torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3392 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–114

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 The ECM supplies 2.5 V to signal circuit of the CKP sensor circuit to reduce the electro-magnetic interference (EMI). If the voltage is not within range, this indicates there is an ECM or an ECM circuit fault condition.

4 The ECM supplies 2.5 V to low reference circuit of the CKP sensor circuit to reduce the electro-magnetic interference (EMI). If the voltage is not within range, this indicates there is an ECM or an ECM circuit fault

condition.

DTC P0335 to P0338 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Start the engine.

3 Increase the engine speed to 1000 rpm for 30 seconds.

4 Using Tech 2, select the DTC display function.

Does DTC P0335, P0336, P0337 or P0338 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Disconnect the CKP sensor connector.

2 Switch on the ignition with the engine not running.

3 Using a digital multimeter, measure the voltage between the signal circuit of the sensor connector and a good ground.

Does the multimeter display 2 – 3 V? Go to Step 4 Go to Step 7

4 Using a digital multimeter, measure the voltage between the CKP

sensor low reference circuit and a good ground.

Does the multimeter display 2 – 3 V? Go to Step 5 Go to Step 7

5 Using a digital multimeter, measure the resistance between the

ground shield circuit of the CKP sensor at the ECM connector and the

ECM housing.

Does the multimeter display 5 Ω? Go to Step 6 Go to Step 7

6 Perform the following CKP sensor inspection:

• Inspect the sensor wiring harness for conditions that may induce

electromagnetic interference. Refer to

5.2 Intermittent Fault Conditions in this Section.

• Inspect the sensor for incorrect sensor installation or incorrect

attaching bolt torque value. Refer to 6C1-3 Engine Management

– V6 – Service Operations.

W as any fault found and rectified? Go to Step 11 Go to Step 9

7 Test the CKP sensor signal circuit and low reference circuit for a high

resistance, open circuit, short to ground, short to voltage or shorted

together fault condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3395 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–117

Step Action Yes No

4 1 Switch off the ignition.

2 Remove ECM Fuse 29 from the engine compartment fuse and relay panel assembly.

3 Using a digital multimeter, measure the resistance between the CMP sensor low reference circuit and the ECM housing.

NOTE

Install the ECM Fuse 29 to the engine compartment fuse

and relay panel assembly after completing this test.

Does the multimeter display 5 Ω?

Go to Step 5 Go to Step 8

5 Test the signal circuit of the CMP sensor for a high resistance, open

circuit, short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 6

6 Perform the following CMP sensor inspection:

• Inspect the sensor wiring harness for conditions that may induce

electromagnetic interference. Refer to

5.2 Intermittent Fault Conditions in this Section.

• Inspect the sensor for incorrect sensor installation or incorrect

attaching bolt torque value. Refer to 6C1-3 Engine Management

– V6 – Service Operations.

• Inspect the CMP sensor reluctor wheel for damage or conditions

that causes misalignment.

W as any fault found and rectified? Go to Step 11 Go to Step 9

7 Test the CMP sensor 5 V reference circuit for a high resistance, open

circuit, short to voltage or short to ground fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

NOTE

Each CMP sensor shares a common 5 V reference circuit.

A fault condition in the 5 V reference circuit may trigger

DTCs on all CMP sensors. Refer to 3 W iring Diagrams

and Connector Charts in this Section, to assist diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

8 Test the CMP sensor low reference circuit for a high resistance or an

open circuit fault condition. Refer to 8A Electrical - Body and Chassis

for information on electrical fault diagnosis.

