heating ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2452 of 6020

ENGINE EXHAUST 6F-3

W hen inspecting or replacing exhaust system components,

make sure there is adequate clearance from all points on the

underbody to prevent overheating the floor pan and possible

damage to the passenger compartment insulation and trim

materials.

Check complete exhaust system and nearby body areas and

rear compartment lid for broken, damaged, missing or

mispositioned parts, open seams, holes, loose connections or

other deterioration which could permit exhaust fumes to seep

into the rear compartment or passenger compartment. Dust or

water in the rear compartment may be an indication of a

problem in one of these areas. Any faulty areas should be

corrected immediately.

Hangers

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps, rubber

rings, and rubber blocks.

The installation of exhaust system supports is very important,

as improperly installed supports can cause annoying vibrations

which can be difficult to diagnose.

Three Way Catalytic Converter (If applicable)

The three way catalytic converter is an emission control device

added to the exhaust system to reduce pollutants from the

exhaust gas stream.

CAUTION: The catalytic converter requires the use of

unleaded fuel only.

Periodic maintenance of the exhaust system is not required. If

the vehicle is raised for other service, it is advisable to check

the condition of the complete exhaust system.

A dual bed monolith catalytic converter is used in combination

with three way catalytic converter.

Catalytic Types:

Three way (Reduction/Oxidation) catalyst

The catalyst coating on the three way (reduction) converter

contains platinum and rhodium which lowers the levels of

nitrous oxide (NOx) as well as hydrocarbons (HC) and carbon

monoxide (Co).

Gasket

The gasket must be replaced whenever a new exhaust pipe,

muffler or catalytic converter is installed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2629 of 6020

Engine Mechanical – V6 Page 6A1–150

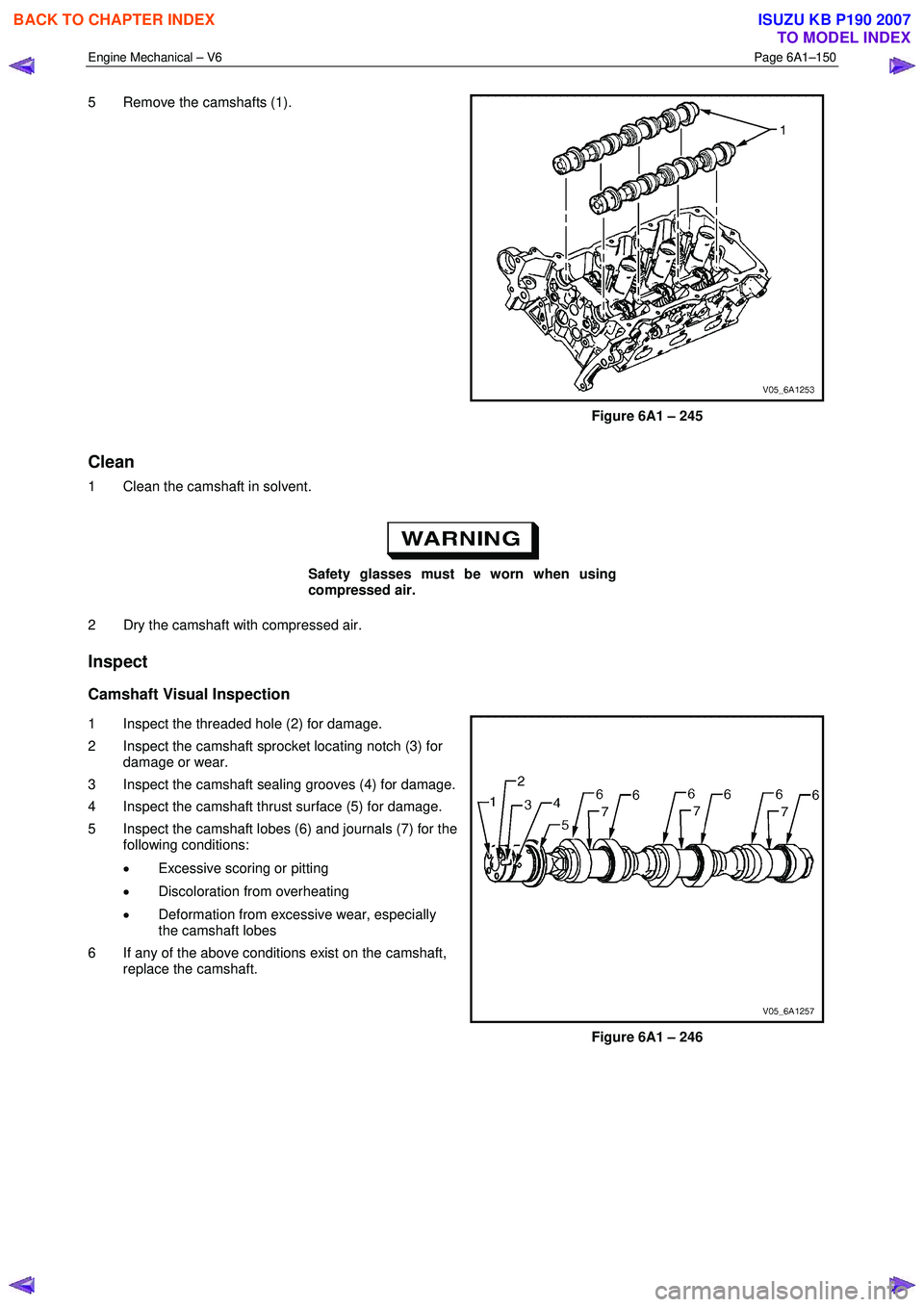

5 Remove the camshafts (1).

Figure 6A1 – 245

Clean

1 Clean the camshaft in solvent.

Safety glasses must be worn when using

compressed air.

