heating ISUZU KB P190 2007 Workshop Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3278 of 6020

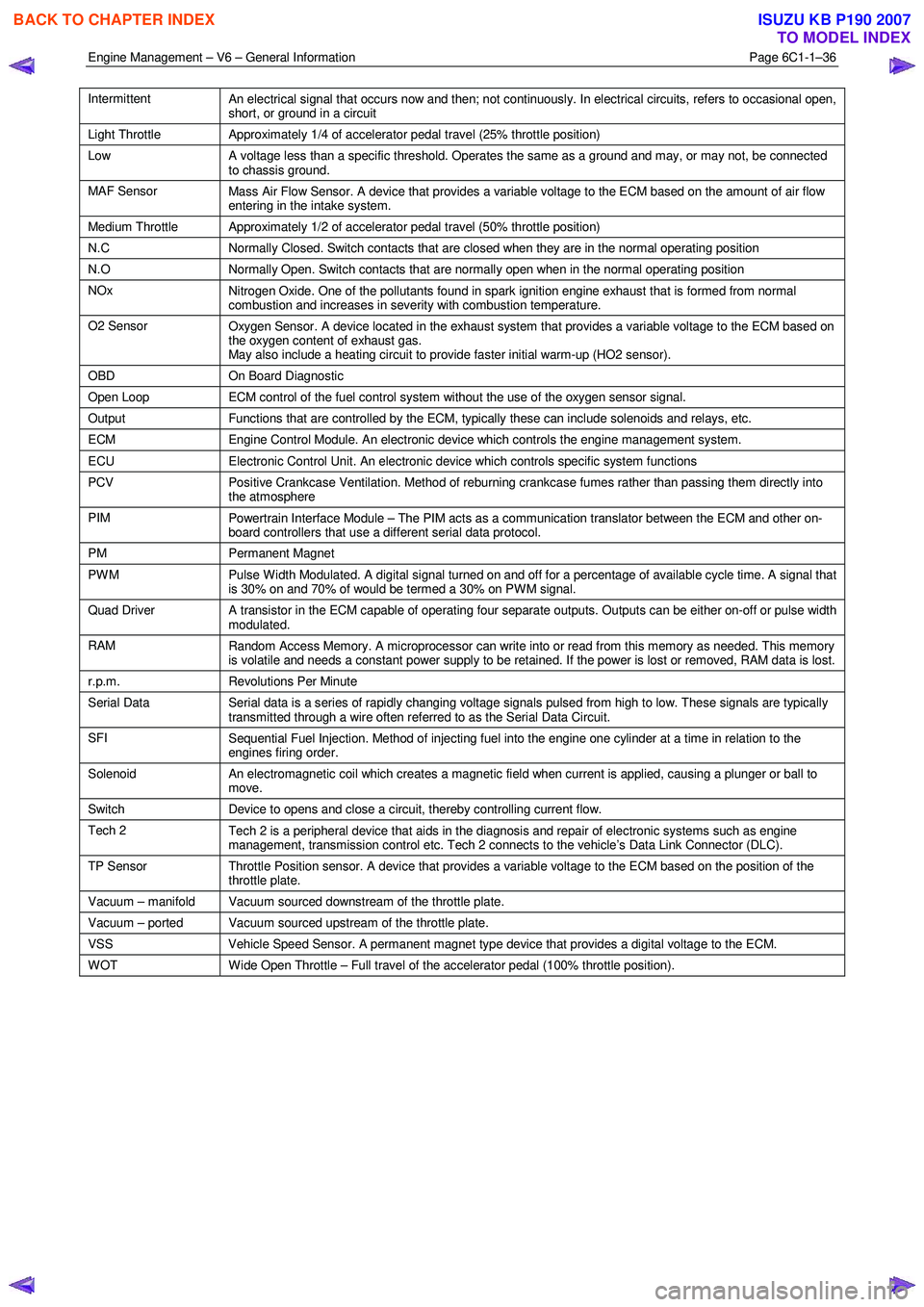

Engine Management – V6 – General Information Page 6C1-1–36

Intermittent

An electrical signal that occurs now and then; not continuously. In electrical circuits, refers to occasional open,

short, or ground in a circuit

Light Throttle Approximately 1/4 of accelerator pedal travel (25% throttle position)

Low

A voltage less than a specific threshold. Operates the same as a ground and may, or may not, be connected

to chassis ground.

MAF Sensor Mass Air Flow Sensor. A device that provides a variable voltage to the ECM based on the amount of air flow

entering in the intake system.

Medium Throttle Approximately 1/2 of accelerator pedal travel (50% throttle position)

N.C Normally Closed. Switch contacts that are closed when they are in the normal operating position

N.O Normally Open. Switch contacts that are normally open when in the normal operating position

NOx

Nitrogen Oxide. One of the pollutants found in spark ignition engine exhaust that is formed from normal

combustion and increases in severity with combustion temperature.

O2 Sensor Oxygen Sensor. A device located in the exhaust system that provides a variable voltage to the ECM based on

the oxygen content of exhaust gas.

May also include a heating circuit to provide faster initial warm-up (HO2 sensor).

OBD On Board Diagnostic

Open Loop ECM control of the fuel control system without the use of the oxygen sensor signal.

Output Functions that are controlled by the ECM, typically these can include solenoids and relays, etc.

ECM Engine Control Module. An electronic device which controls the engine management system.

ECU Electronic Control Unit. An electronic device which controls specific system functions

PCV

Positive Crankcase Ventilation. Method of reburning crankcase fumes rather than passing them directly into

the atmosphere

PIM Powertrain Interface Module – The PIM acts as a communication translator between the ECM and other on-

board controllers that use a different serial data protocol.

PM Permanent Magnet

PWM

Pulse Width Modulated. A digital signal turned on and off for a percentage of available cycle time. A signal that

is 30% on and 70% of would be termed a 30% on PWM signal.

Quad Driver A transistor in the ECM capable of operating four separate outputs. Outputs can be either on-off or pulse width

modulated.