NOTE

The CMP sensor shares the low reference circuit with

other sensors. A fault condition in the low reference circuit

may trigger DTCs on sensors that share this circuit. Refer

to 3 W iring Diagrams and Connector Charts in this

Section, to aid diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

9 Replace the appropriate CMP sensor. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 11 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3410 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–132

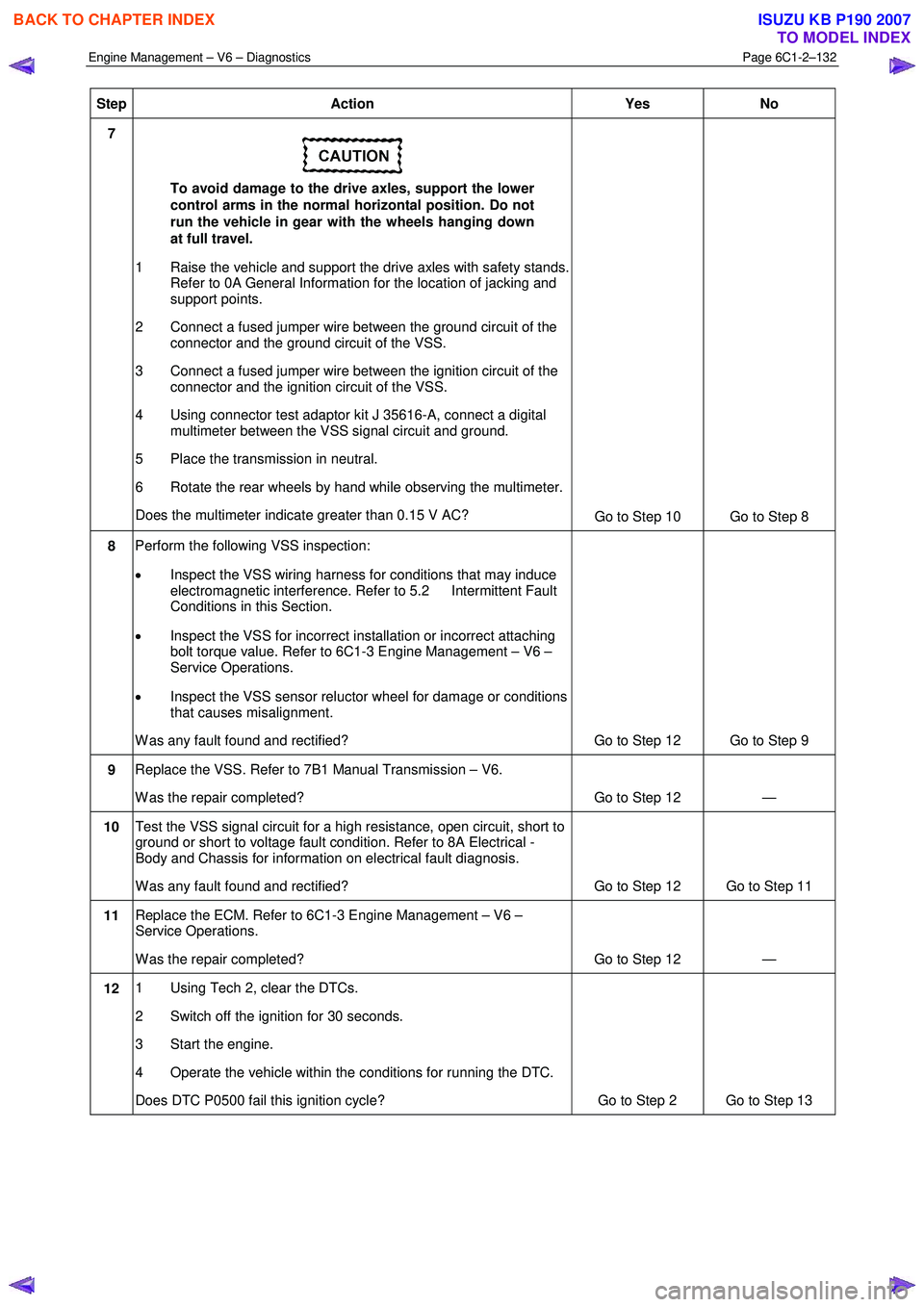

Step Action Yes No

7

To avoid damage to the drive axles, support the lower

control arms in the normal horizontal position. Do not

run the vehicle in gear with the wheels hanging down

at full travel.

1 Raise the vehicle and support the drive axles with safety stands. Refer to 0A General Information for the location of jacking and

support points.

