ignition ISUZU KB P190 2007 Workshop Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 672 of 6020

BRAKE CONTROL SYSTEM 5A-79

Step Action

Value(s) Yes No

6 1. Remove the G sensor.

2. Reconnect G sensor and EHCU

3. Install the Tech 2.

4. Ignition "ON", engine "OFF".

5. Observe the G sensor reading on Tech 2. If G sensor inclines, reading voltage will change.

Is the reading voltage between specified values? 1.0 - 4.0V Go to Step 7 Go to Step 8

7 1. Ignition "OFF". 2. Install the G sensor.

3. Install the Tech 2.

4. Ignition "ON", engine "OFF".

5. Select "Display DTCs" with the Tech 2. Are any DTCs stored? - Go to Step 8 Verify repair

8 1. Replace G sensor.

2. Select "Display DTCs" with the Tech 2. Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 9 Verify repair

9 Replace EHCU.

Note: Check the EHCU type for specification, when

the EHCU is replaced.

(Specification ; 2W D model or 4W D model)

Is the action complete? - Verify repair -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 673 of 6020

5A-80 BRAKE CONTROL SYSTEM

DTC C0277 (Flash Code 77) System Voltage Low

DTC C0278 (Flash Code 78) System Voltage High

RTW 75ALF000301

Step Action Value(s) Yes No

1 W ere the steps of the “Basic Diagnostic Flow Chart”

performed?

- Go to Step 2 Go to Basic

Diagnostic

Flow Chart

2 1. Check for a poor connection at EHCU

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 3

3 1. Ignition “OFF”, disconnect EHCU.

2. Ignition “ON”, engine “OFF”.

3. Check the supply voltage to EHCU. Is the value normal? Battery

Voltage Go to Step 5 Go to Step 4

4 Repair or replace the power supply circuit.

Is the action complete? - Verify repair -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 674 of 6020

BRAKE CONTROL SYSTEM 5A-81

Step Action

Value(s) Yes No

5 1. Check the power supply circuit.

(Check circuit for an open, short to ground, or short

to voltage.)

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 6

6 1. Ignition “ON”, engine “OFF”.

2. Select “Display DTCs” with the Tech 2. Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 7 Verify repair

7 Replace EHCU.

Note: Check the EHCU type for specification, when

the EHCU is replaced.

(Specification ; 2W D model or 4W D model)

Is the action complete? - Verify repair -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 675 of 6020

5A-82 BRAKE CONTROL SYSTEM

DTC C0282 (Flash Code 82) 4 Wheel Drive State Input Signal Failure

RTW 75AMF001501

Step Action Value(s) Yes No

1 W ere the steps of the “Basic Diagnostic Flow Chart”

performed?

- Go to Step 2 Go to Basic

Diagnostic

Flow Chart

2 1. Check for a poor connection at EHCU and 2-4W D control unit.

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 3

3 1. Ignition “OFF”, disconnect the EHCU and 2-4W D

control unit.

2. Check the circuit between EHCU and 2-4W D control unit. (Circuit for an open, short to ground, or

short to voltage.)

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 4

4 1. Check the 2-4W D Control system.

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 676 of 6020

BRAKE CONTROL SYSTEM 5A-83

Step Action

Value(s) Yes No

5 1. Ignition "OFF".

2. Connect 2-4W D control unit.

3. Disconnect EHCU.

4. Ignition "ON," engine "OFF."

5. Install the high impedance digital multimeter.

6. Check the transfer (2-4W D control unit) signal value. (Battery voltage is more than 10V.)

W as the value normal? Transfer 2W D

Mode: 8.3Hz (± 15%)

Transfer 4W D Mode: 4.2Hz (± 15%) Go to Step 7 Go to Step 6

6 Replace 2-4W D control unit.

Is the action complete?

- Go to Step 7 -

7 1. Ignition “ON”, engine “OFF”. 2. Select “Display DTCs” with the Tech 2. Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 8 Verify repair

8 Replace EHCU.

Note: Check the EHCU type for specification, when

the EHCU is replaced.

(Specification ; 2W D model or 4W D model)

Is the action complete? - Verify repair -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 677 of 6020

5A-84 BRAKE CONTROL SYSTEM

DTC C0285 (Flash Code 85) Control Module Vehicle Options Incorrect

RTW 75AMF001501

Step Action Value(s) Yes No

1 W ere the steps of the “Basic Diagnostic Flow Chart”

performed?