RAM Random Access Memory. A microprocessor can write into or read from this memory as needed. This memory

is volatile and needs a constant power supply to be retained. If the power is lost or removed, RAM data is lost.

r.p.m. Revolutions Per Minute

Serial Data

Serial data is a series of rapidly changing voltage signals pulsed from high to low. These signals are typically

transmitted through a wire often referred to as the Serial Data Circuit.

SFI Sequential Fuel Injection. Method of injecting fuel into the engine one cylinder at a time in relation to the

engines firing order.

Solenoid An electromagnetic coil which creates a magnetic field when current is applied, causing a plunger or ball to

move.

Switch Device to opens and close a circuit, thereby controlling current flow.

Tech 2

Tech 2 is a peripheral device that aids in the diagnosis and repair of electronic systems such as engine

management, transmission control etc. Tech 2 connects to the vehicle’s Data Link Connector (DLC).

TP Sensor Throttle Position sensor. A device that provides a variable voltage to the ECM based on the position of the

throttle plate.

Vacuum – manifold Vacuum sourced downstream of the throttle plate.

Vacuum – ported Vacuum sourced upstream of the throttle plate.

VSS Vehicle Speed Sensor. A permanent magnet type device that provides a digital voltage to the ECM.

WOT Wide Open Throttle – Full travel of the accelerator pedal (100% throttle position).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3303 of 6020

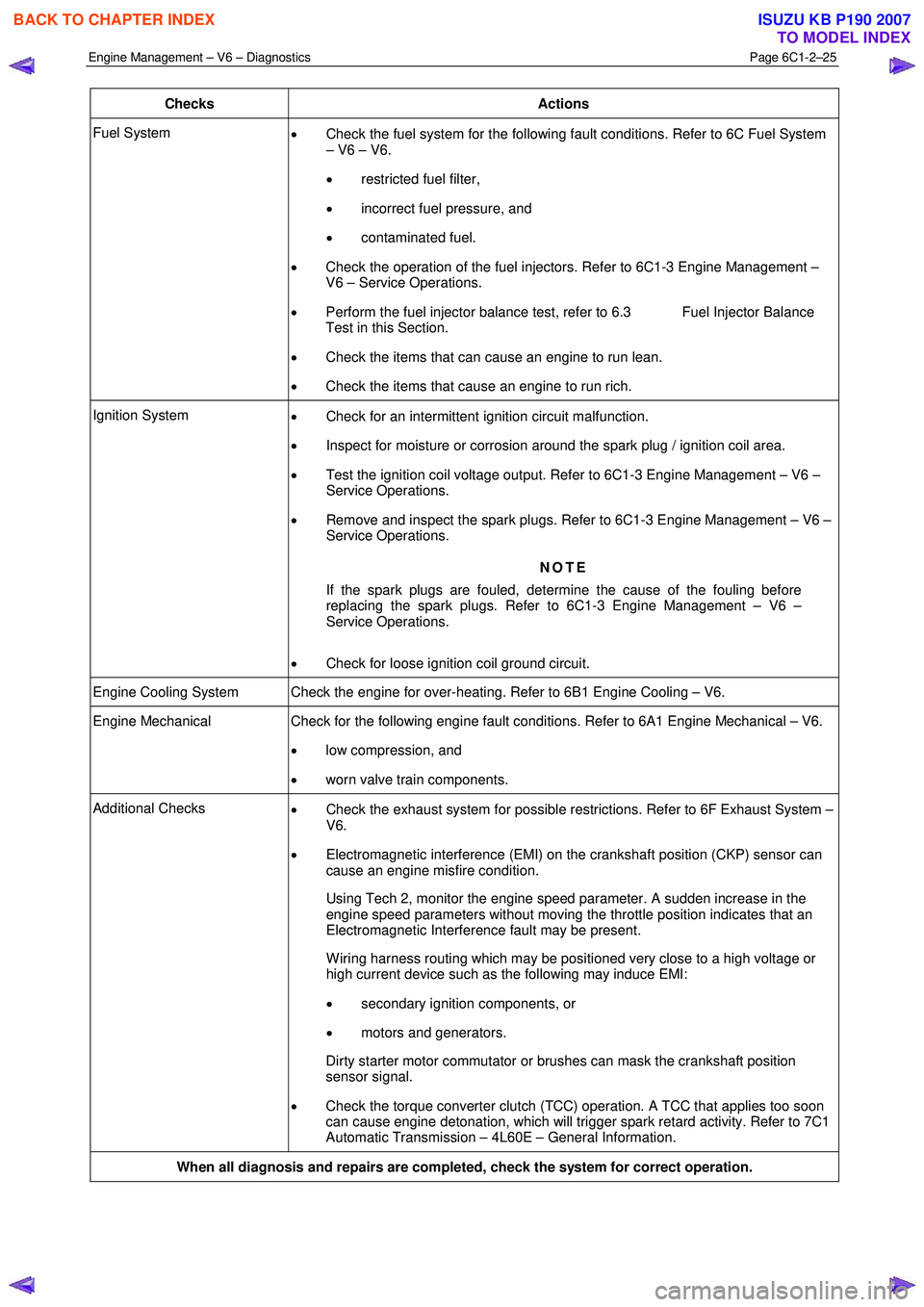

Engine Management – V6 – Diagnostics Page 6C1-2–25

Checks Actions

Fuel System

• Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6 – V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check the items that can cause an engine to run lean.

• Check the items that cause an engine to run rich.

Ignition System

• Check for an intermittent ignition circuit malfunction.

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Engine Cooling System Check the engine for over-heating. Refer to 6B1 Engine Cooling – V6.

Engine Mechanical Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical – V6.

• low compression, and

• worn valve train components.

Additional Checks

• Check the exhaust system for possible restrictions. Refer to 6F Exhaust System –

V6.

• Electromagnetic interference (EMI) on the crankshaft position (CKP) sensor can

cause an engine misfire condition.

Using Tech 2, monitor the engine speed parameter. A sudden increase in the engine speed parameters without moving the throttle position indicates that an

Electromagnetic Interference fault may be present.

W iring harness routing which may be positioned very close to a high voltage or high current device such as the following may induce EMI:

• secondary ignition components, or

• motors and generators.

