torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3066 of 6020

Engine Mechanical – V6 Page 6A1–289

Page 6A1–289

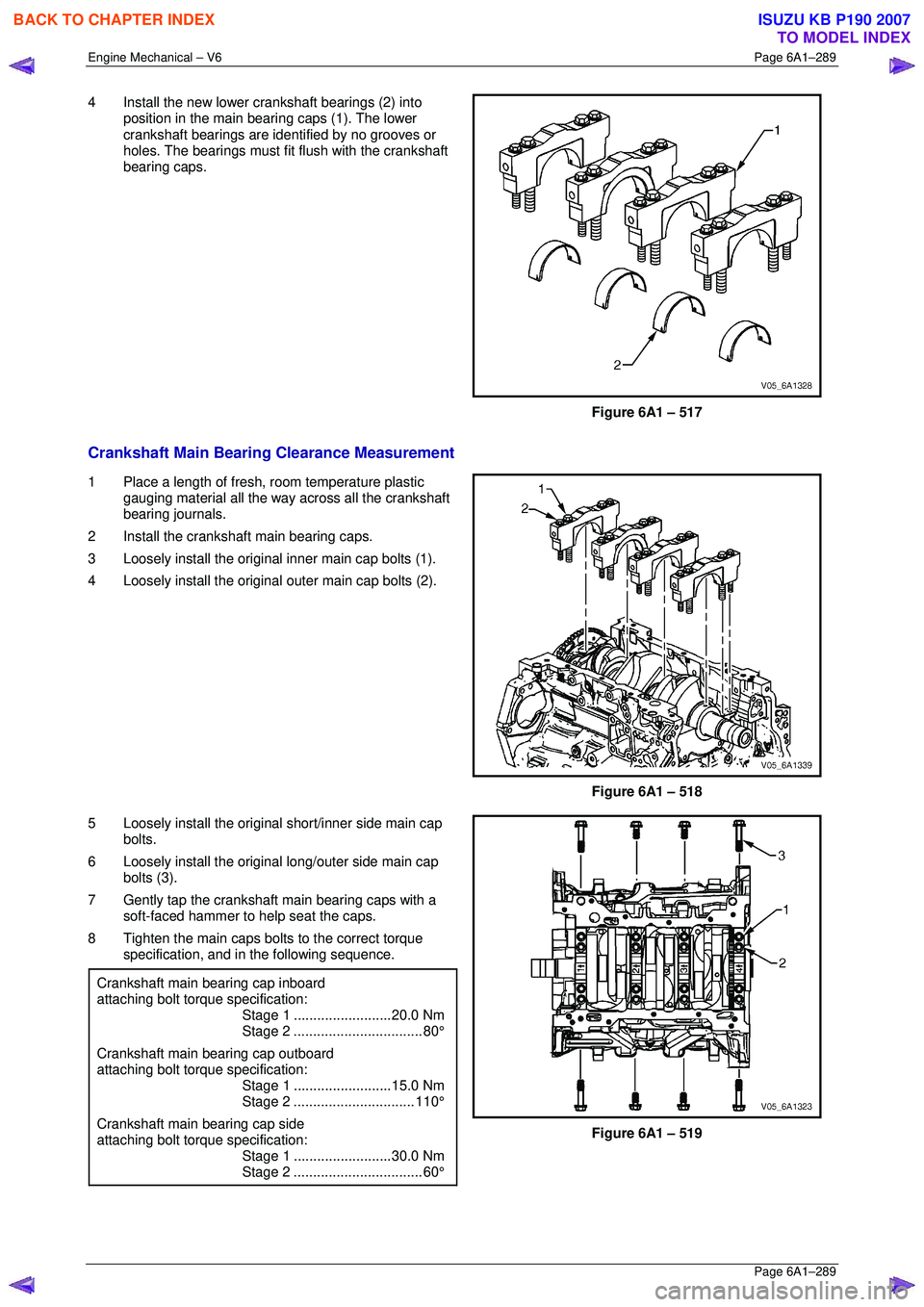

4 Install the new lower crankshaft bearings (2) into

position in the main bearing caps (1). The lower

crankshaft bearings are ident ified by no grooves or

holes. The bearings must fit flush with the crankshaft

bearing caps.

