ECU ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4558 of 6020

UNIT REPAIR (JR405E) 7A4-81

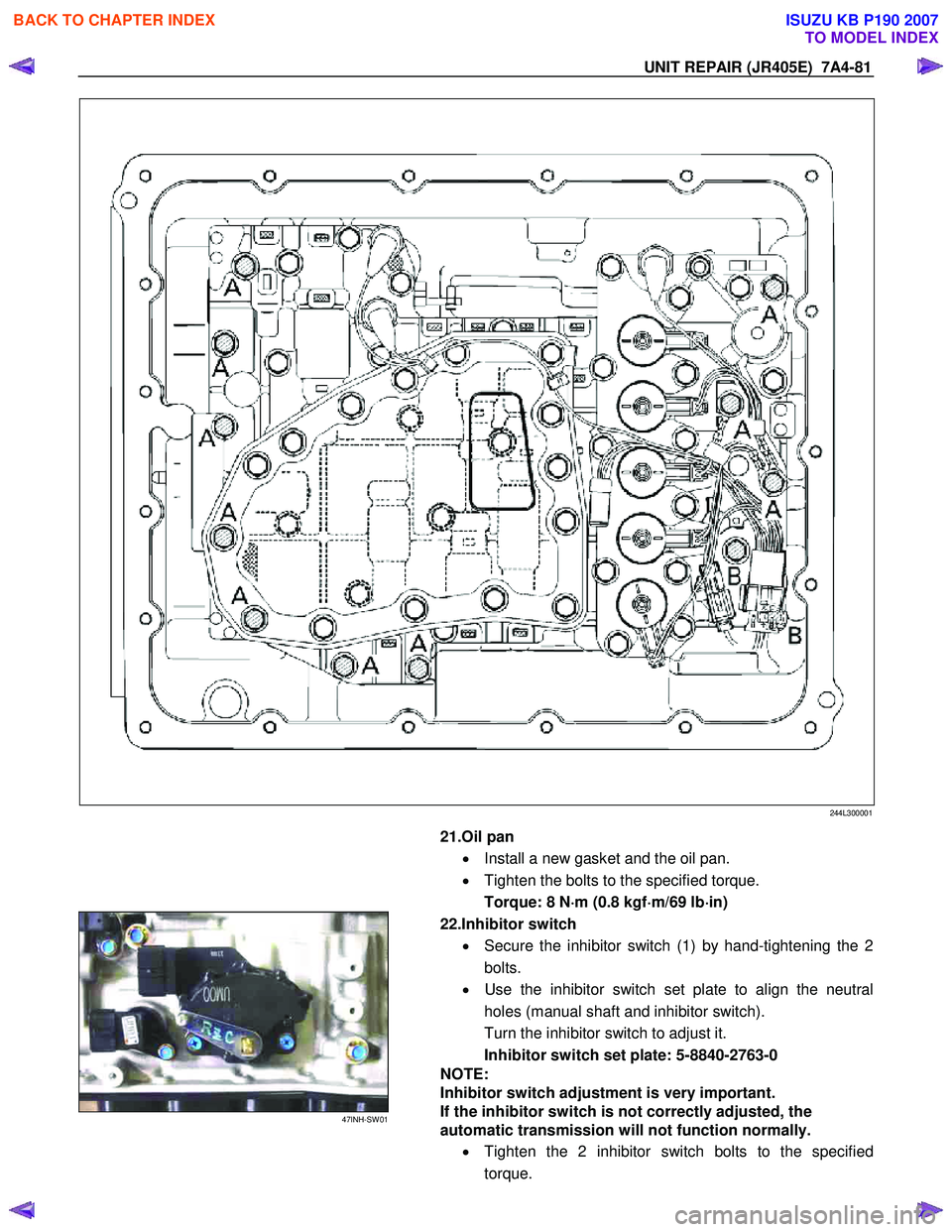

244L300001

21.Oil pan

• Install a new gasket and the oil pan.

• Tighten the bolts to the specified torque.

Torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kgf ⋅

⋅⋅

⋅

m/69 lb ⋅

⋅⋅

⋅

in)

47INH-SW 01

22.Inhibitor switch

• Secure the inhibitor switch (1) by hand-tightening the 2

bolts.

• Use the inhibitor switch set plate to align the neutral

holes (manual shaft and inhibitor switch).

Turn the inhibitor switch to adjust it.

Inhibitor switch set plate: 5-8840-2763-0

NOTE:

Inhibitor switch adjustment is very important.

If the inhibitor switch is not correctly adjusted, the

automatic transmission will not function normally.

• Tighten the 2 inhibitor switch bolts to the specified

torque.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4731 of 6020

7B1-12 Manual Transmission (MUX)

22. Remove the transmission retaining nuts and bolts.Remove the transmission assembly (4x2 model) or

the transmission & transfer assembly (4x4 model)

from the vehicle.