Dirty starter motor commutator or brushes can mask the crankshaft position sensor signal.

• Check the torque converter clutch (TCC) operation. A TCC that applies too soon

can cause engine detonation, which will trigger spark retard activity. Refer to 7C1

Automatic Transmission – 4L60E – General Information.

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3307 of 6020

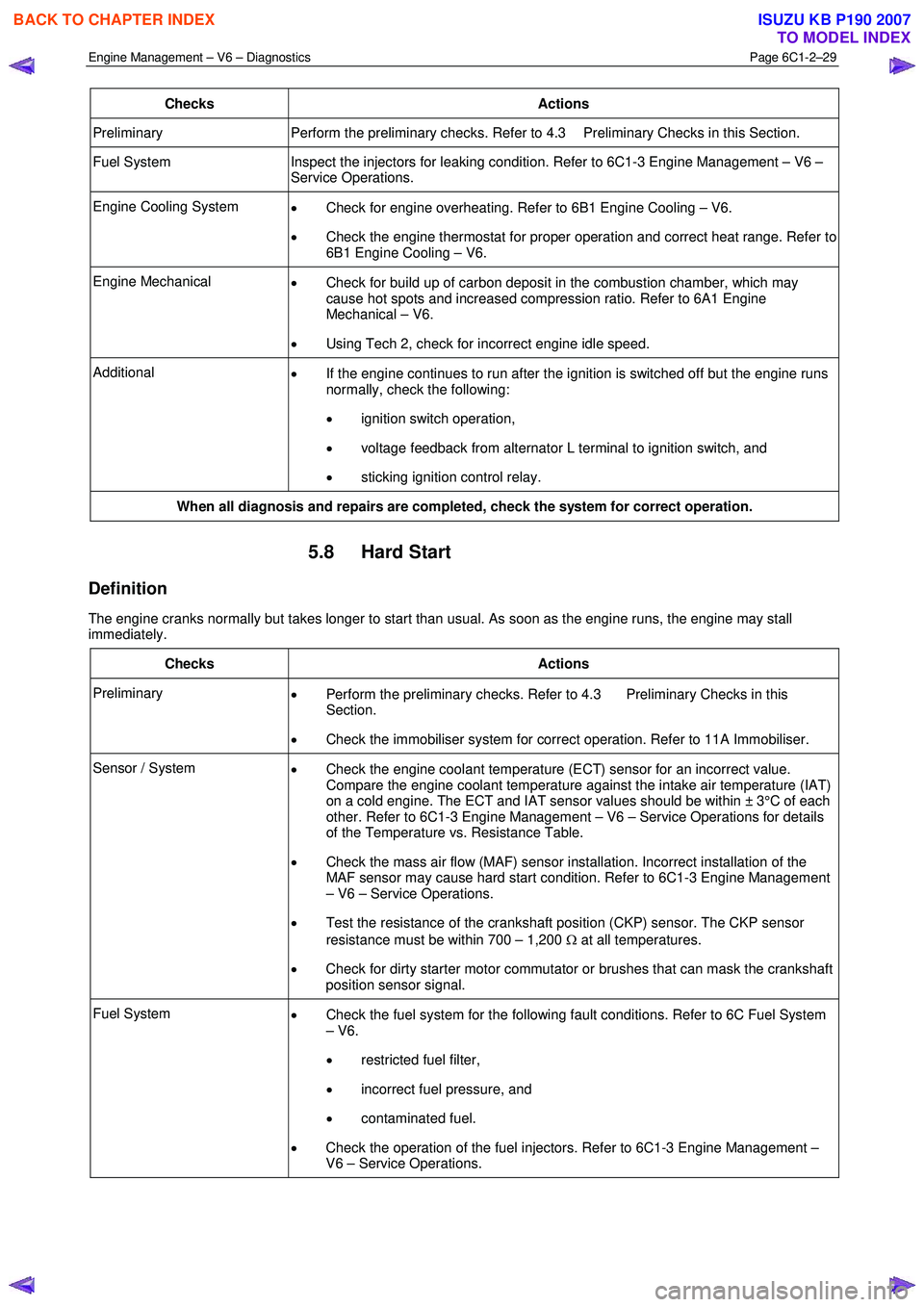

Engine Management – V6 – Diagnostics Page 6C1-2–29

Checks Actions

Preliminary Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this Section.

Fuel System Inspect the injectors for leaking condition. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Engine Cooling System • Check for engine overheating. Refer to 6B1 Engine Cooling – V6.

• Check the engine thermostat for proper operation and correct heat range. Refer to

6B1 Engine Cooling – V6.

Engine Mechanical • Check for build up of carbon deposit in the combustion chamber, which may

cause hot spots and increased compression ratio. Refer to 6A1 Engine

Mechanical – V6.

• Using Tech 2, check for incorrect engine idle speed.

Additional

• If the engine continues to run after the ignition is switched off but the engine runs

normally, check the following:

• ignition switch operation,

• voltage feedback from alternator L terminal to ignition switch, and

• sticking ignition control relay.

When all diagnosis and repairs are completed, check the system for correct operation.

5.8 Hard Start

Definition

The engine cranks normally but takes longer to start than usual. As soon as the engine runs, the engine may stall

immediately.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the immobiliser system for correct operation. Refer to 11A Immobiliser.

Sensor / System

• Check the engine coolant temperature (ECT) sensor for an incorrect value.

Compare the engine coolant temperature against the intake air temperature (IAT)

on a cold engine. The ECT and IAT sensor values should be within ± 3°C of each

other. Refer to 6C1-3 Engine Management – V6 – Service Operations for details

of the Temperature vs. Resistance Table.

• Check the mass air flow (MAF) sensor installation. Incorrect installation of the

MAF sensor may cause hard start condition. Refer to 6C1-3 Engine Management

– V6 – Service Operations.

• Test the resistance of the crankshaft position (CKP) sensor. The CKP sensor

resistance must be within 700 – 1,200 Ω at all temperatures.

