fuel type ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1317 of 6020

Engine Control System (4JH1) 6E-283

Description And Operation

Engine Control Module (ECM) Description

RTW 66ESH001201

The engine control module (ECM) is designed to

withstand normal current draws associated with vehicle

operation. Avoid overloading any circuit. W hen testing

for opens and shorts, do not ground or apply voltage to

any of the ECM circuits unless instructed to do so. In

some cases, these circuits should only be tested using

a digital multi meter (DMM). The ECM should remain

connected to the ECM harness.

The ECM is located on the floor panel. The ECM mainl

y

controls the following.

• The fuel system control

• The exhaust gas recirculation (EGR) system

control

• The preheating (glow) system control

• The A/C compressor control

• On-board diagnostics for engine control

The ECM constantly observes the information from

various sensor s. The ECM controls the systems that

affect vehicle performance. The ECM performs the

diagnostic function of the system. The ECM can

recognize operational problems, alert the driver through

the malfunction indicator lamp (MIL), and store

diagnostic trouble codes (DTCs). DTCs identify the

system faults to aid the technician in making repairs.

ECM Voltage Description

The ECM supplies a buffered voltage to various

switches and sensor s. The ECM can do this because

resistance in the ECM is so high in value that a test

lamp may not illuminate when connected to the circuit.

An ordinary shop voltmeter may not give an accurate

reading because the voltmeter input impedance is too

low. Use a 10-megaohm input impedance DMM, to

ensure accurate voltage readings. The input and/o

r

output devices in the ECM include analog-to-digital

converters, signal buffers, counters, and special drivers.

The ECM controls most components with electronic

switches which complete a ground circuit when turned

ON.

Aftermarket Electrical and Vacuum Equipment

Aftermarket or add-on electrical and vacuum equipment

is defined as any equipment which connects to the

vehicle's electrical or vacuum systems that is installed

on a vehicle after the vehicle leaves the factory. No

allowances have been made in the vehicle design fo

r

this type of equipment. No add-on vacuum equipment

should be added to this vehicle. Add-on electrical

equipment must only be connected to the vehicle's

electrical system at the battery power and ground. Add-

on electrical equipment, even when installed to these

guidelines, may still cause the powertrain system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such as

portable telephones and audios. Therefore, the first

step in diagnosing any powertrain fault is to eliminate all

aftermarket electrical equipment from the vehicle. Afte

r

this is done, if the fault still exists, the fault may be

diagnosed in the normal manner.

Electrostatic Discharge Damage

Electronic components used in the ECM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused b

y

electrostatic discharge. By comparison, as much as

4,000 volts may be needed for a person to feel even the

zap of a static discharge. There are several ways for a

person to become statically charged. The most

common methods of charging are by friction and

induction. •

An example of charging by friction is a person

sliding across a vehicle seat.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1318 of 6020

6E-284 Engine Control System (4JH1)

Important:

To prevent possible electrostatic discharge damage,

follow these guidelines: • Do not touch the ECM connector pins or soldered

components on the ECM circuit board.

• Do not open the replacement part package until

the part is ready to be installed.

• Before removing the part from the package,

ground the package to a known good ground on

the vehicle.

• If the part has been handled while sliding across

the seat, while sitting down from a standing

position, or while walking a distance, touch a

known good ground before installing the part.

• Charge by induction occurs when a person with

well insulated shoes stands near a highly charged

object and momentarily touches ground. Charges

of the same polarity are drained off leaving the

person highly charged with opposite polarity.