23. Remove the transmission-transfer fixing bolts and nut, and disassemble the transfer from the

transmission. (4x4 model)

Installation

1. Apply grease (BESCO L-2 or equivalent) on the splined portion of the output shaft.

2. Connect the transfer to the transmission. (4x4 model)

3. Install the transmission-transfer fixing bolts and nut, and tighten them to the specified torque. (4x4

model)

Torque: 41 N ⋅m (4.2 kgf ⋅m/30 lb ⋅ft)

4. Apply a thin coat of molybdenum disulfide grease on the splined portion of the input shaft spline.

5. Slowly operate the transmission jack until the front of transmission is aligned with the rear of the

engine.

6. Align the input shaft spline with the clutch driven plate spline.

7. Install the transmission assembly (4x2 model) or the transmission & transfer assembly (4x4 model)

to the engine.

• Tighten the transmission bolts to the specified torque.

Torque: 76 N ⋅m (7.7 kgf ⋅m/56 lb ⋅ft)

8. Apply a force 69 N ⋅m (7 kgf ⋅m/51 lb ⋅ft) to the tip of

the shift fork in the direction of the transmission to

engine the clutch pressure plate and release

bearing.

Notice:

A click sound is heard when the release bearing and

the tip of the diaphragm spring engage each other.

Check to see if they are securely engaged by pushing

the tip of the shift fork toward the engine side while

applying a force of about 25 N ⋅m (2.6 kgf ⋅m/19 lb ⋅ft). If

the shift fork will not move, then they are securely

engaged. 9. Connect harness clips on the transmission left

side.

10. Install the starter assembly.

• Tighten the starter bolts to the specified torque.

Torque: 94 N ⋅m (9.6 kgf ⋅m/69 lb ⋅ft)

11. Install the transmission rear mount to the transmission.

• Tighten the transmission rear mount bolts to the specified torque.

Torque: 50 N ⋅m (5.1 kgf ⋅m/37 lb ⋅ft)

12. Install the transmission crossmember by removing four bolts and nuts.

• Tighten the transmission crossmember bolts to the specified torque.

Torque: 67 N ⋅m (6.8 kgf ⋅m/49 lb ⋅ft)

13. Install the transmission rear mount nuts fixing on crossmember from transmission crossmember.

• Tighten the transmission rear mount nuts to the specified torque.

Torque: 52 N ⋅m (5.3 kgf ⋅m/38 lb ⋅ft)

Remove the transmission jack from transmission

side.

14. Install the fuel pipe bracket bolt and connect fuel pipe clip.

• Tighten the fuel pipe bracket bolt to the specified torque.

Torque: 76 N ⋅m (7.7 kgf ⋅m/56 lb ⋅ft)

15. Install the slave cylinder fixing bolts. • Tighten the slave cylinder bolts to the specifiedtorque.

Torque: 43 N ⋅m (4.4 kgf ⋅m/32 lb ⋅ft)

RTW77BSH007201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4837 of 6020

TRANSFER CASE 7D-7

Installation

1. Thoroughly clean around the oil seal bore in the case

and ensure there are no burrs.

2.

Apply the engine oil to the new oil seal outer surfaces

and apply the recommended grease (BESCO L2) o

r

equivalent to the oil seal lip.

3. Tap the oil seal in to place, use an oil seal installe

r

(5-8840-2785-0) and a soft hammer.

RTW 77DSH000301

4. Install the output flange to the front output shaft.

5. Apply the engine oil to the new O-ring and install it to the front output shaft.

6. Secure the output flange with a flange holde

r

(5-8840-0133-0).

7. Install the new end nut and tighten them to specified torque.

Front coupling driver fixing nut torque: 137 N ⋅

⋅⋅

⋅

m (14.0 kgf ⋅

⋅⋅

⋅

m/101 lb ⋅

⋅⋅

⋅

ft)

8. Use a punch (5-8840-2293-0) to caulk the end nut.

226R300012

RUW 34DSH000301

Legend

(1) MAX 26mm (1.02in)

(2) MIN 4mm (0.16in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4856 of 6020

