ECU ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4426 of 6020

7A2-142 TRANSMISSION CONTROL SYSTEM (JR405E)

• Select Programming Process - Identifywhether as existing TCM is being

reprogrammed or an TCM is being replaced

with a new one.

• Select ECU Location - Vehicle

4. Complete all vehicle data on the Preparing for Communication/ Determine Vehicle screen until

“Next” is highlighted, then click “Next”.

5. Follow the instruction on the Preparing for Communication screen, then click “Next”.

Notice: In order to reduce the potential for signal loss,

the RS-232 cable should not be more than 25 feet long.

6. Verify the VIN on the Validate Vehicle Identification Number (VIN) screen, then click “Next”.

Notice: If the TCM is replaced to new one, VIN does

not displayed. Input correct VIN reading from stamped

VIN or affixed VIN plate on the vehicle. If the TCM from

another vehicle is installed, input correct VIN by same

way.

7. Highlight Transmission on the Select System Type screen, then click “Next”, if on-screen instruction

displayed.

8. Complete the following information based on the service ID plate on the Validate Vehicle Data

screen until “Next” is highlighted, then click “Next”.

• Model

• Model year

• Engine type

• Model designator

• Destination code

• Transmission type

9. Verify your selection on the Summary screen.

Notice: Refer to Service Bulletin and Description

column before service programming is performed if the

bulletins are listed along with the calibration files.

Notice: Select Cancel if you receive a message stating

that the calibration selected is already the current

calibration in the TCM and reprogramming with the

same download is not allowed.

10. Click “Reprog”.

11. The Transfer Data screen will appear until the progress bar reaches 100%.

Notice: Some warning lamp may turn ON or blink while

programming the TCM since communication between

the TCM and other modules are interrupted. Clear DTC

in any module after programming.

12. Close the application and return to the TIS application selection screen after the download is

completed.

13. Turn OFF the ignition.

14. Turn OFF the scan tool and disconnect from the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4442 of 6020

7A2-158 TRANSMISSION CONTROL SYSTEM (JR405E)

The TCM controls the torque converter clutch (TCC)

solenoid valve based on the accelerator pedal angle,

input shaft speed, output shaft speed and transmission

fluid temperature.

Smooth lock up control is employed to engage or

disengage the TCC smoothly at the time of lock up On

or Off. When the TCM determines the TCC

engagement, the solenoid valve control duty cycle

(pulse width modulation [PWM]) signal is gradually

increased (5% to 95%) and the transmission fluid

between the TCC piston and torque converter front

cover is gradually drained. As a result, the TCC piston

is fitted slowly to the torque converter front cover under

fluid pressure securing smooth lock up engagement. The lock up control does not start when the

transmission fluid temperature is less than 20 °C (68 °F)

even though the vehicle is at the lock up control speed

area. The lock up control disengages when the

accelerator pedal angle is released.

Direct Electronic Shift Control (DECS)

Legend 1. Oil pump

2. Pressure regulator spool valve

3. ON/ OFF type solenoid valve (pressure control [PC]

solenoid valve 4. Duty cycle type solenoid valve (shift solenoid valve)

5. Amplifier (AMP) valve

6. Clutch

Solenoid valve outputs

Pressure control (PC) solenoid valve

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

TCM

Sensor inputsInput shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Low & reverse brake transmission fluid

pressure (TFP) switch

2-4 brake transmission fluid pressure (TFP)

switch

High clutch transmission fluid pressure (TFP)

switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4459 of 6020

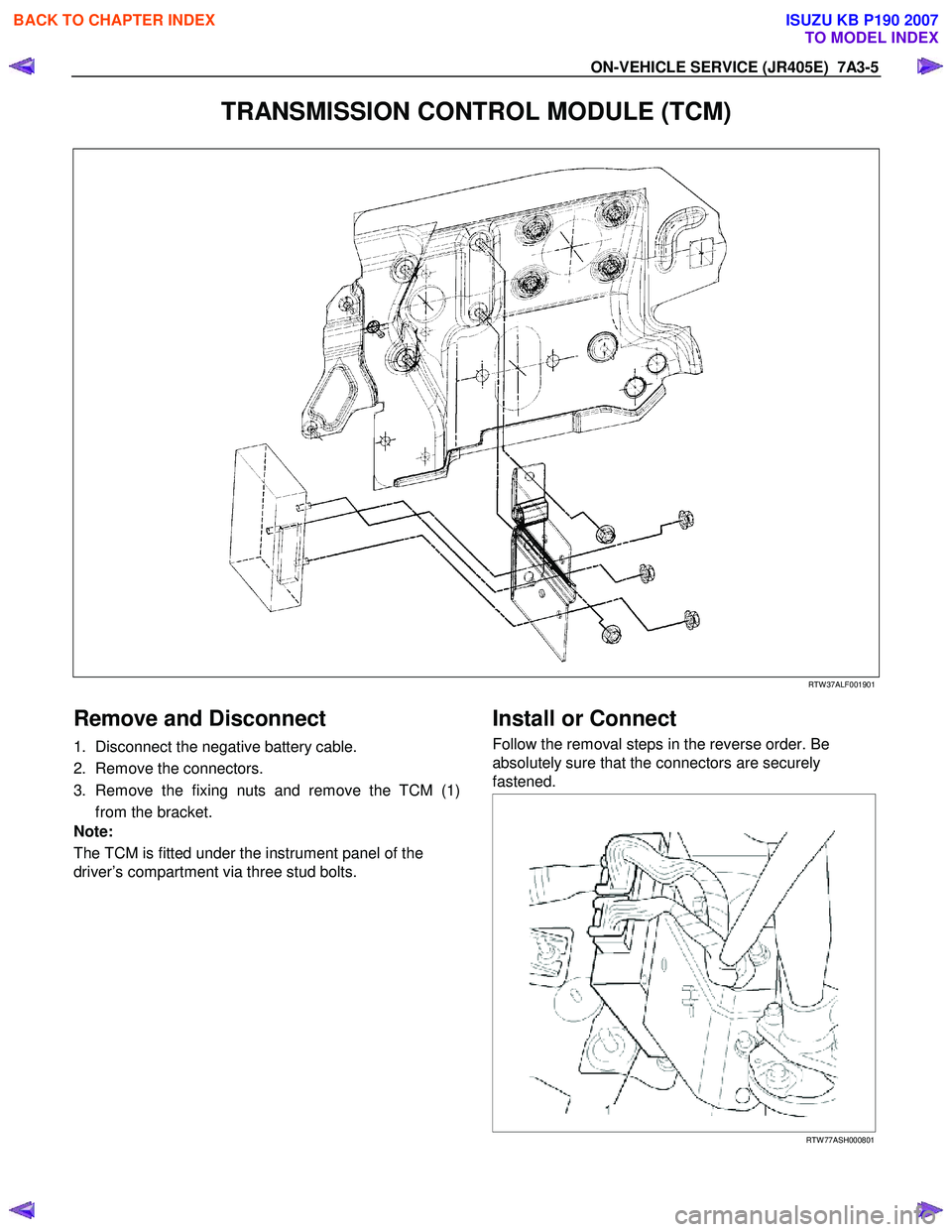

ON-VEHICLE SERVICE (JR405E) 7A3-5

TRANSMISSION CONTROL MODULE (TCM)

RTW 37ALF001901

Remove and Disconnect

1. Disconnect the negative battery cable.

2. Remove the connectors.

3. Remove the fixing nuts and remove the TCM (1) from the bracket.

Note:

The TCM is fitted under the instrument panel of the

driver’s compartment via three stud bolts.

Install or Connect

Follow the removal steps in the reverse order. Be

absolutely sure that the connectors are securely

fastened.

