ECU ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5664 of 6020

SUPPLEMENTAL RESTRAINT SYSTEM 9A-29

5. Strip 13 mm (1/2 inch) of insulation from the yellow

– green and yellow – black wire lead of the

connector.

6. Cut two 900 cm (30 feet) deployment wires from 0.8 mm

2 (18 gauge) or thicker multi–strand wire.

These wires will be used to fabricate the drive

r

deployment harness.

7. Strip 13 mm (1/2 inch) of insulation from both ends of the wires cut in the previous step.

8. Short the wires by twisting together one end from each. Deployment wires shall remain shorted and

not be connected to a power source until the ai

r

bag is to be deployed.

WARNING: FAILURE TO FOLLOW PROCEDURES

IN THE ORDER LISTED COULD RESULT IN

PERSONAL INJURY. NEVER CONNECT

DEPLOYMENT WIRES TO ANY POWER SOURCE

BEFORE CONNECTING DEPLOYMENT WIRES TO

THE AIR BAG ASSEMBLY LEADS. DEPLOYMENT

WIRES SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE

AIR BAG IS TO BE DEPLOYED. THE AIR BAG

ASSEMBLY WILL IMMEDIATELY DEPLOY THE AIR

BAG WHEN A POWER SOURCE IS CONNECTED

TO IT. WEAR SAFETY GLASSES THROUGHOUT

THIS ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

9. Twist together one connector wire lead to one deployment wire. The connection should be

mechanically secure.

10. Bend the twisted connection made in the previous step flat and wrap it tightly with electrical tape to

insulate and secure.

11. Twist together, bend and tape the remaining connector wire lead to the remaining deployment

wire.

12. Connect the deployment harness to the driver ai

r

bag assembly yellow connector at the base of the

steering column. Route the deployment harness

out through the driver’s side of the vehicle.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO

A

POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A POWER SOURCE

IS CONNECTED TO IT.

Connecting the deployment wires to the powe

r

source should always be the final step in the ai

r

bag assembly deployment procedure.

Failure to follow procedures in the order listed

could result in personal injury.

13. Disconnect the passenger air bag assembly yello

w

connector located behind the glove box assembly.

14. Cut the passenger air bag assembly harness

connector from the vehicle leaving at least 15 cm

(six inches) of wire at the connector.

15. Strip 13 mm (1/2 inch) of insulation from the blue– white and pink–blue wire lead of the connector.

16. Cut two 900 cm (30 feet) deployment wires from 0.8 mm

2 (18 gauge) or thicker multi–strand wire.

These wires will be used to fabricate the

passenger deployment harness.

17. Strip 13 mm (1/2 inch) of insulation from both ends of the wires cut in the previous step.

18. Short the wires by twisting together one end from each. The deployment wires shall remain shorted

and not be connected to a power source until the

air bag is to be deployed.

WARNING: FAILURE TO FOLLOW PROCEDURES

IN THE ORDER LISTED COULD RESULT IN

PERSONAL INJURY. NEVER CONNECT

DEPLOYMENT WIRES TO ANY POWER SOURCE

BEFORE CONNECTING DEPLOYMENT WIRES TO

THE AIR BAG ASSEMBLY LEADS. DEPLOYMENT

WIRES SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE

AIR BAG IS TO BE DEPLOYED. THE AIR BAG

ASSEMBLY WILL IMMEDIATELY DEPLOY THE AIR

BAG WHEN A POWER SOURCE IS CONNECTED

TO IT. WEAR SAFETY GLASSES THROUGHOUT

THIS ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

19. Twist together one connector wire lead to one deployment wire. The connection should be

mechanically secure.

20. Bend the twisted connection made in the previous step flat and wrap it tightly with electrical tape to

insulate and secure.

21. Twist together, bend and tape the remaining connector wire lead to the remaining deployment

wire.

22. Connect the deployment harness to the passenge

r

air bag assembly yellow connector located behind

the glove box assembly. Route the deployment

harness out through the passenger side of the

vehicle.

