lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3065 of 6020

Engine Mechanical – V6 Page 6A1–288

Page 6A1–288

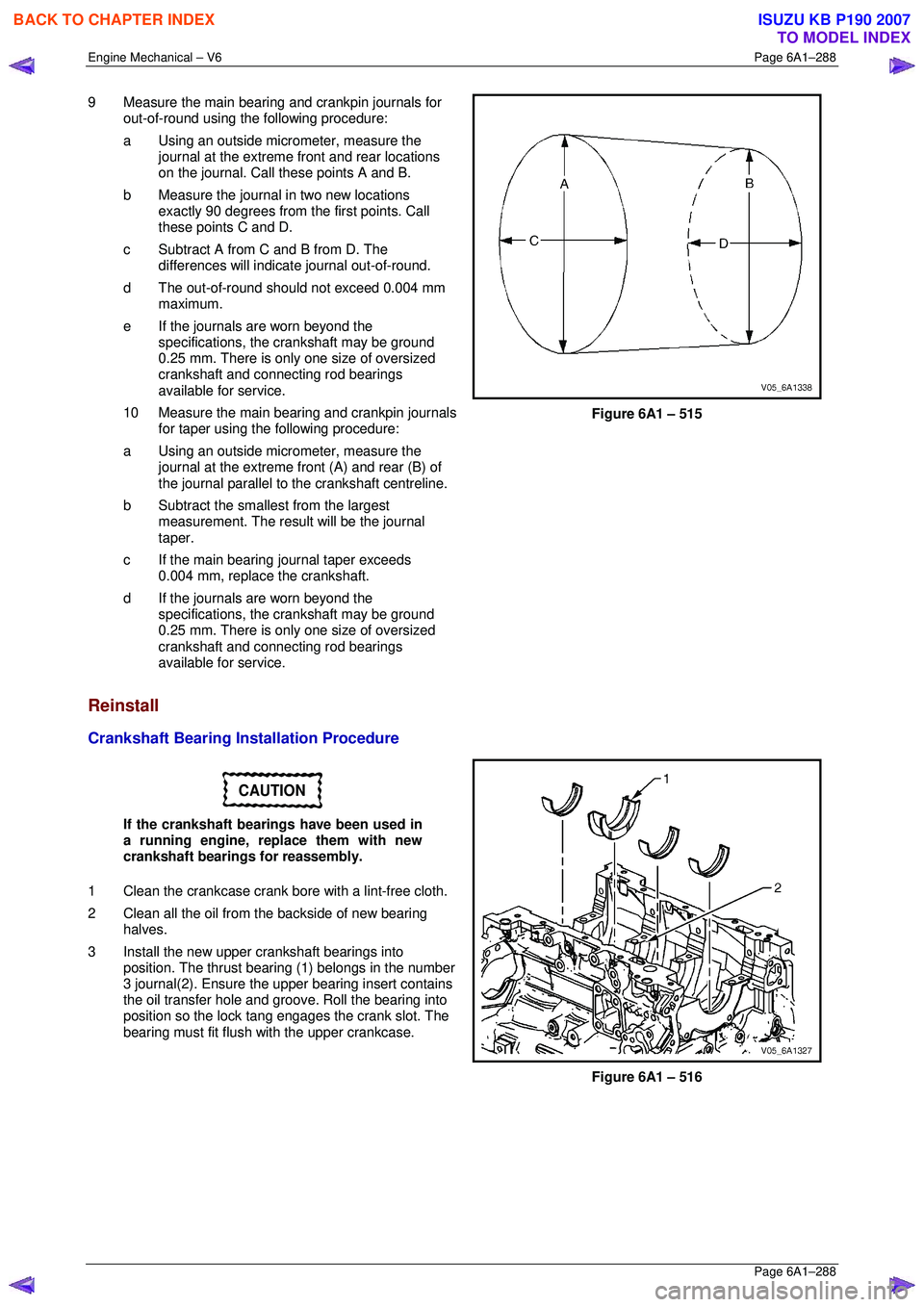

9 Measure the main bearing and crankpin journals for

out-of-round using the following procedure:

a Using an outside micr ometer, measure the

journal at the extreme front and rear locations

on the journal. Call these points A and B.

b Measure the journal in two new locations exactly 90 degrees from the first points. Call

these points C and D.

c Subtract A from C and B from D. The differences will indicate journal out-of-round.

d The out-of-round shoul d not exceed 0.004 mm

maximum.

e If the journals are worn beyond the specifications, the crankshaft may be ground

0.25 mm. There is only one size of oversized

crankshaft and connecting rod bearings

available for service.