Figure 6A1 – 517

Crankshaft Main Bearing Clearance Measurement

1 Place a length of fresh, room temperature plastic

gauging material all the way across all the crankshaft

bearing journals.

2 Install the crankshaft main bearing caps.

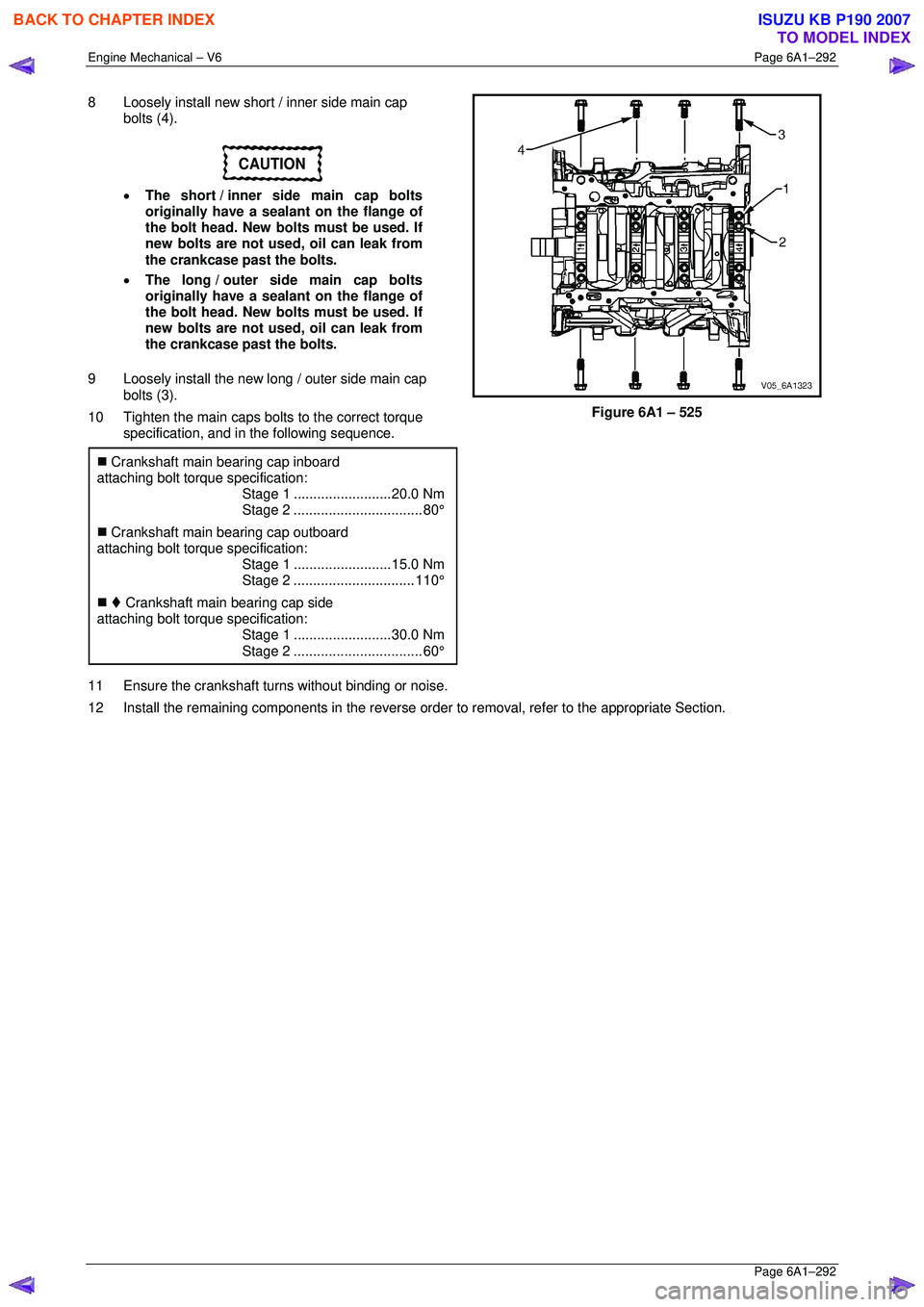

3 Loosely install the original inner main cap bolts (1).

4 Loosely install the original outer main cap bolts (2).

Figure 6A1 – 518

5 Loosely install the original short/inner side main cap bolts.

6 Loosely install the original long/outer side main cap

bolts (3).

7 Gently tap the crankshaft main bearing caps with a soft-faced hammer to help seat the caps.

8 Tighten the main caps bolts to the correct torque specification, and in the following sequence.

Crankshaft main bearing cap inboard

attaching bolt torque specification:

Stage 1 .........................20.0 Nm

Stage 2................................. 80°

Crankshaft main bearing cap outboard

attaching bolt torque specification:

Stage 1 .........................15.0 Nm

Stage 2............................... 110°

Crankshaft main bearing cap side

attaching bolt torque specification:

Stage 1 .........................30.0 Nm

Stage 2................................. 60°

Figure 6A1 – 519

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3068 of 6020

Engine Mechanical – V6 Page 6A1–291

Page 6A1–291

Crankshaft Final Installation Procedure

1 If removed, install the crankshaft sprocket drive

pin (1). Lightly tap the pin in place with a small soft

face, bronze/plastic, hammer until it bottoms in the

hole.

Figure 6A1 – 522

CAUTION

Ensure the crankshaft position sensor has

been removed from the cylinder block prior

to loading the crankshaft, as damage to the

sensor may occur.

2 Apply a liberal amount of clean engine oil to the upper and lower bearing surfaces.

3 Gently lower the crankshaft (1) into position in the cylinder block (2).

Figure 6A1 – 523

4 Install the crankshaft main bearing caps.

5 Loosely install the original inner main cap bolts (1).

CAUTION

The outer crankshaft bearing cap bolts (2)

are yield tightened during assembly and

must be replaced prior to reassembly. Outer

crankshaft bearing cap bolts that are not

replaced will not torque to the correct clamp

load and can lead to serious engine damage.

