display ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5595 of 6020

Cruise Control – HFV6 Page 8C–17

Step Action Yes No

17

NOTE

This procedure is only required on vehicles fitted with

manual transmissions. If the vehicle is fitted with an

automatic transmission go to Step 26.

Test the clutch pedal switch, refer to

3.4 Clutch Pedal Switch.

Is the clutch pedal switch serviceable? Go to Step 28 Go to Step 21

18 Replace the faulty cruise control switch assembly with a serviceable

item. To replace the switch assembly, refer to 8 B Cruise Control

System. Go to Step 32 —

19 Replace the faulty stop lamp switch, refer to 3.3 Stop Lamp

Switch Assembly Go to Step 32 —

20 Replace the faulty stop lamp switch, refer to 3.3 Stop Lamp

Switch Assembly Go to Step 32 —

21

Replace the faulty clutch pedal switch, refer to

3.4 Clutch Pedal Switch Go to Step 32 —

22 1 Disconnect the PIM connector B – 97.

2 Using a multimeter set to measure voltage, back probe between the harness connector B – 97 pin 14 and a known ground.

3 W ith the aid of an assistant, monitor the voltage on the multimeter and press and release the cruise control switch ON–

OFF button.

• W ith the button in the rest position, the multimeter should

display 0 V.

• W ith the button pressed, the multimeter should display

battery voltage.

Does the multimeter display as described? Go to Step 30 Check for short to

ground or open circuit.

Repair as required

(refer to Note 1).

Go to Step 32

23 1 Disconnect the PIM connector B – 97.

2 Using a multimeter set to measure voltage, back probe between the harness connector B – 97 pin 16 and a known ground.

3 With the aid of an assistant, monitor the voltage on the multimeter and rotate and release the cruise control switch to

RES–ACC position.

• With the switch in the rest position, the multimeter should

display 0 V.

• With the switch rotated, the multimeter should display

battery voltage.

Does the multimeter display as described? Go to Step 30 Check for short to

ground or open

circuit on circuit.

Repair as required

(refer to Note 1).