2 Connect a fused jumper wire between the ground circuit of the connector and the ground circuit of the VSS.

3 Connect a fused jumper wire between the ignition circuit of the connector and the ignition circuit of the VSS.

4 Using connector test adaptor kit J 35616-A, connect a digital multimeter between the VSS signal circuit and ground.

5 Place the transmission in neutral.

6 Rotate the rear wheels by hand while observing the multimeter.

Does the multimeter indicate greater than 0.15 V AC? Go to Step 10 Go to Step 8

8 Perform the following VSS inspection:

• Inspect the VSS wiring harness for conditions that may induce

electromagnetic interference. Refer to 5.2 Intermittent Fault

Conditions in this Section.

• Inspect the VSS for incorrect installation or incorrect attaching

bolt torque value. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Inspect the VSS sensor reluctor wheel for damage or conditions

that causes misalignment.

W as any fault found and rectified? Go to Step 12 Go to Step 9

9 Replace the VSS. Refer to 7B1 Manual Transmission – V6.

W as the repair completed? Go to Step 12 —

10 Test the VSS signal circuit for a high resistance, open circuit, short to

ground or short to voltage fault condition. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 12 Go to Step 11

11 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 12 —

12 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P0500 fail this ignition cycle? Go to Step 2 Go to Step 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3411 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–133

Step Action Yes No

13 Using Tech 2, select the DTC display function.

Are there any DTCs displayed? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.28 DTC P0504 or P0571

DTC Descriptor

This diagnostic procedure supports:

• DTC P0504 – Brake Switch Circuit Malfunction.

• DTC P0571 – Cruise Control Brake Switch Circuit

Circuit Description

The brake switch assembly is comprised of two individual switches, a stop lamp switch and cruise control cancel switch.

The ECM uses inputs from both of these switches for enabling cruise control, brake torque management etc. For further

information on the brake switch assemblies, refer to 6C1–1 Engine Management – V6 – General Information.

The ECM monitors both switches, and if the signals do not correlate, DTC P0504 will set. If the ECM determines that a

fault exists in the cruise control cancel circuit, DTC0571 will set.

Conditions for Running the DTC

Run continuously once the following conditions are met:

• The ignition is switched on.

• The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

The ECM detects one of the following conditions:

• Only one switch signal is present when the vehicle accelerates or decelerates rapidly ten times.

NOTE

The ECM will count over several drive cycles.

• A signal is seen from the stop lamp switch and cruise control cancel switch when the vehicle accelerates rapidly.

• The ECM does not detect a signal from the switches during braking.

Conditions for Clearing the DTC

The brake switch circuit DTC is a Type B DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when Type B DTCs set and conditions for clearing Type C DTCs.

Additional Information

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the brake switch operation.

• Refer to 8C Cruise Control – HFV6 for brake pedal switch operation and testing.

• Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3446 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–168

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P1668, P2500 or P2501 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P1668, P2500 or P2501 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Test the charging system for any fault condition that may cause

incorrect generator operation. Refer to 6D1-1 Charging System – V6.

W as any fault found and rectified? Go to Step 6 Go to Step 4

4 Test the Gen L signal circuit for a high resistance, open circuit, short

to ground or short to voltage fault condition. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 6 Go to Step 5

5 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 6 —

6 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the Generator L terminal circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 7

7 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.45 DTC P1845

DTC Descriptor

This diagnostic procedure supports DTC P1845 – Engine Torque Reduction Malfunction

Circuit Description

The ECM monitors and compares the engine torque output against the maximum allowable engine torque. Refer to

6C1-1 Engine Management – V6 – General Information for details of the engine torque limit management operation.

If the requested torque is higher than the maximum allowable torque, the ECM applies engine torque limitation and DTC

P1845 – Engine Torque Reduction Malfunction sets.

Conditions for Running the DTC

DTC P1845 runs continuously when the engine is running at speeds greater than 40 rpm.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3447 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–169

Conditions for Setting the DTC

The engine torque output exceeds the maximum allowable torque output for 10 minutes.