6 Loosely install the new outer main bearing cap bolts (2).

7 Gently tap the crankshaft main bearing caps with a soft-faced hammer to help seat the caps.

Figure 6A1 – 524

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3069 of 6020

Engine Mechanical – V6 Page 6A1–292

Page 6A1–292

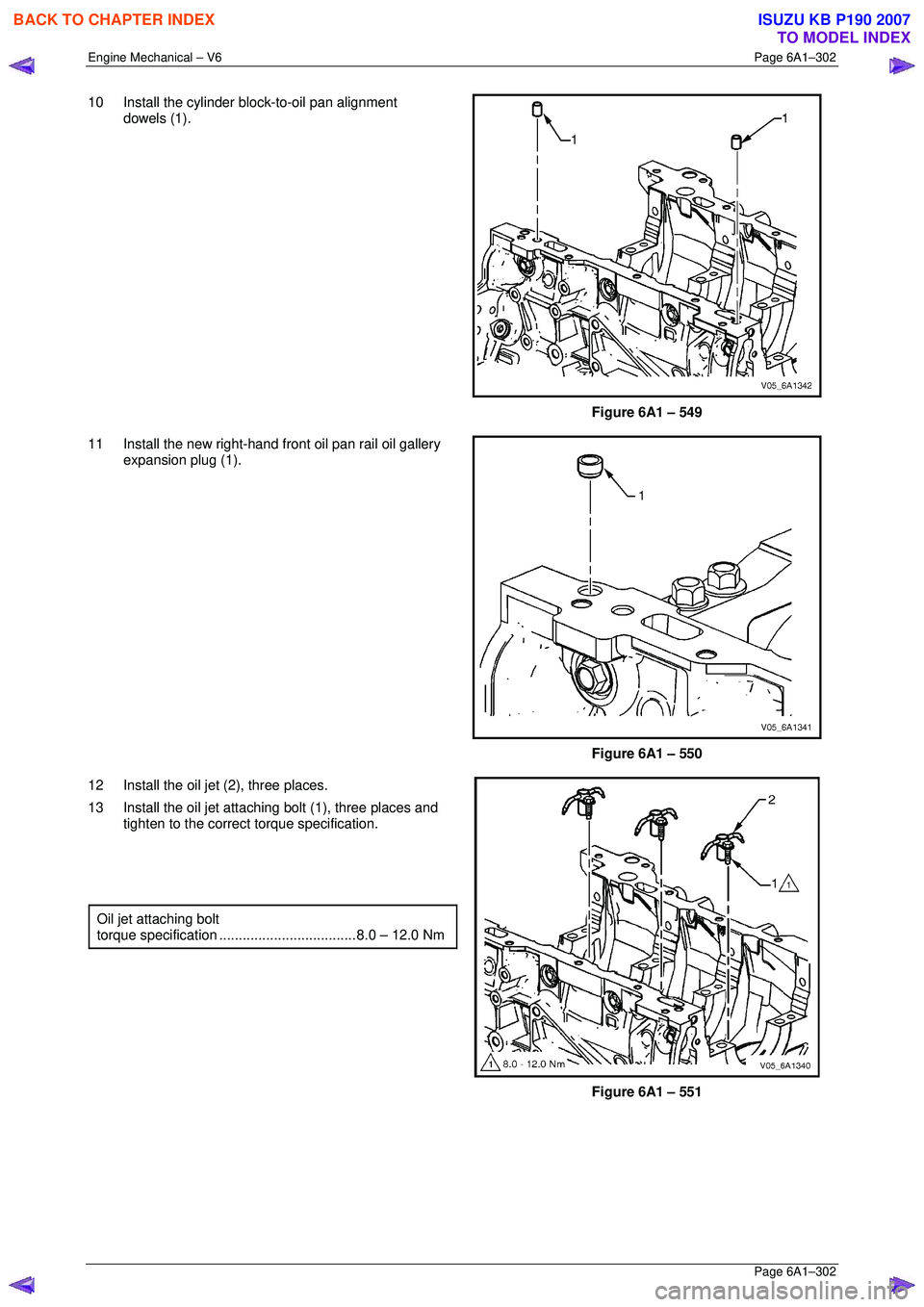

8 Loosely install new short / inner side main cap

bolts (4).

CAUTION

• The short / inner side main cap bolts

originally have a sealant on the flange of

the bolt head. New bolts must be used. If

new bolts are not used, oil can leak from

the crankcase past the bolts.

• The long / outer side main cap bolts

originally have a sealant on the flange of

the bolt head. New bolts must be used. If

new bolts are not used, oil can leak from

the crankcase past the bolts.

9 Loosely install the new long / outer side main cap bolts (3).

10 Tighten the main caps bolts to the correct torque specification, and in the following sequence.

�„ Crankshaft main bearing cap inboard

attaching bolt torque specification:

Stage 1 .........................20.0 Nm

Stage 2................................. 80°

�„ Crankshaft main bearing cap outboard

attaching bolt torque specification:

Stage 1 .........................15.0 Nm

Stage 2............................... 110°

�„ Crankshaft main bearing cap side

attaching bolt torque specification:

Stage 1 .........................30.0 Nm

Stage 2................................. 60°

Figure 6A1 – 525

11 Ensure the crankshaft turns without binding or noise.

12 Install the remaining components in the reverse order to removal, refer to the appropriate Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3077 of 6020

Engine Mechanical – V6 Page 6A1–300

Page 6A1–300

4 Place RTV sealant on new coolant expansion plugs

(1) and install the new coolant expansion plugs.