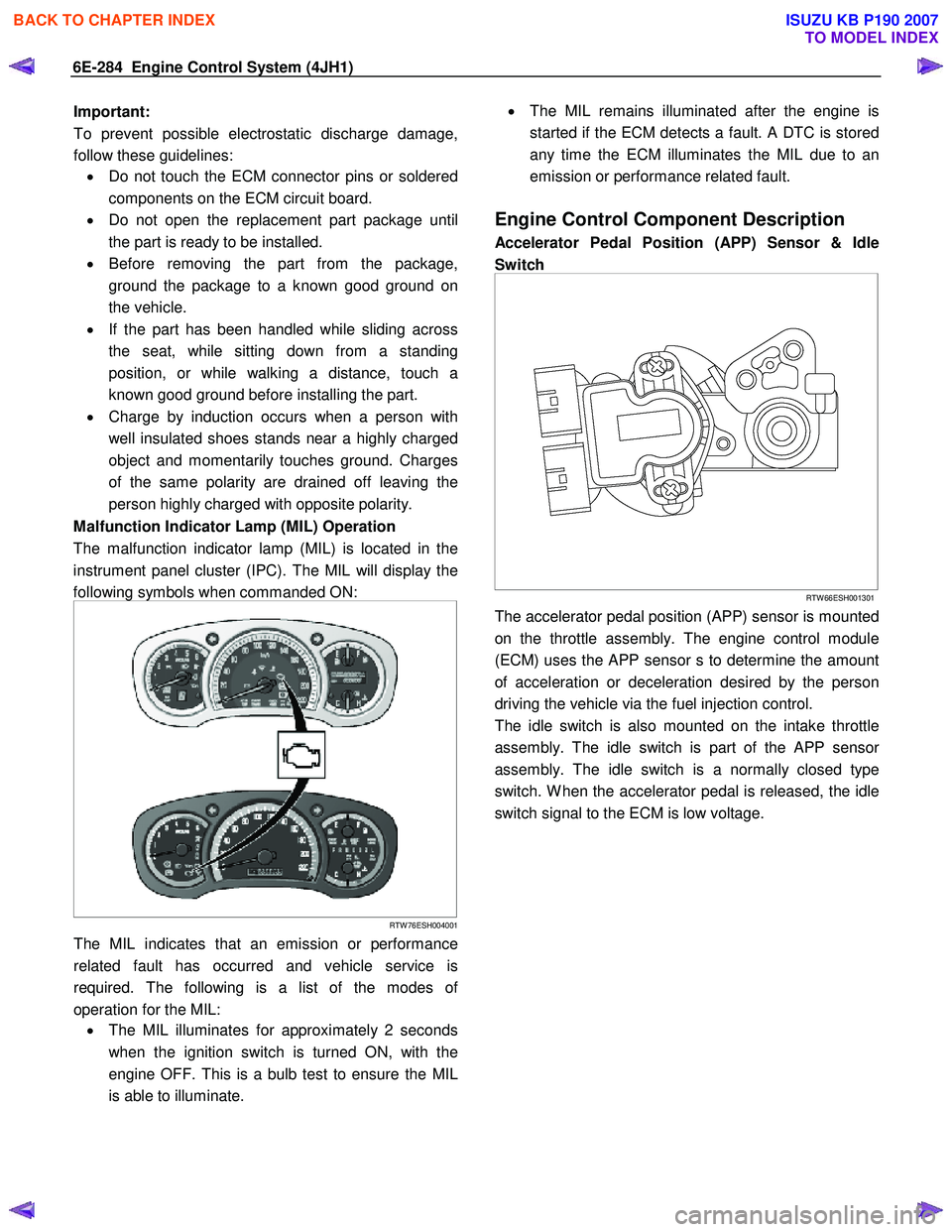

Malfunction Indicator Lamp (MIL) Operation

The malfunction indicator lamp (MIL) is located in the

instrument panel cluster (IPC). The MIL will display the

following symbols when commanded ON:

RTW 76ESH004001

The MIL indicates that an emission or performance

related fault has occurred and vehicle service is

required. The following is a list of the modes o

f

operation for the MIL: • The MIL illuminates for approximately 2 seconds

when the ignition switch is turned ON, with the

engine OFF. This is a bulb test to ensure the MIL

is able to illuminate.

•

The MIL remains illuminated after the engine is

started if the ECM detects a fault. A DTC is stored

any time the ECM illuminates the MIL due to an

emission or performance related fault.

Engine Control Component Description

Accelerator Pedal Position (APP) Sensor & Idle

Switch

RTW 66ESH001301

The accelerator pedal position (APP) sensor is mounted

on the throttle assembly. The engine control module

(ECM) uses the APP sensor s to determine the amount

of acceleration or deceleration desired by the person

driving the vehicle via the fuel injection control.

The idle switch is also mounted on the intake throttle

assembly. The idle switch is part of the APP senso

r

assembly. The idle switch is a normally closed type

switch. W hen the accelerator pedal is released, the idle

switch signal to the ECM is low voltage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1322 of 6020

6E-288 Engine Control System (4JH1)

