ECU ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5476 of 6020

8A-538 ELECTRICAL-BODY AND CHASSIS

TROUBLESHOOTING

Diagnostic procedure

•

Check the operation "Lock / unlock" by using

transmitter (remote key) on the vehicle.

• Check the operation "ON / OFF" for Driver side

door SW on the vehicle.

• Perform the Keyless entry System Check.

Diagnostic Aids

An intermittent may be caused by the following:

• Poor connections.

• Miss routed harness.

• Rubbed through wire insulation.

• Broken wire inside the insulation.

Check for the following conditions:

• Poor connection at keyless entry control unit-

Inspect harness connectors for backed out

terminals, improper mating, broken locks,

improperly formed or damaged terminals, and poo

r

terminal to wire connection.

• Damaged harness-Inspect the wiring harness fo

r

damage.

Check the Electro-Magnetic Interference (EMI)

• Location of vehicle check

Move the vehicle to a new location and perform

the check again.

• Non-OEM Parts.

Switch is “OFF” or remove the Non-OEM parts and

perform the check again.

• Other

Remove the accessory and another key from key.

Check the other items.

• Battery voltage is low.

• Keyless entry programming functions.

• Registration for security code.

• Ignition switch operation.

• Meter system is malfunction.

Check the operation

Check the operation "Lock / unlock" by using

transmitter (remote key) on the vehicle.

Notice

If so equipped the Anti Theft, Refer to ANTI

THEFT SYSTEM in 11B Section.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5478 of 6020

8A-540 ELECTRICAL-BODY AND CHASSIS

ID Code not yet programmed

Step Action Value (s) Yes No

1 W as the Keyless entry System Check performed?

— Go to Step 2 Go to

Keyless

entry

System Check

2 Check the key. Is a key peculiar to a vehicle? — Go to Step 3 Refer to

Diagnostic Aids

3 Check the Keyless entry programming functions.

• All transmitters (Remote Key).

If a problem is found, reprogramming as necessary.

(Refer to “ID code new registration”)

W as the action complete? — Go to Step 4 Go to ID code

new registration

4 Check the operation "Lock / unlock" by using transmitter (Remote key) on the vehicle.

W as the problem found? — Go to Step 5 Verify repair

5

Recheck the following condition.

1. Non-OEM parts switch is “OFF” or remove the Non-OEM parts.

2. Move the vehicle to a new location.

3. Check the operation "Lock / unlock" by using transmitter (Remote key) on the vehicle.

W as the problem found? — Go to Step 6 Verify repair

6 Replace the Keyless entry control unit (KCU).

IMPORTANT: The replacement KCU must be

programmed the security code.

W as the problem found? — Go to Step 7 Verify repair

7 Replace the key and lock cylinder assembly with

Keyless entry system (KCU ).

IMPORTANT:

• KCU is not replacing simultaneously.

• After replace lock cylinders, perform the following

below the items.

• Replace the keys and key cylinders.

• Program the Keyless entry system.

(Refer to “ID code new registration”)

W as the action complete? — Verify repair —

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5479 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-541

No Remote Key Programmed

Step Action Value (s) Yes No

1 W as the Keyless entry System Check performed?

— Go to Step 2 Go to

keyless

entry

System Check

2 Check the key. Is a key peculiar to a vehicle? — Go to Step 3 Refer to

Diagnostic Aids

3 Check the keyless entry programming functions.

• Transmitter (Remote Key).

W as a problem found? — Go to Step 4 Go to Step 5

4 Perform the keyless entry programming functions.

• Transmitter (Remote Key).

(Refer to “ID code new registration”)

W as the action complete? — Go to Step 5 —

5 Replace the transmitter (Remote Key).

IMPORTANT: The replacement transmitter (Remote

Key) must be programmed the ID code.