Conditions for Clearing the DTC

DTC P1845 – Engine Torque Reduction Malfunction is a Type ‘C’ DTC. Refer to 1.4 Diagnostic Trouble Codes in this

Section, for action taken when a Type ‘C’ DTC sets and conditions for clearing Type ‘C’ DTC.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the Engine Torque Limit

Management operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step number in the diagnostic table:

4 Fault conditions that apply excessive load on the engine may trigger this DTC.

DTC P1845 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC or road test the vehicle under various driving condition.

3 Using Tech 2, select the DTC display function.

Does DTC P1845 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Are there any other ECM or TCM DTCs set? Refer to the

appropriate DTC table. Go to Step 4

4 Inspect for fault conditions in the engine or transmission that applies

excessive load on the engine.

W as any fault found and rectified? Go to Step 6 Go to Step 5

5 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 6 —

6 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P1845 fail this ignition cycle? Go to Step 2 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3508 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–230

Vehicle Speed km/h 0 0

Engine Runtime h:m:s 00:00:00 00:10:25

Fuel Pump Relay Off / On Off On

(1) Automatic Transmission Only (2) Manual Transmission Only

Fuel Trim Data

Tech 2 Display Units Displayed Ignition On Engine Running

B1 Short Term Fuel Trim (Bank 1) % 0 –1

B1 LTFT Idle/Deceleration (Bank 1 Long Term Fuel

Trim) % 0 1

B1 LTFT Cruise/Acceleration (Bank 1 Long Term Fuel

Trim) % 0 0

B1 Total Fuel Trim (Bank 1)

% 0 4

B2 Short Term Fuel Trim (Bank 2) % 0 0

B2 LTFT Idle/Deceleration (Bank 2 Long Term Fuel

Trim) % 0 1

B2 LTFT Cruise/Acceleration (Bank 2 Long Term Fuel

Trim) % 0 0

B2 Total Fuel Trim (Bank 2)

% 0 4

Fuel Trim Learn Disabled / Enabled Disabled Disabled

Loop Status B1S1 (Bank 1 Sensor 1) Open / Closed Open Closed

Loop Status B2S1 (Bank 2 Sensor 1) Open / Closed Open Closed

Injection Time Cylinder 1 ms 0.0 2.5

Injection Time Cylinder 2 ms 0.0 2.5

Injection Time Cylinder 3 ms 0.0 2.5

Injection Time Cylinder 4 ms 0.0 2.5

Injection Time Cylinder 5 ms 0.0 2.5

Injection Time Cylinder 6 ms 0.0 2.5

Requested Torque % 99 99

Catalyst Protection Mode Inactive / Active Inactive Inactive

B1 Catalyst Temperature (Bank 1)

°C 300 300

B2 Catalyst Temperature (Bank 2)

°C 300 300

B1S1 O2 Sensor (Bank 1 Sensor 1)

:1 (= Lambda) 0.99 0.99

B1S2 O2 Sensor (Bank 1 Sensor 2) mV 438 520

B2S1 O2 Sensor (Bank 2 Sensor 1) :1 (= Lambda) 0.99 0.99

B2S2 O2 Sensor (Bank 2 Sensor 2) mV 438 516

B1 Average Injection Time (Bank 1) ms 0.0 2.5

B2 Average Injection Time (Bank 2) ms 0.0 2.5

Power Enrichment No / Yes No No

Dec. Fuel Cutoff (Deceleration) Inactive / Active Inactive Inactive

EVAP Purge Solenoid (Evaporative Emission) % 0 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3517 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–239

B1/B2 S1 O2 Sensor 1 (Bank 1 or Bank 2 Sensor 1): This parameter displays the lambda output from the HO2S to the

ECM. A lambda below 1.0 indicates a rich exhaust, while a lambda above 1.0 indicates a lean exhaust.

B1/B2 S2 O2 Sensor 2 (Bank 1 or Bank 2 Sensor 2): This parameter displays the mV output from the HO2S to the

ECM. A lower voltage indicates a lean exhaust, while a higher voltage indicates a rich exhaust.

B1/B2 S1 O2 Sensor Heater (Bank 1 or Bank 2 Sensor 1): This parameter displays the resistance of the sensing

element within the ECM. The front sensors are normally regulated to 80 ohms.