• Check for dirty starter motor commutator or brushes that can mask the crankshaft

position sensor signal.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3341 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–63

• DTC P0032 – O2 Sensor Heater Circuit High Voltage (Bank 1, Sensor 1)

• DTC P0036 – O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 2)

• DTC P0037 – O2 Sensor Heater Circuit Low Voltage (Bank 1, Sensor 2)

• DTC P0038 – O2 Sensor Heater Circuit High Voltage (Bank 1, Sensor 2)

• DTC P0050 – O2 Sensor Heater Circuit Malfunction (Bank 2, Sensor 1)

• DTC P0051 – O2 Sensor Heater Circuit Low Voltage (Bank 2, Sensor 1)

• DTC P0052 – O2 Sensor Heater Circuit High Voltage (Bank 2, Sensor 1)

• DTC P0056 – O2 Sensor Heater Circuit Malfunction (Bank 2, Sensor 2)

• DTC P0057 – O2 Sensor Heater Circuit Low Voltage (Bank 2, Sensor 2)

• DTC P0058 – O2 Sensor Heater Circuit High Voltage (Bank 2, Sensor 2)

Circuit Description

The engine control relay applies positive voltage to the heater ignition voltage circuits of the HO2S. The ECM applies a

pulse width modulated (PW M) ground to the heater control circuit of the HO2S through a device within the ECM called a

driver, to control the HO2S rate of heating.

The driver has a feedback circuit that is pulled-up when the voltage is approximately 3.3 V. The ECM monitors the driver

feedback circuit to determine if the control circuit is open, shorted to ground or shorted to a positive voltage.

An HO2S heater control circuit DTC sets if the ECM detects a high resistance, open circuit, short to ground or short to

voltage fault condition in the HO2S heater control circuit.

Conditions for Running the DTC

Runs continuously once the following conditions are met:

• The ignition voltage is 10.0 – 16.0 V.

• Engine speed is greater than 80 rpm

Conditions for Setting the DTC

DTC P0030, P0036, P0050 or P0056

The ECM detects an open circuit fault condition in the HO2S heater control circuit when the HO2S heater is commanded

off.

DTC P0031, P0037, P0051 or P0057

The ECM detects a short to ground fault condition in the HO2S heater control circuit when the HO2S heater is

commanded off.

DTC P0032, P0038, P0052 or P0058

The ECM detects a short to voltage fault condition in the HO2S heater control circuit for five seconds when the HO2S

heater is commanded on.

Conditions for Clearing the DTC

The HO2S heater control circuit DTCs are Type B DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for

action taken when Type B DTC sets and conditions for clearing Type B DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the HO2S system operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• A faulty HO2S heater element may cause an open heater circuit condition. This fault may be intermittent or only

show up after the sensor has operated for a period.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3343 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–65

Step Action Yes No

6 Test the HO2S heater control circuit for a high resistance, open

circuit, short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 9 Go to Step 8

7 Replace the appropriate HO2S. Refer to 6C1-3 Engine Management

– V6 – Service Operations.

W as the repair completed? Go to Step 9 —

8 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 9 —

9 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the HO2S heater control circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 10

10 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.4 DTC P0040 or P0041

DTC Descriptor

This diagnostic procedure supports the following DTCs:

• DTC P0040 – O2 Sensor Signals Not Plausible (Bank 1, Sensor 1 & Bank 2, Sensor 1)

• DTC P0041 – O2 Sensor Signals Not Plausible (Bank 1, Sensor 2 & Bank 2, Sensor 2)

Circuit Description

The engine control relay applies positive voltage to the heater ignition voltage circuits of the HO2S. The ECM applies a

pulse width modulated (PW M) ground to the heater control circuit of the HO2S through a device within the ECM called a

driver, to control the HO2S rate of heating.

The ECM applies a voltage of approximately 450 mV between the reference signal circuit and low reference circuit of the

HO2S while the sensor temperature is less than the operating range.

Once the HO2S reaches operating temperature, the sensor varies this reference signal voltage, which constantly

fluctuates between the high voltage output and the low voltage output.

• The low voltage output is 0 – 450 mV, which occurs if the air fuel mixture is lean.

• The high voltage output is 450 – 1,000 mV, which occurs if the air fuel mixture is rich.

The ECM monitors, stores and evaluates the HO2S voltage fluctuation information to determine the level of oxygen

concentration in the exhaust.

An HO2S signal not plausible or wire connector swapped DTC sets if the ECM detects the HO2S signal voltages are

heading in the opposite direction of what was commanded.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the HO2S system operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3345 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–67

Step Action Yes No

6 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.5 DTC P0053 or P0059

DTC Descriptor

This diagnostic procedure supports the following DTCs:

• DTC P0053 – O2 Sensor Heater Resistance Range / Performance (Bank 1, Sensor 1)

• DTC P0059 – O2 Sensor Heater Resistance Range / Performance (Bank 2, Sensor 1)

Circuit Description

The engine control relay applies positive voltage to the heater ignition voltage circuits of the HO2S. The ECM applies a

pulse width modulated (PW M) ground to the heater control circuit of the HO2S through a device within the ECM called a

driver, to control the HO2S rate of heating.

The ECM maintains the voltage between the reference signal circuit and low reference circuit of the HO2S 1 to about

450 mV by increasing or decreasing the oxygen content in the HO2S diffusion gap. To achieve this, the ECM controls

the current applied to the oxygen pumping cell in the HO2S.

• If the air / fuel mixture in the exhaust is balanced (lambda = 1), the oxygen pumping cell current is zero.

• If the exhaust gas in the HO2S 1 diffusion gap is lean, the ECM applies a positive current to the oxygen pumping

cell to discharge oxygen from the diffusion gap.

• If the exhaust gas in the HO2S 1 diffusion gap is rich, the ECM applies a negative current to the oxygen pumping

cell to draw oxygen into the diffusion gap.

The pumping current required to maintain the HO2S 1 signal circuit voltage to about 450 mV is proportional to the level

of oxygen concentration in the exhaust gas. The ECM monitors and evaluates the oxygen pumping current to determine

the level of oxygen concentration in the exhaust.

An HO2S internal heater resistance performance DTC sets if the ECM detects an internal fault condition in the ECM

HO2S heater circuit.