Go to Step 32

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5596 of 6020

Cruise Control – HFV6 Page 8C–18

Step Action Yes No

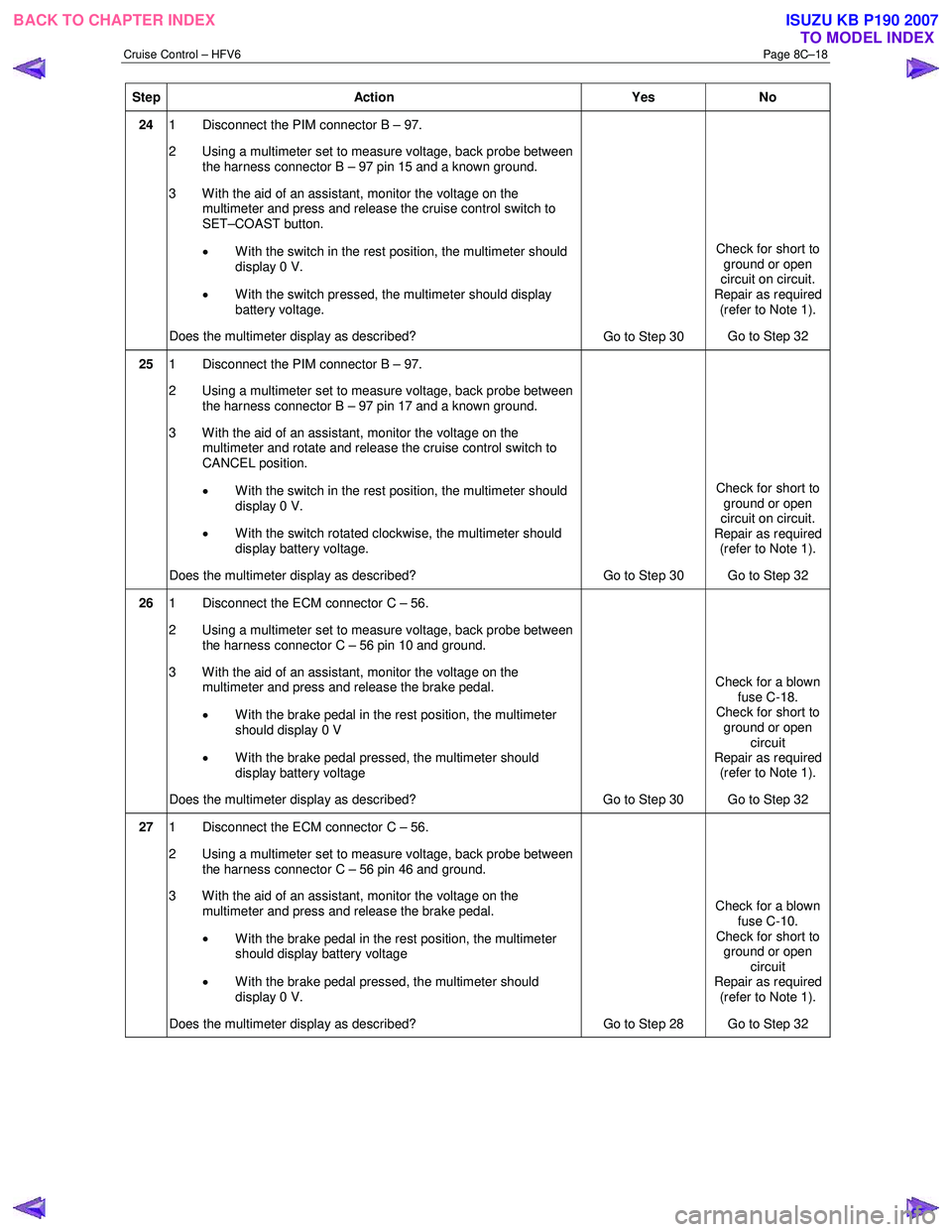

24 1 Disconnect the PIM connector B – 97.

2 Using a multimeter set to measure voltage, back probe between the harness connector B – 97 pin 15 and a known ground.

3 With the aid of an assistant, monitor the voltage on the multimeter and press and release the cruise control switch to

SET–COAST button.

• With the switch in the rest position, the multimeter should

display 0 V.

• With the switch pressed, the multimeter should display

battery voltage.

Does the multimeter display as described? Go to Step 30 Check for short to

ground or open

circuit on circuit.

Repair as required (refer to Note 1).

Go to Step 32

25 1 Disconnect the PIM connector B – 97.

2 Using a multimeter set to measure voltage, back probe between the harness connector B – 97 pin 17 and a known ground.

3 W ith the aid of an assistant, monitor the voltage on the multimeter and rotate and release the cruise control switch to

CANCEL position.

• With the switch in the rest position, the multimeter should

display 0 V.

• W ith the switch rotated clockwise, the multimeter should

display battery voltage.

Does the multimeter display as described? Go to Step 30 Check for short to

ground or open

circuit on circuit.

Repair as required (refer to Note 1).

Go to Step 32

26 1 Disconnect the ECM connector C – 56.

2 Using a multimeter set to measure voltage, back probe between the harness connector C – 56 pin 10 and ground.

3 With the aid of an assistant, monitor the voltage on the multimeter and press and release the brake pedal.

• W ith the brake pedal in the rest position, the multimeter

should display 0 V

• W ith the brake pedal pressed, the multimeter should

display battery voltage

Does the multimeter display as described? Go to Step 30 Check for a blown

fuse C-18.

Check for short to

ground or open circuit

Repair as required (refer to Note 1).

Go to Step 32

27 1 Disconnect the ECM connector C – 56.

2 Using a multimeter set to measure voltage, back probe between the harness connector C – 56 pin 46 and ground.

3 With the aid of an assistant, monitor the voltage on the multimeter and press and release the brake pedal.

• W ith the brake pedal in the rest position, the multimeter

should display battery voltage

• W ith the brake pedal pressed, the multimeter should

display 0 V.

Does the multimeter display as described? Go to Step 28 Check for a blown

fuse C-10.

Check for short to ground or open

circuit

Repair as required (refer to Note 1).

Go to Step 32

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5597 of 6020

Cruise Control – HFV6 Page 8C–19

Step Action Yes No

28 1 Disconnect the ECM connector C – 56.

2 Using a multimeter set to measure voltage, back probe between the harness connector C – 56 pin 53 and ground.

3 W ith the aid of an assistant, monitor the voltage on the multimeter and press and release the clutch pedal.

• With the clutch pedal in the rest position, the multimeter

should display battery voltage

• W ith the clutch pedal pressed, the multimeter should

display 0 V

Does the multimeter display as described? Go to Step 31 Check for a blown

fuse C-4.

Check for short to ground or open circuit

Repair as required (refer to Note 2).

Go to Step 32

29 Check all associated circuits and connectors for the following:

• Loose or damaged connections

• Intermittent faults.