WARNING: DEPLOYMENT WIRES SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO

A

POWER SOURCE UNTIL THE AIR BAG IS TO BE

DEPLOYED. THE AIR BAG ASSEMBLY WILL

IMMEDIATELY DEPLOY THE AIR BAG WHEN

A

POWER SOURCE IS CONNECTED TO IT.

CONNECTING THE DEPLOYMENT WIRES

SHOULD ALWAYS BE THE FINAL STEP IN THE

AIR BAG ASSEMBLY DEPLOYMENT PROCEDURE.

FAILURE TO FOLLOW PROCEDURES IN THE

ORDER LISTED COULD RESULT IN PERSONAL

INJURY.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5695 of 6020

RESTRAINT CONTROL SYSTEM 9A1-13

Chart B “SRS” warning lamp comes “ON” Steady

Step Action Yes No

1

1. W hen measurements are requested in this chart use a 5-

8840-0366-0DMM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch is at “LOCK”.

3. Connect the scan tool to the data link connector, following

directions as given in the scan tool instruction MANUAL.

4. Ignition switch is “ON”.

5. Request the SRS diagnostic trouble code display.

Does the scan tool indicate “No Data Received”? Go to Step 2 Go to Step 3

2

1. Ignition switch is at “LOCK”.

2. Inspect the SRS control unit harness connector connection to

the SRS control unit.

Is it securely connected to the SRS control unit? Ignition switch

“LOCK”.

Replace SRS control unit.

Go to Step 5 Connect SRS

control unit

securely to de–

activate shorting

clip in SRS control unit harness connector.

Go to Step 5

3 Using scan tool, request the SRS data list.

Is “ignition” more than 9 volts? Go to Step 4 Ignition switch

“LOCK”.

Replace SRS control unit.

Go to Step 5

4

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS coil and the passenger air bag assembly

yellow connector located at the base of the steering column

and behind the glove box assembly.

Disconnect the SRS control unit.

3. Disconnect the connector of the “SRS W arning Lamp” on the

instrument cluster.

4. Measure the resistance on the SRS control unit harness connector as follow.

�z From terminals "3" and "23" to ground (ground) (without

the pretensioner)

�z From terminals "3" and "15" to ground (ground) (with the

pretensioner and the passenger air bag)

�z From terminals "3", "12" and "15" to ground (with the

pretensioner and without the passenger air bag)

Does 5-8840-0366-0DMM display “OL” (Infinite)? Go to Chart A Replace SRS

harness.

Go to Step 5

5 Reconnect all SRS components and ensure all components are

properly mounted.

Is this step finished? Repeat the “SRS

Diagnostic System Check” —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5761 of 6020