Figure 6A1 – 543

5 Install the left-hand side M20 oil gallery threaded plug (1) and tighten to the correct torque specification.

Left-hand side M20 cylinder block

oil gallery threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 544

6 Install the left-hand side M14 coolant drain threaded

plug (1) and tighten to the co rrect torque specification.

Left-hand side M14 cylinder block

coolant drain threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 545

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3078 of 6020

Engine Mechanical – V6 Page 6A1–301

Page 6A1–301

7 Install the M14 rear oil gallery threaded plug (1) and

tighten to the correct torque specification.

M14 cylinder block rear oil gallery

threaded plug torque specif ication .......... 27.0 – 35.0 Nm

Figure 6A1 – 546

8 Install the right-hand side M14 coolant drain threaded

plug (1) and tighten to the co rrect torque specification.

Right-hand side M14 cylinder block

coolant drain threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 547

9 Install the right-hand side M14 oil gallery threaded plug (1) and tighten to the co rrect torque specification.

Right-hand side M14 cylinder block

oil gallery threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 548

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3079 of 6020

Engine Mechanical – V6 Page 6A1–302

Page 6A1–302

10 Install the cylinder block-to-oil pan alignment

dowels (1).

Figure 6A1 – 549

11 Install the new right-hand front oil pan rail oil gallery expansion plug (1).

Figure 6A1 – 550

12 Install the oil jet (2), three places.

13 Install the oil jet attaching bolt (1), three places and tighten to the correct torque specification.

Oil jet attaching bolt

torque specificatio n ................................... 8. 0 – 12.0 Nm

Figure 6A1 – 551

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3128 of 6020

Engine Mechanical – V6 Page 6A1–351

Page 6A1–351

6 Torque Wrench Specifications

ATTENTION

�„ Fasteners must be replaced after loosening.

Fasteners either have micro encapsulated sealant a pplied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

Oil Pan Drain Plug ................................................................................ 25.0 Nm

Oil Filter Adaptor Attach ing Bolt................................................ 20.0 – 26.0 Nm

Oil Level Indicator Tube Atta ching Bolt........................................ 8.0 – 12.0 Nm

Accessory Drive Belt Idler Pu lley Attaching Bolt................................... 50.0 Nm

Accessory Drive Belt Tensio ner Attaching Bolt .................................... 50.0 Nm

Power Steering Reserv oir Bracket Attaching Screw.............................. 9.0 Nm

Power Steering Pump Bracket A ttaching Bolt ........................... 49. 0 – 67.0 Nm

Upper Intake Manifold to Lower Intake Manifold Attaching Bolt ........... 23.0 Nm

Upper Intake Manifold to Cylinder Head Attaching Bolt........................ 23.0 Nm

Lower Intake Manifold to Cylind er Head Attaching Bolt........................ 23.0 Nm

Fuel Injector Wiring Harness Br acket Attaching bolt .............................. 9. 0 Nm

Exhaust Manifold to Cylinder He ad Attaching Bolt..................... 17.0 - 23.0 Nm

Exhaust Manifold Heat Shield Attaching Bolt ............................... 8.0 - 12.0 Nm

Battery Harness Ground Terminal Attaching Nut ................................. 13. 0 Nm

Camshaft Cover Attachi ng Bolt................................................... 8.0 – 12.0 Nm

Engine Ground Connec tor Bolt............................................................. 10.0 Nm

Engine Wiring Harness Former A ttaching Bolt .......................... 12.0 – 16.0 Nm

�„ Crankshaft Balancer A ssembly Attaching Bolt:

Stage 1 ..................................................................................... 90.0 –110.0 Nm

Stage 2 ....................................................................................................... 150 °

Engine Front Cover Assembly A ttaching Bolt ............................ 20. 0 – 26.0 Nm

Camshaft Intermediate Sprocket Attaching Bolt ........................ 58. 0 – 72.0 Nm