7D-26 TRANSFER CASE

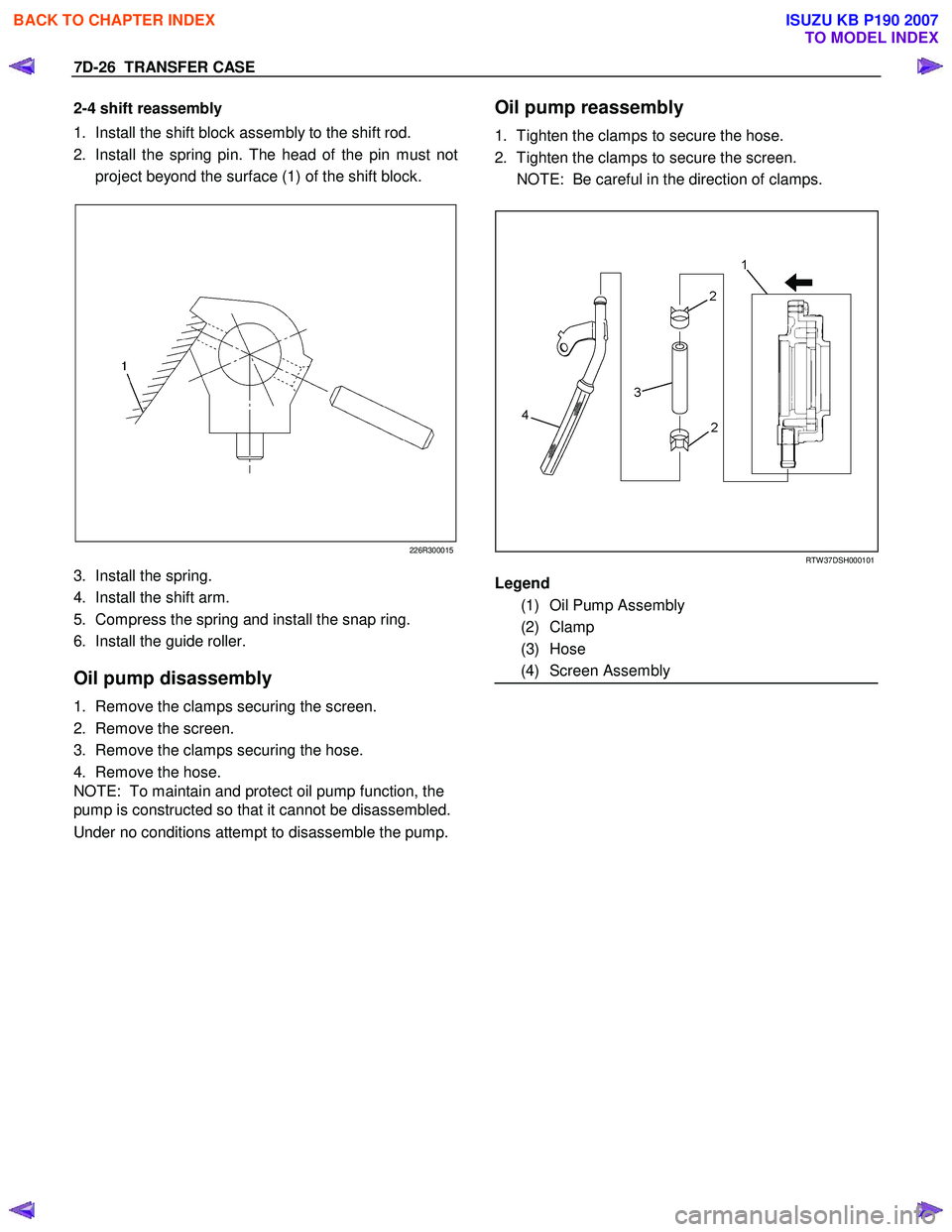

2-4 shift reassembly

1. Install the shift block assembly to the shift rod.

2. Install the spring pin. The head of the pin must not

project beyond the surface (1) of the shift block.

226R300015

3. Install the spring.

4. Install the shift arm.

5. Compress the spring and install the snap ring.

6. Install the guide roller.

Oil pump disassembly

1. Remove the clamps securing the screen.

2. Remove the screen.

3. Remove the clamps securing the hose.

4. Remove the hose.

NOTE: To maintain and protect oil pump function, the

pump is constructed so that it cannot be disassembled.

Under no conditions attempt to disassemble the pump.

Oil pump reassembly

1. Tighten the clamps to secure the hose.

2. Tighten the clamps to secure the screen.

NOTE: Be careful in the direction of clamps.