Conditions for Running the DTC

Run continuously once the following conditions are met:

• DTCs P0030, P0031, P0032, P0101, P0121, P012, P0123, P0131, P0132, P0133, P0221, P0222, P0223, P0336,

P0338, P2237, P2243 and P2626 ran and passed.

• The calculated exhaust temperature is greater than 400ºC.

• The engine does not misfire.

• The ignition voltage is 10.0 – 16.0 V.

• The HO2S is commanded on.

• The engine is running at speed greater than 25 rpm

Conditions for Setting the DTC

There is an internal fault condition in the ECM HO2S heater circuit.

Conditions for Clearing the DTC

The HO2S internal heater resistance performance DTCs are Type B DTCs. Refer to 1.4 Diagnostic Trouble Codes in

this Section, for action taken when Type B DTC sets and conditions for clearing Type B DTCs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3360 of 6020

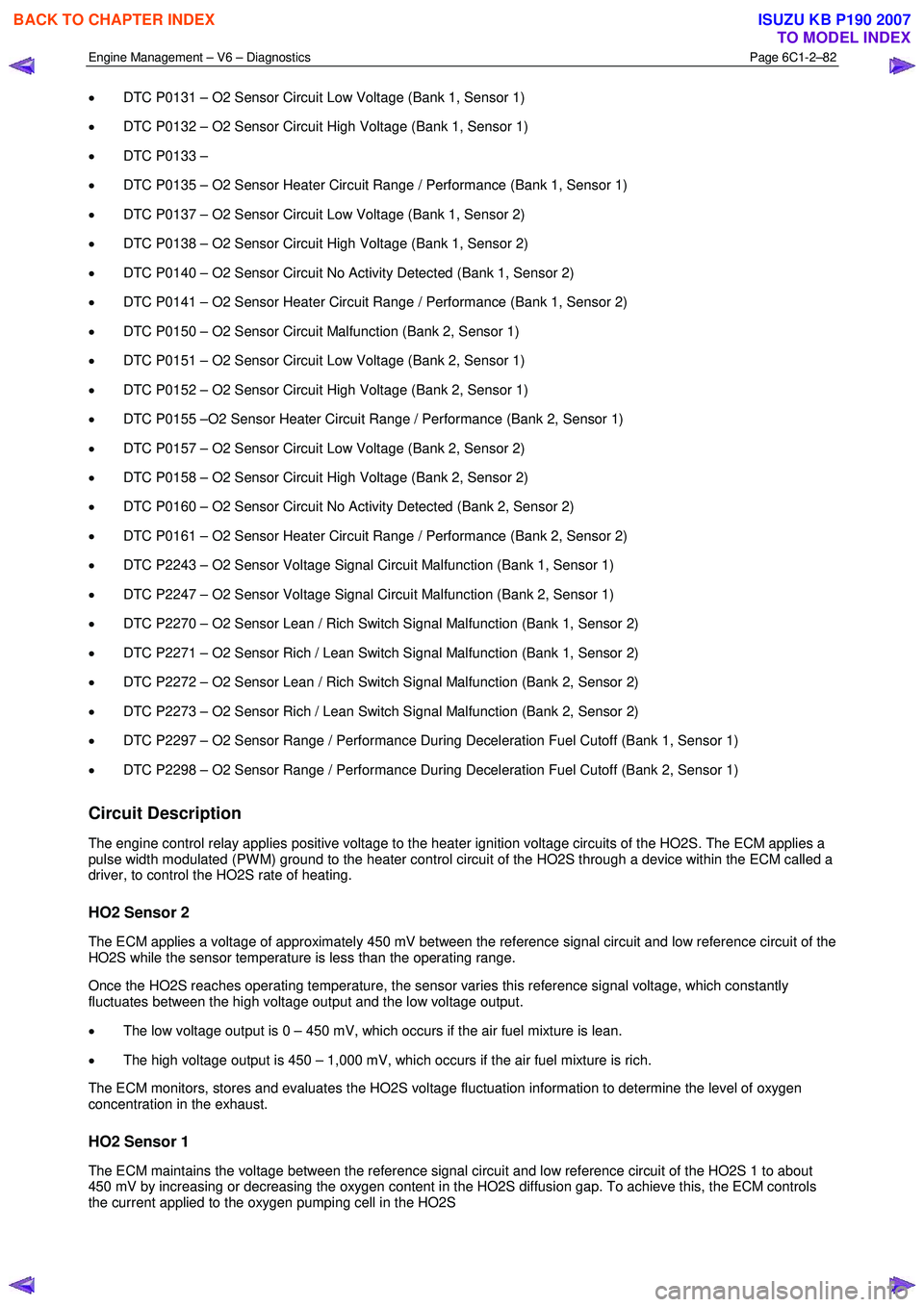

Engine Management – V6 – Diagnostics Page 6C1-2–82

• DTC P0131 – O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1)

• DTC P0132 – O2 Sensor Circuit High Voltage (Bank 1, Sensor 1)

• DTC P0133 –

• DTC P0135 – O2 Sensor Heater Circuit Range / Performance (Bank 1, Sensor 1)

• DTC P0137 – O2 Sensor Circuit Low Voltage (Bank 1, Sensor 2)

• DTC P0138 – O2 Sensor Circuit High Voltage (Bank 1, Sensor 2)

• DTC P0140 – O2 Sensor Circuit No Activity Detected (Bank 1, Sensor 2)

• DTC P0141 – O2 Sensor Heater Circuit Range / Performance (Bank 1, Sensor 2)

• DTC P0150 – O2 Sensor Circuit Malfunction (Bank 2, Sensor 1)

• DTC P0151 – O2 Sensor Circuit Low Voltage (Bank 2, Sensor 1)

• DTC P0152 – O2 Sensor Circuit High Voltage (Bank 2, Sensor 1)

• DTC P0155 –O2 Sensor Heater Circuit Range / Performance (Bank 2, Sensor 1)

• DTC P0157 – O2 Sensor Circuit Low Voltage (Bank 2, Sensor 2)

• DTC P0158 – O2 Sensor Circuit High Voltage (Bank 2, Sensor 2)