W as the action complete? — Verify repair —

Door Lock Actuators Short Circuit to Ground

Step Action Value (s) Yes No

1 W as the Keyless entry System Check performed?

— Go to Step 2 Go to

keyless

entry

System Check

2 Check the door lock actuators circuit.

1. Ignition key position is “OFF”.

2. Disconnect the keyless entry control unit (KCU).

3. Check the door lock actuator circuit for short to ground.

If the problem found, repair as necessary.

W as a problem found? — Verify repair Go to Step 3

3 Check the operation "Lock / unlock" by using

transmitter (Remote key) on the vehicle.

W as the problem found? — Go to Step 4 Verify repair

4 Check the door lock actuator.

If the problem found, repair as necessary.

W as a problem found? — Verify repair Go to Step 5

5 Replace the Keyless entry control unit (KCU).

IMPORTANT: The replacement KCU must be

programmed the security code.

W as the problem found? — Go to Step 7 Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5482 of 6020

8A-544 ELECTRICAL-BODY AND CHASSIS

Keyless Entry System

General Description

The system’s main features are summarized as follows.

・ Keyless entry with visual feedback

・ Highly secure encrypted transmission format

incorporating rolling code strategy

・ Field programmable remote keys

・ Door lock control

・ Illuminated entry with fade out

・ Illuminated exit

・ Remote door lock / ignition key interlock

・ Door ajar warning indicator in the cluster

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5515 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-577