10 Measure the main bearing and crankpin journals for taper using the following procedure:

a Using an outside micr ometer, measure the

journal at the extreme fr ont (A) and rear (B) of

the journal parallel to t he crankshaft centreline.

b Subtract the smallest from the largest measurement. The result will be the journal

taper.

c If the main bearing journal taper exceeds 0.004 mm, replace the crankshaft.

d If the journals are worn beyond the specifications, the crankshaft may be ground

0.25 mm. There is only one size of oversized

crankshaft and connecting rod bearings

available for service.

Figure 6A1 – 515

Reinstall

Crankshaft Bearing Installation Procedure

CAUTION

If the crankshaft bearings have been used in

a running engine, replace them with new

crankshaft bearings for reassembly.

1 Clean the crankcase crank bore with a lint-free cloth.

2 Clean all the oil from the backside of new bearing halves.

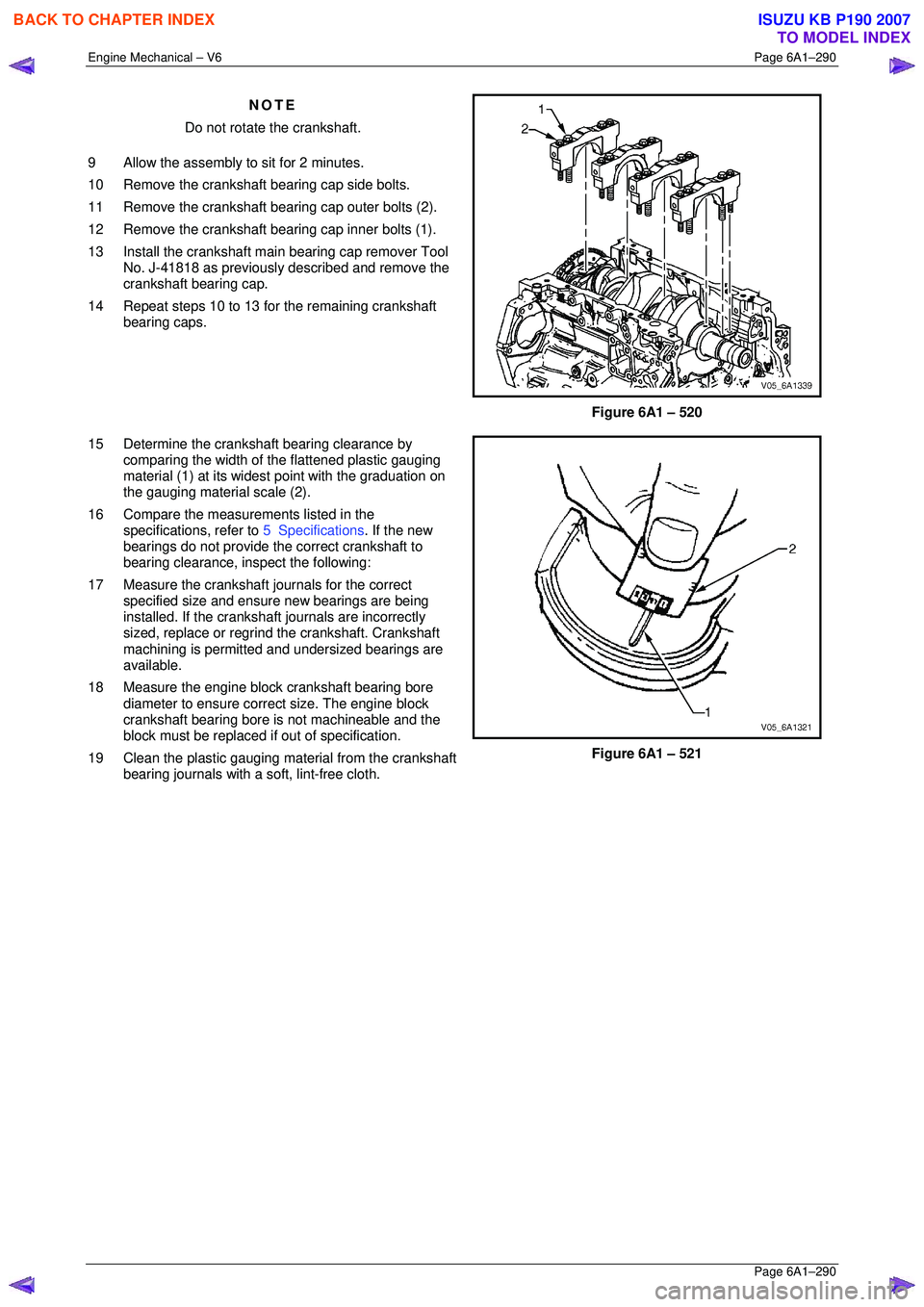

3 Install the new upper crankshaft bearings into position. The thrust beari ng (1) belongs in the number

3 journal(2). Ensure the upper bearing insert contains

the oil transfer hole and groove. Roll the bearing into

position so the lock tang engages the crank slot. The

bearing must fit flush with the upper crankcase.