RTW 77ASH000801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4465 of 6020

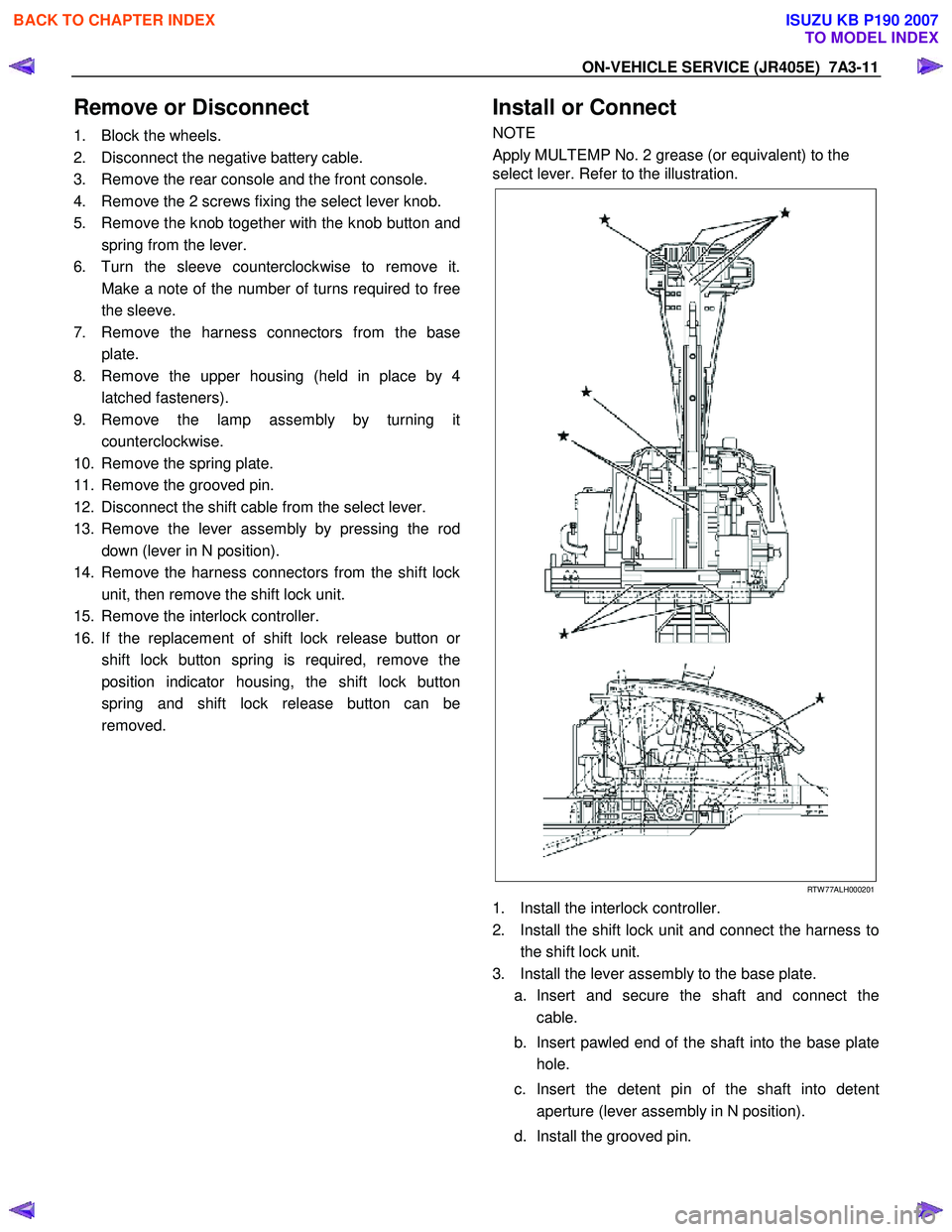

ON-VEHICLE SERVICE (JR405E) 7A3-11

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Remove the rear console and the front console.

4. Remove the 2 screws fixing the select lever knob.

5. Remove the knob together with the knob button and spring from the lever.

6. Turn the sleeve counterclockwise to remove it. Make a note of the number of turns required to free

the sleeve.

7. Remove the harness connectors from the base plate.

8. Remove the upper housing (held in place by 4 latched fasteners).

9. Remove the lamp assembly by turning it counterclockwise.

10. Remove the spring plate.

11. Remove the grooved pin.

12. Disconnect the shift cable from the select lever.

13. Remove the lever assembly by pressing the rod down (lever in N position).

14. Remove the harness connectors from the shift lock unit, then remove the shift lock unit.

15. Remove the interlock controller.

16. If the replacement of shift lock release button o

r

shift lock button spring is required, remove the

position indicator housing, the shift lock button

spring and shift lock release button can be

removed.

Install or Connect

NOTE

Apply MULTEMP No. 2 grease (or equivalent) to the

select lever. Refer to the illustration.

RTW 77ALH000201

1. Install the interlock controller.

2. Install the shift lock unit and connect the harness to the shift lock unit.

3. Install the lever assembly to the base plate. a. Insert and secure the shaft and connect the cable.

b. Insert pawled end of the shaft into the base plate hole.

c. Insert the detent pin of the shaft into detent aperture (lever assembly in N position).

d. Install the grooved pin.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4466 of 6020