B1/B2 S1/S2 O2 Sensor Heater Circuit Status (Bank 1 or Bank 2 Sensor 1 or Sensor 2): The parameter displays

‘Fault’ if the oxygen sensor heater control circuit is open, shorted to ground, or shorted to voltage. The parameter

displays ‘Undefined’ until the circuit has been commanded ON.

Barometric Pressure: This parameter displays the barometric pressure in kPa. The ECM uses the barometric pressure

for fuel control to compensate for altitude differences.

Barometric Pressure: This parameter displays the barometric pressure voltage. The control module uses the

barometric pressure for fuel control to compensate for altitude differences.

Brake Lamp Switch: This parameter displays the status of the brake lamp switch. W hen the brake pedal is pressed the

switch contacts close causing the vehicles brake lamps to illuminate.

Brake Switch Signal Status: This parameter displays the position of the torque converter clutch (TCC) brake pedal

switch input to the ECM.

Calculated ECT – Closed Loop Fuel Control (Engine Coolant Temperature): This parameter displays the modelled

temperature that the control module calculates from air entering the engine, coolant temperature, and ambient air

temperature. If the actual engine coolant temperature does not reach this calculated temperature within a predetermined

amount of time, a DTC will set.

Calculated ECT – Thermostat Diagnosis (Engine Coolant Temperature): This parameter displays the modelled

temperature that the control module calculates from air entering the engine, coolant temperature, and ambient air

temperature. If the actual engine coolant temperature does not reach this calculated temperature within a predetermined

amount of time, a DTC will set.

Calculated Pedal Position: This parameter displays the angle of the accelerator pedal position (APP) as calculated by

the ECM, using the signals from the APP sensors, as a percentage of throttle opening.

Calculated Throttle Position: This parameter displays the percentage of throttle opening, based on the two TP sensor

inputs to the ECM.

Catalyst Protection Mode: This parameter displays if the control module is commanding catalytic converter protection

or not.

Catalyst Temperature (Bank 1 or Bank 2): This parameter displays the catalytic converter temperature as calculated

by the control module.

Clutch Pedal Switch: This parameter displays the state of the clutch pedal as determined by the ECM from the clutch

start switch position.

Clutch Pedal Switch: This parameter displays the state of the clutch pedal as determined by the ECM from the clutch

pedal switch.

Commanded Exhaust Camshaft Position (Bank 1 or Bank 2): This parameter displays the exhaust camshaft position

in percent of range as commanded by the control module.

Commanded Exhaust Camshaft Position (Bank 1 or Bank 2): This parameter displays the exhaust camshaft position

in crankshaft degrees, as commanded by the ECM.

Commanded Intake Camshaft Position (Bank 1 or Bank 2): This parameter displays the intake camshaft position in

crankshaft degrees, as commanded by the ECM.

Commanded B1/B2 S1 O2 Sensor Heater (Bank 1 or Bank 2 Sensor 1): This parameter displays the state of the

oxygen sensor heater control circuit, as a percentage.

Commanded B1/B2 S1 O2 Sensor Value (Bank 1 or Bank 2 Sensor 1): This parameter displays the lambda output

from the HO2S to the ECM. A lambda below 1.0 indicates a rich exhaust, while a lambda above 1.0 indicates a lean

exhaust.

Coolant Temperature: This parameter displays the temperature of the engine coolant based on input to the control

module from the engine coolant temperature (ECT) sensor.

Crank Request: This parameter displays whether the ignition switch has been cycled to the crank position, requesting

the ECM to activate the starter relay.

Cruise Control Active: This parameter displays the status of the cruise control system as determined by the ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3520 of 6020