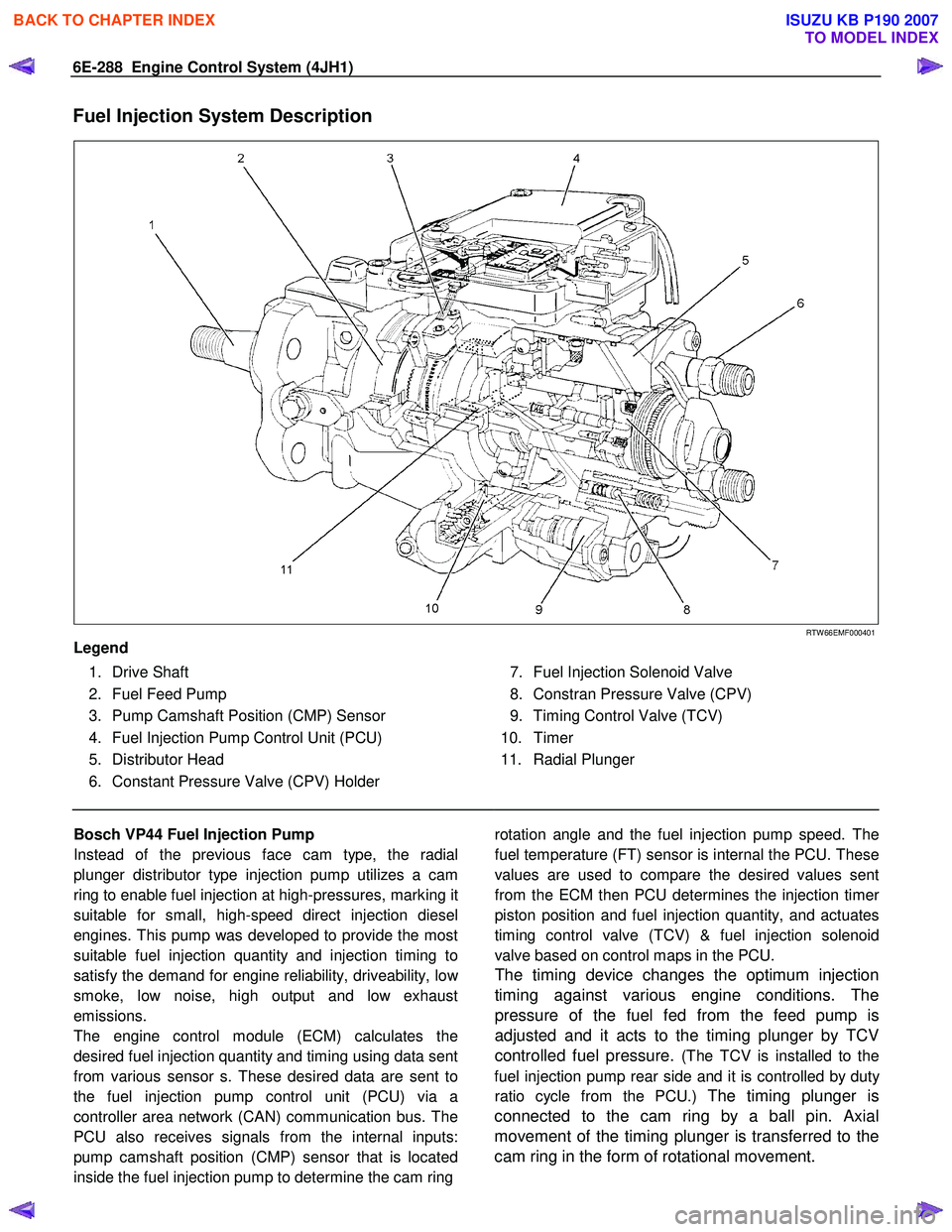

Fuel Injection System Description

RTW 66EMF000401

Legend

1. Drive Shaft

2. Fuel Feed Pump

3. Pump Camshaft Position (CMP) Sensor

4. Fuel Injection Pump Control Unit (PCU)

5. Distributor Head

6. Constant Pressure Valve (CPV) Holder

7. Fuel Injection Solenoid Valve

8. Constran Pressure Valve (CPV)

9. Timing Control Valve (TCV)

10. Timer

11. Radial Plunger

Bosch VP44 Fuel Injection Pump

Instead of the previous face cam type, the radial

plunger distributor type injection pump utilizes a cam

ring to enable fuel injection at high-pressures, marking it

suitable for small, high-speed direct injection diesel

engines. This pump was developed to provide the most

suitable fuel injection quantity and injection timing to

satisfy the demand for engine reliability, driveability, lo

w

smoke, low noise, high output and low exhaust

emissions.

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensor s. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The timing device changes the optimum injection

timing against various engine conditions. The

pressure of the fuel fed from the feed pump is

adjusted and it acts to the timing plunger by TCV

controlled fuel pressure.

(The TCV is installed to the

fuel injection pump rear side and it is controlled by dut

y

ratio cycle from the PCU.) The timing plunger is

connected to the cam ring by a ball pin. Axial

movement of the timing plunger is transferred to the

cam ring in the form of rotational movement.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1364 of 6020

6A-4 ENGINE MECHANICAL (4JK1/4JJ1)