Refer to the Wiring Diagrams in this Section and repair as required.

W as the repair completed? Go to Step 32 —

30 Replace the PIM, refer to 6E1 Powertrain Interface Module – V6.

W as the repair completed? Go to Step 32 —

31 Replace the ECM module, refer to 6C1-3 Engine Management – V6

Service Operations.

W as the repair completed? Go to Step 32 —

32 Operate the system in order to verify the repair.

Did you correct the condition? System OK Go to Step 1

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5649 of 6020

9A-14 SUPPLEMENTAL RESTRAINT SYSTEM

Component Description

SRS Control Unit

WARNING: DURING SERVICE PROCEDURES, BE

VERY CAREFUL WHEN HANDLING A SRS

CONTROL UNIT. NEVER STRIKE OR JAR THE SRS

CONTORL UNIT. NEVER POWER UP THE SRS

WHEN THE SRS CONTROL UNIT IS NOT RIGIDLY

ATTACHED TO THE VEHICLE. ALL SRS CONTROL

UNIT AND MOUNTING BRACKET FASTENERS

MUST BE CAREFULLY TORQUED AND THE

ARROW MUST BE POINTED TOWARD THE FRONT

OF THE VEHICLE TO ENSURE PROPER

OPERATION OF THE SRS. THE SRS CONTROL

UNIT COULD BE ACTIVATED WHEN POWERED

WHILE NOT RIGIDLY ATTACHED TO THE

VEHICLE WHICH COULD CAUSE DEPLOYMENT

AND RESULT IN PERSONAL INJURY.

The SRS control unit is designed to perform the

following functions in the SRS:

1. Energy Reserve — The SRS control unit maintains 30–Volt Loop Reserve (30VLR) energy supply to

provide deployment energy when ignition voltage is

lost in a frontal crash.

2. Frontal Crash Detection — The SRS control unit monitors vehicle velocity changes to detect frontal

crashes which are severe enough to warrant

deployment.

3. Air Bag Deployment — W hen a frontal crash o

f

sufficient force is detected, the SRS control unit

will cause enough current to flow through the ai

r

bag assembly to deploy the air bag.

4. Malfunction Detection — The SRS control unit performs diagnostic monitoring of SRS electrical

components and sets a diagnostic trouble code

when a malfunction is detected.

5. Frontal Crash Recording — The SRS control unit records information regarding SRS status during

frontal crash.

6. Malfunction Diagnosis — The SRS control unit displays SRS diagnostic trouble codes and system

status information through the use of a scan tool.

7. Driver Notification — The SRS control unit warns the vehicle driver of SRS malfunctions b

y

controlling the “SRS” warning lamp.

The SRS control unit is connected to the SRS wiring

harness by a 52–pin connector. This harness

connector uses a shorting clip across certain terminals

in the contact area. This shorting clip connects the

“SRS” warning lamp to ground when the SRS control

unit harness connector is disconnected or CP

A

(Connector Position Assurance) is not inserted even i

f

completely connected. This will cause the “SRS”

warning lamp to come “ON” steady whenever the

ignition switch is at the ON or START positions with

the SRS control unit disconnected.

RTW 79ASH000401

Legend

(1) SRS Control Unit

(2) SRS Harness

“SRS” Warning Lamp

Ignition voltage is applied to the “SRS” warning lamp

when the ignition switch is at the ON or START

positions. The SRS control unit controls the lamp b

y

providing ground with a lamp driver. The “SRS”

warning lamp is used in the SRS to do the following:

1. Verify lamp and SRS control unit operation b

y

flashing SEVEN (7) times when the ignition switch

is first turned “ON”.

2. W arn the vehicle driver of SRS electrical system malfunctions which could potentially affect the

operation of the SRS. These malfunctions could

result in nondeployment in case of a frontal crash

or deployment for conditions less severe than

intended.

The “SRS “ warning lamp is the key to drive

r

notification of SRS malfunctions. For proper lamp

operation, refer to the “SRS Diagnostic System Check”

in this section.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5686 of 6020

9A1-4 RESTRAINT CONTROL SYSTEM

Basic Knowledge Required

Before using this section of the Service Manual, some

basic knowledge is required. W ithout this knowledge,

you will have trouble using the diagnostic procedures in

this section. Use care to prevent any harm or unwanted

deployment. Read all cautions in the service manual

and on warning labels attached to SRS components.