RTW 37DSH000101

Legend

(1) Oil Pump Assembly

(2) Clamp

(3) Hose

(4) Screen Assembly

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4867 of 6020

TRANSFER CASE 7D-37

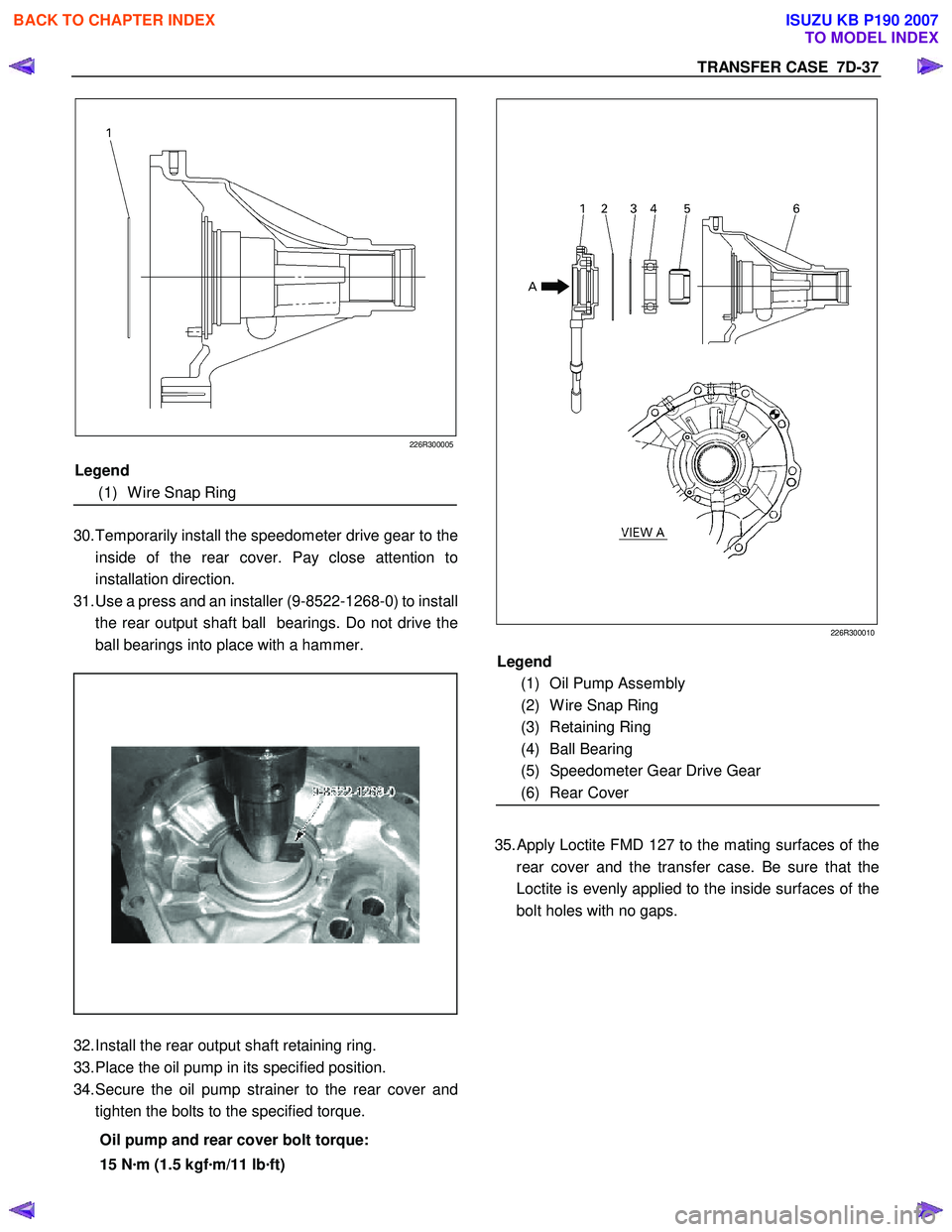

226R300005

30. Temporarily install the speedometer drive gear to the

inside of the rear cover. Pay close attention to

installation direction.

31. Use a press and an installer (9-8522-1268-0) to install

the rear output shaft ball bearings. Do not drive the

ball bearings into place with a hammer.

32. Install the rear output shaft retaining ring.

33. Place the oil pump in its specified position.

34. Secure the oil pump strainer to the rear cover and

tighten the bolts to the specified torque.

Oil pump and rear cover bolt torque:

15 N ·m (1.5 kgf ·m/11 lb ·ft)

226R300010

35.

Apply Loctite FMD 127 to the mating surfaces of the

rear cover and the transfer case. Be sure that the

Loctite is evenly applied to the inside surfaces of the

bolt holes with no gaps.