- Go to Step 2 Go to Basic

Diagnostic

Flow Chart

2 1. Ignition “OFF”.

2. Check for vehicle type and EHCU type.

(Vehicle type : 2W D or 4W D)

3. Check that the EHCU type is the same as the vehicle type.

If the EHCU type differs from the vehicle type, EHCU is replaced.

Note: Check the EHCU type for specification, when

the EHCU is replaced.

(Specification ; 2W D model or 4W D model)

Is the action complete? - Go to Step 3 -

3 1. Check for vehicle type. (Vehicle type : 2W D or

4W D)

Is vehicle type 2W D? - Go to Step 4 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 678 of 6020

BRAKE CONTROL SYSTEM 5A-85

Step Action Value(s) Yes No

4 1. Ignition "OFF".

2. Check for a poor condition at the EHCU harness connector.

3. Check the EHCU circuit for an open, short to ground, or short to voltage. Also, check the EHCU

ignition feed circuit for an open or short to ground

and the EHCU ground circuit for an open or short to

voltage.

4. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 9

5 1. Ignition "OFF", disconnect the EHCU and G sensor.

2. Check the circuit between EHCU and G sensor. (short to ground, or short to voltage.)

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair

Go to Step 6 Go to Step 6

6 1. Remove the G sensor. 2. Reconnect G sensor and EHCU

3. Install the Tech 2.

4. Ignition "ON", engine "OFF".

5. Observe the G sensor reading on Tech 2. If G sensor inclines, reading voltage will change.

Is the reading voltage between specified values? 1.0 – 4.0 V Go to Step 7 Go to Step 8

7 1. Ignition "OFF". 2. Install the G sensor.

3. Install the Tech 2.

4. Ignition "ON", engine "OFF".

5. Select "Display DTCs" with the Tech 2. Are any DTCs stored? - Go to Step 8 Verify repair

8 1. Replace G sensor.

2. Select "Display DTCs" with the Tech 2. Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 9 Verify repair

9 Replace EHCU.

Note: Check the EHCU type for specification, when

the EHCU is replaced.

(Specification ; 2W D model or 4W D model)

Is the action complete? - Verify repair -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 771 of 6020

PARKING BRAKE SYSTEM 5D-1

Service Precaution

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNECESSARY SRS

SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

General Description

Pulling up the parking brake lever by hand will set the

parking brake. By means of a ratchet type lock, the

lever can be held in that position until it is released. The

position of the lever is transmitted through cable/leve

r

systems to the rear wheels. These parts are designed

to obtain sufficient braking force even when parking on

slopes. W hen the parking brake is set, or when the

ignition SW is in the “ON” position, the brake warning

light illuminates. The rear wheel parking brake is a

leading-trailing brake (mechanical inside expansion

type) built in the rear drum brake. Parking brake

adjustment is made through the adjusting hole (bored

through back plate). Parking brake lever stroke should

be adjusted to 8 −14 notches with 294N (30 kg / 66 lb)

(bench seat) or 6 −9 notches with 294N (30 kg / 66 lb)