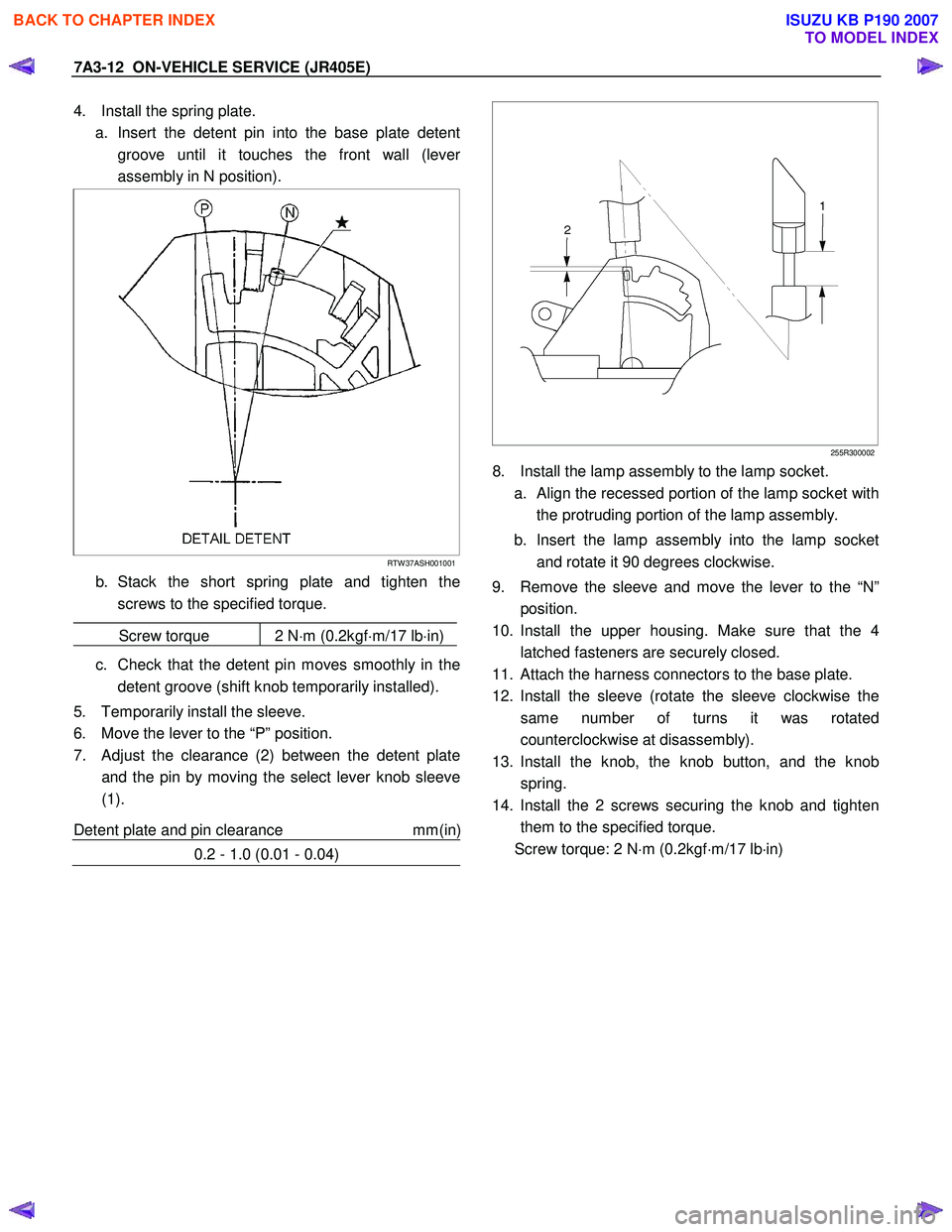

7A3-12 ON-VEHICLE SERVICE (JR405E)

4. Install the spring plate.

a. Insert the detent pin into the base plate detent groove until it touches the front wall (leve

r

assembly in N position).

RTW 37ASH001001

b. Stack the short spring plate and tighten thescrews to the specified torque.

Screw torque 2 N ⋅m (0.2kgf ⋅m/17 lb ⋅in)

c. Check that the detent pin moves smoothly in the

detent groove (shift knob temporarily installed).

5. Temporarily install the sleeve.

6. Move the lever to the “P” position.

7. Adjust the clearance (2) between the detent plate and the pin by moving the select lever knob sleeve

(1).

Detent plate and pin clearance mm(in

)

0.2 - 1.0 (0.01 - 0.04)

255R300002

8. Install the lamp assembly to the lamp socket.

a.

Align the recessed portion of the lamp socket with

the protruding portion of the lamp assembly.

b. Insert the lamp assembly into the lamp socket and rotate it 90 degrees clockwise.

9. Remove the sleeve and move the lever to the “N” position.

10. Install the upper housing. Make sure that the 4 latched fasteners are securely closed.

11. Attach the harness connectors to the base plate.

12. Install the sleeve (rotate the sleeve clockwise the same number of turns it was rotated

counterclockwise at disassembly).

13. Install the knob, the knob button, and the knob spring.

14. Install the 2 screws securing the knob and tighten them to the specified torque.

Screw torque: 2 N ⋅m (0.2kgf ⋅m/17 lb ⋅in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4468 of 6020