• DTC P0160 – O2 Sensor Circuit No Activity Detected (Bank 2, Sensor 2)

• DTC P0161 – O2 Sensor Heater Circuit Range / Performance (Bank 2, Sensor 2)

• DTC P2243 – O2 Sensor Voltage Signal Circuit Malfunction (Bank 1, Sensor 1)

• DTC P2247 – O2 Sensor Voltage Signal Circuit Malfunction (Bank 2, Sensor 1)

• DTC P2270 – O2 Sensor Lean / Rich Switch Signal Malfunction (Bank 1, Sensor 2)

• DTC P2271 – O2 Sensor Rich / Lean Switch Signal Malfunction (Bank 1, Sensor 2)

• DTC P2272 – O2 Sensor Lean / Rich Switch Signal Malfunction (Bank 2, Sensor 2)

• DTC P2273 – O2 Sensor Rich / Lean Switch Signal Malfunction (Bank 2, Sensor 2)

• DTC P2297 – O2 Sensor Range / Performance During Deceleration Fuel Cutoff (Bank 1, Sensor 1)

• DTC P2298 – O2 Sensor Range / Performance During Deceleration Fuel Cutoff (Bank 2, Sensor 1)

Circuit Description

The engine control relay applies positive voltage to the heater ignition voltage circuits of the HO2S. The ECM applies a

pulse width modulated (PW M) ground to the heater control circuit of the HO2S through a device within the ECM called a

driver, to control the HO2S rate of heating.

HO2 Sensor 2

The ECM applies a voltage of approximately 450 mV between the reference signal circuit and low reference circuit of the

HO2S while the sensor temperature is less than the operating range.

Once the HO2S reaches operating temperature, the sensor varies this reference signal voltage, which constantly

fluctuates between the high voltage output and the low voltage output.

• The low voltage output is 0 – 450 mV, which occurs if the air fuel mixture is lean.

• The high voltage output is 450 – 1,000 mV, which occurs if the air fuel mixture is rich.

The ECM monitors, stores and evaluates the HO2S voltage fluctuation information to determine the level of oxygen

concentration in the exhaust.

HO2 Sensor 1

The ECM maintains the voltage between the reference signal circuit and low reference circuit of the HO2S 1 to about

450 mV by increasing or decreasing the oxygen content in the HO2S diffusion gap. To achieve this, the ECM controls

the current applied to the oxygen pumping cell in the HO2S

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3486 of 6020

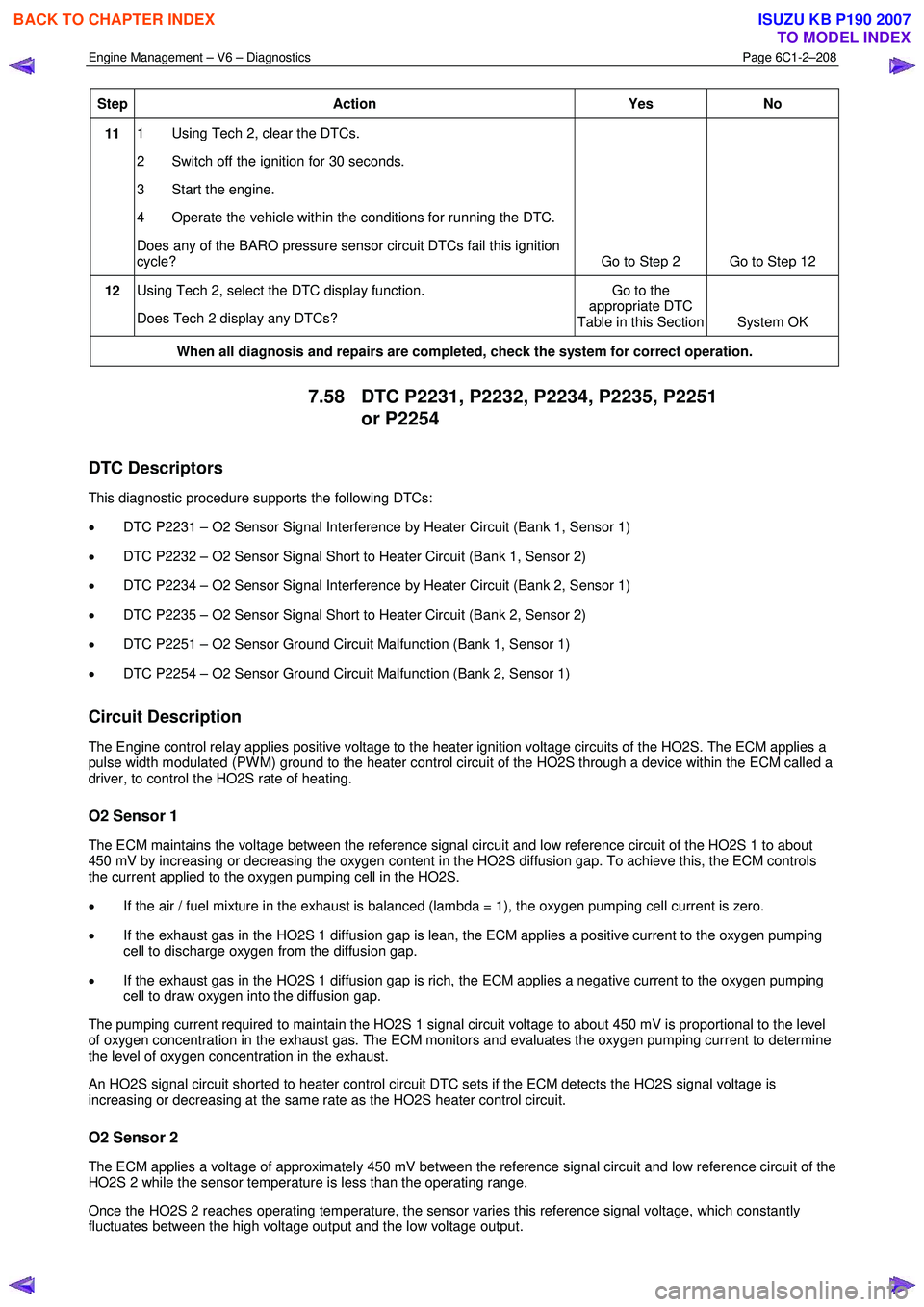

Engine Management – V6 – Diagnostics Page 6C1-2–208

Step Action Yes

No

11 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the BARO pressure sensor circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 12