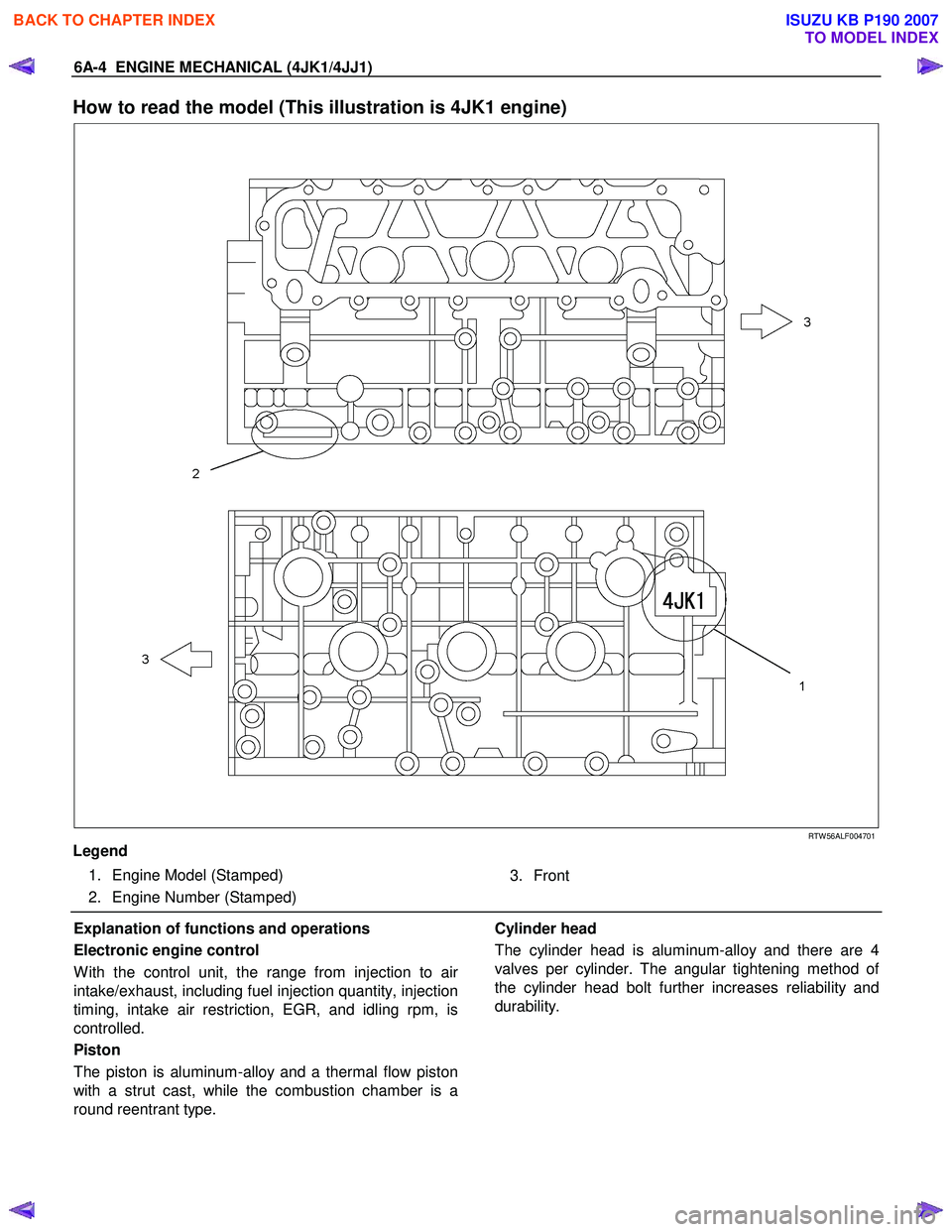

How to read the model (This illustration is 4JK1 engine)

RTW 56ALF004701

Legend

1. Engine Model (Stamped)

2. Engine Number (Stamped)

3. Front

Explanation of functions and operations

Electronic engine control

W ith the control unit, the range from injection to ai

r

intake/exhaust, including fuel injection quantity, injection

timing, intake air restriction, EGR, and idling rpm, is

controlled.

Piston

The piston is aluminum-alloy and a thermal flow piston

with a strut cast, while the combustion chamber is a

round reentrant type.

Cylinder head

The cylinder head is aluminum-alloy and there are 4

valves per cylinder. The angular tightening method o

f

the cylinder head bolt further increases reliability and

durability.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1365 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-5

EGR system

Based upon data, including water temperature, engine

speeds or engine loads, it is controlled via Engine

Control Module (ECM) to purify exhaust by recycling

part of it.

Its main components include an EGR valve, an EGR

cooler and various sensors.

Connecting rod cap bolt

The angular tightening method of the connecting rod

cap bolt further increases reliability and durability.

Fuel rail-type electronic control injection system

The fuel rail-type electronic control injection system is

composed of a fuel supply pump that sets the target

pressure of high-pressure fuel and supply it, a fuel rail

that measures such high-pressure fuel and a fuel

injector that turns it into a fine spray and injects it. Each

is controlled via ECM based upon various signals, while

injection timing or fuel injection quantity is controlled

under every possible driving condition.

Fuel injector

The fuel injector is a 6-hole nozzle that adjusts fuel

injection quantity or injection timing by opening o

r

closing an electromagnetic valve on the head of the fuel

injector.

ECM corrects the dispersion of fuel injection quantit

y

between fuel injector according to ID code data in

memory. At the replacement of fuel injector, ID code

data should be stored in ECM.

Fuel filter with sedimenter

It is a fuel filter with sedimenter that gets rid of water by

making use of the difference in specific gravity between

light oil and water, which comes with an indicator that

notifies you that it is filled with water.

Preheating system

The preheating system consists of the ECM, the glow

relay, glow plugs and the glow indicator lamp. The

preheating system is operated when the engine coolant

temperature is low, and makes the engine easy to start.

Lubrication system

It is an oil filter with full-flow bypass, which uses a

water-cool oil cooler and oil jet to cool the piston.

Functional inspection

Inspection/adjustment of valve clearance 1. Inspection of valve clearance

• Remove the fuel injector harness assembly.

