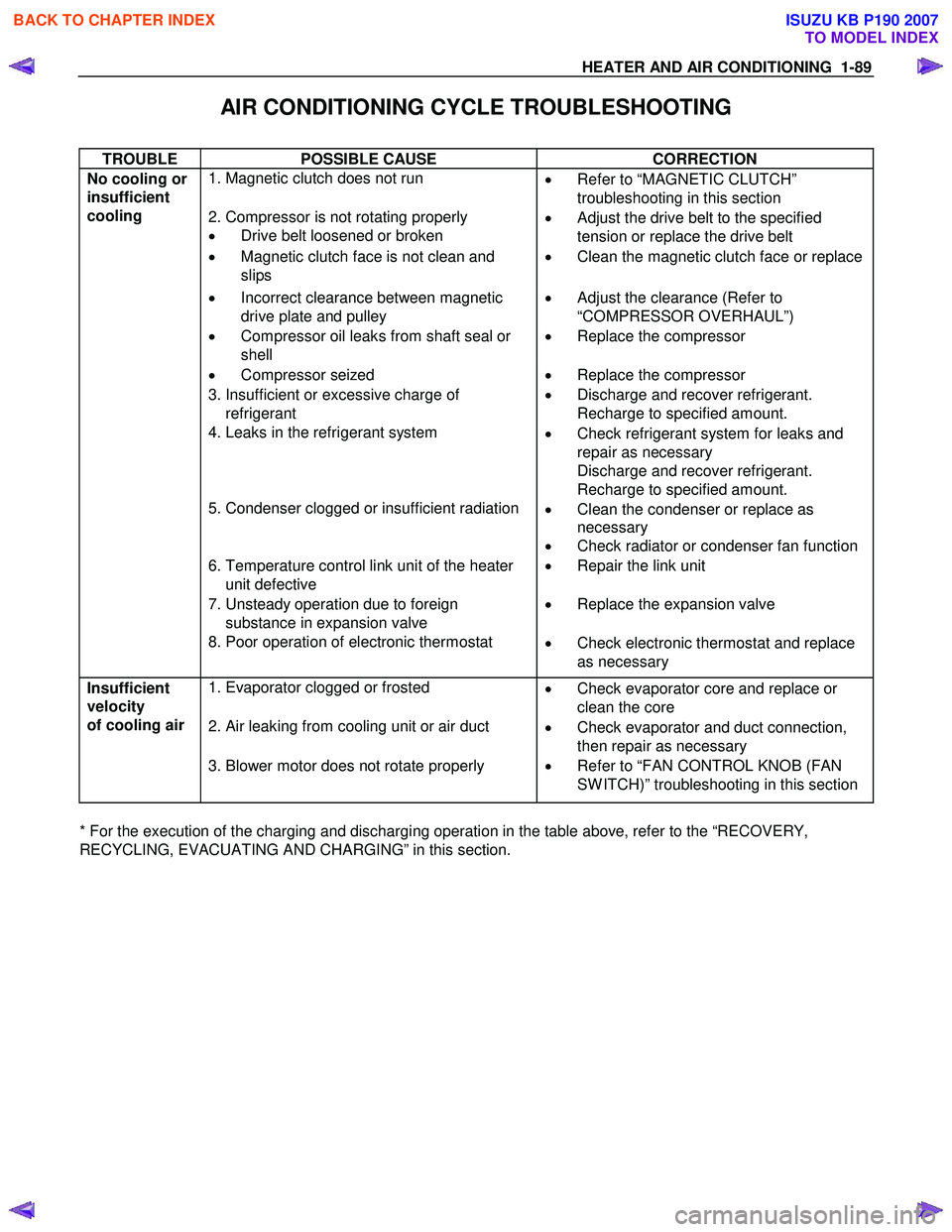

HEATER AND AIR CONDITIONING 1-89

AIR CONDITIONING CYCLE TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE CORRECTION

1. Magnetic clutch does not run

•

Refer to “MAGNETIC CLUTCH”

troubleshooting in this section

2. Compressor is not rotating properly

• Drive belt loosened or broken •

Adjust the drive belt to the specified

tension or replace the drive belt

• Magnetic clutch face is not clean and

slips •

Clean the magnetic clutch face or replace

• Incorrect clearance between magnetic

drive plate and pulley •

Adjust the clearance (Refer to

“COMPRESSOR OVERHAUL”)

• Compressor oil leaks from shaft seal or

shell •

Replace the compressor

• Compressor seized • Replace the compressor

3. Insufficient or excessive charge of

refrigerant •

Discharge and recover refrigerant.

Recharge to specified amount.

4. Leaks in the refrigerant system

•

Check refrigerant system for leaks and

repair as necessary

Discharge and recover refrigerant.

Recharge to specified amount.

5. Condenser clogged or insufficient radiation

•

Clean the condenser or replace as

necessary

• Check radiator or condenser fan function

6. Temperature control link unit of the heater

unit defective •

Repair the link unit

7. Unsteady operation due to foreign

substance in expansion valve •

Replace the expansion valve

No cooling or

insufficient

cooling

8. Poor operation of electronic thermostat

•

Check electronic thermostat and replace

as necessary

1. Evaporator clogged or frosted

•

Check evaporator core and replace or

clean the core

2. Air leaking from cooling unit or air duct

•

Check evaporator and duct connection,

then repair as necessary

Insufficient

velocity

of cooling air

3. Blower motor does not rotate properly

• Refer to “FAN CONTROL KNOB (FAN

SW ITCH)” troubleshooting in this section

* For the execution of the charging and discharging operation in the table above, refer to the “RECOVERY,

RECYCLING, EVACUATING AND CHARGING” in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 125 of 6020