Figure 6A1 – 516

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3067 of 6020

Engine Mechanical – V6 Page 6A1–290

Page 6A1–290

NOTE

Do not rotate the crankshaft.

9 Allow the assembly to sit for 2 minutes.

10 Remove the crankshaft bearing cap side bolts.

11 Remove the crankshaft bearing cap outer bolts (2).

12 Remove the crankshaft bearing cap inner bolts (1).

13 Install the crankshaft main bearing cap remover Tool No. J-41818 as previously described and remove the

crankshaft bearing cap.

14 Repeat steps 10 to 13 for the remaining crankshaft bearing caps.

Figure 6A1 – 520

15 Determine the crankshaft bearing clearance by comparing the width of the flattened plastic gauging

material (1) at its widest point with the graduation on

the gauging material scale (2).

16 Compare the measur ements listed in the

specifications, refer to 5 Specifications. If the new

bearings do not provide the correct crankshaft to

bearing clearance, inspect the following:

17 Measure the crankshaft journals for the correct specified size and ensure new bearings are being

installed. If the crankshaft journals are incorrectly

sized, replace or regrind the crankshaft. Crankshaft

machining is permitted and undersized bearings are

available.

18 Measure the engine block crankshaft bearing bore diameter to ensure correct size. The engine block

crankshaft bearing bore is not machineable and the

block must be replaced if out of specification.

19 Clean the plastic gauging material from the crankshaft bearing journals with a soft, lint-free cloth.

Figure 6A1 – 521

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3068 of 6020

Engine Mechanical – V6 Page 6A1–291

Page 6A1–291

Crankshaft Final Installation Procedure

1 If removed, install the crankshaft sprocket drive

pin (1). Lightly tap the pin in place with a small soft

face, bronze/plastic, hammer until it bottoms in the

hole.

Figure 6A1 – 522

CAUTION

Ensure the crankshaft position sensor has

been removed from the cylinder block prior

to loading the crankshaft, as damage to the

sensor may occur.

2 Apply a liberal amount of clean engine oil to the upper and lower bearing surfaces.

3 Gently lower the crankshaft (1) into position in the cylinder block (2).

Figure 6A1 – 523

4 Install the crankshaft main bearing caps.

5 Loosely install the original inner main cap bolts (1).

CAUTION

The outer crankshaft bearing cap bolts (2)

are yield tightened during assembly and

must be replaced prior to reassembly. Outer

crankshaft bearing cap bolts that are not

replaced will not torque to the correct clamp

load and can lead to serious engine damage.