2 Dry the camshaft with compressed air.

Inspect

Camshaft Visual Inspection

1 Inspect the threaded hole (2) for damage.

2 Inspect the camshaft sprocket locating notch (3) for damage or wear.

3 Inspect the camshaft sealing grooves (4) for damage.

4 Inspect the camshaft thrust surface (5) for damage.

5 Inspect the camshaft lobes (6) and journals (7) for the following conditions:

• Excessive scoring or pitting

• Discoloration from overheating

• Deformation from excessive wear, especially

the camshaft lobes

6 If any of the above conditions exist on the camshaft, replace the camshaft.

Figure 6A1 – 246

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2646 of 6020

Engine Mechanical – V6 Page 6A1–167

Inspect

Visual Inspection

1 Inspect the cylinder head (1) camshaft bearing

surfaces for the following conditions:

• excessive scoring or pitting,

• discoloration from overheating, and

• deformation from excessive wear.

2 If any of the above conditions exist on the camshaft bearing surfaces, replace the cylinder head. Do not

machine the camshaft bearing journals.

Figure 6A1 – 287

3 Inspect the cylinder head for the following: • Cracks, damage or pitting in the combustion chambers.

• Debris in the oil galleries. continue to clean the galleries until all debris is removed.

• Coolant leaks or damage to the deck face sealing surface. if coolant leaks are present, measure the surface

warpage as described under Cylinder Head Measurement within this Section.

• Burrs or any defects that would degrade the sealing of a new secondary camshaft chain tensioner gasket.

• Damage to any gasket surfaces.

• Damage to any threaded bolt holes.

• Burnt or eroded areas in the combustion chamber.

• Cracks in the exhaust ports and combustion chambers.

• External cracks in the water passages.

• Restrictions in the intake or exhaust passages.

• Restrictions in the cooling system passages.

• Rusted, damaged or leaking core plugs.

4 If the cylinder head is cracked or damaged, it must be replaced. No welding or patching of the cylinder head is recommended.

Cylinder Head Measurement

NOTE

For all cylinder head and associated component

specifications, refer to 5 Specifications.

Camshaft Journal Clearance

1 Install the camshaft bearing cap in the cylinder head without the camshaft.

2 Install the camshaft cap bolts and tighten to the correct torque specification

Camshaft bearing cap attaching bolt........8.0 – 12.0 Nm.

3 Measure the camshaft bearings using an inside micrometer.

4 Subtract the camshaft journal diameter from the camshaft bearing diameter. This will provide the running clearance. If the running clearance exceeds specifications and the camshaft journals are within specification, replace the

cylinder head.

Camshaft Journal Alignment

1 Ensure the camshafts are serviceable, refer to 3.19 Camshaft for measuring procedures.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2982 of 6020