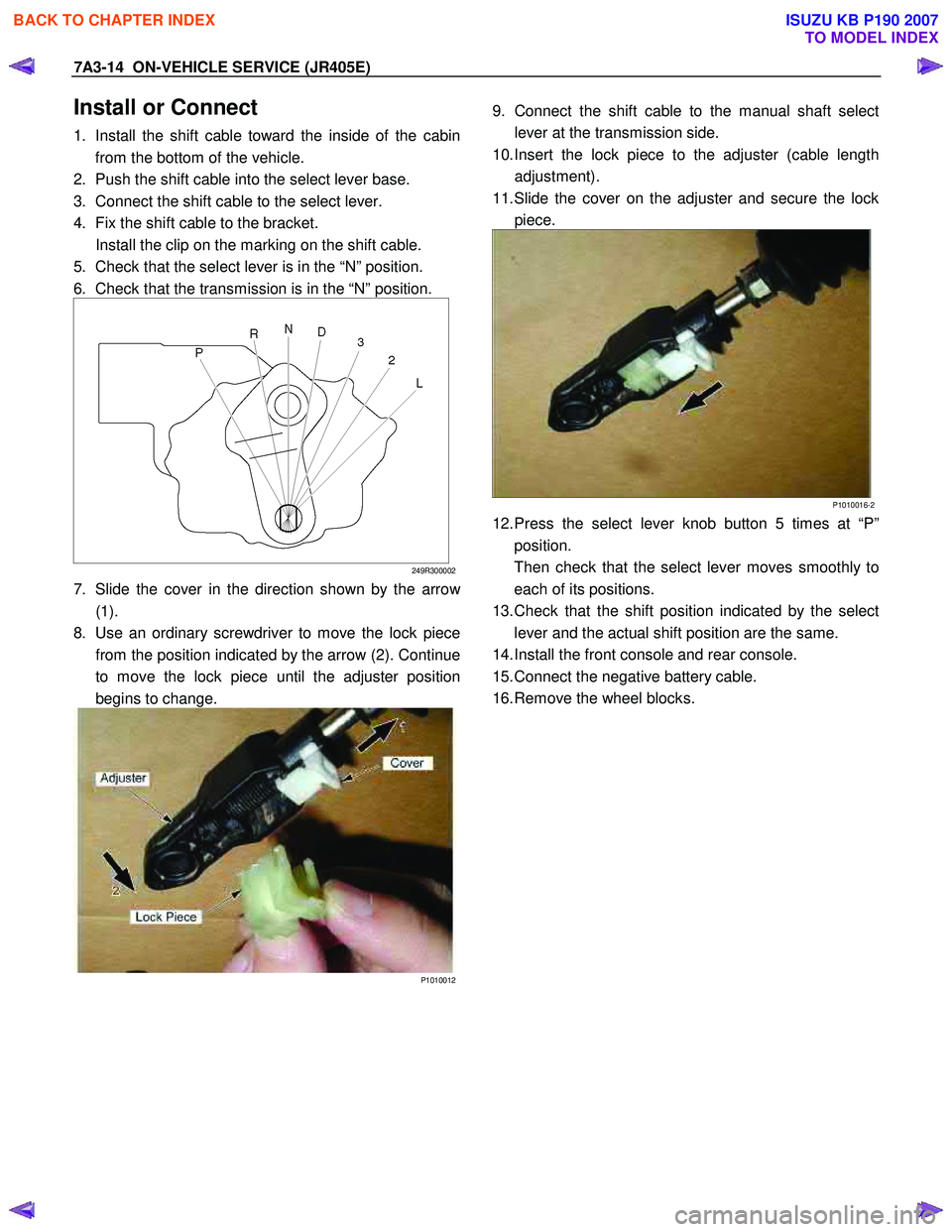

7A3-14 ON-VEHICLE SERVICE (JR405E)

Install or Connect

1. Install the shift cable toward the inside of the cabin

from the bottom of the vehicle.

2. Push the shift cable into the select lever base.

3. Connect the shift cable to the select lever.

4. Fix the shift cable to the bracket.

Install the clip on the marking on the shift cable.

5. Check that the select lever is in the “N” position.

6. Check that the transmission is in the “N” position.

249R300002

7. Slide the cover in the direction shown by the arrow

(1).

8. Use an ordinary screwdriver to move the lock piece from the position indicated by the arrow (2). Continue

to move the lock piece until the adjuster position

begins to change.

P1010012

9. Connect the shift cable to the manual shaft select

lever at the transmission side.

10. Insert the lock piece to the adjuster (cable length adjustment).

11. Slide the cover on the adjuster and secure the lock piece.

P1010016-2

12. Press the select lever knob button 5 times at “P”position.

Then check that the select lever moves smoothly to each of its positions.

13. Check that the shift position indicated by the select lever and the actual shift position are the same.

14. Install the front console and rear console.

15. Connect the negative battery cable.

16. Remove the wheel blocks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4475 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-21