Secondary Timing Chai n Guide Attaching Bolt.......................... 20.0 – 26.0 Nm

Secondary Timing Chai n Shoe Attaching Bolt ........................... 20.0 – 26.0 Nm

Secondary Timing Chain Tensioner Attachi ng Bolt ................... 20.0 – 26.0 Nm

Primary Timing Chain Upper Gui de Attaching Bolt.................... 20.0 – 26.0 Nm

Primary Timing Chain Tensioner Attaching Bolt........................ 20. 0 – 26.0 Nm

Oil Pump Assembly Attach ing Bolt............................................ 20.0 – 26.0 Nm

Camshaft Sprocket Attachi ng Bolt............................................. 49.0 – 67.0 Nm

Exhaust Camshaft Sprocket Atta ching Bolt............................... 49.0 – 67.0 Nm

Camshaft Bearing Cap Attach ing Bolt......................................... 8.0 – 12.0 Nm

Cylinder Head Thr eaded Plug.............................................................. 31.0 Nm

�„ Cylinder Head M11 Attaching Bolt:

Stage 1 ...................................................................................... 40.0 – 50.0 Nm

Stage 2 ....................................................................................................... 120 °

�„ Cylinder Head M8 Attaching Bolt:

Stage 1 ...................................................................................... 12.0 – 18.0 Nm

Stage 2 ......................................................................................................... 60 °

Engine Mount Bracket to Cylinder Bl ock Attaching Bolt............ 43.0 – 57.0 Nm

Engine Mount to Bracket Atta ching Nut..................................... 70.0 – 90.0 Nm

Engine Mount to Frame Atta ching Nut...................................... 44.0 – 60.0 Nm

Engine Lift Bracket Attachi ng Bolt.......................................... 58.0 – 72.0.0 Nm

Knock Sensor Attach ing Nut................................................................. 23.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3132 of 6020