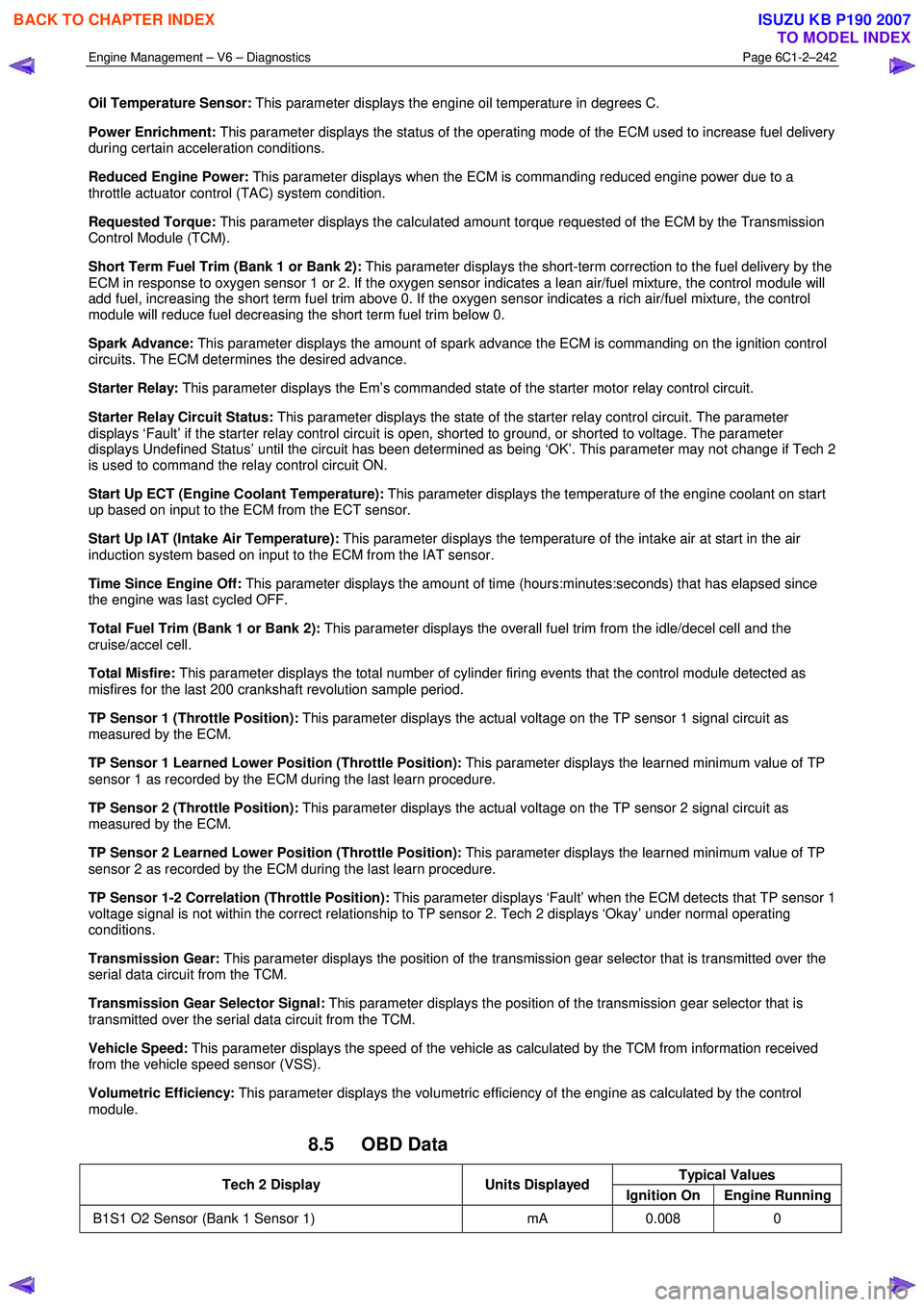

Engine Management – V6 – Diagnostics Page 6C1-2–242

Oil Temperature Sensor: This parameter displays the engine oil temperature in degrees C.

Power Enrichment: This parameter displays the status of the operating mode of the ECM used to increase fuel delivery

during certain acceleration conditions.

Reduced Engine Power: This parameter displays when the ECM is commanding reduced engine power due to a

throttle actuator control (TAC) system condition.

Requested Torque: This parameter displays the calculated amount torque requested of the ECM by the Transmission

Control Module (TCM).

Short Term Fuel Trim (Bank 1 or Bank 2): This parameter displays the short-term correction to the fuel delivery by the

ECM in response to oxygen sensor 1 or 2. If the oxygen sensor indicates a lean air/fuel mixture, the control module will

add fuel, increasing the short term fuel trim above 0. If the oxygen sensor indicates a rich air/fuel mixture, the control

module will reduce fuel decreasing the short term fuel trim below 0.