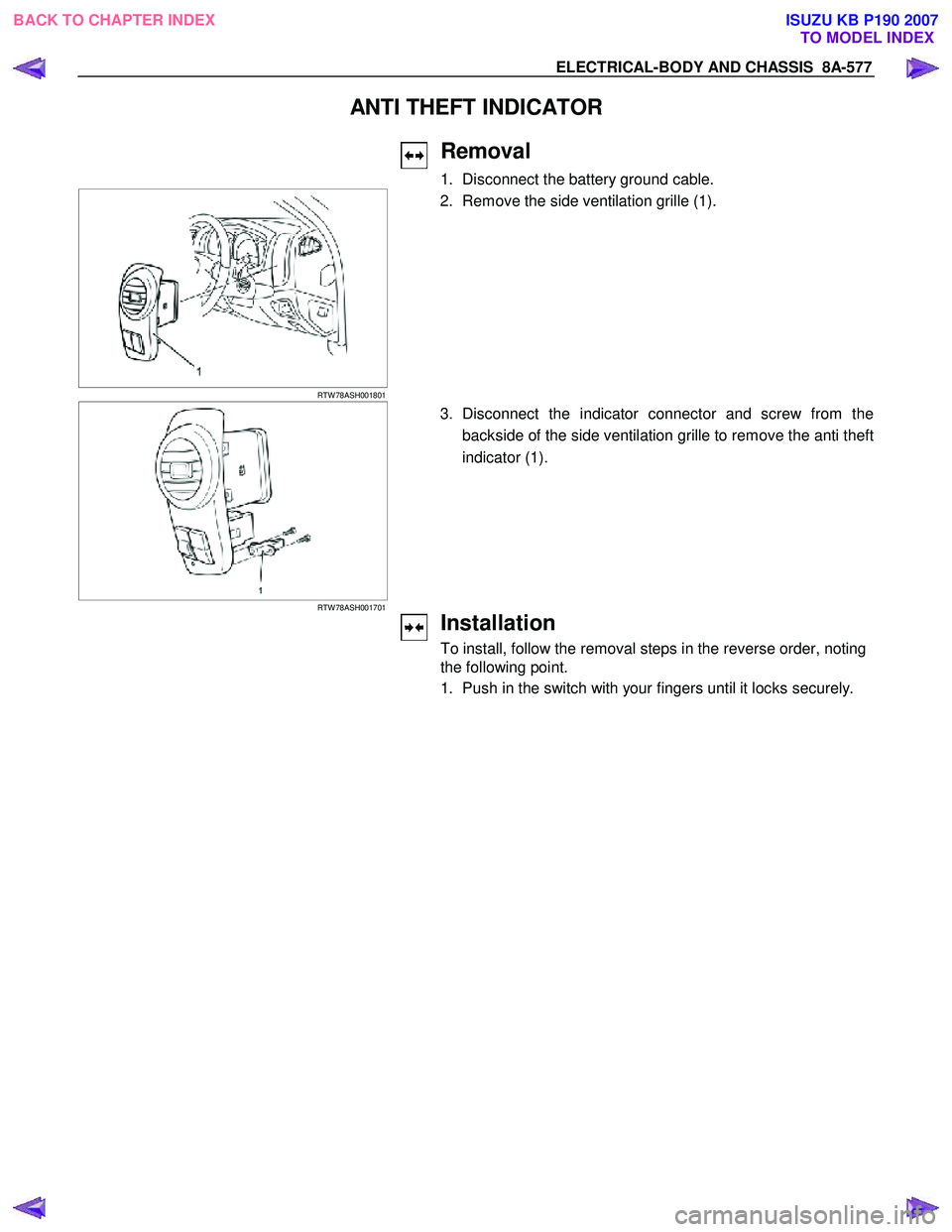

ANTI THEFT INDICATOR

Removal

1. Disconnect the battery ground cable.

RTW 78ASH001801

2. Remove the side ventilation grille (1).

RTW 78ASH001701

3. Disconnect the indicator connector and screw from the

backside of the side ventilation grille to remove the anti theft

indicator (1).

Installation

To install, follow the removal steps in the reverse order, noting

the following point.

1. Push in the switch with your fingers until it locks securely.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5518 of 6020