Engine Mechanical – V6 Page 6A1–205

Page 6A1–205

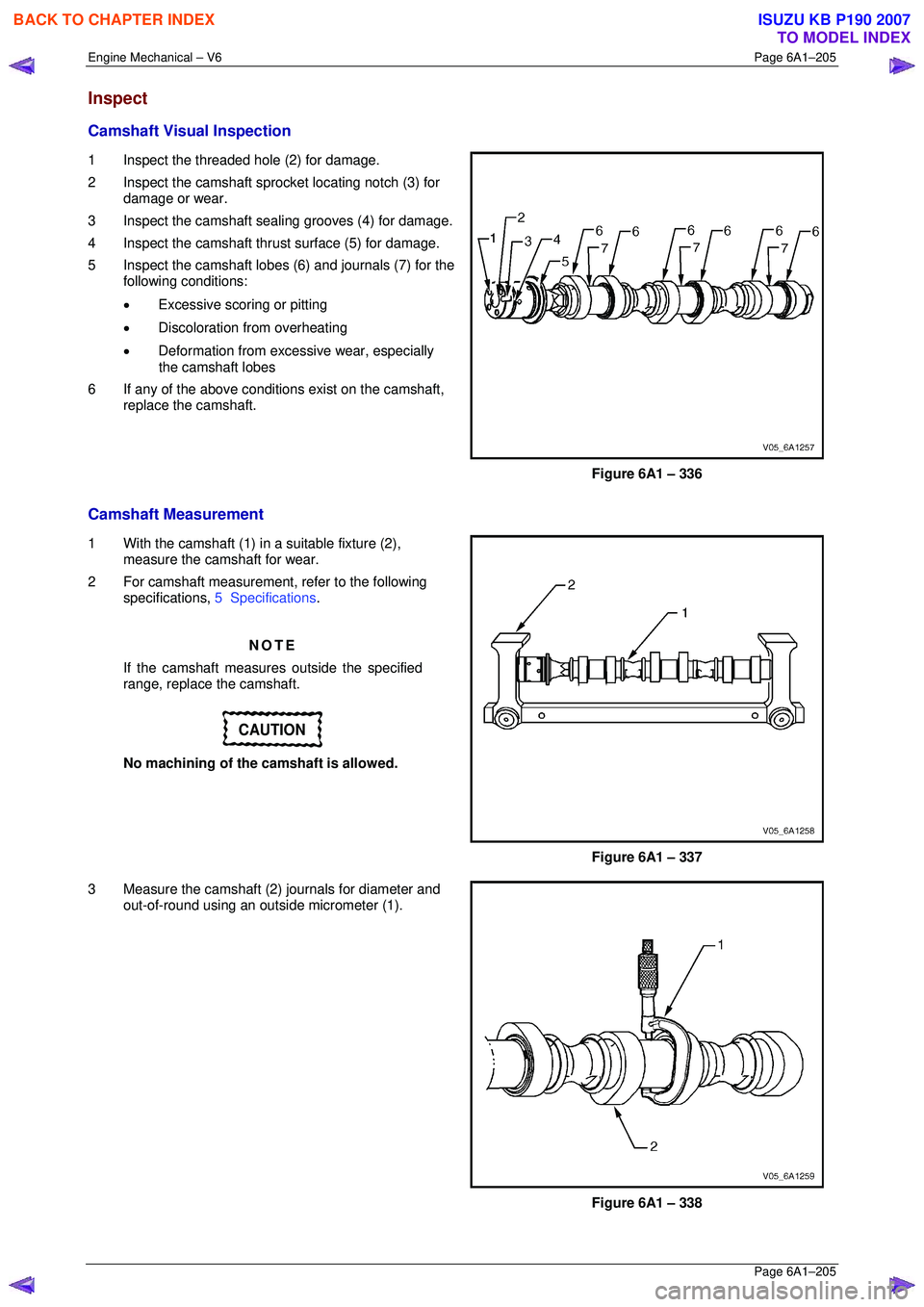

Inspect

Camshaft Visual Inspection

1 Inspect the threaded hole (2) for damage.

2 Inspect the camshaft spro cket locating notch (3) for

damage or wear.

3 Inspect the camshaft sealing grooves (4) for damage.

4 Inspect the camshaft thrust surface (5) for damage.

5 Inspect the camshaft lobes (6) and journals (7) for the following conditions:

• Excessive scoring or pitting

• Discoloration from overheating

• Deformation from excessive wear, especially

the camshaft lobes

6 If any of the above conditions exist on the camshaft, replace the camshaft.

Figure 6A1 – 336

Camshaft Measurement

1 With the camshaft (1) in a suitable fixture (2), measure the camshaft for wear.

2 For camshaft measurement, refer to the following specifications, 5 Specifications .

NOTE

If the camshaft measures outside the specified

range, replace the camshaft.

CAUTION

No machining of the camshaft is allowed.

Figure 6A1 – 337

3 Measure the camshaft (2) journals for diameter and out-of-round using an outsi de micrometer (1).

Figure 6A1 – 338

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2999 of 6020

Engine Mechanical – V6 Page 6A1–222

Page 6A1–222

Clean

CAUTION

Due to the aluminium alloy construction of

the cylinder head, wire brushes and steel

scrapers must not be used during the

cleaning process, as damage to sealing

surfaces may occur. Use a wood or plastic

scraper as an alternative.

1 Remove any old thread sealant, gasket material or seal ant using commercially available plastic or wooden scraper.

2 Clean all cylinder head surfaces with non-corrosive solvent.

Safety glasses must be worn when using

compressed air.

3 Blow out all the oil galleries using compressed air.

4 Remove any carbon deposits fr om the combustion chambers.

5 Clean any debris or build-up from the lifter pockets.

Inspect

Visual Inspection

1 Inspect the cylinder head (1) camshaft bearing surfaces for the following conditions:

• excessive scoring or pitting,

• discoloration from overheating, and

• deformation from excessive wear.

2 If any of the above conditions exist on the camshaft bearing surfaces, replace the cylinder head. Do not

machine the camshaft bearing journals.

Figure 6A1 – 377

3 Inspect the cylinder head for the following: • Cracks, damage or pitting in the combustion chambers.

• Debris in the oil galleries. continue to cl ean the galleries until all debris is removed.

• Coolant leaks or damage to the deck face sealing surfac e. if coolant leaks are present, measure the surface

warpage as described under Cylinder Head M easurement within this Section.

• Burrs or any defects that would degrade the sealing of a new secondar y camshaft chain tensioner gasket.