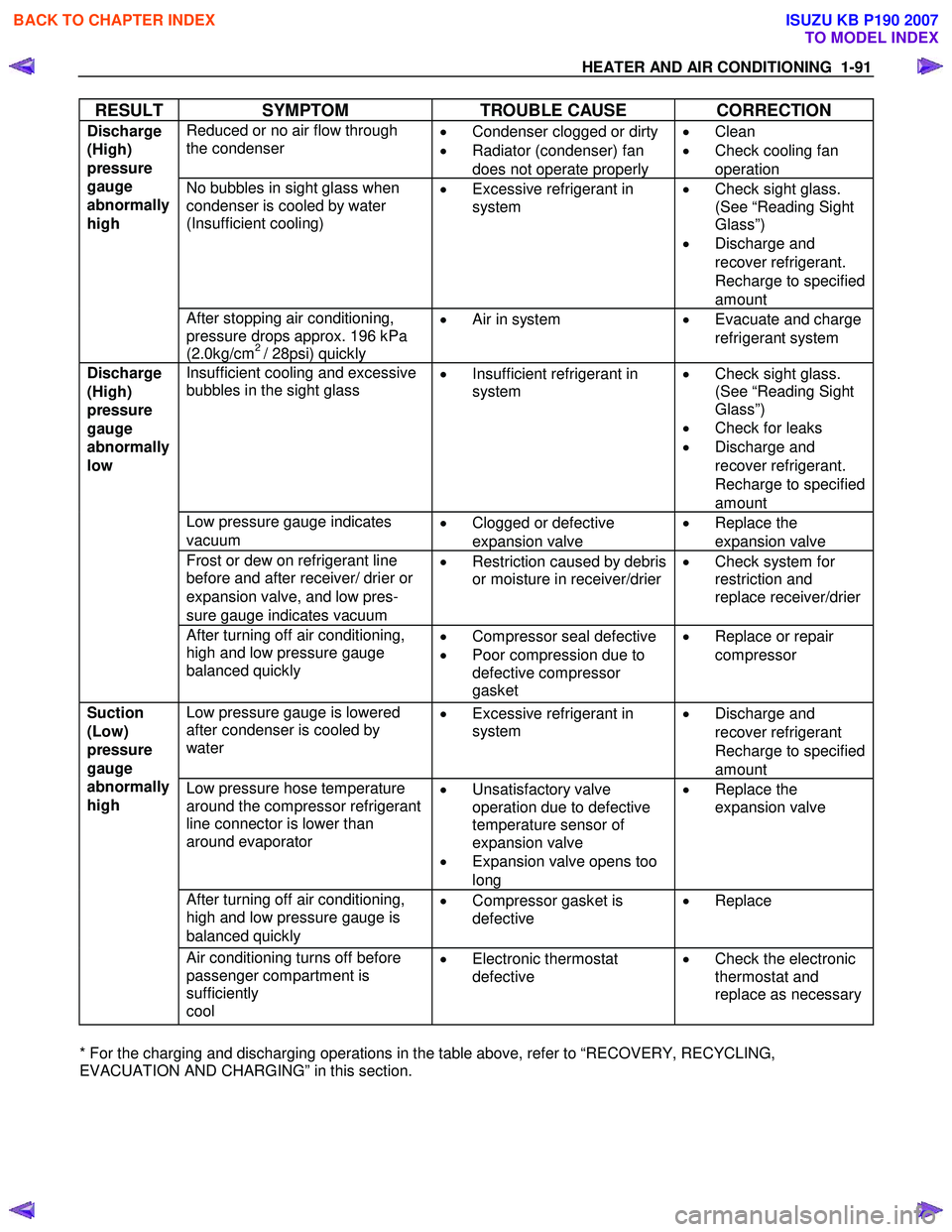

HEATER AND AIR CONDITIONING 1-91

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Reduced or no air flow through

the condenser

•

Condenser clogged or dirty

• Radiator (condenser) fan

does not operate properly •

Clean

• Check cooling fan

operation

No bubbles in sight glass when

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Discharge

(High)

pressure

gauge

abnormally

high

After stopping air conditioning,

pressure drops approx. 196 kPa

(2.0kg/cm

2 / 28psi) quickly •

Air in system

•

Evacuate and charge

refrigerant system

Insufficient cooling and excessive

bubbles in the sight glass

•

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Low pressure gauge indicates

vacuum •

Clogged or defective

expansion valve •

Replace the

expansion valve

Frost or dew on refrigerant line

before and after receiver/ drier or

expansion valve, and low pres-

sure gauge indicates vacuum •

Restriction caused by debris

or moisture in receiver/drier

•

Check system for

restriction and

replace receiver/drier

Discharge

(High)

pressure

gauge

abnormally

low

After turning off air conditioning,

high and low pressure gauge

balanced quickly

•

Compressor seal defective

• Poor compression due to

defective compressor

gasket •

Replace or repair

compressor

Low pressure gauge is lowered

after condenser is cooled by

water

•

Excessive refrigerant in

system

•

Discharge and

recover refrigerant

Recharge to specified

amount

Low pressure hose temperature

around the compressor refrigerant

line connector is lower than

around evaporator

•

Unsatisfactory valve

operation due to defective

temperature sensor of

expansion valve

• Expansion valve opens too

long •

Replace the

expansion valve

After turning off air conditioning,

high and low pressure gauge is

balanced quickly •

Compressor gasket is

defective

•

Replace

Suction

(Low)

pressure

gauge

abnormally

high

Air conditioning turns off before

passenger compartment is

sufficiently

cool •

Electronic thermostat

defective

•

Check the electronic

thermostat and

replace as necessary

* For the charging and discharging operations in the table above, refer to “RECOVERY, RECYCLING,

EVACUATION AND CHARGING” in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007