8A-580 ELECTRICAL-BODY AND CHASSIS

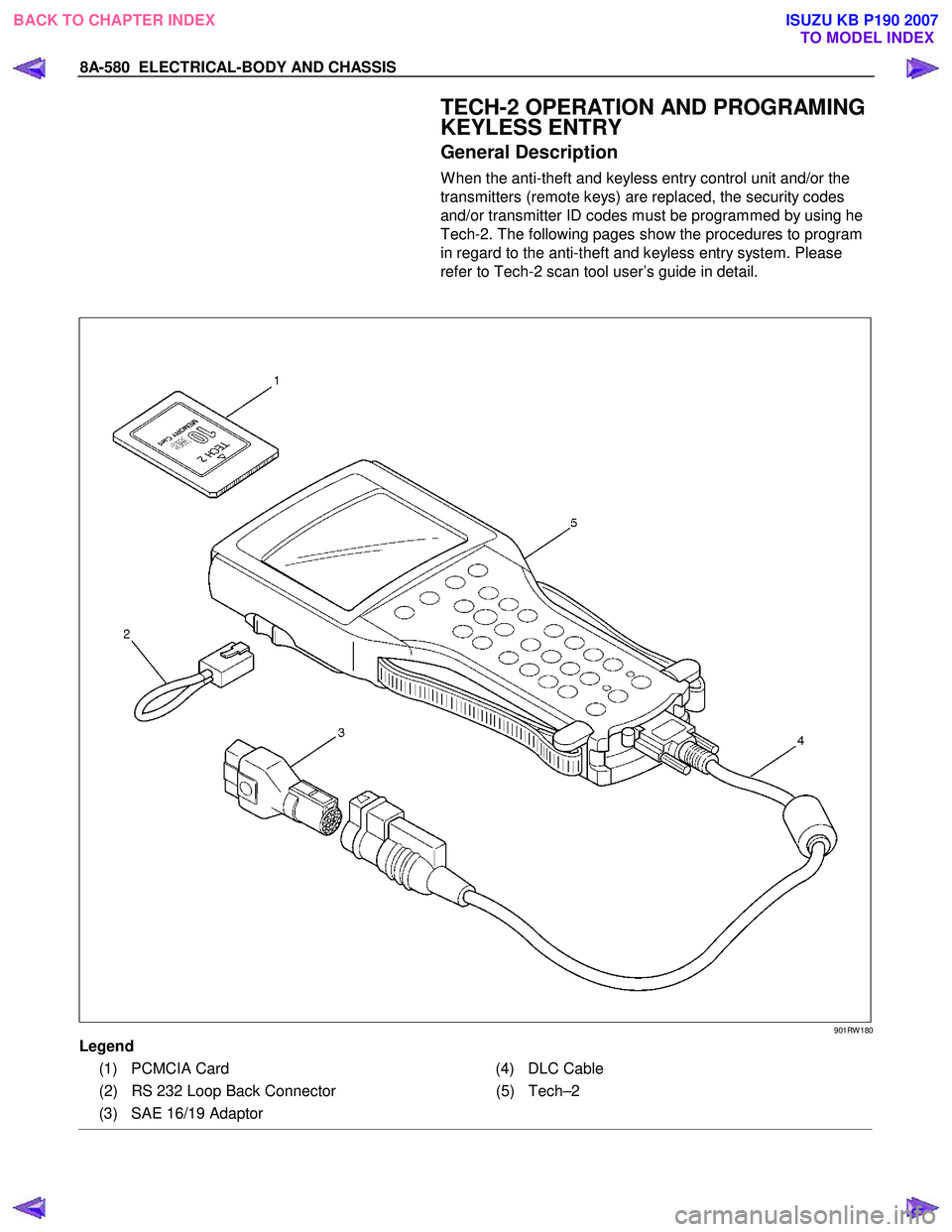

TECH-2 OPERATION AND PROGRAMING

KEYLESS ENTRY

General Description

W hen the anti-theft and keyless entry control unit and/or the

transmitters (remote keys) are replaced, the security codes

and/or transmitter ID codes must be programmed by using he

Tech-2. The following pages show the procedures to program

in regard to the anti-theft and keyless entry system. Please

refer to Tech-2 scan tool user’s guide in detail.

901RW 180

Legend

(1) PCMCIA Card (4) DLC Cable

(2) RS 232 Loop Back Connector (5)Tech–2

(3) SAE 16/19 Adaptor

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5522 of 6020

8A-584 ELECTRICAL-BODY AND CHASSIS

RTW 38DLH000101

Menu

The left table shows witch functions are used for the

available equipment versions.

NOTE: Marked items are not applied for keyless entry

system.

DTC

On OBD has three options available in the Tech-2

DTC mode to display the enhanced information

available.

• Read DTC Info Ordered By Priority.

• Read DTC Info As Stored By ECU.

• Clear DTC and Alarm Code Info.

Clear DTC Information

To clear Diagnostic Trouble Codes (DTCs), Use the

diagnostic scan tool “Clear DTC Information” function.

Tech-2 Data Display

The Tech-2 data values represent values that would

be seen on a normally-keyless entry system.

RTW 38DSH001601

Actuator Test

Unlock/Lock Test

Check whether opening and closing of a door lock

can be performed by operation of Tech-2.

1. Turn the key “OFF”.

2. Turn the key “ON”.

3. Check the display and test menu.

4. Operate the Tech-2.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5523 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-585

RTW 38DSH001701

Turn Signal Test

Check the turn signal lamp lights up by operation of

Tech-2.

1. Turn the key “OFF”.

2. Turn the key “ON”.

3. Check the display and test menu.

4. Operate the Tech-2.

060R200289

Programming

Erase Remove Key

To erase remove control key code in the control unit.

1. Check the display of Tech-2 and press “Confirm”

key.