• Damage to any gasket surfaces.

• Damage to any threaded bolt holes.

• Burnt or eroded areas in the combustion chamber.

• Cracks in the exhaust ports and combustion chambers.

• External cracks in the water passages.

• Restrictions in the intake or exhaust passages.

• Restrictions in the cooling system passages.

• Rusted, damaged or leaking core plugs.

4 If the cylinder head is cracked or damaged, it must be r eplaced. No welding or patching of the cylinder head is

recommended.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3168 of 6020

Engine Cooling – V6 Engine Page 6B1–33

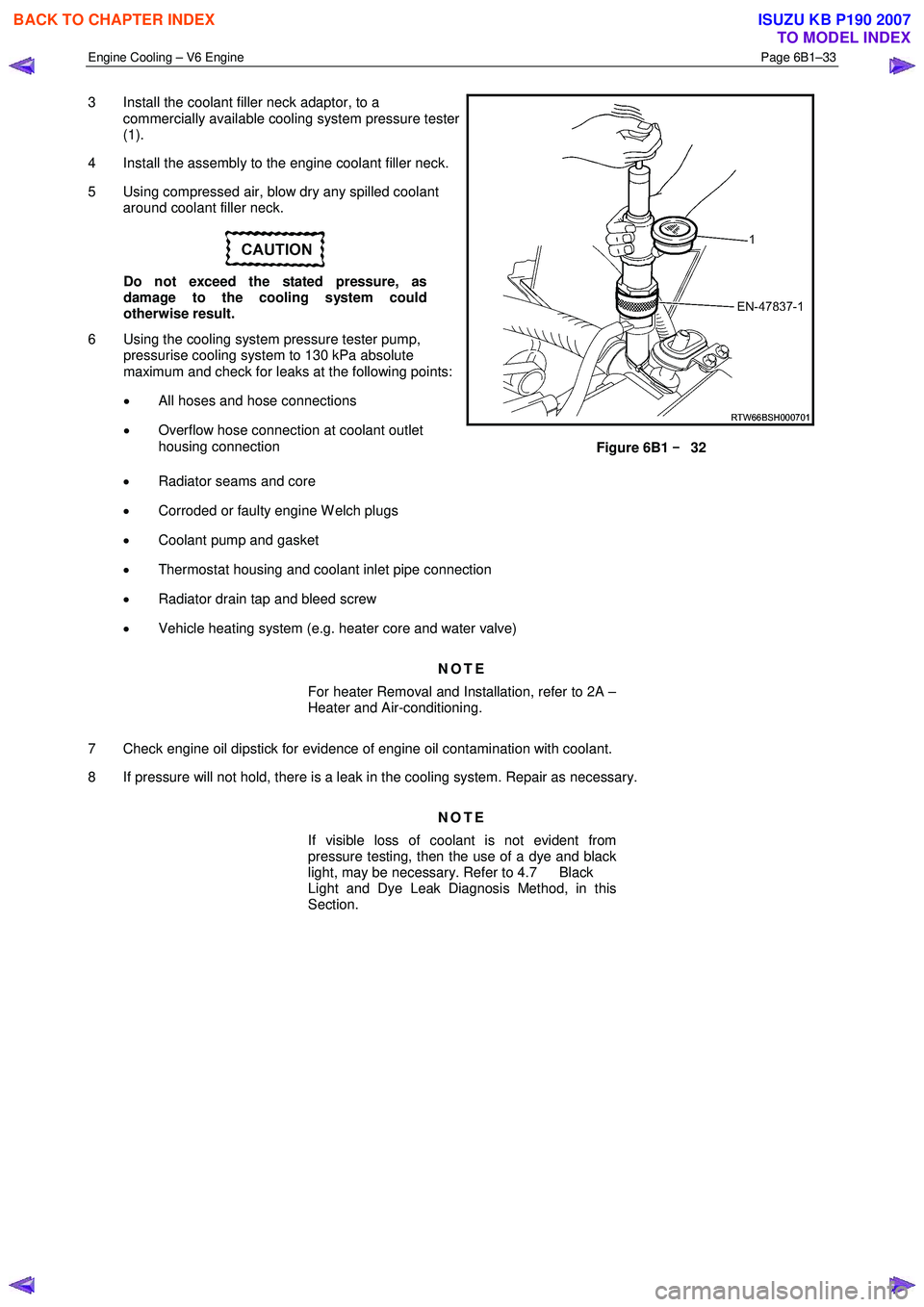

3 Install the coolant filler neck adaptor, to a

commercially available cooling system pressure tester

(1).

4 Install the assembly to the engine coolant filler neck.

5 Using compressed air, blow dry any spilled coolant around coolant filler neck.

Do not exceed the stated pressure, as

damage to the cooling system could

otherwise result.