CAB 10-3

RUW 5A0SH002901

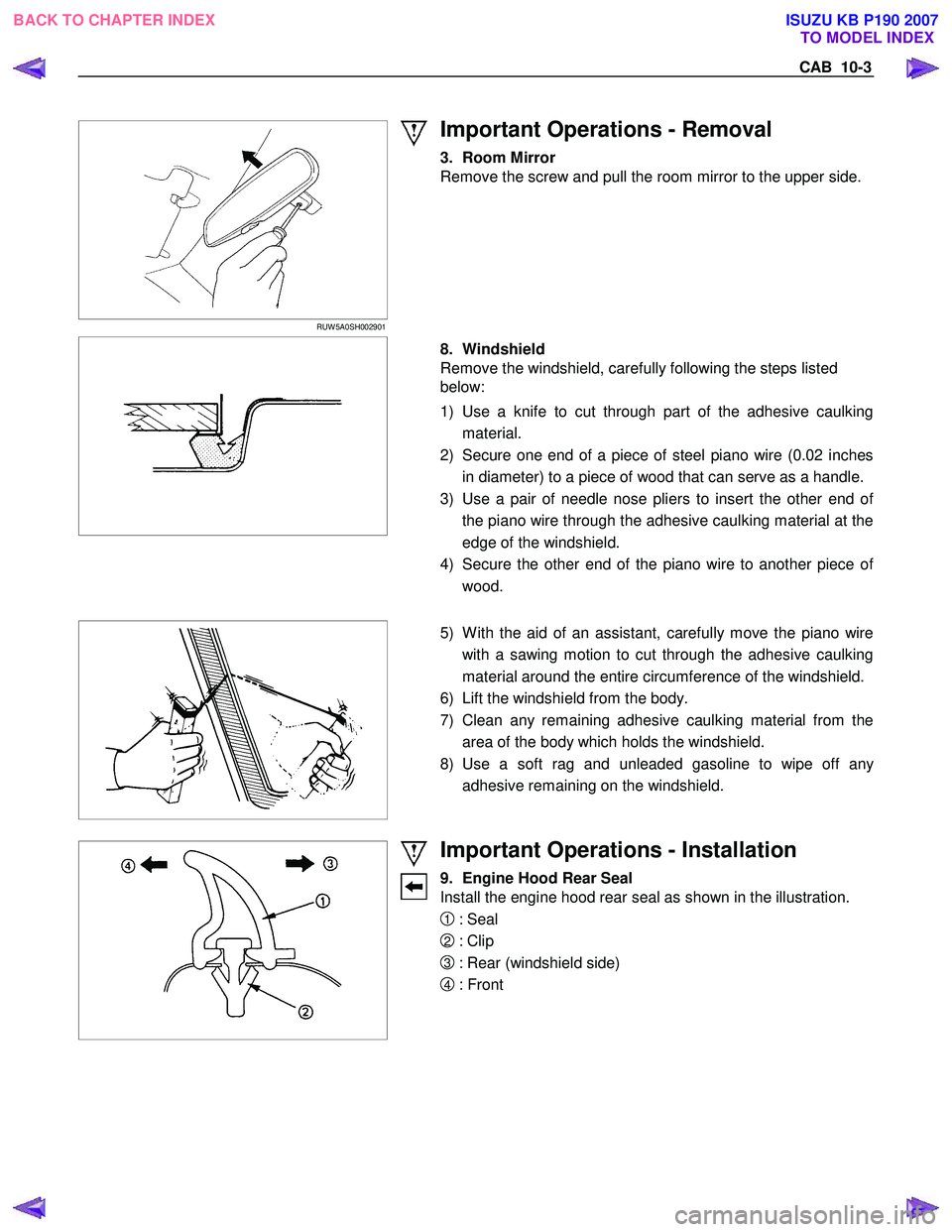

Important Operations - Removal

3. Room Mirror

Remove the screw and pull the room mirror to the upper side.

8. Windshield

Remove the windshield, carefully following the steps listed

below:

1) Use a knife to cut through part of the adhesive caulking material.

2) Secure one end of a piece of steel piano wire (0.02 inches in diameter) to a piece of wood that can serve as a handle.

3) Use a pair of needle nose pliers to insert the other end o

f

the piano wire through the adhesive caulking material at the

edge of the windshield.

4) Secure the other end of the piano wire to another piece o

f

wood.

5) W ith the aid of an assistant, carefully move the piano wire

with a sawing motion to cut through the adhesive caulking

material around the entire circumference of the windshield.

6) Lift the windshield from the body.

7) Clean any remaining adhesive caulking material from the area of the body which holds the windshield.

8) Use a soft rag and unleaded gasoline to wipe off an

y

adhesive remaining on the windshield.

Important Operations - Installation

9. Engine Hood Rear Seal

Install the engine hood rear seal as shown in the illustration.

1 : Seal

2 : Clip

3 : Rear (windshield side)