• Remove the leak off hose.

• Remove the cylinder head cover.

• Rotate the crankshaft to make the No.1

cylinder meet the compression top dead cente

r

(TDC).

RTW 76ASH001301

Legend

1. TDC

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1373 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-13

Main Data and specifications

Item Engine model 4JK1 Engine model 4JJ1

Type Diesel/4-cycle/water cooling-type in-line DOHC

Combustion chamber type Direct injection type

Cylinder liner type Liner less

Number of cylinders -cylinder

bore × strokes mm (in) 4-95.4 (3.76) × 87.4 (3.44) 4-95.4(3.76) × 104.9(4.13)

Displacement

cc (cu.in) 2499 (152) 2999 (183)

Compression ratio 18.3 17.5

Compression pressure MPa (psi)/rpm 3 (435)/200

Idling speed rpm 700 ± 25

Valve clearance Intake 0.15 (0.006) (cold)

mm (in) Exhaust 0.15 (0.006) (cold)

Ignition type Compressed ignition

Injection order 1 - 3 - 4 - 2

Lubricating system

Lubricating type Pressure delivery type

Oil pump type Gear type

Volume of lubricating oil L (qts) 8.0 (8.5)

Oil filter type Full flow filter (cartridge type)

Oil cooling type Built-in-type, water cooling

Cooling system

Cooling type W ater cooling type

Radiator type Corrugated fin (pressure type)

W ater pump type Centrifugal, belt drive type

Thermostat type W ax-type units

Thermostat valve-opening temperature °C ( °F) 85 (185)

Volume of coolant L (qts) M/T8.7 (9.2) A/T 8.6 (9.1) (incl. radiator)

Fuel system

Injection pump type Fuel supply pump fuel rail type

Fuel injector type Electronic control injector

6-hole

Fuel pump type Into the fuel tank type

Charging system

Generator type AC type

Power output V-A 12 - 90

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1588 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-47

Fuel Filler Cap

General Description

A vacuum valve and pressure valve are built into the

fuel filler cap which adjusts the fuel pressure in the fuel

tank to prevent fuel tank damage.

RTW 46CSH000301

Legend

1. Seal Ring

Inspection

The fuel filler cap must be inspected for seal condition.

The fuel filler cap must be replaced if found defective.

Note: A replacement fuel filler cap must be the same as

the original. The fuel filler cap valve was designed

primarily for this application and must be replaced with

the same type or decreased engine performance ma

y

occur.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1618 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-1

SECTION 6E

ENGINE CONTROL SYSTEM(4JK1/4JJ1)

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6E-3 Temperature vs Resistance . . . . . . . . . . . . . . . . 6E-3

Altitude vs Barometric Pressure . . . . . . . . . . . . . 6E-3

Diagnostic Trouble Code (DTC) Type Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6E-4

Diagnostic Trouble Code (DTC) List . . . . . . . . . 6E-4

Schematic and Rounting Diagrams. . . . . . . . . . . . 6E-9 Fuel System Routing Diagram . . . . . . . . . . . . . . 6E-9

Vacuum Hose Routing Diagram . . . . . . . . . . . . . 6E-9

Engine Controls Schematics . . . . . . . . . . . . . . 6E-10

Component Locator. . . . . . . . . . . . . . . . . . . . . . . 6E-27 Engine Controls Component Views . . . . . . . . . 6E-27

Engine Control Module (ECM) Connector End Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6E-30

Engine Control Connector End Views . . . . . . . 6E-33

Diagnostic Information and Procedures . . . . . . . 6E-42 Engine Control System Check Sheet . . . . . . . . 6E-42

Diagnostic Starting Point - Engine Controls . . . 6E-43

Diagnostic System Check - Engine Controls . . 6E-44

Scan Tool Data List . . . . . . . . . . . . . . . . . . . . . 6E-46

Scan Tool Data Definitions . . . . . . . . . . . . . . . . 6E-49

Scan Tool Output Controls . . . . . . . . . . . . . . . . 6E-54

Scan Tool Does Not Power Up. . . . . . . . . . . . . 6E-55

Scan Tool Does Not Communicate with CAN Device. . . . . . . . . . . . . . . . . . . . . . . . . . . 6E-56

Lost Communication with The Engine Control Module (ECM) . . . . . . . . . . . . . . . . . . 6E-59