(bucket seat). Refer to “Parking Brake Adjustment” in

this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 831 of 6020

6A – 26 ENGINE MECHANICAL

041RY00011

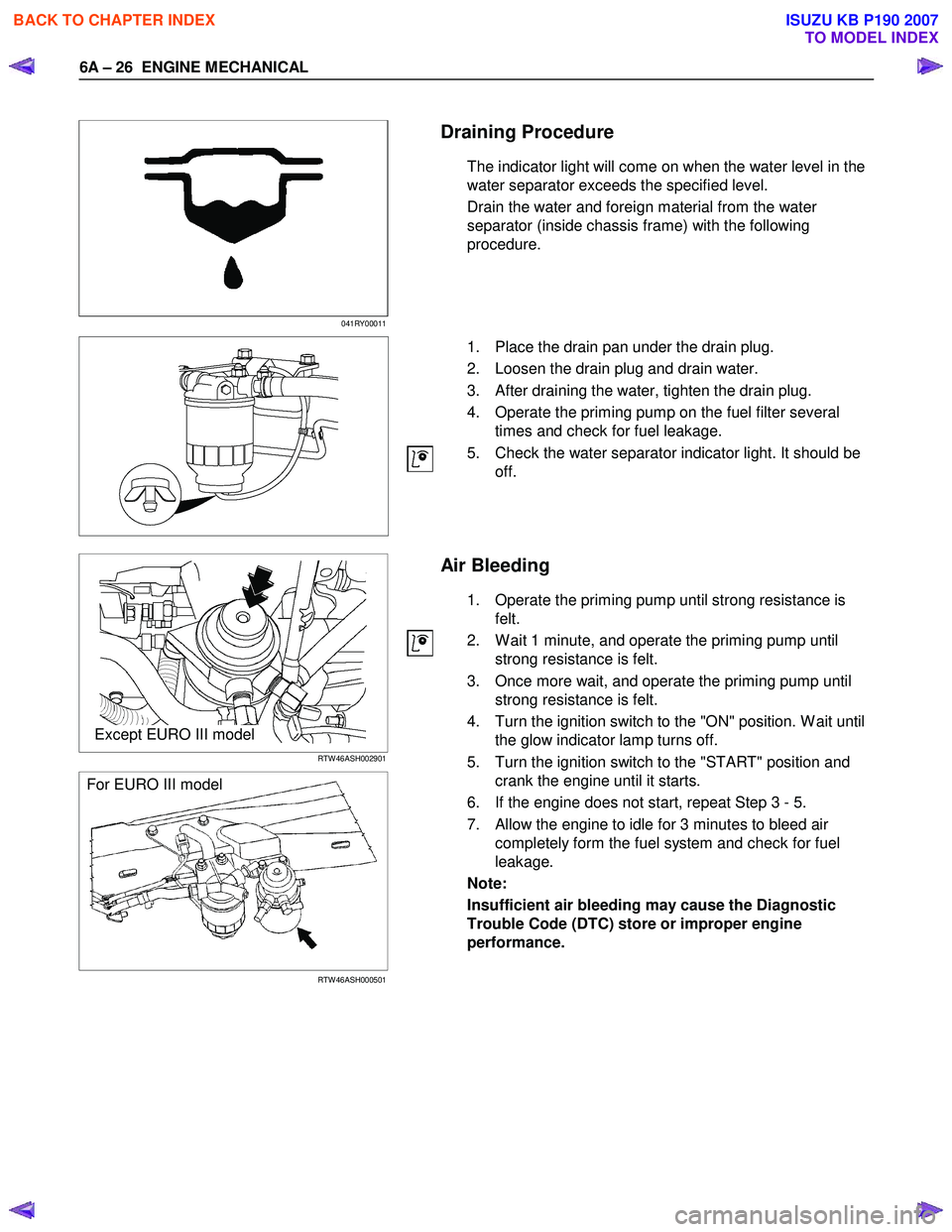

Draining Procedure

The indicator light will come on when the water level in the

water separator exceeds the specified level.

Drain the water and foreign material from the water

separator (inside chassis frame) with the following

procedure.

1. Place the drain pan under the drain plug.

2. Loosen the drain plug and drain water.

3. After draining the water, tighten the drain plug.

4. Operate the priming pump on the fuel filter several times and check for fuel leakage.

5. Check the water separator indicator light. It should be off.

Except EURO III model

RTW 46ASH002901

For EURO III model

RTW 46ASH000501

Air Bleeding

1. Operate the priming pump until strong resistance is felt.

2. W ait 1 minute, and operate the priming pump until strong resistance is felt.

3. Once more wait, and operate the priming pump until strong resistance is felt.

4. Turn the ignition switch to the "ON" position. W ait until the glow indicator lamp turns off.

5. Turn the ignition switch to the "START" position and crank the engine until it starts.

6. If the engine does not start, repeat Step 3 - 5.

7. Allow the engine to idle for 3 minutes to bleed air completely form the fuel system and check for fuel

leakage.