6 Using the cooling system pressure tester pump, pressurise cooling system to 130 kPa absolute

maximum and check for leaks at the following points:

• All hoses and hose connections

• Overflow hose connection at coolant outlet

housing connection

Figure 6B1 –

––

–

32

• Radiator seams and core

• Corroded or faulty engine W elch plugs

• Coolant pump and gasket

• Thermostat housing and coolant inlet pipe connection

• Radiator drain tap and bleed screw

• Vehicle heating system (e.g. heater core and water valve)

NOTE

For heater Removal and Installation, refer to 2A –

Heater and Air-conditioning.

7 Check engine oil dipstick for evidence of engine oil contamination with coolant.

8 If pressure will not hold, there is a leak in the cooling system. Repair as necessary.

NOTE

If visible loss of coolant is not evident from

pressure testing, then the use of a dye and black

light, may be necessary. Refer to 4.7 Black

Light and Dye Leak Diagnosis Method, in this

Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3196 of 6020

Engine Cooling – V6 Engine Page 6B1–61

4 Engine Cooling System

Diagnosis

4.1 Poor Heater Operation

Little or no heat coming from the heater, especially at idle could be an indication of a cooling system problem.

As the coolant level begins to get lower than normal, air enters the system to replace the missing coolant. The heater

core is one of the highest parts of the cooling system and therefore, the first area to lose coolant circulation.

At first, with a small amount of coolant loss, lack of heat will be most noticeable at idle. As driving speed increases, the

engine pumps more coolant and more heat is now able to pass through the heater core.

If coolant level drops even lower, heater operation will become less effective, even during normal driving. Cooling and

engine systems can be adversely affected if problem is not corrected before overheating occurs.

4.2 Leaking Cylinder Head Gasket

Combustion gases leaking past the cylinder head gasket can pressurise the cooling system, forcing coolant out of the

system and into the coolant recovery reservoir.

Indications are air bubbles in the coolant or an overflow condition of the recovery reservoir.

4.3 Question the Customer

To avoid needless time and cost in diagnosing cooling system complaints, the customer should be questioned about

driving conditions that place abnormal loads on the cooling system.

1 Is overheating occurring after prolonged idle, in gear, with air conditioning system operating?

If answer is YES – instruct owner on driving techniques that would avoid overheating such as:

• Idle in neutral as much as possible – increase engine rpm to get higher air flow (due to an increase in voltage

to the fan) and coolant flow through the radiator

• Turn air conditioning system off during extended idling periods if overheating is indicated on temperature

gauge. Further diagnostic checks should not be required

2 Is overheating occurring after prolonged driving in slow city traffic, traffic jams, parades, etc?

If answer is YES, explain driving technique to the customer, that would avoid overheating – same as for prolonged idle – No.1. Further diagnostic checks should not be required.

4.4 Diagnostic Chart

If none of the above conditions apply, refer to the following Diagnosis Chart.

To effectively use this chart, question the customer to determine which of the following three categories apply to the

complaint:

1 If complaint is hot indication on temperature gauge.

W as temperature reading accompanied by boiling?

• If answer is YES, go to overheating on diagnosis chart

• If answer is NO, check temperature gauge and sender

2 If complaint is boiling – go to overheating on diagnosis chart.

3 If complaint is coolant loss. Determine if customer is filling the system correctly.

4 If incorrect filling is not the problem, go to coolant loss in the diagnosis chart.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3269 of 6020