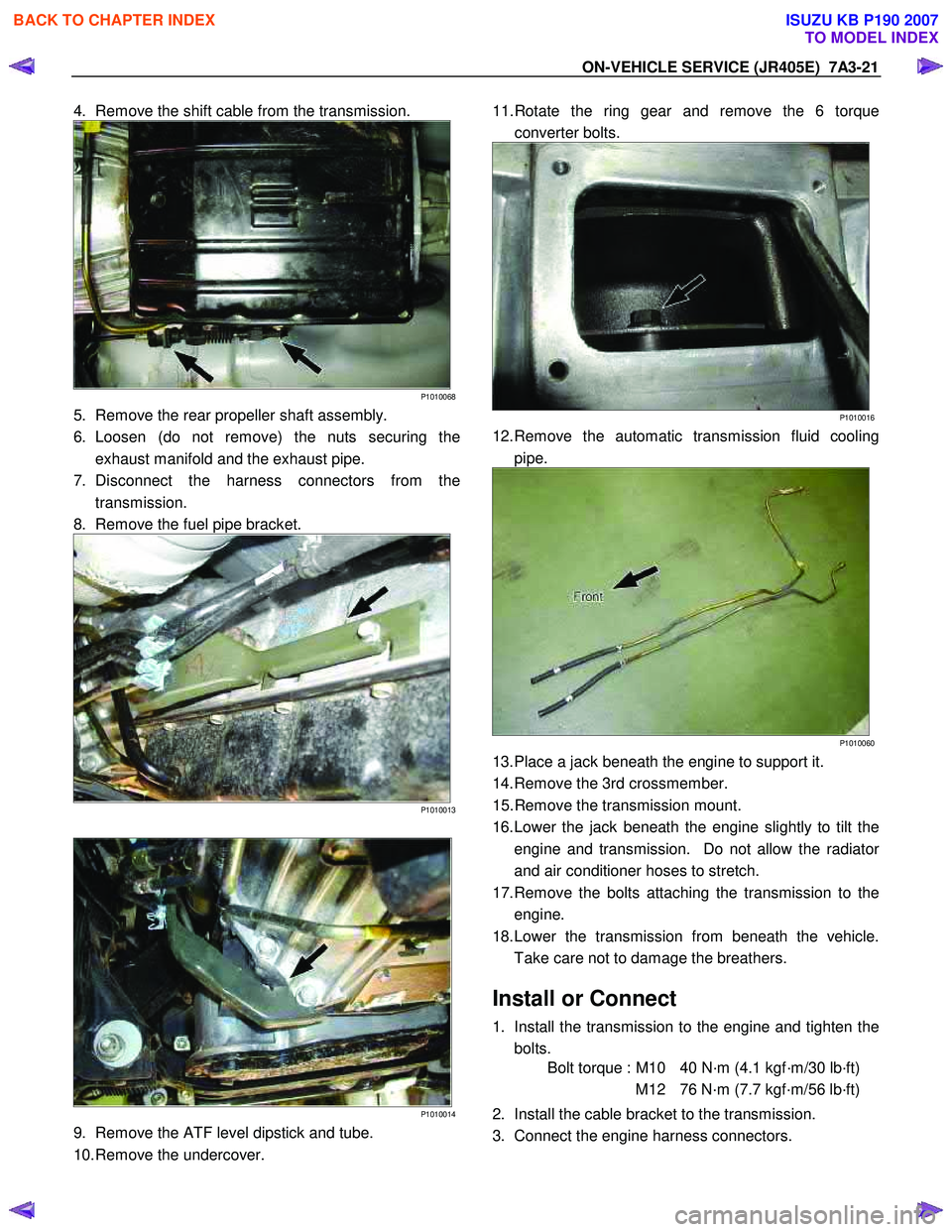

4. Remove the shift cable from the transmission.

P1010068

5. Remove the rear propeller shaft assembly.

6. Loosen (do not remove) the nuts securing the exhaust manifold and the exhaust pipe.

7. Disconnect the harness connectors from the transmission.

8. Remove the fuel pipe bracket.

P1010013

P1010014

9. Remove the ATF level dipstick and tube.

10. Remove the undercover.

11. Rotate the ring gear and remove the 6 torque

converter bolts.

P1010016

12. Remove the automatic transmission fluid cooling pipe.

P1010060

13. Place a jack beneath the engine to support it.

14. Remove the 3rd crossmember.

15. Remove the transmission mount.

16. Lower the jack beneath the engine slightly to tilt the engine and transmission. Do not allow the radiato

r

and air conditioner hoses to stretch.

17. Remove the bolts attaching the transmission to the engine.

18. Lower the transmission from beneath the vehicle. Take care not to damage the breathers.

Install or Connect

1. Install the transmission to the engine and tighten the bolts.

Bolt torque : M10 40 N·m (4.1 kgf·m/30 lb·ft)

M12 76 N·m (7.7 kgf·m/56 lb·ft)

2. Install the cable bracket to the transmission.

3. Connect the engine harness connectors.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4476 of 6020

7A3-22 ON-VEHICLE SERVICE (JR405E)

4. Install the transmission mount.

Bolt torque (rubber to transmission) :

50N·m (5.1 kgf·m/37 lb·ft)

Nut torque (rubber to crossmember) :

52N·m (5.3 kgf·m/38 lb·ft)

5. Install the 3rd crossmember.

Bolt and Nut torque : 67 N·m (6.8 kgf·m/49 lb·ft)

Bolt torque : 50 N·m (5.1 kgf·m/37 lb·ft)

6. Install the automatic transmission fluid cooling pipe.

7. Install the torque converter bolts.

Bolt torque : 29 N·m (3.0 kgf·m/22 lb·ft)

8. Install the undercover.

Bolt torque : 9 N·m (0.9 kgf·m/78 lb·in)

9. Install the ATF level dipstick and tube.

10. Install the fuel hose bracket.

Bolt torque : 10 N·m (1.0 kgf·m/87 lb·in)

11. Tighten the nuts securing the exhaust manifold and the exhaust pipe.

Bolt torque : 43 N·m (4.4 kgf·m/32 lb·ft)

12. Install the rear propeller shaft assembly.

Flange bolt torque : 59 N·m (6.0 kgf·m/43 lb·ft)

Center bearing bracket bolt torque :