Engine Mechanical – V6 Page 6A1–355

Page 6A1–355

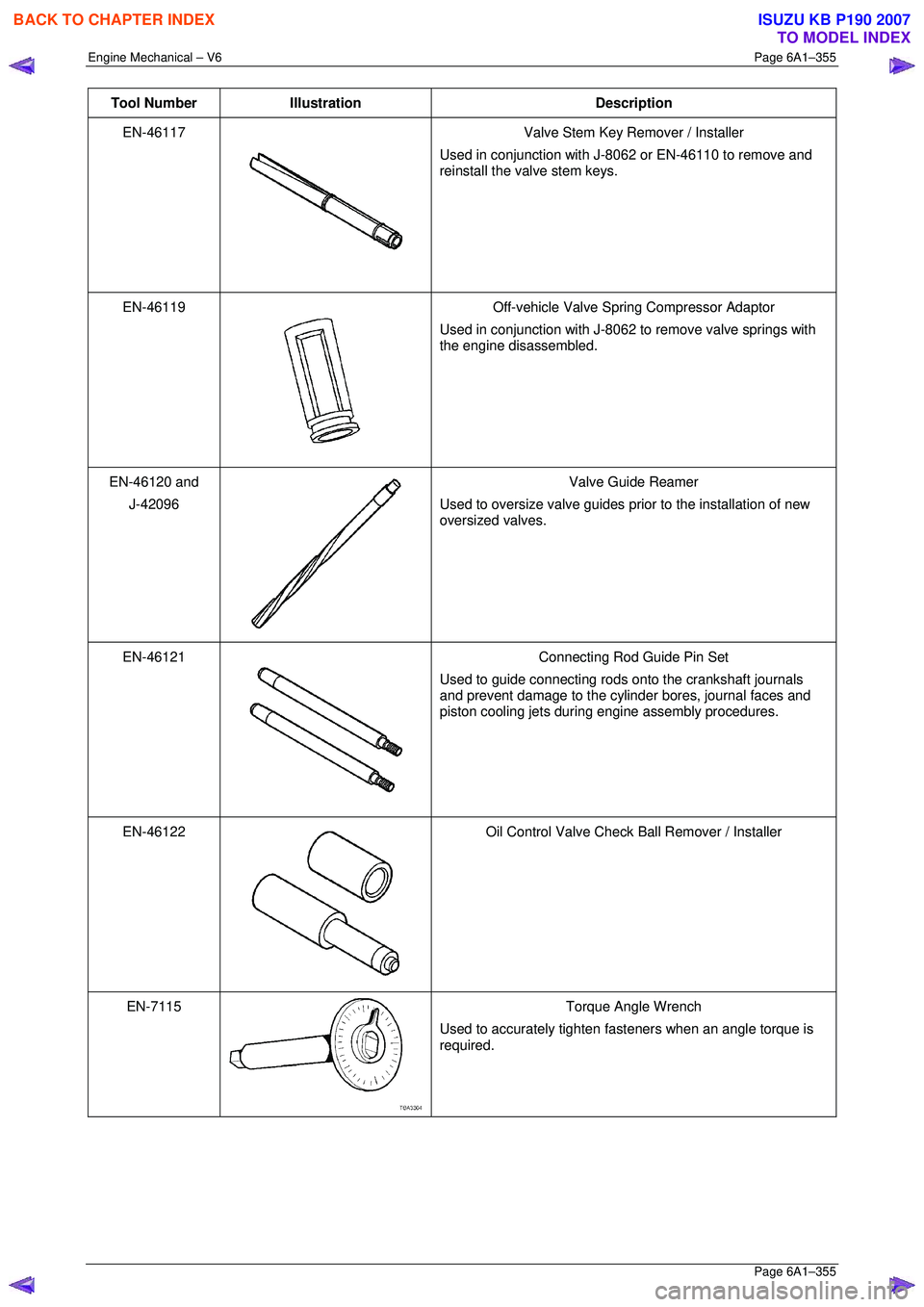

Tool Number Illustration Description

EN-46117

Valve Stem Key Remover / Installer

Used in conjunction with J-8062 or EN-46110 to remove and

reinstall the valve stem keys.

EN-46119

Off-vehicle Valve Spring Compressor Adaptor

Used in conjunction with J-8062 to remove valve springs with

the engine disassembled.

EN-46120 and

J-42096

Valve Guide Reamer

Used to oversize valve guides prior to the installation of new

oversized valves.

EN-46121

Connecting Rod Guide Pin Set

Used to guide connecting rods onto the crankshaft journals

and prevent damage to the cylinder bores, journal faces and

piston cooling jets during engine assembly procedures.

EN-46122

Oil Control Valve Check Ball Remover / Installer

EN-7115

Torque Angle Wrench

Used to accurately tighten fasteners when an angle torque is

required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3137 of 6020

Engine Cooling – V6 Engine Page 6B1–2

Cooling System Pressure Testing ................................................................................................ ...................... 32

3.8 Thermostat ........................................................................................................................................................... 34

Remove ................................................................................................................................................................. 34

Test ....................................................................................................................................................................... 37

Dismantle ...................................................................................................................... ........................................ 37

Reassembly .......................................................................................................................................................... 37

Install .................................................................................................................................................................... 38

3.9 Coolant Recovery Reservoir ..................................................................................................... .......................... 39

Remove ................................................................................................................................................................. 39

Inspect .................................................................................................................................................................. 39

Install .................................................................................................................................................................... 39

3.10 Coolant Pump................................................................................................................... .................................... 40

Remove ................................................................................................................................................................. 40

Inspect .................................................................................................................................................................. 43

Reinstall ................................................................................................................................................................ 43

3.11 Coolant Outlet Housing ......................................................................................................... .............................. 45

Remove ................................................................................................................................................................. 45

Reinstall ................................................................................................................................................................ 46

3.12 Coolant Inlet Pipe............................................................................................................. .................................... 46

Remove ................................................................................................................................................................. 46

Install .................................................................................................................................................................... 48