6 Loosely install the new outer main bearing cap bolts (2).

7 Gently tap the crankshaft main bearing caps with a soft-faced hammer to help seat the caps.

Figure 6A1 – 524

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3070 of 6020

Engine Mechanical – V6 Page 6A1–293

Page 6A1–293

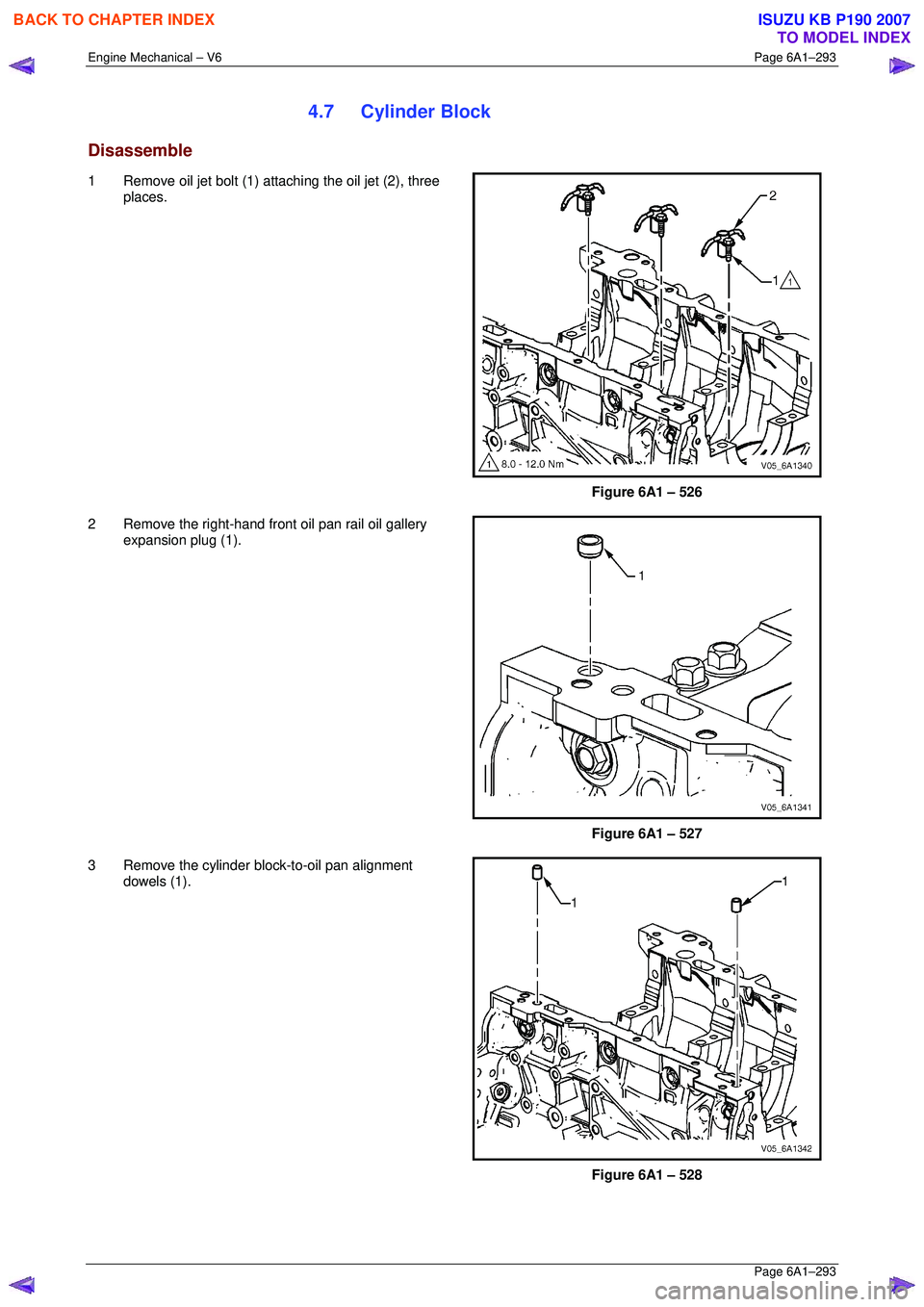

4.7 Cylinder Block

Disassemble

1 Remove oil jet bolt (1) attaching the oil jet (2), three

places.

Figure 6A1 – 526

2 Remove the right-hand front oil pan rail oil gallery expansion plug (1).

Figure 6A1 – 527

3 Remove the cylinder block-to-oil pan alignment dowels (1).

Figure 6A1 – 528

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3072 of 6020

Engine Mechanical – V6 Page 6A1–295

Page 6A1–295

7 Remove the left-hand side M14 coolant drain

threaded plug (1).

Figure 6A1 – 532

8 Remove the left-hand side M20 oil gallery threaded plug (1).

Figure 6A1 – 533

CAUTION

Do not force coolant expansion plugs

downwards during removal procedure as the

cylinder block will be damaged.