RTW 38DSH001001

2. Enter security code.

3. Press “Not Okay” or “Okay” key.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5578 of 6020

8B-6 CRUISE CONTROL SYSTEM

Cruise Control Main Switch

Removal

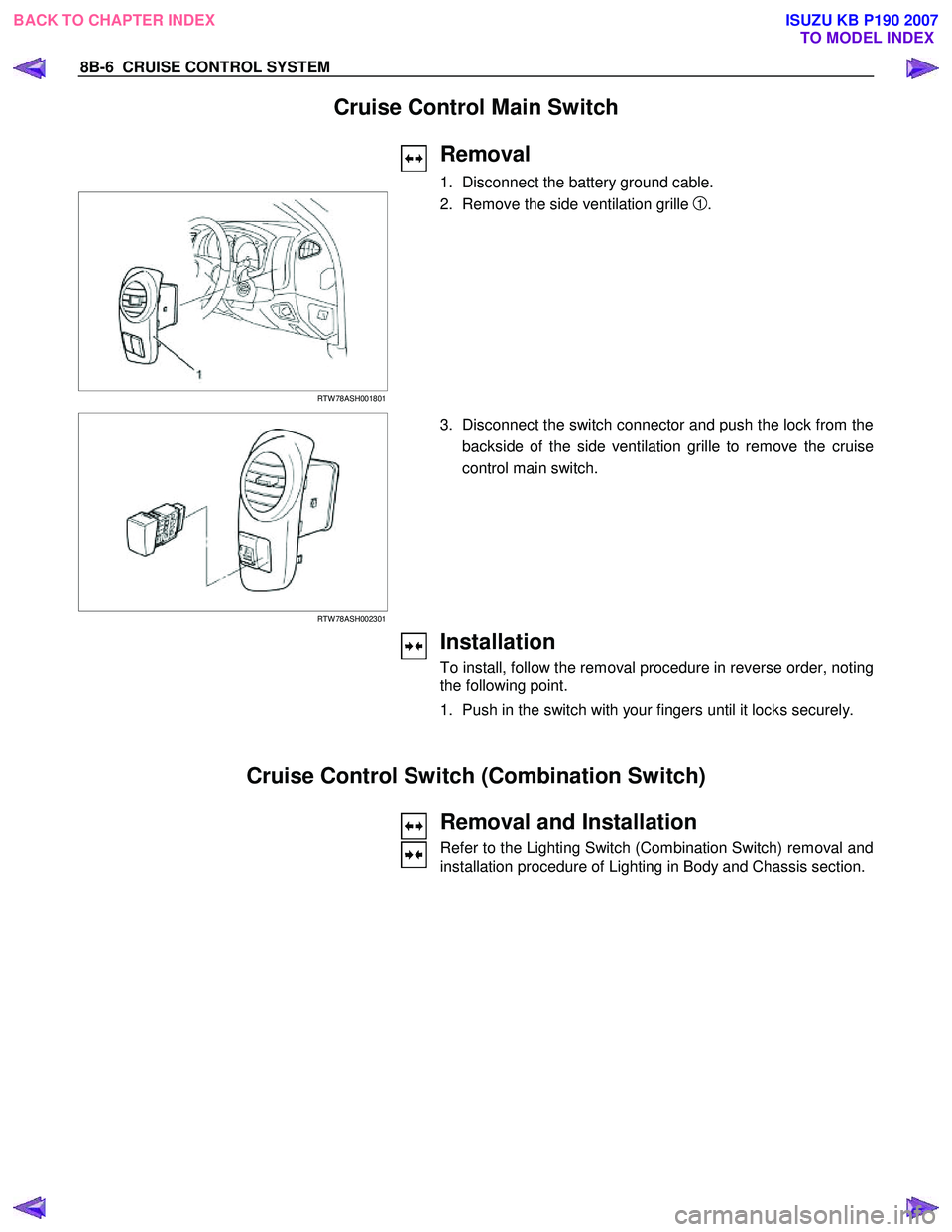

1. Disconnect the battery ground cable.

RTW 78ASH001801

2. Remove the side ventilation grille 1.

RTW 78ASH002301

3. Disconnect the switch connector and push the lock from the

backside of the side ventilation grille to remove the cruise

control main switch.

Installation

To install, follow the removal procedure in reverse order, noting

the following point.