3.13 Cooling Fan and Shroud Assembly ................................................................................................ ................... 48

Remove ................................................................................................................................................................. 48

Install .................................................................................................................................................................... 50

Disassemble ......................................................................................................................................................... 51

Reassemble .......................................................................................................................................................... 51

3.14 Flexible Transmission Cooler Hose .............................................................................................. ..................... 51

Replace ................................................................................................................................................................. 51

Reinstall ................................................................................................................................................................ 53

3.15 Radiator ....................................................................................................................... ......................................... 54

Remove ......................................................................................................................... ........................................ 54

Reinstall ................................................................................................................................................................ 56

Radiator Repair Procedure...................................................................................................... ............................ 57

Repairable Leaks ............................................................................................................................................. 57

Repair Method.................................................................................................................................................. 58

Tube Blocking................................................................................................................................................... 58

Header Repair .................................................................................................................. ................................ 58

General Core Repair ............................................................................................................ ............................ 59

Transmission Oil Cooler Leak Test .............................................................................................. .................... 60

Transmission Oil Cooler Seal Replacement. ...................................................................................... .............. 60

4 Engine Cooling System Diagnosis .....................................................................................................61

4.1 Poor Heater Operation......................................................................................................................................... 61

4.2 Leaking Cylinder Head Gasket ................................................................................................... ........................ 61

4.3 Question the Customer ....................................................................................................................................... 61

4.4 Diagnostic Chart .................................................................................................................................................. 61

4.5 Problems Not Requiring Disassembly of Cooling System ........................................................................... .... 63

4.6 Problems Requiring Disassembly of Cooling System ...................................................................................... 63

4.7 Black Light and Dye Leak Diagnosis Method .................................................................................................... 63

5 Specifications .......................................................................................................................................64

6 Torque Wrench Specifications................................................................................................... .........66

7 Special Tools ........................................................................................................................................67

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3173 of 6020

Engine Cooling – V6 Engine Page 6B1–38

Install

Always wear protective safety glasses when

working with spring-loaded devices. Failure to

do so could result in eye injury.

1 Install the thermostat into the housing (reverse to removal procedure).

2 Ensure that the engine block and thermostat housing mating surfaces are clean and dry.

3 Install a new gasket to the thermostat housing.

4 Install the thermostat housing to the engine block and secure with the attaching bolts (with rubber grommets installed). Tighten all bolts to the correct torque specification.

Thermostat housing to engine

block bolt torque specification ..............................10 N.m

5 Ensure that the heater pipe assembly and thermostat housing mating surfaces are clean and dry.

6 Install new O-rings to the heater pipe assembly.

7 Install heater pipe assembly to thermostat housing and secure with the attaching bolts. Tighten all bolts to the correct torque specification.

Heater pipe assembly to thermostat

housing bolt torque specification ..........................10 N.m

8 Install heater pipe assembly to right-hand cylinder head bolt. Tighten bolt to the correct torque specification. Heater pipe assembly to cylinder

head bolt torque specification ..............................35 N.m

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

9 Reinstall the engine wiring harness, securing the rear harness former to the rear of the engine with the two retaining bolts, tightened to the correct torque specification.

Rear engine harness former

retaining bolts torque specification .......................15 N.m

10 Reinstall the left side engine harness former to the two locating pegs, then push inward to secure.

11 Reinstall the bolt securing the engine harness ground terminal, to the left side of the cylinder block and tighten to the correct torque specification.

Engine harness ground terminal

attaching bolt torque specification ........................12 N.m

12 Reinstall each wiring harness connector to its correct location, ensuring that all security clips are installed correctly.

13 Connect the heater hoses to the heater pipe assembly.

14 Install the coolant inlet pipe. Refer to 3.12 Coolant Inlet Pipe in this Section.

15 Close the radiator drain tap on the lower LHS of the radiator and remove the piece of rubber tubing to the tap outlet.

16 Reinstall the complete intake manifold assembly. Refer to 6A1 Engine Mechanical.

17 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007