Basic Electrical Circuits

You should understand the basic theory of electricity

including series and parallel circuits, and understand

the voltage drops across series resistors. You should

know the meaning of voltage (volts), current (amps),

and resistance (ohms). You should understand what

happens in a circuit with an open or a shorted wire. You

should be able to read and understand a wiring

diagram.

“Flash Code” Diagnostics

Flash code diagnostics can be used to read active

codes and to determine if history codes are present but

cannot be used to clear codes or read history codes.

Flash code diagnostics is enabled by grounding

terminal 4, shorting to terminal 13 of the DLC, with the

ignition switched “ON”. Grounding terminal 4 of the DLC

pulls the “Diagnostics Request” input (Terminal 1) of the

SRS control unit low and signals the SRS control unit to

enter the flash code diagnostic display mode.

060R300052

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5687 of 6020

RESTRAINT CONTROL SYSTEM 9A1-5

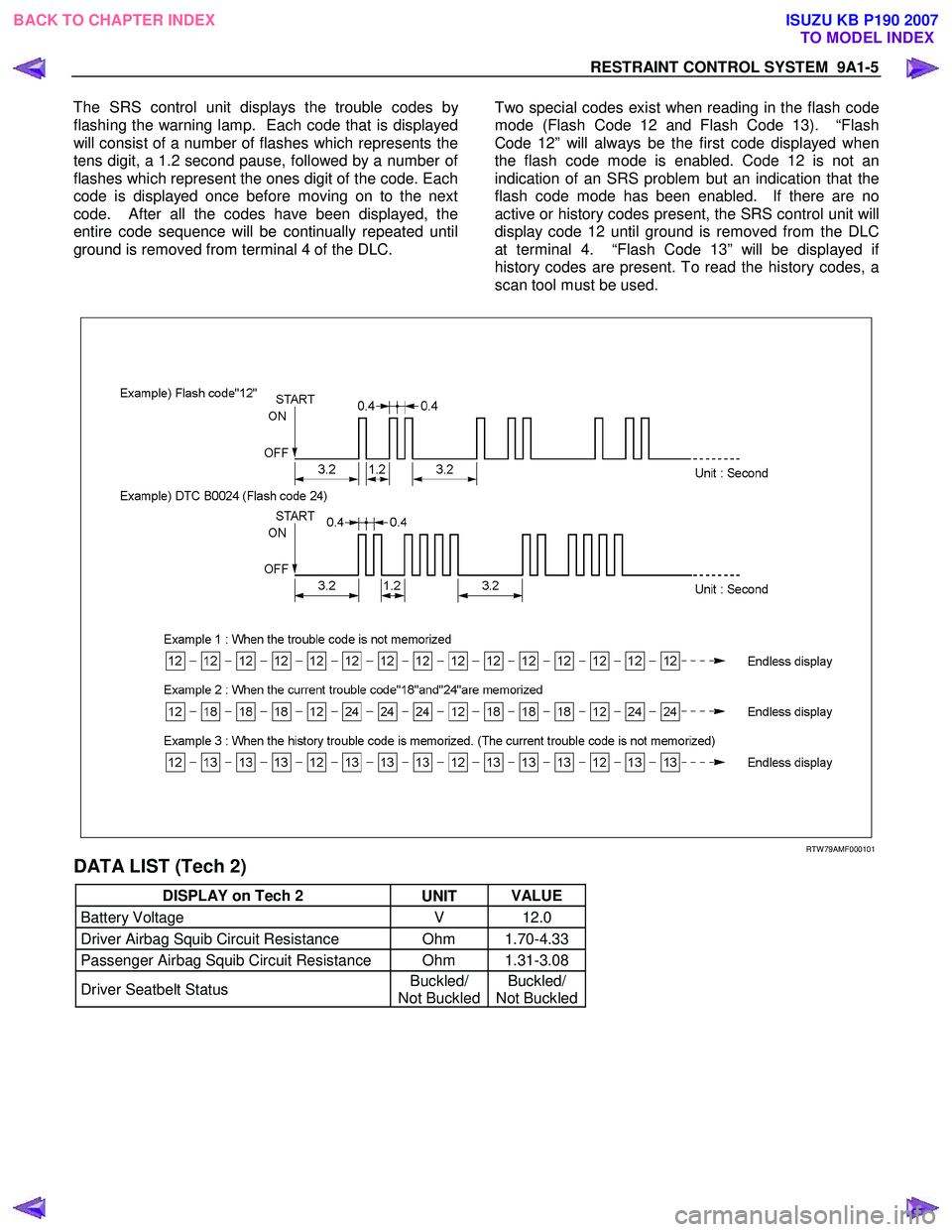

The SRS control unit displays the trouble codes b

y

flashing the warning lamp. Each code that is displayed

will consist of a number of flashes which represents the

tens digit, a 1.2 second pause, followed by a number o

f

flashes which represent the ones digit of the code. Each

code is displayed once before moving on to the next

code. After all the codes have been displayed, the

entire code sequence will be continually repeated until

ground is removed from terminal 4 of the DLC.