9 Remove the coolant expansion plugs (1).

Figure 6A1 – 534

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3073 of 6020

Engine Mechanical – V6 Page 6A1–296

Page 6A1–296

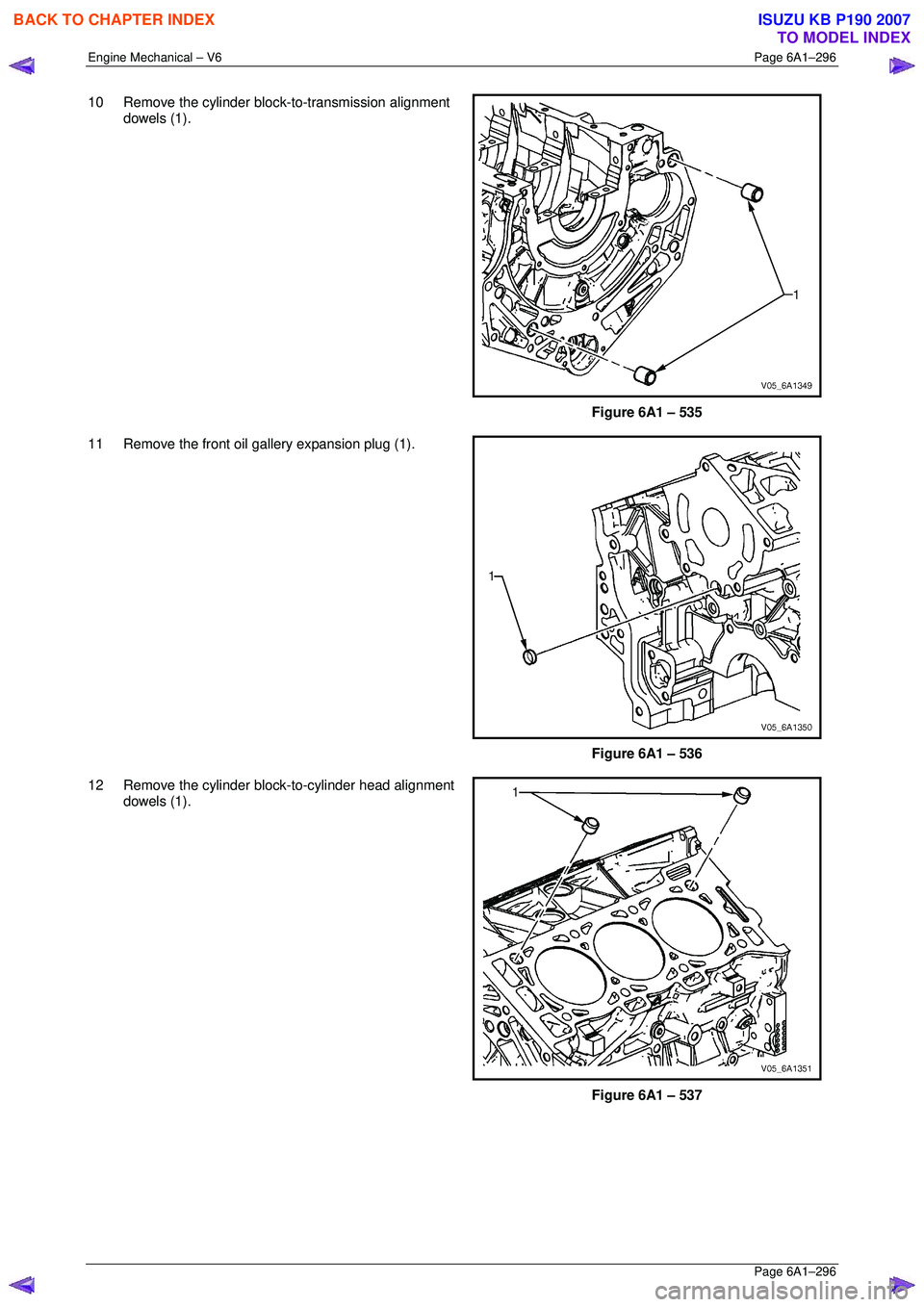

10 Remove the cylinder block-to-transmission alignment

dowels (1).

Figure 6A1 – 535

11 Remove the front oil gallery expansion plug (1).

Figure 6A1 – 536

12 Remove the cylinder block-to-cylinder head alignment dowels (1).

Figure 6A1 – 537

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3074 of 6020

Engine Mechanical – V6 Page 6A1–297

Page 6A1–297

Clean

1 Remove all thread sealant, gasket material or sealant using a commercially available plastic or wood scraper.

2 Clean all the following areas with a suitable solvent:

• sealing surfaces,

• cooling passages,

• oil passages, and

• bearing journals.

3 Clean all threaded and through holes with a suitable solvent.

Safety glasses must be worn when using

compressed air.

4 Dry the engine block with compressed air.

Inspect

Visual Inspection

NOTE

The following procedure assumes the engine has

been disassembled and cleaned, as described

above.

1 Inspect the crankshaft bearing journals for damage or spun bearings. The crankshaft bearing journals are not

repairable and if damage is f ound, the cylinder block assembly must be replaced.

2 Inspect the primary camshaft chain t ensioner mounting surface on the engine block for burrs or any defects that

would affect the sealing of the new primary camshaft chain tensioner gasket.

3 Inspect all sealing and mating surfaces for damage, repair or replace the cylinder block assembly if required.

4 Inspect all threaded and through holes for damage or excessive debris.

5 Inspect all bolts for damage, if damaged replace with new bolts only.

6 Inspect the cylinder walls for cracks or damage. The cyli nder sleeves are not serviced separately, if the cylinders

are damaged the cylinder block assembly must be replaced.

7 Inspect the engine block for cracks. Do not repair any cra cks. If cracks are found, the cylinder block assembly must

be replaced. Repair any damaged threaded holes, refer to 4.9 Thread Repair Specifications.