Legend

(1) Oil Pump Assembly

(2) W ire Snap Ring

(3) Retaining Ring

(4) Ball Bearing

(5) Speedometer Gear Drive Gear

(6) Rear Cover

Legend

(1) W ire Snap Ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4868 of 6020

7D-38 TRANSFER CASE

226R300011

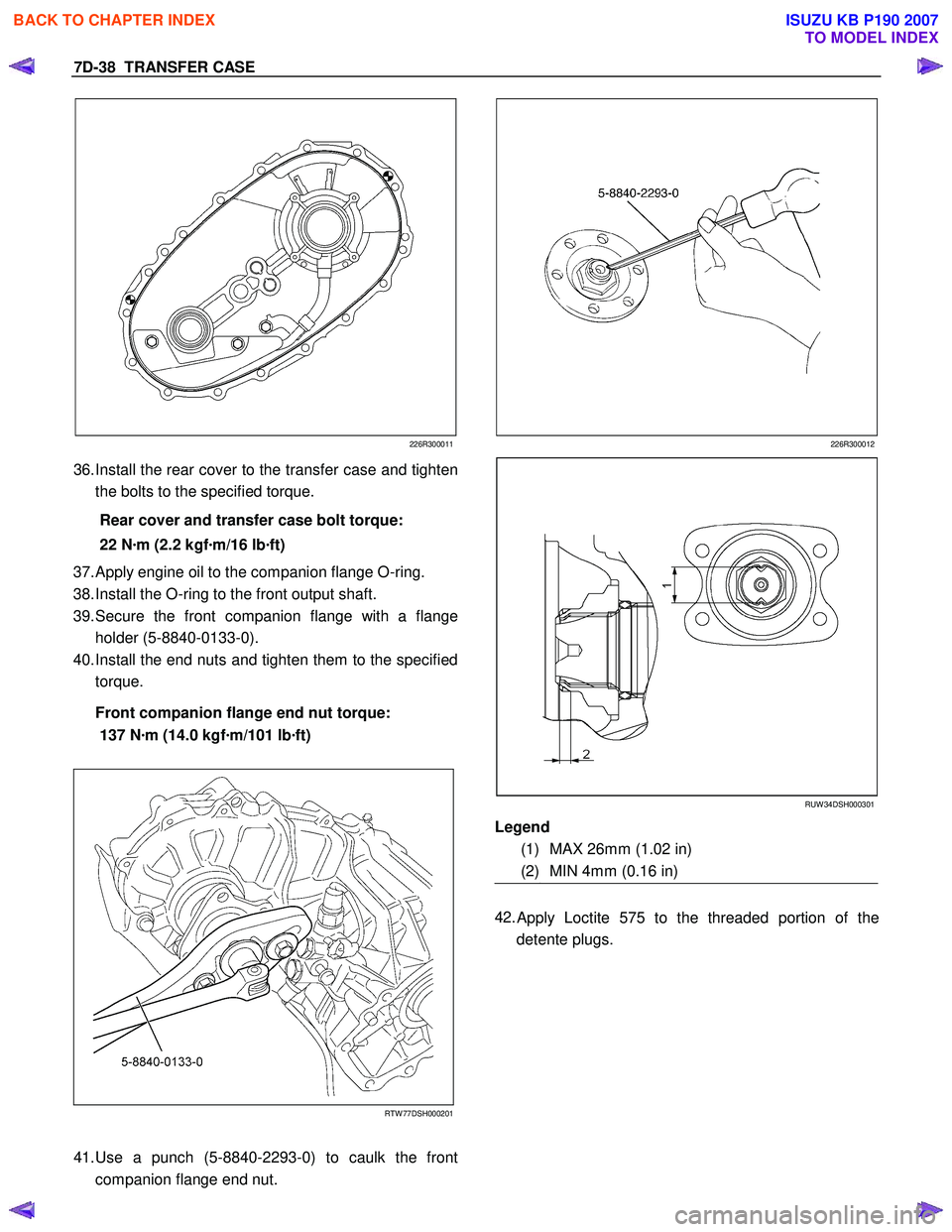

36. Install the rear cover to the transfer case and tighten

the bolts to the specified torque.

Rear cover and transfer case bolt torque:

22 N ·m (2.2 kgf ·m/16 lb ·ft)

37. Apply engine oil to the companion flange O-ring.

38. Install the O-ring to the front output shaft.

39. Secure the front companion flange with a flange

holder (5-8840-0133-0).

40. Install the end nuts and tighten them to the specified

torque.

Front companion flange end nut torque:

137 N ·m (14.0 kgf ·m/101 lb ·ft)

RTW 77DSH000201

41. Use a punch (5-8840-2293-0) to caulk the front

companion flange end nut.

226R300012

RUW 34DSH000301

Legend

(1) MAX 26mm (1.02 in)

(2) MIN 4mm (0.16 in)

42.

Apply Loctite 575 to the threaded portion of the

detente plugs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4923 of 6020

TRANSFER CONTROL SYSTEM 7D1-49

Step 4-3: (Same procedure as the step 3-3)

Stop the vehicle (close the accelerator and decrease the engine speed to L4: 3000rpm V6: 2000rpm or below).

(In case of AT): Set the transmission select lever to the N position.

(In case of MT): Set the transmission lever to the neutral position (stepping on the clutch lever is recommended).

Push the 4H button.

If shifting is not complete (indicator flashes at 2Hz), go to step 4-1.

5. When shifting from 4H or 4L to neutral

(Same procedure is required when shifting from 2H but in such a case, requirements for shifting from

2H to 4H are also applied.)

5-1 Neutral indicator continues flashing at 2Hz The neutral indicator continues flashing at 2Hz until 4H (4L) is completely separated in the transfer. If torsional

torque has accumulated between the transmission and road surface, separation may be difficult.

Step 5-1:

If the operation is not complete, execute step 7 for confirmation.

(In case of AT): Set the transmission select lever to the D position. After confirming that the gears are at the neutral position, return the lever to the N

position.

(In case of MT): Set the transmission lever to a vehicle running position and engage the clutch gently. After confirming that the gears are at the neutral position, return the lever to the

neutral position

5-2 When the neutral indicator flashes at 4Hz

As in the case of shifting from 4L to 4H, restriction is imposed to the operation from 4L or 4H (including 2H). If

the transmission lever is at a running range and engine speed is high (L4: 3000rpm, V6: 2000rpm or more)

while the vehicle is running, operation from the 4L or 4H (including 2H) of the transfer to the neutral is

impossible (restriction on operation).

Step 5-2:

Stop the vehicle.

(In case of AT): Set the transmission select lever to the N (or P) position.

(In case of MT): Set the transmission lever to the neutral position (at this time, stepping on the clutch is recommended).

Keep pushing the 2H and 4L button for 10 seconds.