Two special codes exist when reading in the flash code

mode (Flash Code 12 and Flash Code 13). “Flash

Code 12” will always be the first code displayed when

the flash code mode is enabled. Code 12 is not an

indication of an SRS problem but an indication that the

flash code mode has been enabled. If there are no

active or history codes present, the SRS control unit will

display code 12 until ground is removed from the DLC

at terminal 4. “Flash Code 13” will be displayed i

f

history codes are present. To read the history codes, a

scan tool must be used.

RTW 79AMF000101

DATA LIST (Tech 2)

DISPLAY on Tech 2 UNIT VALUE

Battery Voltage

V 12.0

Driver Airbag Squib Circuit Resistance Ohm 1.70-4.33

Passenger Airbag Squib Circuit Resistance Ohm 1.31-3.08

Driver Seatbelt Status Buckled/

Not Buckled Buckled/

Not Buckled

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5688 of 6020

9A1-6 RESTRAINT CONTROL SYSTEM

Diagnostic Trouble Codes

Choose and trace an appropriate flowchart by the numbers listed below to find fault and repair.

DTC Flash Code Description

– 12 Diagnostic Display Mode (Flash Code only)

– 13 Diagnostic Display Mode (Flash Code only)

B0015 15 Passenger Air Bag Squib Circuit High Resistance

B0016 16 Passenger Air Bag Squib Circuit Low Resistance

B0018 18 Passenger Air Bag Squib Circuit Short to GND

B0019 19 Passenger Air Bag Squib Circuit Short to Battery Voltage

B0021 21 Driver Air Bag Squib Circuit High Resistance

B0022 22 Driver Air Bag Squib Circuit Low Resistance

B0025 25 Driver Air Bag Squib Circuit Short to GND

B0026 26 Driver Air Bag Squib Circuit Short to Battery Voltage

B0029 29 Passenger Pretensioner Squib Circuit High Resistance

B0031 31 Passenger Pretensioner Squib Circuit Low Resistance

B0033 33 Passenger Pretensioner Squib Circuit Short to GND

B0034 34 Passenger Pretensioner Squib Circuit Short to Battery Voltage

B0041 41 Driver Pretensioner Squib Circuit High Resistance

B0042 42 Driver Pretensioner Squib Circuit Low Resistance

B0045 45 Driver Pretensioner Squib Circuit Short to GND

B0046 46 Driver Pretensioner Squib Circuit Short to Battery Voltage

B0051 51 Air Bag Squib Circuit Activated (Clash)

B0052 52 Pretensioner Squib Circuit Activated

B0055 55 Vehicle Variant Missing

B0061 61 Warning Lamp Circuit Failure

B0062 62 Battery Voltage Too High

B0063 63 Battery Voltage Too Low

B0071 71 SRS Control Unit Internal Fault

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5690 of 6020

9A1-8 RESTRAINT CONTROL SYSTEM

Circuit Description

W hen the ignition switch is first turned “ON”, “Ignition 1”

voltage is applied from the “SRS” fuse to the SRS

control unit at the “Ignition 1” input terminals “1”. The

SRS control unit responds by flashing the “SRS”

warning lamp seven times, while performing tests on

the SRS.

Notes On System Check Chart

1. The “SRS” warning lamp should flash seven times after the ignition is first turned “ON”.

2.

After the “SRS” warning lamp flashes seven times, it

should turn to “LOCK”

3. This test checks for the proper operation of the “Serial Data” line. This test will also determine

whether history diagnostic trouble codes are stored

and, if so, identify them.

4. Improper operation of the “SRS” warning lamp is indicated. This test differentiates between ‘a

warning lamp stays “ON” condition’ and ‘a warning

lamp does not come “ON” condition’.

5. This test checks for proper operation of the “Serial Data” line. This test will also identify the stored

diagnostic trouble codes and whether they are

current or history.