Engine Cranks but Does Not Run . . . . . . . . . . 6E-62

DTC P0016 (Flash Code 16) . . . . . . . . . . . . . . 6E-68

DTC P0045 (Flash Code 33) . . . . . . . . . . . . . . 6E-70

DTC P0087 (Flash Code 225) . . . . . . . . . . . . . 6E-72

DTC P0088 (Flash Code 118) . . . . . . . . . . . . . 6E-77

DTC P0089 (Flash Code 151) . . . . . . . . . . . . . 6E-82

DTC P0091 or P0092 (Flash Code 247) . . . . . 6E-85

DTC P0093 (Flash Code 227) . . . . . . . . . . . . . 6E-88

DTC P0101 (Flash Code 92) . . . . . . . . . . . . . . 6E-93

DTC P0102 or P0103 (Flash Code 91) . . . . . . 6E-96

DTC P0107 or P0108 (Flash Code 32) . . . . . 6E-100

DTC P0112 or P0113 (Flash Code 22) . . . . . 6E-104

DTC P0116 (Flash Code 23) . . . . . . . . . . . . . 6E-108

DTC P0117 or P0118 (Flash Code 23) . . . . . 6E-110

DTC P0122 or P0123 (Flash Code 43) . . . . . 6E-114

DTC P0182 or P0183 (Flash Code 211) . . . . 6E-118

DTC P0192 or P0193 (Flash Code 245) . . . . 6E-122

DTC P0201, P0202, P0203 or P0204 (Flash Code 271, 272, 273 or 274) . . . . . . . . 6E-126

DTC P0217 (Flash Code 542) . . . . . . . . . . . . 6E-133

DTC P0219 (Flash Code 543) . . . . . . . . . . . . 6E-135

DTC P0231 or P0232 (Flash Code 69) . . . . . 6E-137

DTC P0234 (Flash Code 42) . . . . . . . . . . . . . 6E-140 DTC P0299 (Flash Code 65) . . . . . . . . . . . . . 6E-143

DTC P0335 (Flash Code 15) . . . . . . . . . . . . . 6E-146

DTC P0336 (Flash Code 15) . . . . . . . . . . . . . 6E-149

DTC P0340 (Flash Code 14) . . . . . . . . . . . . . 6E-151

DTC P0341 (Flash Code 14) . . . . . . . . . . . . . 6E-154

DTC P0380 (Flash Code 66) . . . . . . . . . . . . . 6E-156

DTC P0401 (Flash Code 93) . . . . . . . . . . . . . 6E-159

DTC P0403 (Flash Code 37) . . . . . . . . . . . . . 6E-161

DTC P0404 (Flash Code 45) . . . . . . . . . . . . . 6E-164

DTC P0405 or P0406 (Flash Code 44) . . . . . 6E-166

DTC P0500 (Flash Code 25) . . . . . . . . . . . . . 6E-170

DTC P0501 (Flash Code 25) . . . . . . . . . . . . . 6E-174

DTC P0512 (Flash Code 417) . . . . . . . . . . . . 6E-176

DTC P0562 or P0563 (Flash Code 35) . . . . . 6E-178

DTC P0565 (Flash Code 515) . . . . . . . . . . . . 6E-181

DTC P0566 (Flash Code 516) . . . . . . . . . . . . 6E-183

DTC P0567 (Flash Code 517) . . . . . . . . . . . . 6E-185

DTC P0568 (Flash Code 518) . . . . . . . . . . . . 6E-187

DTC P0571 (Flash Code 26) . . . . . . . . . . . . . 6E-189

DTC P0601 (Flash Code 53) . . . . . . . . . . . . . 6E-192

DTC P0602 (Flash Code 154) . . . . . . . . . . . . 6E-193

DTC P0604 or P0606 (Flash Code 153 or 51) . . . . . . . . . . . . . . . . . 6E-195

DTC P0615 (Flash Code 19) . . . . . . . . . . . . . 6E-196

DTC P0633 (Flash Code 176) . . . . . . . . . . . . 6E-198

DTC P0638 (Flash Code 61) . . . . . . . . . . . . . 6E-199

DTC P0642 or P0643 (Flash Code 55) . . . . . 6E-201

DTC P0650 (Flash Code 77) . . . . . . . . . . . . . 6E-204

DTC P0652 or P0653 (Flash Code 56) . . . . . 6E-207

DTC P0661 or P0662 (Flash Code 58) . . . . . 6E-211

DTC P0698 or P0699 (Flash Code 57) . . . . . 6E-215

DTC P0700 (Flash Code 185) . . . . . . . . . . . . 6E-219

DTC P1064 or P1065 (Flash Code 247) . . . . 6E-220

DTC P1093 (Flash Code 227) . . . . . . . . . . . . 6E-224

DTC P1094 (Flash Code 226) . . . . . . . . . . . . 6E-229

DTC P1196, P1197 or P1198 (Flash Code 461) . . . . . . . . . . . . . . . . . . . . . 6E-235

DTC P124B (Flash Code 157) . . . . . . . . . . . . 6E-237

DTC P1261 (Flash Code 34) . . . . . . . . . . . . . 6E-240

DTC P1262 (Flash Code 34) . . . . . . . . . . . . . 6E-242

DTC P1404 (Flash Code 45) . . . . . . . . . . . . . 6E-244

DTC P1411, P1412 or P1413 (Flash Code 445) . . . . . . . . . . . . . . . . . . . . . 6E-246

DTC P156A or P156B (Flash Code 135) . . . . 6E-248

DTC P161B (Flash Code 179) . . . . . . . . . . . . 6E-251

DTC P1621 (Flash Code 54, 254) . . . . . . . . . 6E-253

DTC P1664 (Flash Code 76) . . . . . . . . . . . . . 6E-255

DTC P2100, P2101 or P2103 (Flash Code 446) . . . . . . . . . . . . . . . . . . . . . 6E-258

DTC P2122 or P2123 (Flash Code 121) . . . . 6E-261

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1621 of 6020

6E-4 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Diagnostic Trouble Code (DTC) Type

Definitions

Emission Related DTC

Action Taken When the DTC Sets - Type A • The ECM illuminates the malfunction indicator lamp (MIL) when the diagnostic runs and fails.