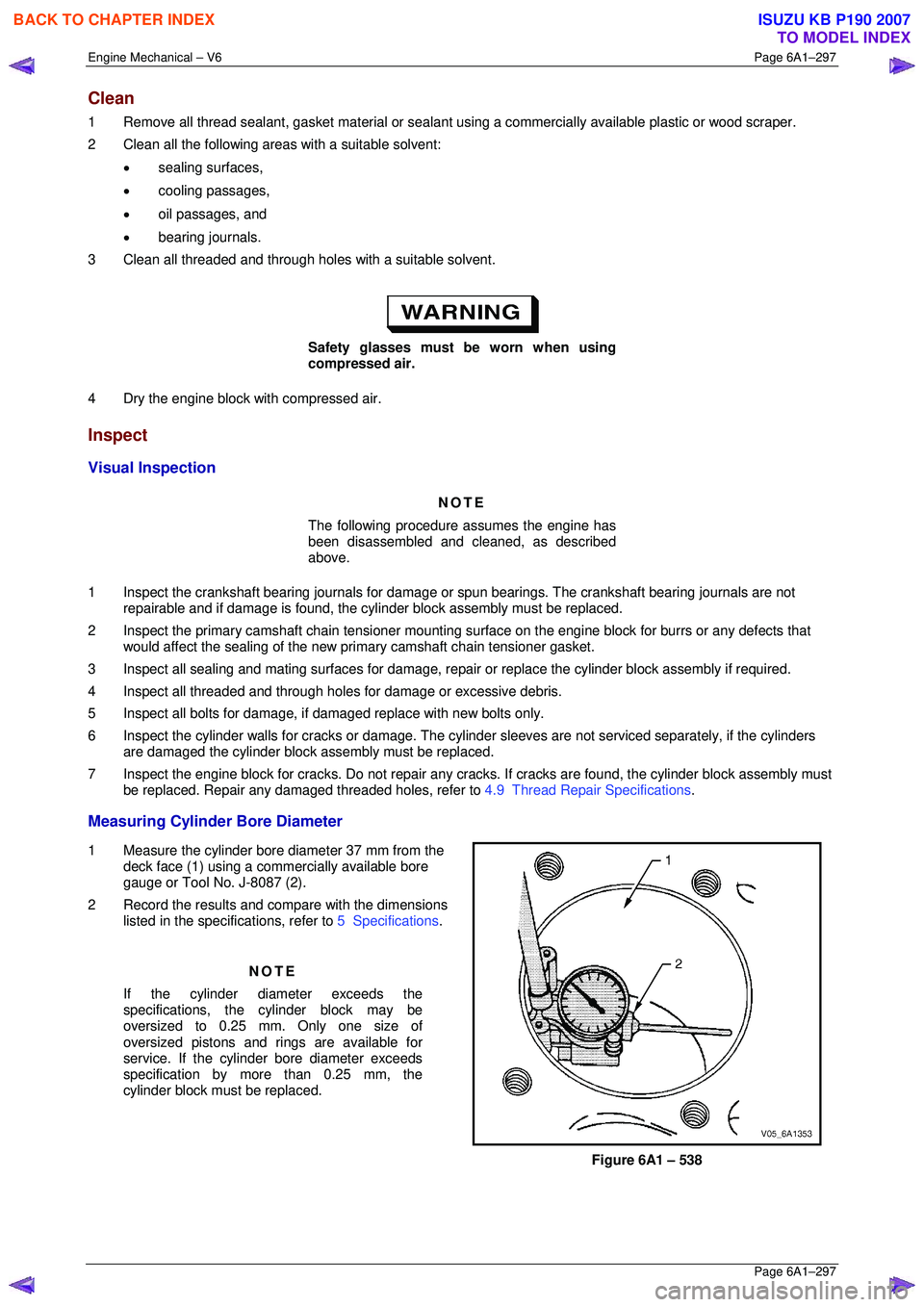

Measuring Cylinder Bore Diameter

1 Measure the cylinder bore diameter 37 mm from the

deck face (1) using a commercially available bore

gauge or Tool No. J-8087 (2).

2 Record the results and compare with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of

oversized pistons and rings are available for

service. If the cylinder bore diameter exceeds

specification by mo re than 0.25 mm, the

cylinder block must be replaced.

Figure 6A1 – 538

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3075 of 6020

Engine Mechanical – V6 Page 6A1–298

Page 6A1–298

Measuring Cylinder Bore Taper

1 Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centreline, at 10 mm below the

deck surface and record the measurement.

2 Measure the cylinder bore along the th rust surfaces, perpendicular to the crankshaft centreline, at 100 mm below

the deck surface and record the measurement.

3 Calculate the difference betw een the two measurements. The re sult will be the cylinder taper.

4 Compare the results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter ex ceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

Measuring Cylinder Bore Out-of-Round

1 Measure both the thrust and non-thrust cylinder diameter at 10 mm below the deck. Record your measurements.

2 Calculate the difference bet ween the two measurements. The result will indicate out-of-r ound at the upper end of

the cylinder.

3 Measure both the thrust and non-thru st cylinder diameter at 100 mm below the deck surface. Record your

measurements.

4 Calculate the difference between the tw o measurements. The result will indicate out-of-round at the lower end of

the cylinder.