1. Push in the switch with your fingers until it locks securely.

Cruise Control Switch (Combination Switch)

Removal and Installation

Refer to the Lighting Switch (Combination Switch) removal and

installation procedure of Lighting in Body and Chassis section.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5662 of 6020

SUPPLEMENTAL RESTRAINT SYSTEM 9A-27

5. Remove the passenger air bag assembly from the

vehicle. Refer to “Passenger Air Bag Assembl

y

Removal “.

6. Clear a space on the ground approximately 183 cm (six feet) in diameter where the fixture with

attached air bag assembly is to be placed fo

r

deployment. A paved outdoor location where there

is no activity is preferred. If an outdoor location is

not available, a space on the shop floor where

there is no activity and there is sufficient ventilation

is recommended. Ensure that no loose o

r

flammable objects are within the deployment area.

7. Place the 5-8840-2420-0 on the bench vise. This is necessary to provide sufficient stabilization o

f

the fixture during deployment.

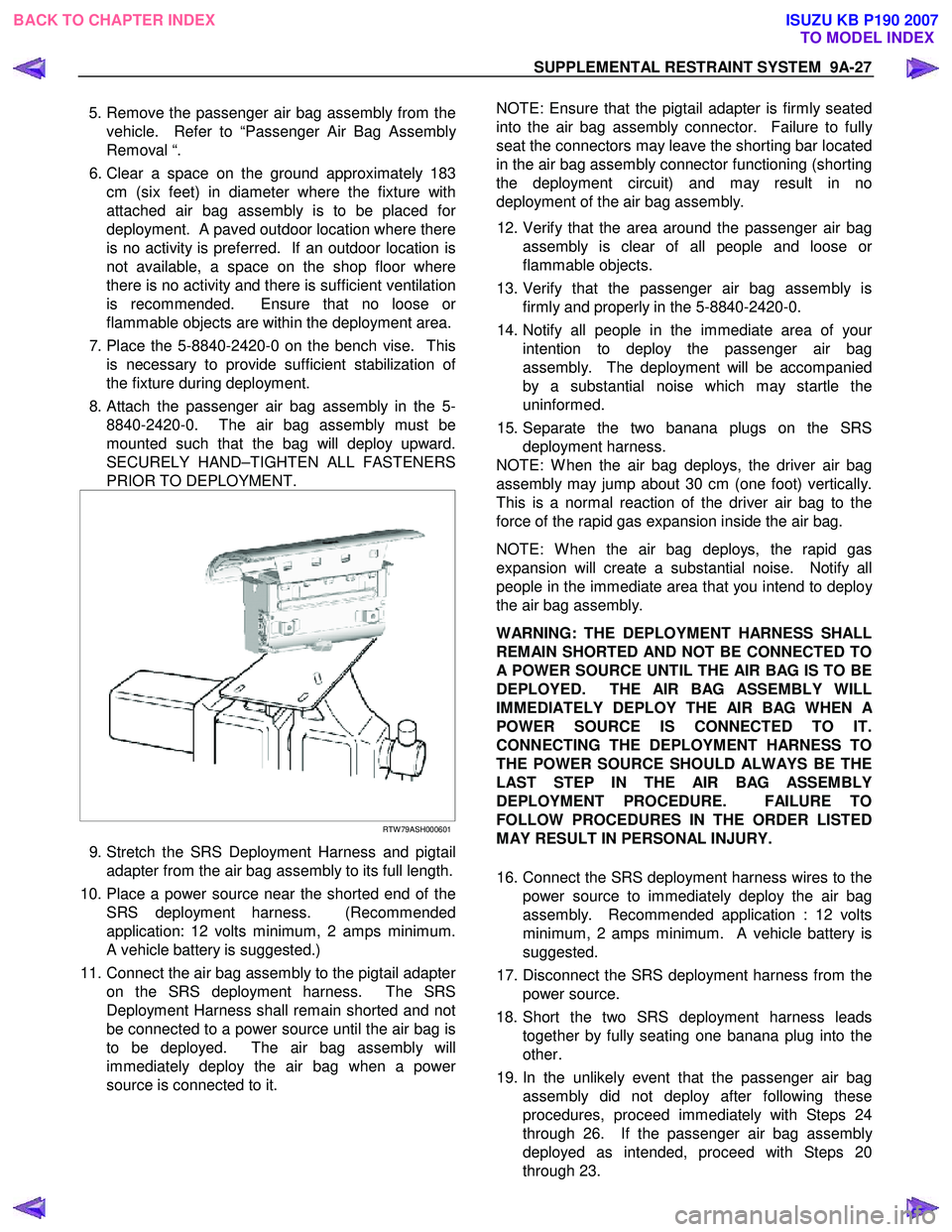

8. Attach the passenger air bag assembly in the 5- 8840-2420-0. The air bag assembly must be

mounted such that the bag will deploy upward.

SECURELY HAND–TIGHTEN ALL FASTENERS

PRIOR TO DEPLOYMENT.

RTW 79ASH000601

9. Stretch the SRS Deployment Harness and pigtail

adapter from the air bag assembly to its full length.

10. Place a power source near the shorted end of the SRS deployment harness. (Recommended

application: 12 volts minimum, 2 amps minimum.

A vehicle battery is suggested.)

11. Connect the air bag assembly to the pigtail adapte

r

on the SRS deployment harness. The SRS

Deployment Harness shall remain shorted and not

be connected to a power source until the air bag is

to be deployed. The air bag assembly will

immediately deploy the air bag when a powe

r

source is connected to it.

NOTE: Ensure that the pigtail adapter is firmly seated

into the air bag assembly connector. Failure to full

y

seat the connectors may leave the shorting bar located

in the air bag assembly connector functioning (shorting