Follow the start procedure for confirmation. (Confirmation of drive force is not transferred; same as in

step 5-1)

After the confirmation, set the transmission to the neutral position in the case of MT or to the neutral

position in the case of AT.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4947 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-9

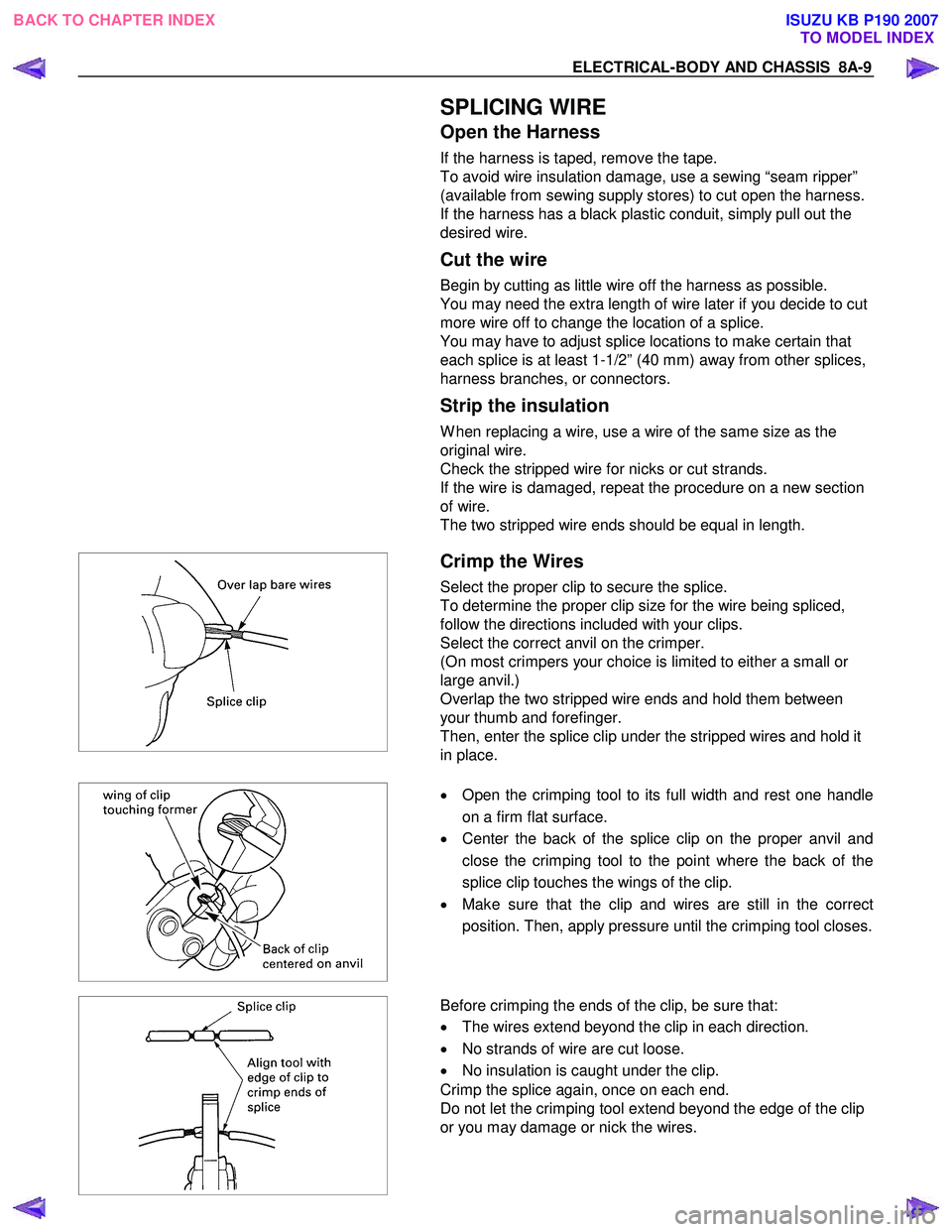

SPLICING WIRE

Open the Harness

If the harness is taped, remove the tape.

To avoid wire insulation damage, use a sewing “seam ripper”

(available from sewing supply stores) to cut open the harness.

If the harness has a black plastic conduit, simply pull out the

desired wire.

Cut the wire

Begin by cutting as little wire off the harness as possible.

You may need the extra length of wire later if you decide to cut

more wire off to change the location of a splice.

You may have to adjust splice locations to make certain that

each splice is at least 1-1/2” (40 mm) away from other splices,

harness branches, or connectors.

Strip the insulation

W hen replacing a wire, use a wire of the same size as the

original wire.

Check the stripped wire for nicks or cut strands.

If the wire is damaged, repeat the procedure on a new section

of wire.

The two stripped wire ends should be equal in length.

Crimp the Wires

Select the proper clip to secure the splice.

To determine the proper clip size for the wire being spliced,

follow the directions included with your clips.

Select the correct anvil on the crimper.

(On most crimpers your choice is limited to either a small or

large anvil.)

Overlap the two stripped wire ends and hold them between

your thumb and forefinger.

Then, enter the splice clip under the stripped wires and hold it

in place.

•

Open the crimping tool to its full width and rest one handle

on a firm flat surface.

• Center the back of the splice clip on the proper anvil and

close the crimping tool to the point where the back of the

splice clip touches the wings of the clip.

• Make sure that the clip and wires are still in the correct

position. Then, apply pressure until the crimping tool closes.

Before crimping the ends of the clip, be sure that:

• The wires extend beyond the clip in each direction.

• No strands of wire are cut loose.

• No insulation is caught under the clip.