5 Compare your results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter ex ceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

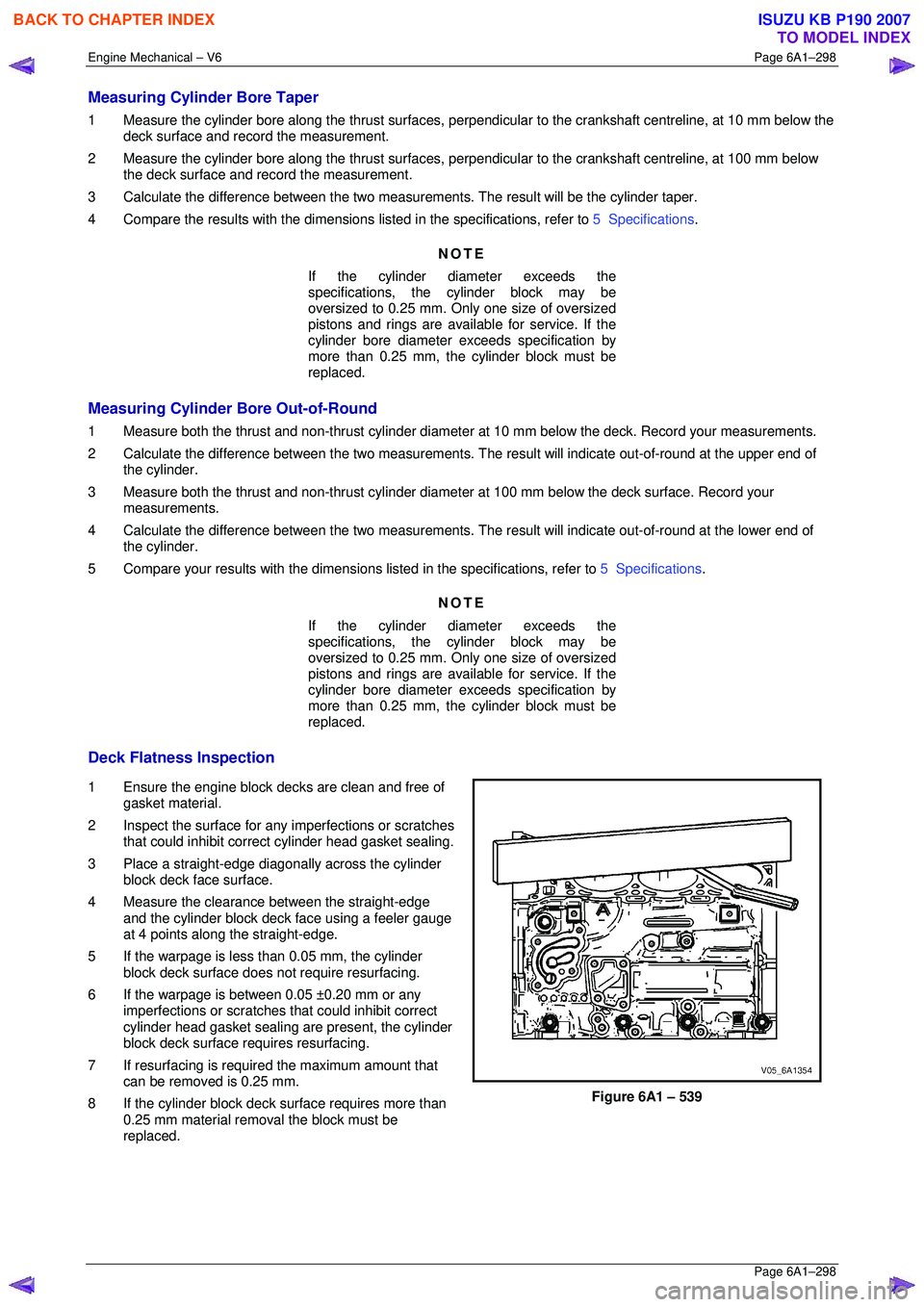

Deck Flatness Inspection

1 Ensure the engine block decks are clean and free of gasket material.

2 Inspect the surface for any imperfections or scratches

that could inhibit correct cylinder head gasket sealing.

3 Place a straight-edge diagonally across the cylinder block deck face surface.

4 Measure the clearance between the straight-edge

and the cylinder block deck face using a feeler gauge

at 4 points along the straight-edge.

5 If the warpage is less t han 0.05 mm, the cylinder

block deck surface does not require resurfacing.

6 If the warpage is between 0.05 ±0.20 mm or any imperfections or scratches that could inhibit correct

cylinder head gasket sealing are present, the cylinder

block deck surface requires resurfacing.

7 If resurfacing is requir ed the maximum amount that

can be removed is 0.25 mm.

8 If the cylinder block deck surface requires more than 0.25 mm material removal the block must be

replaced.