4 : Front

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5765 of 6020

CAB 10-7

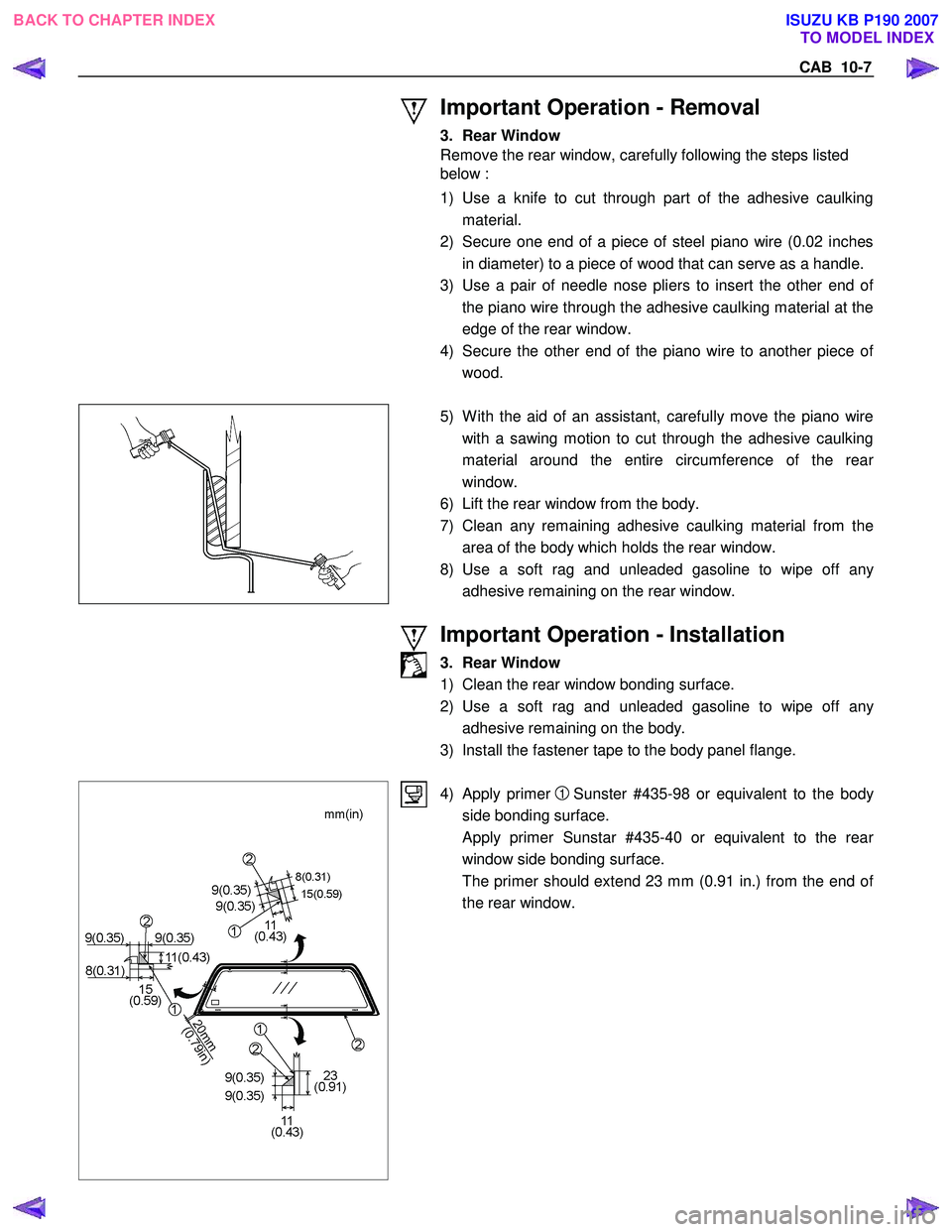

Important Operation - Removal

3. Rear Window

Remove the rear window, carefully following the steps listed

below :

1) Use a knife to cut through part of the adhesive caulking material.

2) Secure one end of a piece of steel piano wire (0.02 inches in diameter) to a piece of wood that can serve as a handle.

3) Use a pair of needle nose pliers to insert the other end o

f

the piano wire through the adhesive caulking material at the

edge of the rear window.

4) Secure the other end of the piano wire to another piece o

f

wood.

5) W ith the aid of an assistant, carefully move the piano wire

with a sawing motion to cut through the adhesive caulking

material around the entire circumference of the rea

r

window.

6) Lift the rear window from the body.

7) Clean any remaining adhesive caulking material from the area of the body which holds the rear window.

8) Use a soft rag and unleaded gasoline to wipe off an

y

adhesive remaining on the rear window.

Important Operation - Installation

3. Rear Window

1) Clean the rear window bonding surface.

2) Use a soft rag and unleaded gasoline to wipe off an

y

adhesive remaining on the body.