Crimp the splice again, once on each end.

Do not let the crimping tool extend beyond the edge of the clip

or you may damage or nick the wires.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 4950 of 6020

8A-12 ELECTRICAL-BODY AND CHASSIS

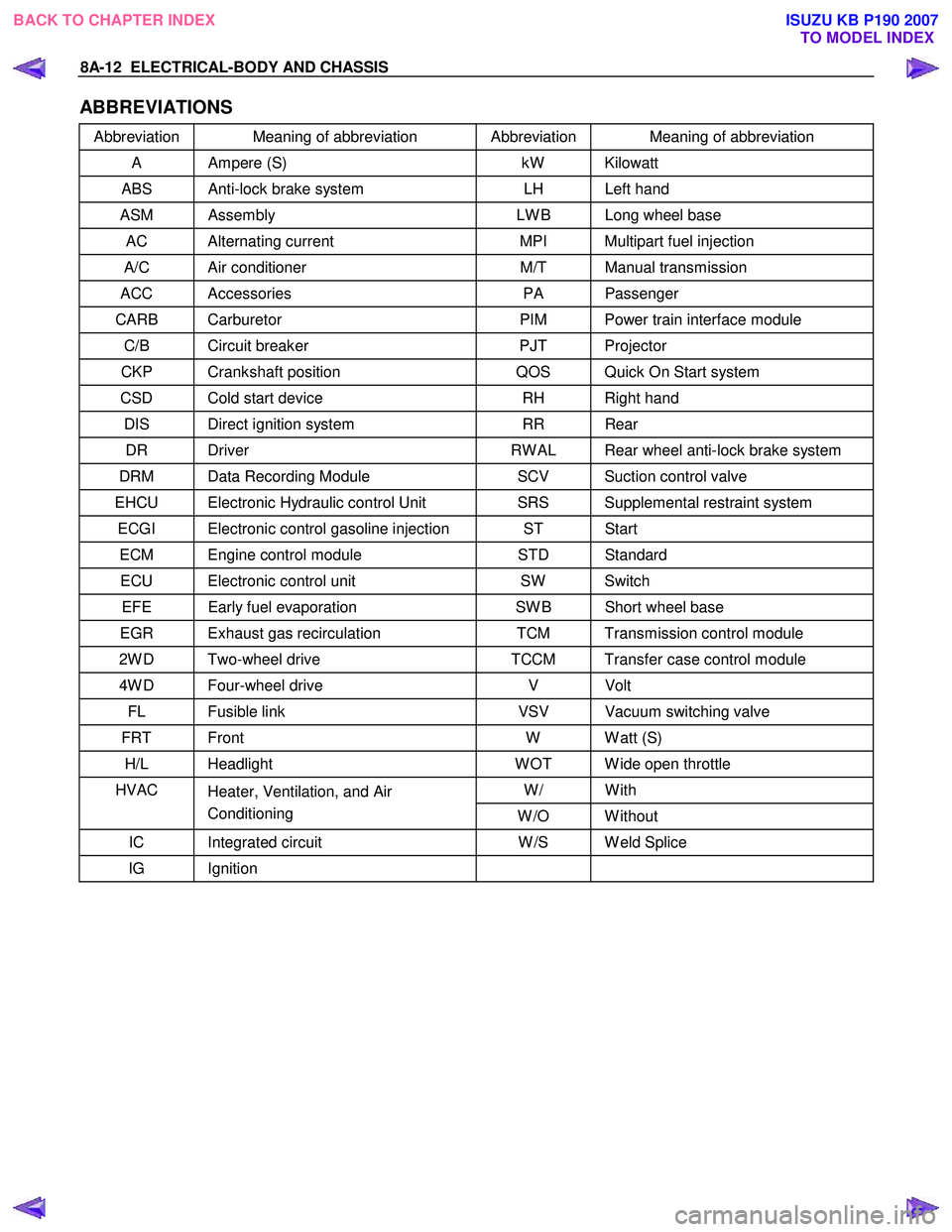

ABBREVIATIONS

Abbreviation Meaning of abbreviation Abbreviation Meaning of abbreviation

A Ampere (S) kW Kilowatt

ABS Anti-lock brake system LH Left hand

ASM Assembly LW B Long wheel base

AC Alternating current MPI Multipart fuel injection

A/C Air conditioner M/T Manual transmission

ACC Accessories PA Passenger

CARB Carburetor PIM Power train interface module

C/B Circuit breaker PJT Projector

CKP Crankshaft position QOS Quick On Start system

CSD Cold start device RH Right hand

DIS Direct ignition system RR Rear

DR Driver RW AL Rear wheel anti-lock brake system

DRM Data Recording Module SCV Suction control valve

EHCU Electronic Hydraulic control Unit SRS Supplemental restraint system

ECGI Electronic control gasoline injection ST Start

ECM Engine control module STD Standard

ECU Electronic control unit SW Switch

EFE Early fuel evaporation SW B Short wheel base

EGR Exhaust gas recirculation TCM Transmission control module

2W D Two-wheel drive TCCM Transfer case control module

4W D Four-wheel drive V Volt

FL Fusible link VSV Vacuum switching valve

FRT Front W W att (S)