Spark Advance: This parameter displays the amount of spark advance the ECM is commanding on the ignition control

circuits. The ECM determines the desired advance.

Starter Relay: This parameter displays the Em’s commanded state of the starter motor relay control circuit.

Starter Relay Circuit Status: This parameter displays the state of the starter relay control circuit. The parameter

displays ‘Fault’ if the starter relay control circuit is open, shorted to ground, or shorted to voltage. The parameter

displays Undefined Status’ until the circuit has been determined as being ‘OK’. This parameter may not change if Tech 2

is used to command the relay control circuit ON.

Start Up ECT (Engine Coolant Temperature): This parameter displays the temperature of the engine coolant on start

up based on input to the ECM from the ECT sensor.

Start Up IAT (Intake Air Temperature): This parameter displays the temperature of the intake air at start in the air

induction system based on input to the ECM from the IAT sensor.

Time Since Engine Off: This parameter displays the amount of time (hours:minutes:seconds) that has elapsed since

the engine was last cycled OFF.

Total Fuel Trim (Bank 1 or Bank 2): This parameter displays the overall fuel trim from the idle/decel cell and the

cruise/accel cell.

Total Misfire: This parameter displays the total number of cylinder firing events that the control module detected as

misfires for the last 200 crankshaft revolution sample period.

TP Sensor 1 (Throttle Position): This parameter displays the actual voltage on the TP sensor 1 signal circuit as

measured by the ECM.

TP Sensor 1 Learned Lower Position (Throttle Position): This parameter displays the learned minimum value of TP

sensor 1 as recorded by the ECM during the last learn procedure.

TP Sensor 2 (Throttle Position): This parameter displays the actual voltage on the TP sensor 2 signal circuit as

measured by the ECM.

TP Sensor 2 Learned Lower Position (Throttle Position): This parameter displays the learned minimum value of TP

sensor 2 as recorded by the ECM during the last learn procedure.

TP Sensor 1-2 Correlation (Throttle Position): This parameter displays ‘Fault’ when the ECM detects that TP sensor 1

voltage signal is not within the correct relationship to TP sensor 2. Tech 2 displays ‘Okay’ under normal operating

conditions.

Transmission Gear: This parameter displays the position of the transmission gear selector that is transmitted over the

serial data circuit from the TCM.

Transmission Gear Selector Signal: This parameter displays the position of the transmission gear selector that is

transmitted over the serial data circuit from the TCM.

Vehicle Speed: This parameter displays the speed of the vehicle as calculated by the TCM from information received

from the vehicle speed sensor (VSS).

Volumetric Efficiency: This parameter displays the volumetric efficiency of the engine as calculated by the control

module.

8.5 OBD Data

Typical Values Tech 2 Display Units Displayed

Ignition On Engine Running

B1S1 O2 Sensor (Bank 1 Sensor 1) mA 0.008 0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3527 of 6020