3) Install the fastener tape to the body panel flange.

4) Apply primer 1 Sunster #435-98 or equivalent to the body

side bonding surface.

Apply primer Sunstar #435-40 or equivalent to the rea

r

window side bonding surface.

The primer should extend 23 mm (0.91 in.) from the end o

f

the rear window.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5851 of 6020

Immobilizer Control System(4jk1/4jj1/hfv6)...................................................................5962 PAGE

Immobilizer System(C24se,4ja1-t)..................................................................................6010

S ection 11B Antitheft System.........................................................................................6066

SECTION 11

TA BLE OF CONTENTS

SECURITY

SECURITY 11-1

TO MODEL INDEX

BACK TO MAIN INDEX

ISUZU KB P190 2007

Page 5859 of 6020

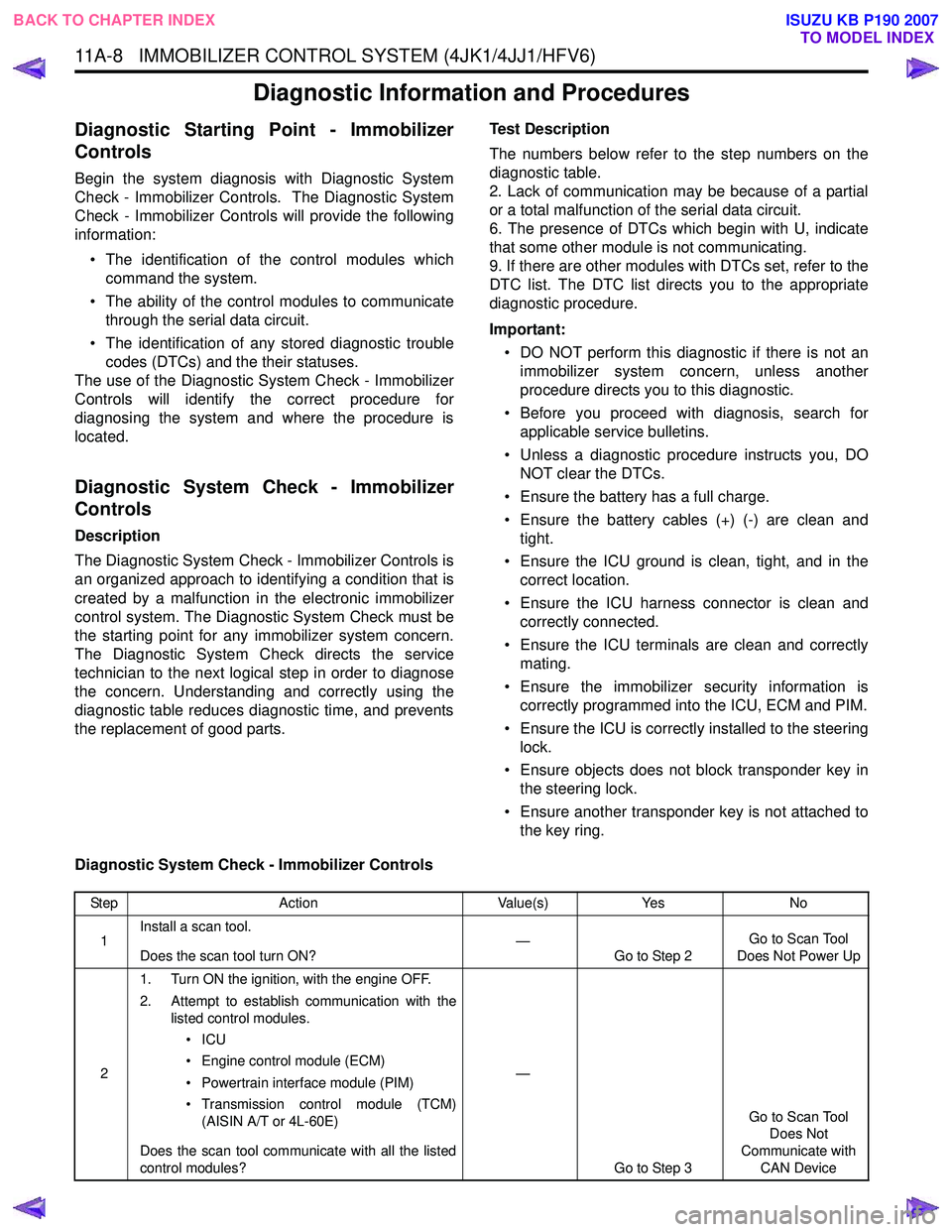

11A-8 IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6)