69 N·m (7.0 kgf·m/51 lb·ft)

13. Install the shift cable.

14. Connect the negative battery cable.

15. Remove the safety stands.

16. Remove the wheels blocks.

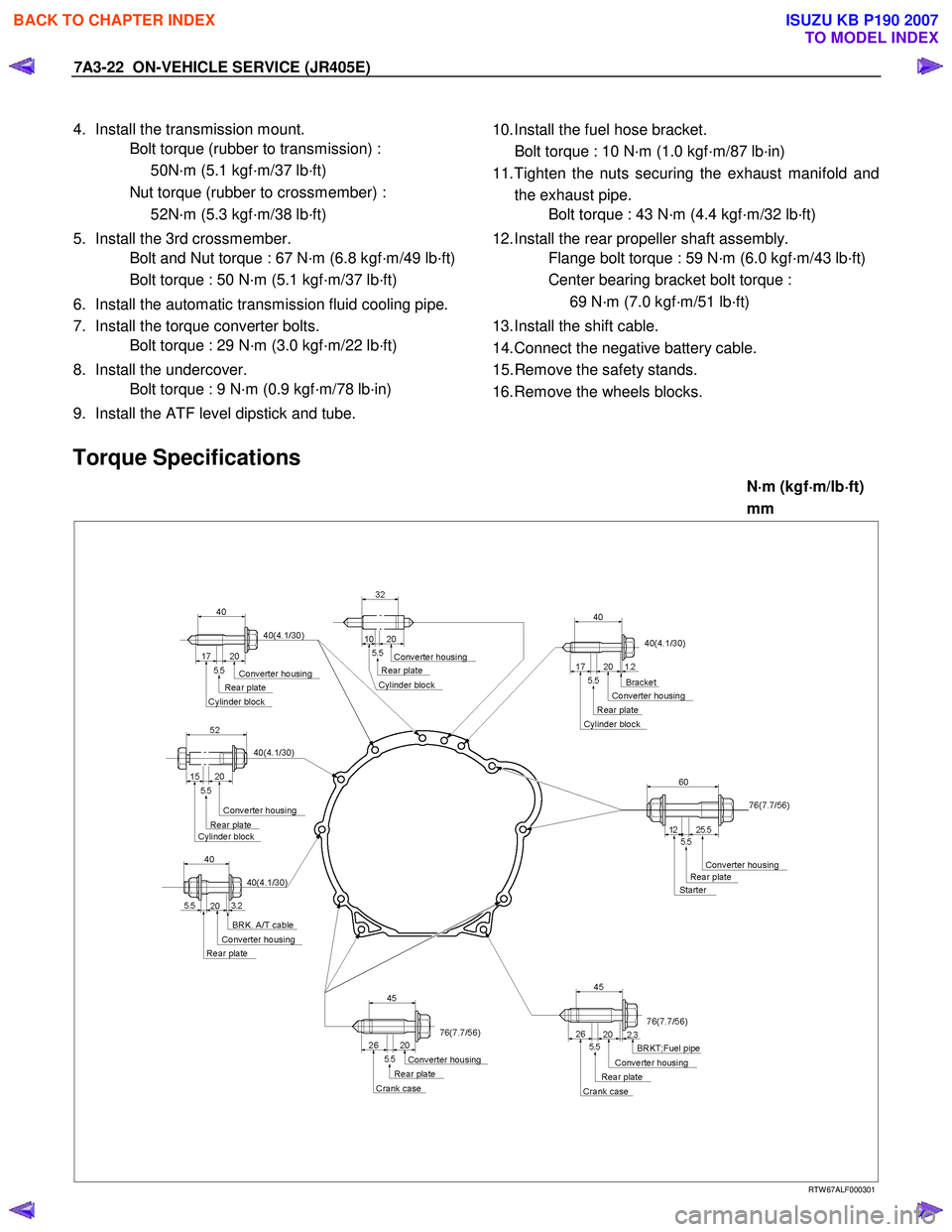

Torque Specifications

N ⋅

⋅⋅

⋅

m (kgf ⋅

⋅⋅

⋅

m/lb ⋅

⋅⋅

⋅

ft)

mm

RTW 67ALF000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4486 of 6020

UNIT REPAIR (JR405E) 7A4-9

29ASSY091

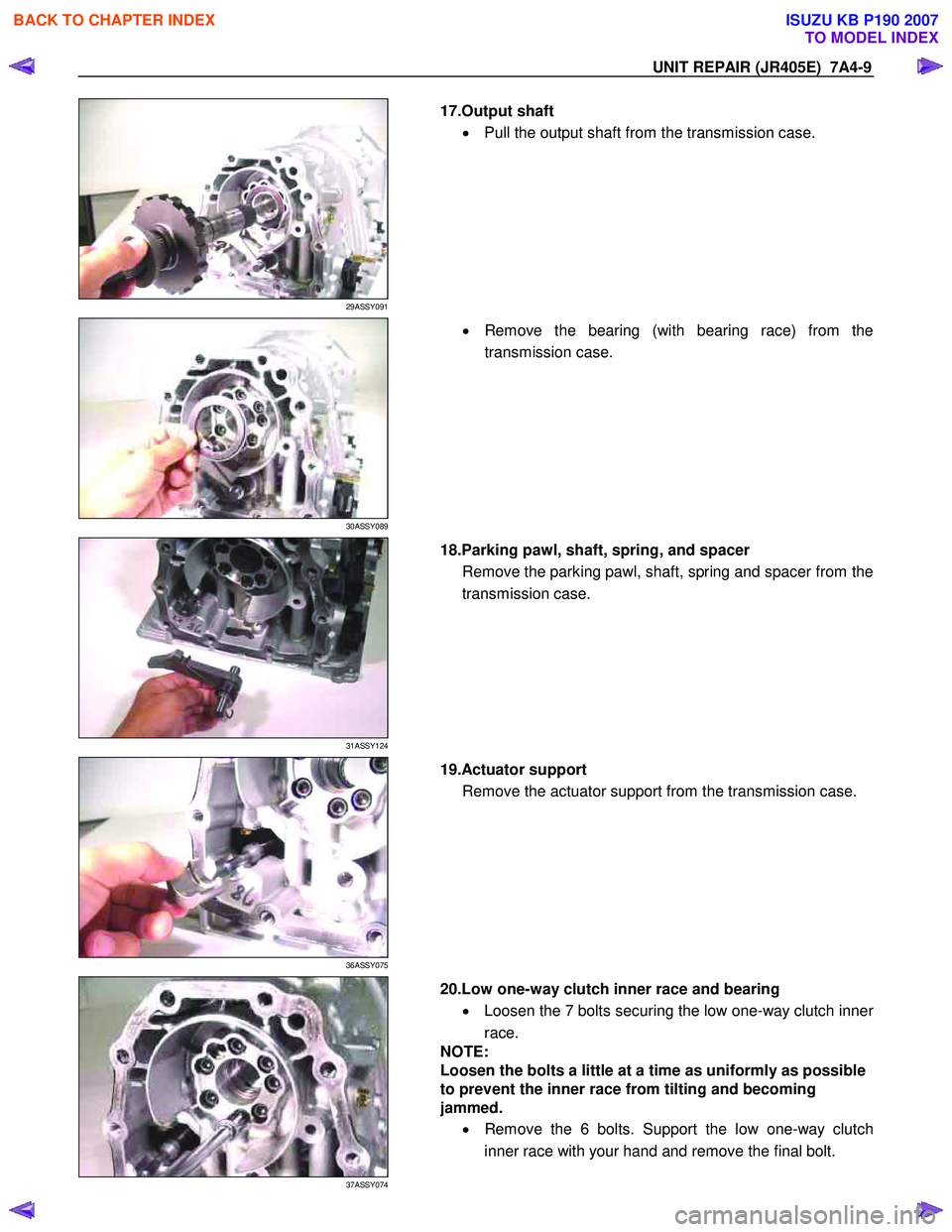

17.Output shaft

• Pull the output shaft from the transmission case.