• The ECM records the operating conditions at the time the diagnostic fails. The ECM stores this

information in the Freeze Frame/ Failure Records.

Action Taken When the DTC Sets - Type B • The ECM illuminates the MIL on the second consecutive driving cycle when the diagnostic runs

and fails.

• The ECM records the operating conditions at the time the diagnostic fails. The first time the

diagnostic fails, the ECM stores this information in

the Failure Records. If the diagnostic reports a

failure on the second consecutive driving cycle, the

ECM records the operating conditions at the time

of failure and stores this information in the Freeze

Frame and updates the Failure Records.

Conditions for Clearing the MIL/ DTC - Type A or

Ty p e B

• The ECM turns OFF the MIL after 3 consecutive driving cycles when the diagnostic runs and does

not fail. (Euro 4 Specification)

• The ECM turns OFF the MIL after 1 driving cycle when the diagnostic runs and does not fail. (Except

Euro 4 Specification)

• A current DTC clears when the diagnostic runs and passes after 1 driving cycle.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported. • Use a scan tool to clear the MIL and the DTC.

Non-Emissions Related DTCs

Action Taken When the DTC Sets - Type C

• The ECM illuminates the Service Vehicle Soon (SVS) lamp when the diagnostic runs and fails.

• The ECM records the operating conditions at the time the diagnostic fails. The ECM stores this

information in the Failure Records.

Conditions for Clearing the SVS Lamp/ DTC - Type

C

• The ECM turns OFF the SVS lamp after 1 driving cycle when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and passes after 1 driving cycle.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported.

• Use a scan tool to clear the SVS lamp and the DTC.

Action Taken When the DTC Sets - Type D • The ECM will not illuminate the MIL or SVS lamp.

• The ECM records the operating conditions at the time the diagnostic fails. The ECM stores this

information in the Failure Records.

Conditions for Clearing the DTC - Type D • A current DTC clears when the diagnostic runs and passes after 1 driving cycle.

• A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported.

• Use a scan tool to clear the DTC.