12 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.58 DTC P2231, P2232, P2234, P2235, P2251

or P2254

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P2231 – O2 Sensor Signal Interference by Heater Circuit (Bank 1, Sensor 1)

• DTC P2232 – O2 Sensor Signal Short to Heater Circuit (Bank 1, Sensor 2)

• DTC P2234 – O2 Sensor Signal Interference by Heater Circuit (Bank 2, Sensor 1)

• DTC P2235 – O2 Sensor Signal Short to Heater Circuit (Bank 2, Sensor 2)

• DTC P2251 – O2 Sensor Ground Circuit Malfunction (Bank 1, Sensor 1)

• DTC P2254 – O2 Sensor Ground Circuit Malfunction (Bank 2, Sensor 1)

Circuit Description

The Engine control relay applies positive voltage to the heater ignition voltage circuits of the HO2S. The ECM applies a

pulse width modulated (PW M) ground to the heater control circuit of the HO2S through a device within the ECM called a

driver, to control the HO2S rate of heating.

O2 Sensor 1

The ECM maintains the voltage between the reference signal circuit and low reference circuit of the HO2S 1 to about

450 mV by increasing or decreasing the oxygen content in the HO2S diffusion gap. To achieve this, the ECM controls

the current applied to the oxygen pumping cell in the HO2S.

• If the air / fuel mixture in the exhaust is balanced (lambda = 1), the oxygen pumping cell current is zero.

• If the exhaust gas in the HO2S 1 diffusion gap is lean, the ECM applies a positive current to the oxygen pumping

cell to discharge oxygen from the diffusion gap.

• If the exhaust gas in the HO2S 1 diffusion gap is rich, the ECM applies a negative current to the oxygen pumping

cell to draw oxygen into the diffusion gap.

The pumping current required to maintain the HO2S 1 signal circuit voltage to about 450 mV is proportional to the level

of oxygen concentration in the exhaust gas. The ECM monitors and evaluates the oxygen pumping current to determine

the level of oxygen concentration in the exhaust.

An HO2S signal circuit shorted to heater control circuit DTC sets if the ECM detects the HO2S signal voltage is

increasing or decreasing at the same rate as the HO2S heater control circuit.

O2 Sensor 2

The ECM applies a voltage of approximately 450 mV between the reference signal circuit and low reference circuit of the

HO2S 2 while the sensor temperature is less than the operating range.

Once the HO2S 2 reaches operating temperature, the sensor varies this reference signal voltage, which constantly

fluctuates between the high voltage output and the low voltage output.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3489 of 6020

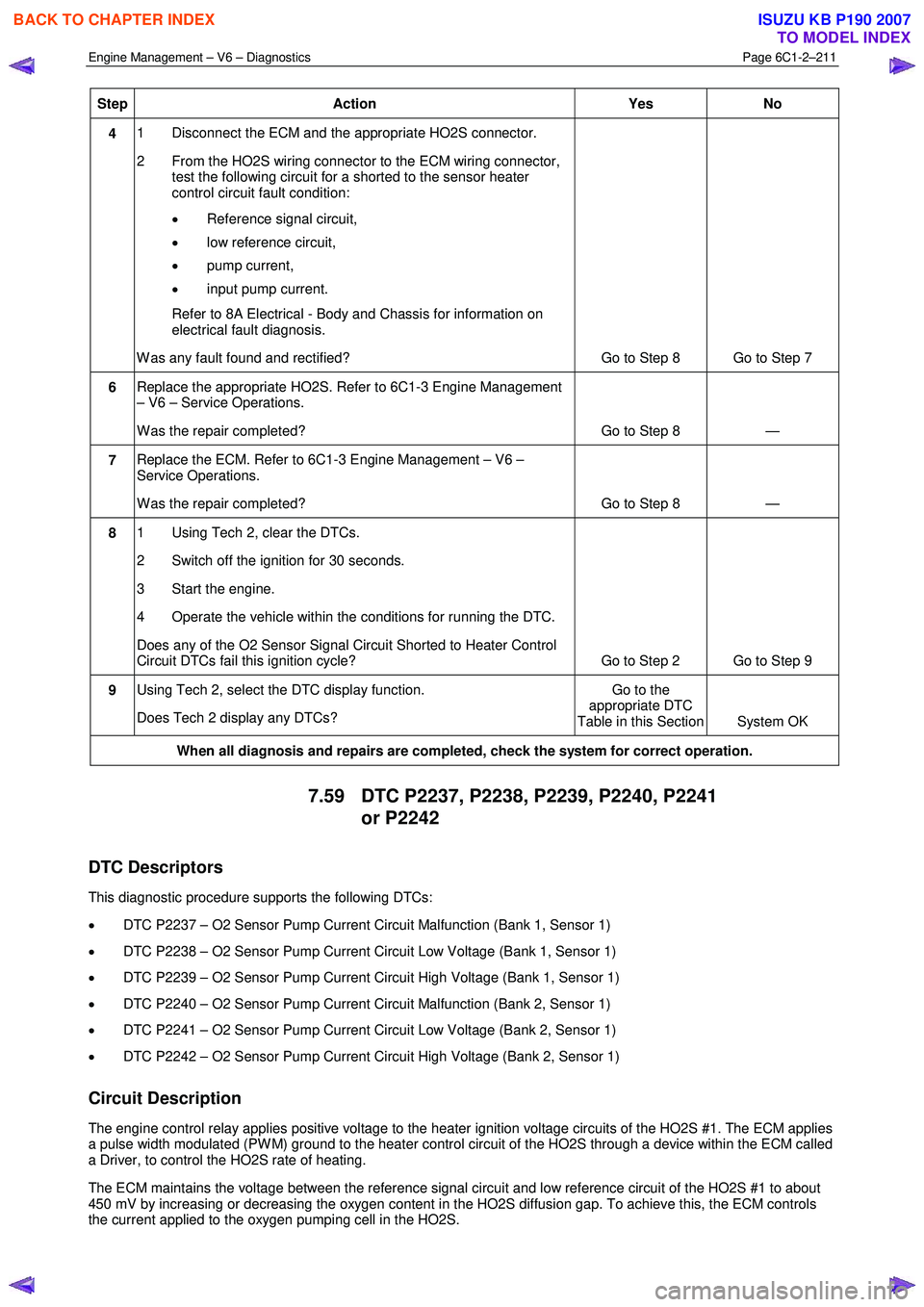

Engine Management – V6 – Diagnostics Page 6C1-2–211

Step Action Yes No

4 1 Disconnect the ECM and the appropriate HO2S connector.