Engine Management – V6 – General Information Page 6C1-1–27

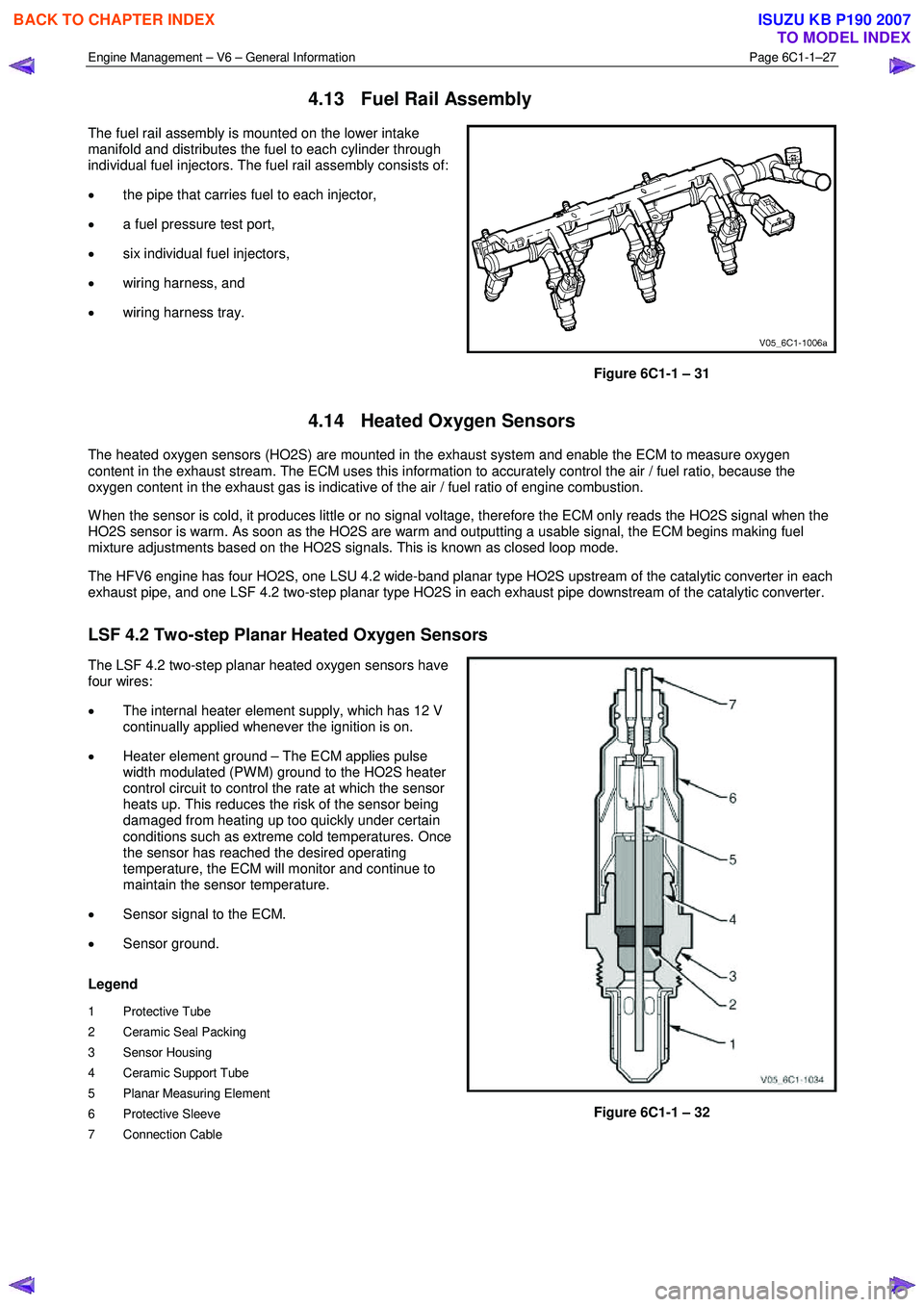

4.13 Fuel Rail Assembly

The fuel rail assembly is mounted on the lower intake

manifold and distributes the fuel to each cylinder through

individual fuel injectors. The fuel rail assembly consists of:

• the pipe that carries fuel to each injector,

• a fuel pressure test port,

• six individual fuel injectors,

• wiring harness, and

• wiring harness tray.

Figure 6C1-1 – 31

4.14 Heated Oxygen Sensors

The heated oxygen sensors (HO2S) are mounted in the exhaust system and enable the ECM to measure oxygen

content in the exhaust stream. The ECM uses this information to accurately control the air / fuel ratio, because the

oxygen content in the exhaust gas is indicative of the air / fuel ratio of engine combustion.

W hen the sensor is cold, it produces little or no signal voltage, therefore the ECM only reads the HO2S signal when the

HO2S sensor is warm. As soon as the HO2S are warm and outputting a usable signal, the ECM begins making fuel

mixture adjustments based on the HO2S signals. This is known as closed loop mode.

The HFV6 engine has four HO2S, one LSU 4.2 wide-band planar type HO2S upstream of the catalytic converter in each

exhaust pipe, and one LSF 4.2 two-step planar type HO2S in each exhaust pipe downstream of the catalytic converter.