Diagnostic Information and Procedures

Diagnostic Starting Point - Immobilizer

Controls

Begin the system diagnosis with Diagnostic System

Check - Immobilizer Controls. The Diagnostic System

Check - Immobilizer Controls will provide the following

information:

• The identification of the control modules which command the system.

• The ability of the control modules to communicate through the serial data circuit.

• The identification of any stored diagnostic trouble codes (DTCs) and the their statuses.

The use of the Diagnostic System Check - Immobilizer

Controls will identify the correct procedure for

diagnosing the system and where the procedure is

located.

Diagnostic System Check - Immobilizer

Controls

Description

The Diagnostic System Check - Immobilizer Controls is

an organized approach to identifying a condition that is

created by a malfunction in the electronic immobilizer

control system. The Diagnostic System Check must be

the starting point for any immobilizer system concern.

The Diagnostic System Check directs the service

technician to the next logical step in order to diagnose

the concern. Understanding and correctly using the

diagnostic table reduces diagnostic time, and prevents

the replacement of good parts. Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the serial data circuit.

6. The presence of DTCs which begin with U, indicate

that some other module is not communicating.

9. If there are other modules with DTCs set, refer to the

DTC list. The DTC list directs you to the appropriate

diagnostic procedure.

Important: • DO NOT perform this diagnostic if there is not an immobilizer system concern, unless another

procedure directs you to this diagnostic.

• Before you proceed with diagnosis, search for applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO NOT clear the DTCs.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and tight.

• Ensure the ICU ground is clean, tight, and in the correct location.

• Ensure the ICU harness connector is clean and correctly connected.

• Ensure the ICU terminals are clean and correctly mating.

• Ensure the immobilizer security information is correctly programmed into the ICU, ECM and PIM.

• Ensure the ICU is correctly installed to the steering lock.

• Ensure objects does not block transponder key in the steering lock.

• Ensure another transponder key is not attached to the key ring.

Diagnostic System Check - Immobilizer Controls

Step Action Value(s)Yes No

1 Install a scan tool.

Does the scan tool turn ON? —

Go to Step 2 Go to Scan Tool

Does Not Power Up

2 1. Turn ON the ignition, with the engine OFF.

2. Attempt to establish communication with the listed control modules.

•ICU

• Engine control module (ECM)

• Powertrain interface module (PIM)

• Transmission control module (TCM) (AISIN A/T or 4L-60E)

Does the scan tool communicate with all the listed

control modules? —

Go to Step 3 Go to Scan Tool

Does Not

Communicate with CAN Device

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5861 of 6020

11A-10 IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6)

Scan Tool Data List

The Immobilizer Scan Tool Data List contains all

immobilizer related parameters that are available on

the scan tool. Use the Immobilizer Scan Tool Data List

only after the following is determined:

• The Immobilizer Controls - Diagnostic System Check is completed. • On-board diagnostics are functioning properly.

A scan tool that displays faulty data should not be used.

Use of a faulty scan tool can result in misdiagnosis and

unnecessary parts replacement.

Only the parameters listed below are referenced in this

service manual for use in diagnosis.

Scan Tool Data Definitions

This information will assist in immobilizer problems.

Always perform the Diagnostic System Check -

Immobilizer Controls first. The Diagnostic System

Check will confirm proper system operation.

Ignition Status

This parameter displays the state of the ignition switch

input to the ICU. On indicates the ignition switch is

turned ON position.