Diagnostic Aids

The order in which diagnostic trouble codes are

diagnosed is very important. Failure to diagnose the

diagnostic trouble codes in the order specified ma

y

result in extended diagnostic time, incorrect diagnosis

and incorrect parts replacement.

SRS Diagnostic System Check

Step Action Yes No

1 Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Does the “SRS” warning lamp flash seven (7) times? Go to Step 2 Go to Step 3

2 Note the “SRS” warning lamp after it flashed 7 times.

Does the “SRS” warning lamp go “OFF”? Go to Step 4 Go to Step 5

3 Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Does the “SRS” warning lamp come “ON” steady? Go to Chart B. Go to Chart C.

4

1. Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Ignition switch is at “LOCK”.

2. Connect a scan tool to data link connector.

3. Follow direction given in the scan tool instruction manual.

Ignition switch is “ON”.

4. Request the SRS diagnostic trouble code display, recode all

history diagnostic trouble code(s), specifying as current or

history in repair order.

Is (are) diagnostic trouble code(s) displayed?

Ignition switch

“LOCK”.

W hen DTC B0071 is set, go to DTC B0071 Chart.

For all other history codes refer to

“Diagnostic Aids” For that specific DTC.

A history DTC indicates the

malfunction has

been repaired or is intermittent. SRS is functional

and free of

malfunctions, no

further diagnosis is required.

If scan tool

indicated “NO DATA

RECEIVED,” refer to chassis

electrical section 8.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5691 of 6020

RESTRAINT CONTROL SYSTEM 9A1-9

Step Action Yes No

5 1. Ignition switch is at “LOCK”.

2. Connect a scan tool to data link connector.

3. Follow directions as given in the scan tool instruction manual.

4. Ignition switch is “ON”.

5. Request the SRS diagnostic trouble code display, Recode all diagnostic trouble code(s), specifying as current or history in

repair order.

Is (are) diagnostic trouble code (s) displayed? Ignition switch

“LOCK”.

W hen the current DTC is set, go to applicable DTC chart.

And then if DTC B0019, B0025,

B0051, B0055 or

B0071 is set, go to these DTC chart first.

W hen only history

DTCs exist, refer to “Diagnostics Aids” for that specific DTC.

A history DTC indicates the

malfunction has

been repaired or is intermittent. If scan tool indicates

“No Data Received,” refer to chassis

electrical section 8.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5693 of 6020

RESTRAINT CONTROL SYSTEM 9A1-11

3. W hen all circuitry outside the SRS control unit has been found to operate properly, as indicated by the

appropriate diagnostic chart, then and only then

should the SRS control unit be replaced.

Chart A SRS control unit Integrity Check

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SRS CONTROL UNIT.

NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS CONTROL

UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SRS CONTROL UNIT AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT

OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT COULD BE

ACTIVATED WHEN POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY

Step Action Yes No

1 1. This chart assumes that the “SRS Diagnostic System Check”

and either a symptom chart or a diagnostic trouble code chart

diagnosis has been performed. W hen all circuitry outside the

SRS control unit has been found to operate properly, as

indicated by the appropriate diagnostic chart, and the

symptom or DTC remains current, check the following.

2. Diagnostic procedures must be performed to verify the need

for SRS control unit replacement.

3. Ignition switch is at “LOCK”.

4. Reconnect all SRS components and ensure all components are properly mounted.

5. Ensure the ignition switch has been in the “LOCK” position for

at least 15 seconds.

6. Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Does the warning lamp flash 7 times then go “OFF”? The symptom or

DTC is no longer occurring.

Clear SRS

diagnostic trouble codes.

Repeat “SRS

Diagnostic System Check” Go to Step 2

2 Using a scan tool, request the diagnostic trouble code display.

Is the same symptom or DTC occurring that was occurring when

the “SRS Diagnostic System Check” was first performed? Go to Step 3 Ignition switch

“LOCK”.

Go to the

appropriate chart for the indicated malfunction.

3 1. Clear the “SRS Diagnostic Trouble Codes”.

2. Ignition switch is in the “LOCK” position for at least two

minutes.

3. Note the “SRS” warning lamp as the ignition switch is turned

“ON”.

Does warning lamp flash 7 times then go “OFF”? SRS is functional

and free of

malfunctions.

No further

diagnosis is required.

Go to Step 4 Ignition switch

“LOCK”.

Replace SRS control unit.

Go to Step 4

4 Reconnect all SRS components, ensure all components are properly mounted.

Is this step finished? Repeat the “SRS

Diagnostic System Check” —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007