Figure 6A1 – 539

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3076 of 6020

Engine Mechanical – V6 Page 6A1–299

Page 6A1–299

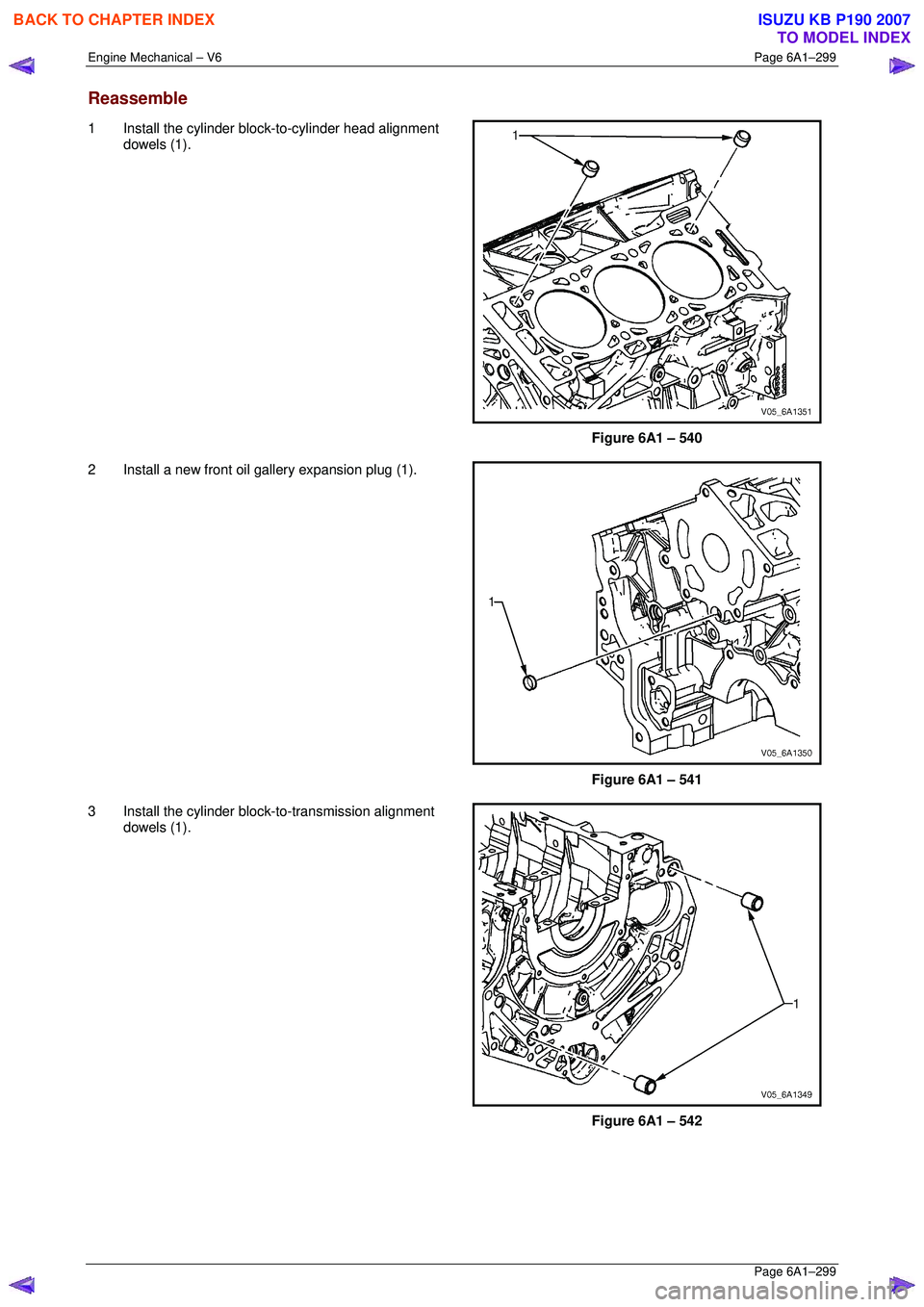

Reassemble

1 Install the cylinder block-to-cylinder head alignment

dowels (1).

Figure 6A1 – 540

2 Install a new front oil gallery expansion plug (1).

Figure 6A1 – 541

3 Install the cylinder blo ck-to-transmission alignment

dowels (1).

Figure 6A1 – 542

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3077 of 6020

Engine Mechanical – V6 Page 6A1–300

Page 6A1–300

4 Place RTV sealant on new coolant expansion plugs

(1) and install the new coolant expansion plugs.

Figure 6A1 – 543

5 Install the left-hand side M20 oil gallery threaded plug (1) and tighten to the correct torque specification.

Left-hand side M20 cylinder block

oil gallery threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 544

6 Install the left-hand side M14 coolant drain threaded

plug (1) and tighten to the co rrect torque specification.

Left-hand side M14 cylinder block

coolant drain threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 545

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007