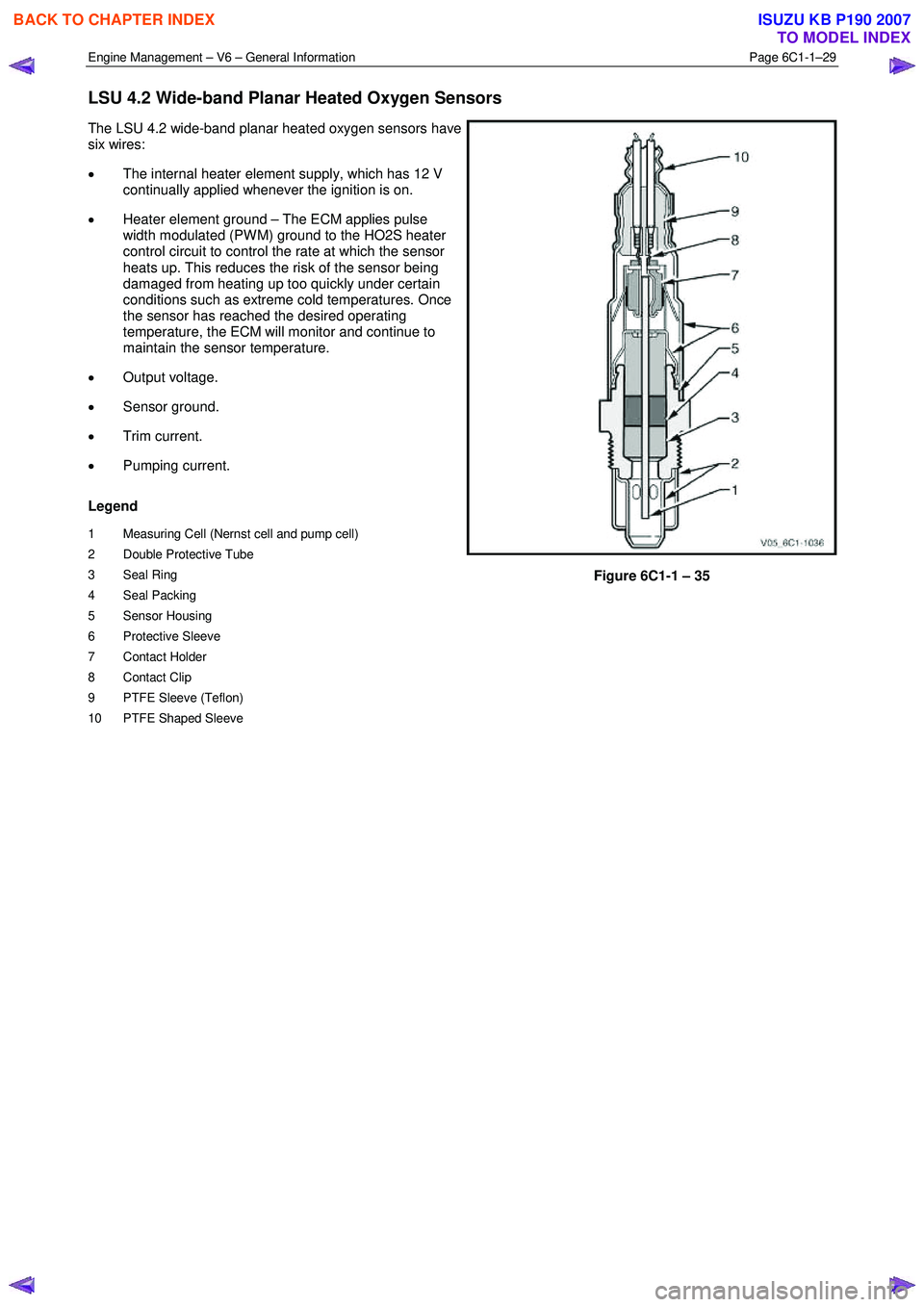

LSF 4.2 Two-step Planar Heated Oxygen Sensors

The LSF 4.2 two-step planar heated oxygen sensors have

four wires:

• The internal heater element supply, which has 12 V

continually applied whenever the ignition is on.

• Heater element ground – The ECM applies pulse

width modulated (PW M) ground to the HO2S heater

control circuit to control the rate at which the sensor

heats up. This reduces the risk of the sensor being

damaged from heating up too quickly under certain

conditions such as extreme cold temperatures. Once

the sensor has reached the desired operating

temperature, the ECM will monitor and continue to

maintain the sensor temperature.

• Sensor signal to the ECM.

• Sensor ground.