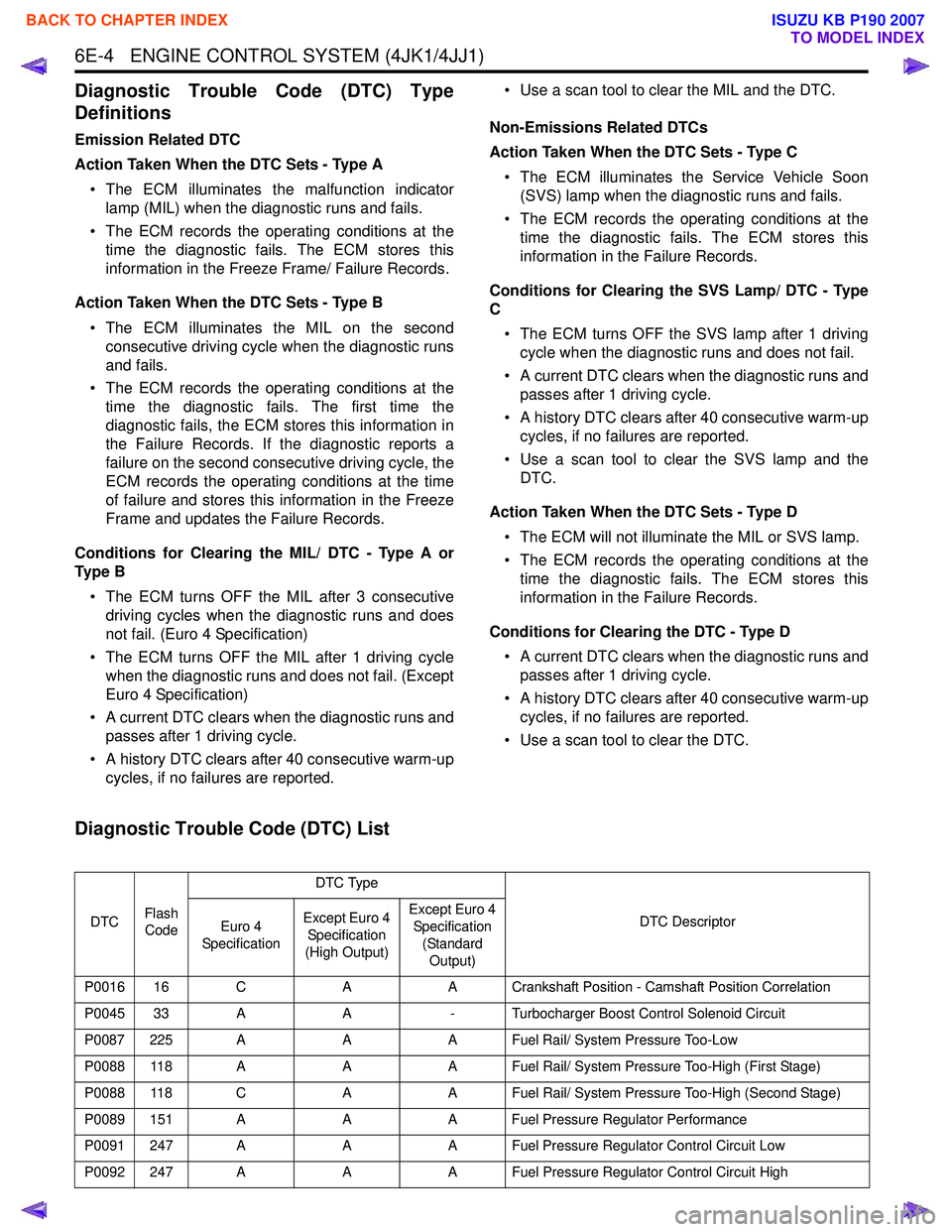

Diagnostic Trouble Code (DTC) List

DTC Flash

Code DTC Type

DTC Descriptor

Euro 4

Specification Except Euro 4

Specification

(High Output) Except Euro 4

Specification

(Standard Output)

P0016 16 C AA Crankshaft Position - Camshaft Position Correlation

P0045 33 A A- Turbocharger Boost Control Solenoid Circuit

P0087 225 A AA Fuel Rail/ System Pressure Too-Low

P0088 118 A AA Fuel Rail/ System Pressure Too-High (First Stage)

P0088 118 C AA Fuel Rail/ System Pressure Too-High (Second Stage)

P0089 151 A AA Fuel Pressure Regulator Performance

P0091 247 A AA Fuel Pressure Regulator Control Circuit Low

P0092 247 A AA Fuel Pressure Regulator Control Circuit High

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1622 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-5

P0093 227 AAA Fuel System Leak Detected

P0101 92 A -- Mass Air Flow Sensor Circuit Range/ Performance

P0102 91 A AA Mass Air Flow Sensor Circuit Low Input

P0103 91 A AA Mass Air Flow Sensor Circuit High Input

P0107 32 A A- Manifold Absolute Pressure Sensor Circuit Low Input

P0108 32 A A- Manifold Absolute Pressure Sensor Circuit High Input

P0112 22 A AA Intake Air Temperature Sensor Circuit Low

P0113 22 A AA Intake Air Temperature Sensor Circuit High

P0116 23 A --Engine Coolant Temperature Sensor Circuit Range/

Performance

P0117 23 A AA Engine Coolant Temperature Sensor Circuit Low

P0118 23 A AA Engine Coolant Temperature Sensor Circuit High

P0122 43 B AA Throttle Position Sensor Circuit Low

P0123 43 B AA Throttle Position Sensor Circuit High

P0182 211 A AA Fuel Temperature Sensor Circuit Low

P0183 211 A AA Fuel Temperature Sensor Circuit High

P0192 245 A AA Fuel Rail Pressure Sensor Circuit Low

P0193 245 A AA Fuel Rail Pressure Sensor Circuit High

P0201 271 A AA Injector Circuit Open - Cylinder 1

P0202 272 A AA Injector Circuit Open - Cylinder 2

P0203 273 A AA Injector Circuit Open - Cylinder 3

P0204 274 A AA Injector Circuit Open - Cylinder 4

P0217 542 D DD Engine Coolant Over Temperature Condition

P0219 543 C AA Engine Overspeed Condition

P0231 69 C AA Fuel Pump Secondary Circuit Low

P0232 69 C AA Fuel Pump Secondary Circuit High

P0234 42 A A- Turbocharger Overboost Condition

P0299 65 A A- Turbocharger Underboost

P0335 15 A AA Crankshaft Position Sensor Circuit

P0336 15 A AA Crankshaft Position Sensor Circuit Range/ Performance

P0340 14 C AA Camshaft Position Sensor Circuit

P0341 14 C AA Camshaft Position Sensor Circuit Range/ Performance

P0380 66 C AA Glow Plug Circuit

P0401 93 A -- EGR Flow Insufficient Detected

P0403 37 B AA EGR Control Circuit

P0404 45 A AA EGR Control Circuit Range/ Performance

P0405 44 B AA EGR Sensor Circuit Low

P0406 44 B AA EGR Sensor Circuit High

P0500 25 A AA Vehicle Speed Sensor

DTC

Flash

Code DTC Type

DTC Descriptor

Euro 4

Specification Except Euro 4

Specification

(High Output) Except Euro 4

Specification (Standard Output)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007