the deployment circuit) and may result in no

deployment of the air bag assembly.

12. Verify that the area around the passenger air bag assembly is clear of all people and loose o

r

flammable objects.

13. Verify that the passenger air bag assembly is firmly and properly in the 5-8840-2420-0.

14. Notify all people in the immediate area of you

r

intention to deploy the passenger air bag

assembly. The deployment will be accompanied

by a substantial noise which may startle the

uninformed.

15. Separate the two banana plugs on the SRS deployment harness.

NOTE: W hen the air bag deploys, the driver air bag

assembly may jump about 30 cm (one foot) vertically.

This is a normal reaction of the driver air bag to the

force of the rapid gas expansion inside the air bag.

NOTE: W hen the air bag deploys, the rapid gas

expansion will create a substantial noise. Notify all

people in the immediate area that you intend to deplo

y

the air bag assembly.

WARNING: THE DEPLOYMENT HARNESS SHALL

REMAIN SHORTED AND NOT BE CONNECTED TO

A POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED. THE AIR BAG ASSEMBLY WILL

IMMEDIATELY DEPLOY THE AIR BAG WHEN

A

POWER SOURCE IS CONNECTED TO IT.

CONNECTING THE DEPLOYMENT HARNESS TO

THE POWER SOURCE SHOULD ALWAYS BE THE

LAST STEP IN THE AIR BAG ASSEMBLY

DEPLOYMENT PROCEDURE. FAILURE TO

FOLLOW PROCEDURES IN THE ORDER LISTED

MAY RESULT IN PERSONAL INJURY.

16. Connect the SRS deployment harness wires to the power source to immediately deploy the air bag

assembly. Recommended application : 12 volts

minimum, 2 amps minimum. A vehicle battery is

suggested.

17. Disconnect the SRS deployment harness from the power source.

18. Short the two SRS deployment harness leads together by fully seating one banana plug into the

other.

19. In the unlikely event that the passenger air bag assembly did not deploy after following these

procedures, proceed immediately with Steps 24

through 26. If the passenger air bag assembl

y

deployed as intended, proceed with Steps 20

through 23.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007