Transponder Key

This parameter displays the state of the transponder

key in the steering lock. Transponder Key 1 to 5

indicates a correctly programmed transponder key is

used. The number 1 to 5 indicates which transponder

key is used. Invalid indicates an incorrect key is in

used. Not Programmed Key indicates a non-

programmed new transponder key is used. No

Transponder Key indicates ICU does not recognize a

transponder key. Transponder Status

This parameter displays the state of the transponder

key in the steering lock. Correct Transponder-Key

indicates a correctly programmed transponder key is

used. Wrong Transponder-Key indicates an incorrect

key is in used. New Transponder-Key indicates a non-

programmed new transponder key is used. No

Transponder Detected indicates ICU does not

recognize a transponder key.

Transponder-Key 1 to 5 Status

This parameter displays the state of number of

programmed transponder key(s). Programmed

indicates transponder key 1 to 5 is correctly

programmed. The number 1 to 5 indicates programmed

order.

Security Code Programmed

This parameter displays the state of the security code

programming. Yes indicates a security code is correctly

programmed. No indicates a security code is not

programmed.

Scan Tool Parameter Units DisplayedTypical Data Value

Operating Conditions: Ignition switch ON/ Two transponder keys programmed

Ignition Status On/ OffOn

Transponder Key Transponder Key 1 to 5/ Invalid/ Not

Programmed Key/ No Transponder Key Transponder Key 1 or 2

Transponder Status Correct Transponder-Key/ Wrong

Transponder-Key/ New Transponder- Key/ No Transponder Detected Correct Transponder-Key

Transponder-Key 1 Status Programmed/ Not Programmed Programmed

Transponder-Key 2 Status Programmed/ Not Programmed Programmed

Transponder-Key 3 Status Programmed/ Not Programmed Not Programmed

Transponder-Key 4 Status Programmed/ Not Programmed Not Programmed

Transponder-Key 5 Status Programmed/ Not Programmed Not Programmed

Security Code Programmed Yes/ NoYes

Security Wait Time Inactive/ Time (hour: minute: second) Inactive

While Security Lock Inactive/ Active Inactive

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5862 of 6020

IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6) 11A-11

Security Wait Time

This parameter displays the security wait time length in

the ICU. Inactive indicates not in security wait time.

Time indicates under security wait time. This wait time

stage will prevent any further attempts to enter the

security code until the wait time has elapsed. The wait

time will increase each time an incorrect security code

is entered. Note that this parameter is not count

downed. It keeps displaying the same time until that

wait time has elapsed. The ignition switch must be kept

at ON position during the wait time period.

While Security Lock

This parameter displays the state of the security wait

time. Inactive indicates not in security wait time. Active

indicates under security wait time.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5872 of 6020

IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6) 11A-21

Diagnostic Trouble Code (DTC) List

DTCDTC Descriptor

B0001 Replace Electronic Control Unit (ECU)

B0002 Immobilizer Not Programmed

B0003 Transponder Key Problem

B0004 Immobilizer Coil Circuit

B0007 No Engine Request Received

B0008 Wrong Transponder Key

B0009 No Transponder Key Programmed

B0010 Unknown Transponder Key

B0012 Default Transponder Detected

B0013 Previously Erased Transponder

B0014 Secret Key Error

U0100 Lost Communication With ECM

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5873 of 6020

11A-22 IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6)

DTC B0001

Description

This diagnostic applies to internal microprocessor

integrity conditions within the ICU.

Condition for Setting the DTC • The ECM detects a faulty writing in its internal electrically erasable & programmable read only

memory (EEPROM). Action Taken When the DTC Sets

• The engine will fail to run if the fault occurs before starting the engine.

Condition for Clearing the DTC • A current DTC clears once ignition cycle has occurred without the fault recurring.

• A history DTC will clear after 50 consecutive ignition cycles, if the condition for malfunction is no

longer present.

• Use a scan tool to clear the DTC.

Circuit/ System Testing DTC B0001

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Immobilizer Controls? —

Go to Step 2 Go to Diagnostic

System Check - Immobilizer

Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Step 4

3 Important

: Replacement ICU must be

programmed.

Replace the ICU. Refer to ICU Replacement.

Did you complete the replacement? —

Go to Step 4

—

41. Clear the DTCs with a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 5

5 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007