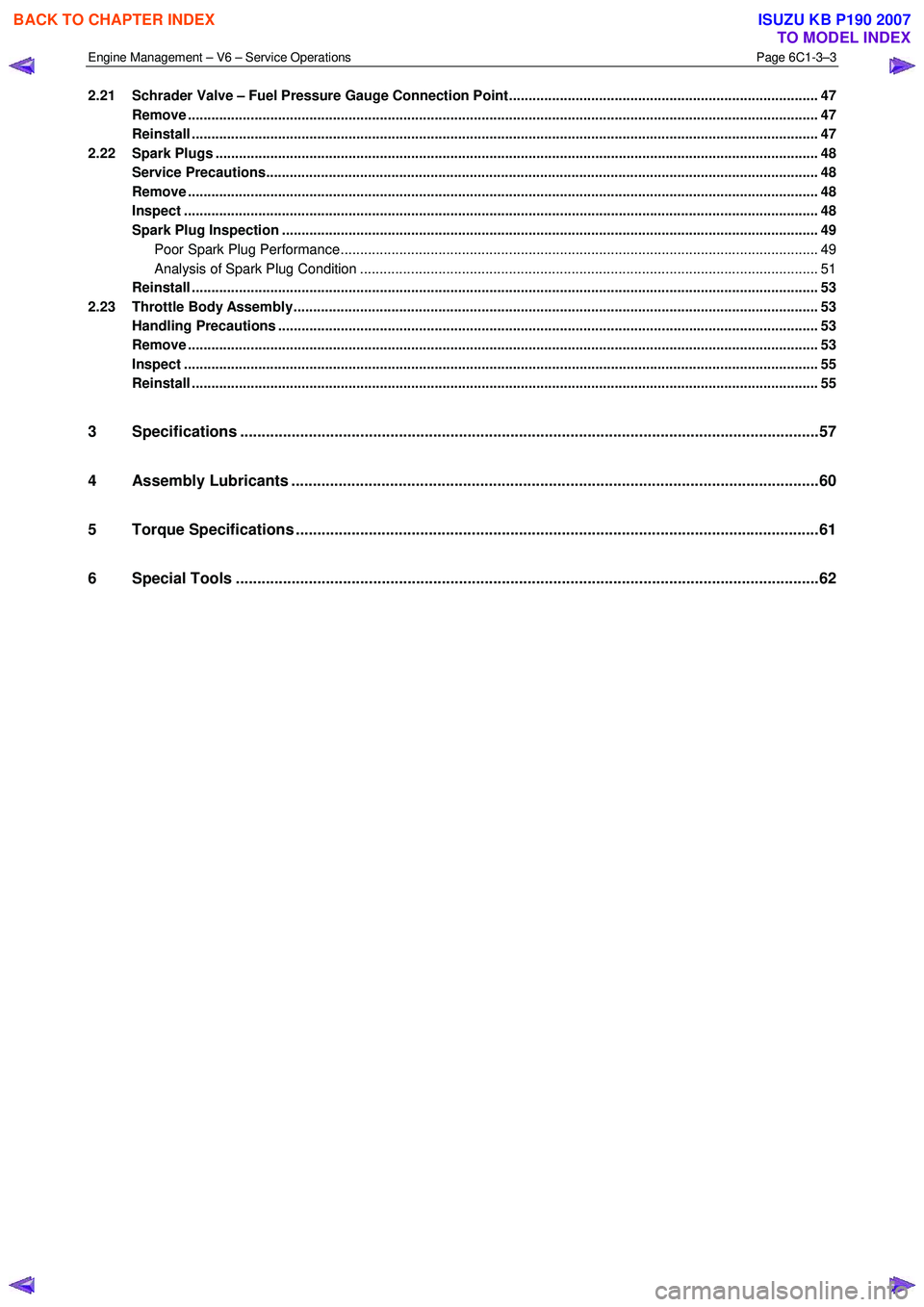

Engine Management – V6 – Service Operations Page 6C1-3–3

2.21 Schrader Valve – Fuel Pressure Gauge Connection Point............................................................................... 47

Remove ................................................................................................................................................................. 47

Reinstall ................................................................................................................................................................ 47

2.22 Spark Plugs .................................................................................................................... ...................................... 48

Service Precautions............................................................................................................ ................................. 48

Remove ................................................................................................................................................................. 48

Inspect .................................................................................................................................................................. 48

Spark Plug Inspection .......................................................................................................... ............................... 49

Poor Spark Plug Performance.................................................................................................... ...................... 49

Analysis of Spark Plug Condition ..................................................................................................................... 51

Reinstall ................................................................................................................................................................ 53

2.23 Throttle Body Assembly......................................................................................................... ............................. 53

Handling Precautions .......................................................................................................................................... 53

Remove ................................................................................................................................................................. 53

Inspect .................................................................................................................................................................. 55

Reinstall ................................................................................................................................................................ 55

3 Specifications ................................................................................................................. ......................57

4 Assembly Lubricants ............................................................................................................ ...............60

5 Torque Specifications ..........................................................................................................................61

6 Special Tools ........................................................................................................................................62

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007