30ASSY089

•

Remove the bearing (with bearing race) from the

transmission case.

31ASSY124

18.Parking pawl, shaft, spring, and spacer

Remove the parking pawl, shaft, spring and spacer from the

transmission case.

36ASSY075

19.Actuator support

Remove the actuator support from the transmission case.

37ASSY074

20.Low one-way clutch inner race and bearing

• Loosen the 7 bolts securing the low one-way clutch inne

r

race.

NOTE:

Loosen the bolts a little at a time as uniformly as possible

to prevent the inner race from tilting and becoming

jammed.

• Remove the 6 bolts. Support the low one-way clutch

inner race with your hand and remove the final bolt.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4489 of 6020

7A4-12 UNIT REPAIR (JR405E)

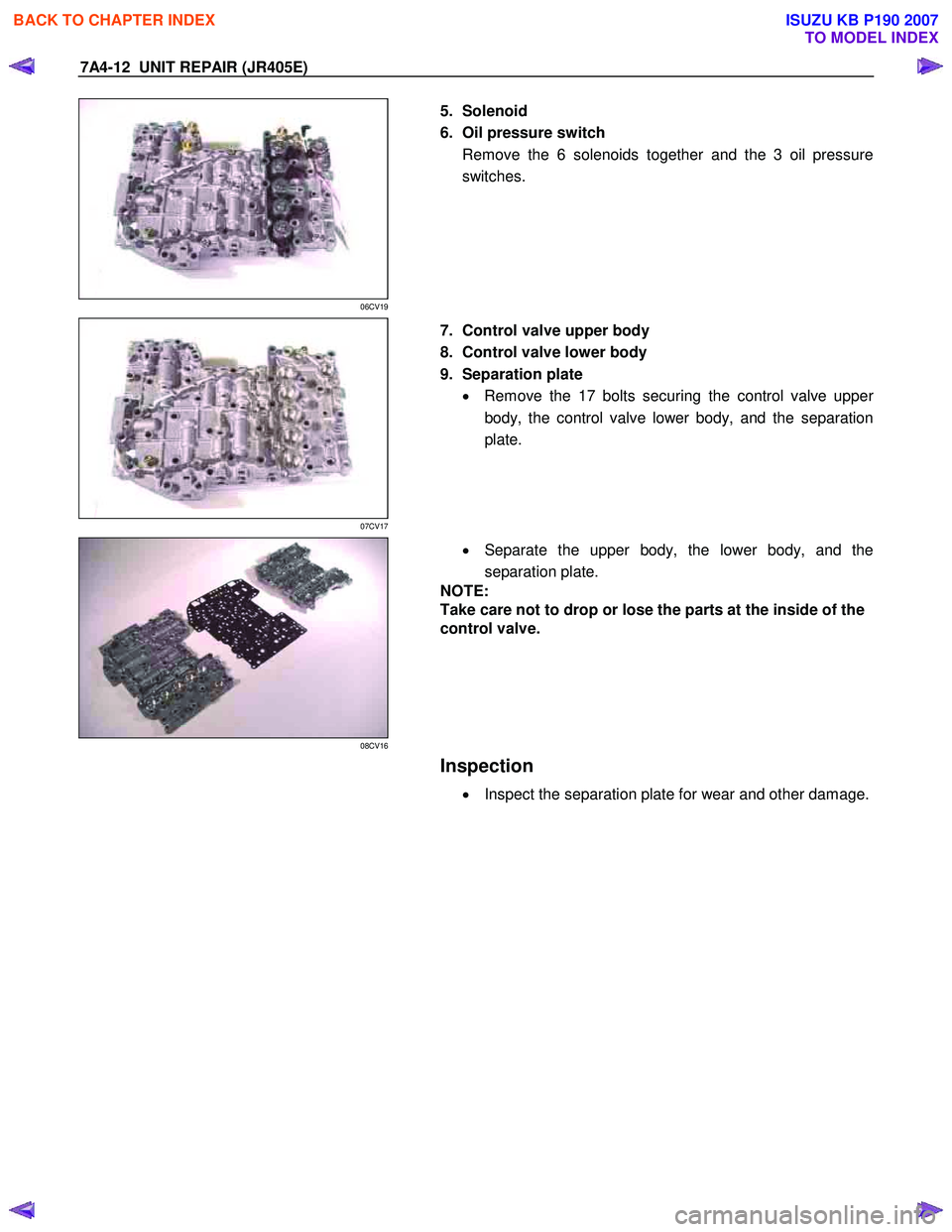

06CV19

5. Solenoid

6. Oil pressure switch Remove the 6 solenoids together and the 3 oil pressure

switches.

07CV17

7. Control valve upper body

8. Control valve lower body

9. Separation plate • Remove the 17 bolts securing the control valve uppe

r

body, the control valve lower body, and the separation

plate.

08CV16

•

Separate the upper body, the lower body, and the

separation plate.

NOTE:

Take care not to drop or lose the parts at the inside of the

control valve.

Inspection

•

Inspect the separation plate for wear and other damage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007