H/L Headlight W OT W ide open throttle

W/ With HVAC

Heater, Ventilation, and Air

Conditioning W /O W ithout

IC Integrated circuit W /S W eld Splice

IG Ignition

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 4971 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-33

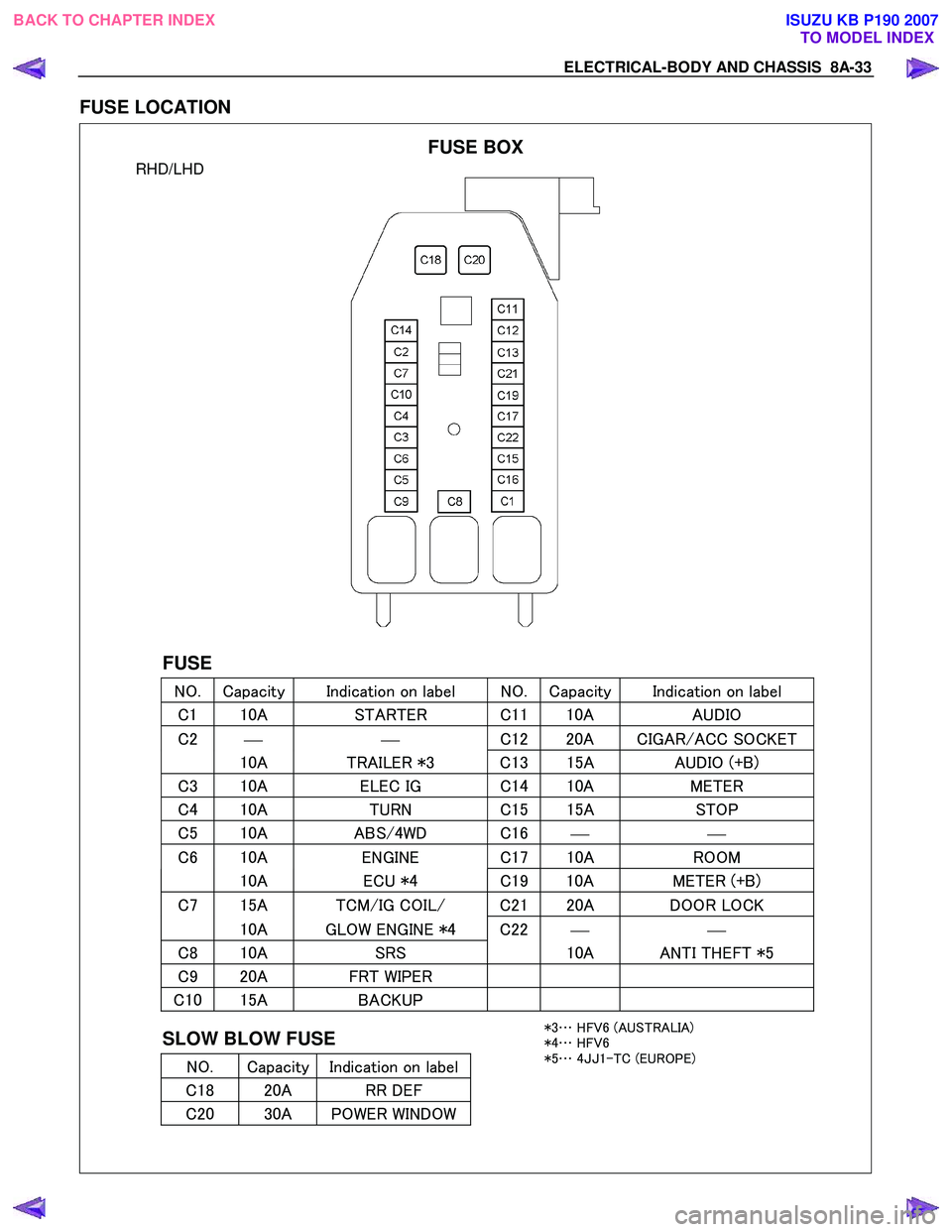

FUSE LOCATION

RHD/LHD

FUSE

NO. Capacity Indication on label NO. Capacity Indication on label

C 1 10A STARTER C 1110A AUDIO

C2

C

12 20A CIGAR/ACC SOCKET

10A TRAILER *3 C 13 15A AUDIO (+B)

C3 10A ELEC IG C 14 10A METER

C4 10A TURN C 15 15A STOP

C5 10A ABS/4WD C 16

C6 10A ENGINE C 17 10A ROOM

10A ECU *4 C19 10A METER (+B)

C7 15A TCM/IG COIL/ C2 120A DOOR LOCK

10A GLOW ENGINE *4 C22

C8 10A SRS 10A ANTI THEFT *5

C9 20A FRT WIPER

C10 15A BACKUP

SLOW BLOW FUSE

NO. Capacity Indication on label

C 18 20A RR DEF

C20 30A POWER WINDOW

FUSE BOX

*3 … HFV6 (AUSTRALIA)

*4 … HFV6

*5 … 4JJ 1-TC (EUROPE)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007