Legend

1 Protective Tube

2 Ceramic Seal Packing

3 Sensor Housing

4 Ceramic Support Tube

5 Planar Measuring Element

6 Protective Sleeve

7 Connection Cable

Figure 6C1-1 – 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3271 of 6020

Engine Management – V6 – General Information Page 6C1-1–29

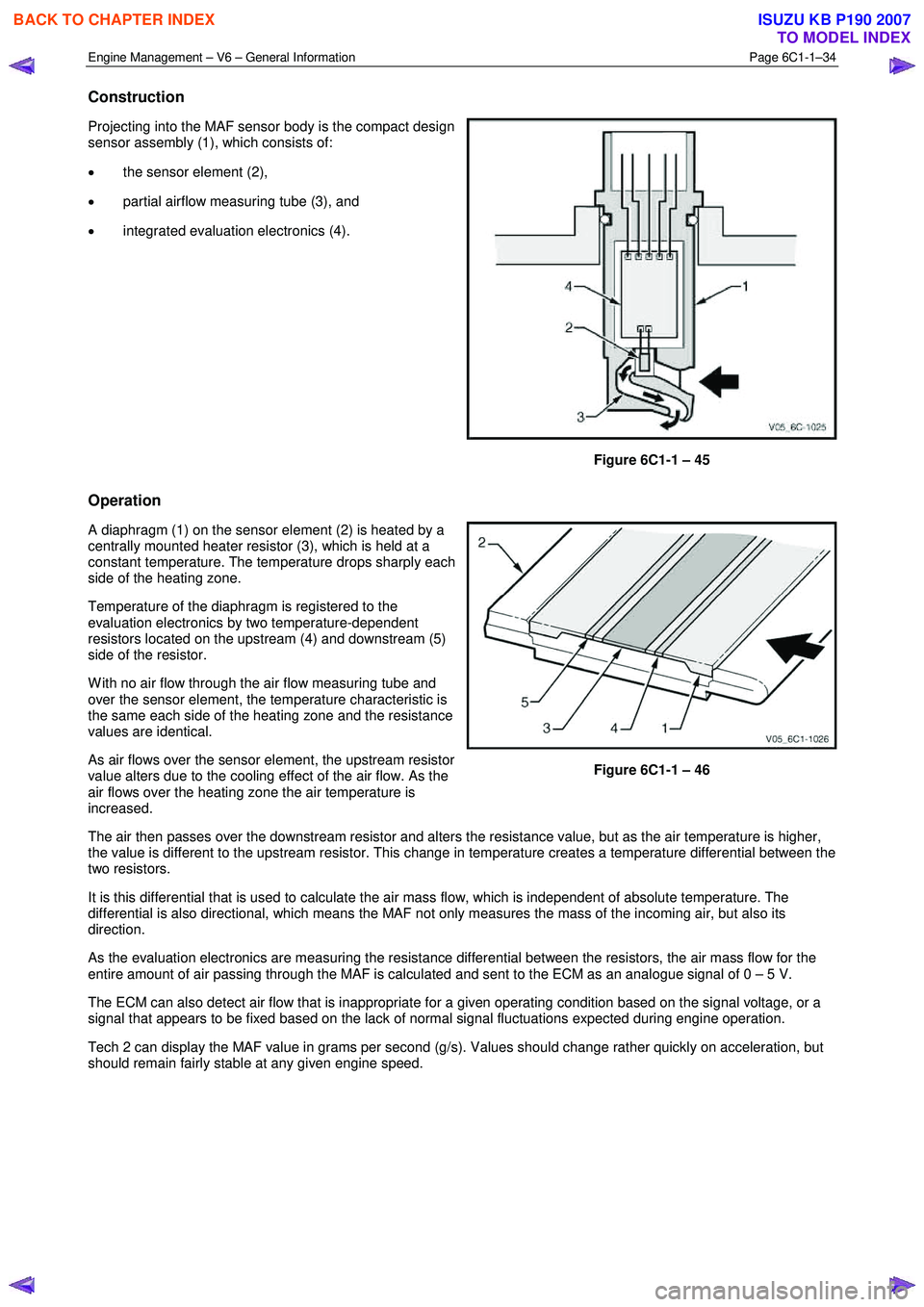

LSU 4.2 Wide-band Planar Heated Oxygen Sensors

The LSU 4.2 wide-band planar heated oxygen sensors have

six wires:

• The internal heater element supply, which has 12 V

continually applied whenever the ignition is on.

• Heater element ground – The ECM applies pulse

width modulated (PW M) ground to the HO2S heater

control circuit to control the rate at which the sensor

heats up. This reduces the risk of the sensor being

damaged from heating up too quickly under certain

conditions such as extreme cold temperatures. Once

the sensor has reached the desired operating

temperature, the ECM will monitor and continue to

maintain the sensor temperature.

• Output voltage.

• Sensor ground.

• Trim current.

• Pumping current.

Legend

1 Measuring Cell (Nernst cell and pump cell)

2 Double Protective Tube

3 Seal Ring

4 Seal Packing

5 Sensor Housing

6 Protective Sleeve

7 Contact Holder

8 Contact Clip

9 PTFE Sleeve (Teflon)

10 PTFE Shaped Sleeve

Figure 6C1-1 – 35

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3276 of 6020

Engine Management – V6 – General Information Page 6C1-1–34

Construction

Projecting into the MAF sensor body is the compact design

sensor assembly (1), which consists of:

• the sensor element (2),

• partial airflow measuring tube (3), and

• integrated evaluation electronics (4).

Figure 6C1-1 – 45

Operation

A diaphragm (1) on the sensor element (2) is heated by a

centrally mounted heater resistor (3), which is held at a

constant temperature. The temperature drops sharply each

side of the heating zone.

Temperature of the diaphragm is registered to the

evaluation electronics by two temperature-dependent

resistors located on the upstream (4) and downstream (5)

side of the resistor.

W ith no air flow through the air flow measuring tube and

over the sensor element, the temperature characteristic is

the same each side of the heating zone and the resistance

values are identical.

As air flows over the sensor element, the upstream resistor

value alters due to the cooling effect of the air flow. As the

air flows over the heating zone the air temperature is

increased.

Figure 6C1-1 – 46

The air then passes over the downstream resistor and alters the resistance value, but as the air temperature is higher,

the value is different to the upstream resistor. This change in temperature creates a temperature differential between the

two resistors.

It is this differential that is used to calculate the air mass flow, which is independent of absolute temperature. The

differential is also directional, which means the MAF not only measures the mass of the incoming air, but also its

direction.

As the evaluation electronics are measuring the resistance differential between the resistors, the air mass flow for the

entire amount of air passing through the MAF is calculated and sent to the ECM as an analogue signal of 0 – 5 V.

The ECM can also detect air flow that is inappropriate for a given operating condition based on the signal voltage, or a

signal that appears to be fixed based on the lack of normal signal fluctuations expected during engine operation.

Tech 2 can display the MAF value in grams per second (g/s). Values should change rather quickly on acceleration, but

should remain fairly stable at any given engine speed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007