2 From the HO2S wiring connector to the ECM wiring connector, test the following circuit for a shorted to the sensor heater

control circuit fault condition:

• Reference signal circuit,

• low reference circuit,

• pump current,

• input pump current.

Refer to 8A Electrical - Body and Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 8 Go to Step 7

6 Replace the appropriate HO2S. Refer to 6C1-3 Engine Management

– V6 – Service Operations.

W as the repair completed? Go to Step 8 —

7 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 8 —

8 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the O2 Sensor Signal Circuit Shorted to Heater Control

Circuit DTCs fail this ignition cycle? Go to Step 2 Go to Step 9

9 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.59 DTC P2237, P2238, P2239, P2240, P2241

or P2242

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P2237 – O2 Sensor Pump Current Circuit Malfunction (Bank 1, Sensor 1)

• DTC P2238 – O2 Sensor Pump Current Circuit Low Voltage (Bank 1, Sensor 1)

• DTC P2239 – O2 Sensor Pump Current Circuit High Voltage (Bank 1, Sensor 1)

• DTC P2240 – O2 Sensor Pump Current Circuit Malfunction (Bank 2, Sensor 1)

• DTC P2241 – O2 Sensor Pump Current Circuit Low Voltage (Bank 2, Sensor 1)

• DTC P2242 – O2 Sensor Pump Current Circuit High Voltage (Bank 2, Sensor 1)

Circuit Description

The engine control relay applies positive voltage to the heater ignition voltage circuits of the HO2S #1. The ECM applies

a pulse width modulated (PW M) ground to the heater control circuit of the HO2S through a device within the ECM called

a Driver, to control the HO2S rate of heating.

The ECM maintains the voltage between the reference signal circuit and low reference circuit of the HO2S #1 to about

450 mV by increasing or decreasing the oxygen content in the HO2S diffusion gap. To achieve this, the ECM controls

the current applied to the oxygen pumping cell in the HO2S.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3516 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–238

B2 Average Injection Time (Bank 2) ms 0.0 1.9

Mass Air Flow Sensor V 1.0 1.1

Mass Air Flow g/s 0.00 2.92

Power Enrichment No / Yes No No

Spark Advance °CA 0 13

Calculated Throttle Position % 5 1

Vehicle Speed km/h 0 0

Volumetric Efficiency % 99 13

(1) Automatic Transmission Only (2) Manual Transmission Only

8.4 Tech 2 Data Definitions

NOTE

This listing is arranged in alphabetical order and

defines each parameter shown in the Data Lists.

A/C Cutoff Mode (Air Conditioning): This parameter displays whether the control module is commanding the A/C

compressor clutch relay OFF for a number of reasons, among which is; operating pressure outside given parameters or

throttle position at wide open throttle (W OT).

A/C Disengagement 1 – 8 History: The parameter displays the last 8 air conditioning (A/C) compressor disengages in

order from 1 to 8 with 8 being the most recent. There are 8 possible causes listed for the A/C compressor to disengage;

High Pressure, Engine Speed, Battery Voltage, Stall Prevention, Full Load, Performance, Engine Temperature or Signal

not Present. Any of these causes need to be outside calibrated values, to cause the A/C to disengage.

A/C Pressure Sensor (Air Conditioning): This parameter displays the voltage from the A/C high side pressure sensor

signal circuit to the control module.

A/C Pressure Sensor (Air Conditioning): This parameter displays the pressure in kPa from the A/C high side pressure

sensor signal circuit to the control module.

A/C Relay (Air Conditioning): This parameter displays the state of the A/C clutch relay control circuit, either as ‘ON’ or

‘OFF’.

A/C Relay Status: This parameter displays the state of the A/C request input to the control module from the heating,

ventilation, and air conditioning (HVAC) controls.

A/C Request: Represents the commanded state of the A/C clutch control relay. Clutch should be engaged when ON is

displayed.

Actual Gear: This parameter displays the transmission range input to the control module, determined directly from the

decoding of the PRNDL – A, B, C, and P inputs from the transmission internal mode switch (IMS).

Actual Gear: Based on the evaluation of the PRNDL – A, B, C, and P inputs, the ECM determines whether the

parameter is valid or invalid.

Actual Intake Camshaft Position (Bank 1 or Bank 2): This parameter displays the actual intake camshaft position in

degrees of crankshaft angle.

Alternator L Terminal Duty Cycle: This parameter displays the ECM commanded state of the voltage regulator on the

alternator, expressed as a percentage from 0 to 100.

APP Sensor 1 (Accelerator Pedal Position): This parameter displays the actual voltage on the APP sensor 1 signal

circuit as measured by the ECM, that can range from 0.9 – 4.5 volts.

APP Sensor 2 (Accelerator Pedal Position): This parameter displays the actual voltage on the APP sensor 1 signal

circuit as measured by the ECM, that can range from 0.45 – 2.25 volts.

APP Sensor 1 and 2 Correlation (Accelerator Pedal Position): This parameter displays ‘Okay’ under normal

operating conditions or ‘Fault’ if the control module detects the signal voltage from APP sensor 1 that is not in the

correct relationship to APP sensor 2.

Average Injection Time (Bank 1 or Bank 2): This parameter displays the average pulse width of the fuel injectors for

each bank of the engine as determined by the ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007