Note:

Insufficient air bleeding may cause the Diagnostic

Trouble Code (DTC) store or improper engine

performance.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1056 of 6020

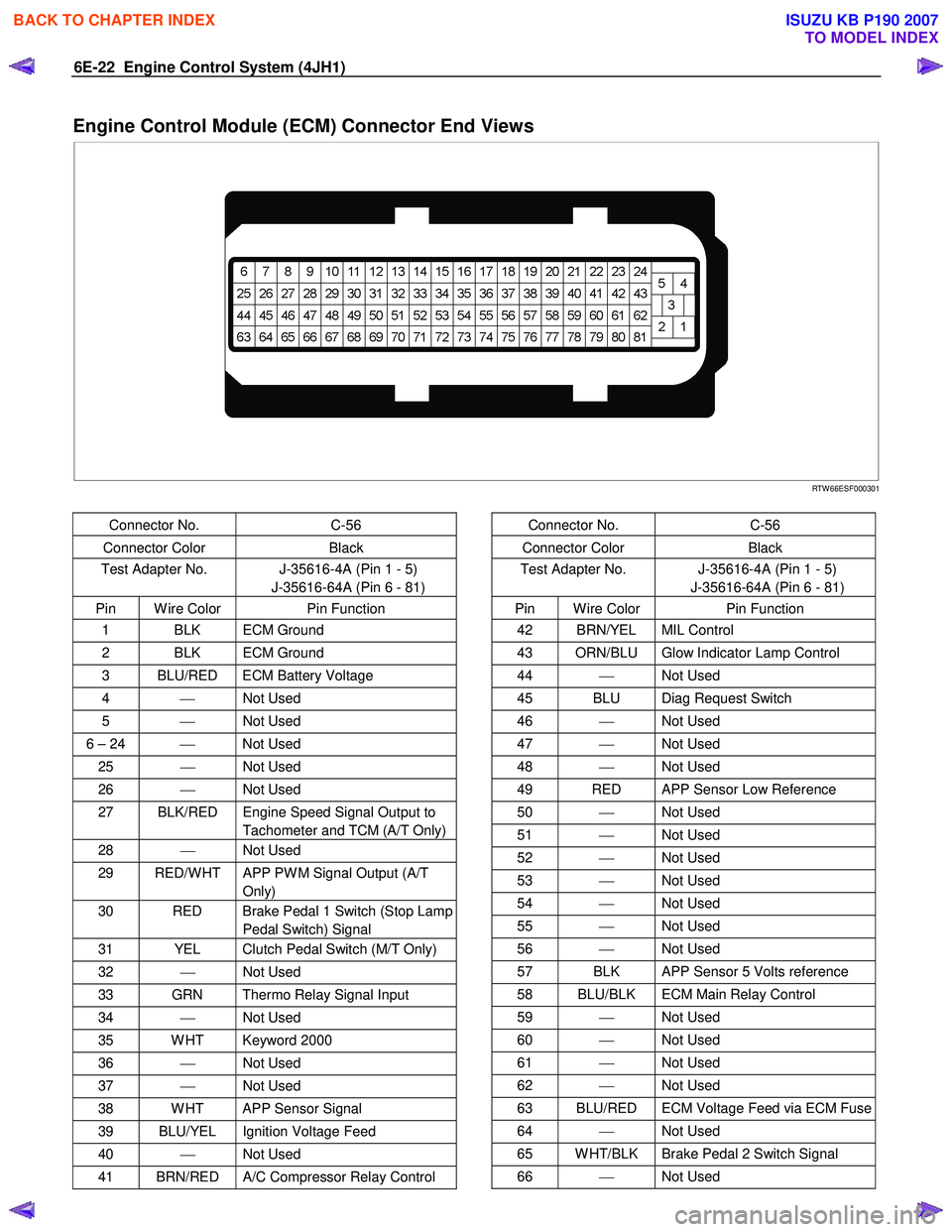

6E-22 Engine Control System (4JH1)

Engine Control Module (ECM) Connector End Views

RTW 66ESF000301

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

1 BLK ECM Ground

2 BLK ECM Ground

3 BLU/RED ECM Battery Voltage

4 Not Used

5 Not Used

6 – 24 Not Used

25 Not Used

26 Not Used

27 BLK/RED Engine Speed Signal Output to

Tachometer and TCM (A/T Only)

28 Not Used

29 RED/W HT APP PW M Signal Output (A/T

Only)

30 RED Brake Pedal 1 Switch (Stop Lamp Pedal Switch) Signal

31 YEL Clutch Pedal Switch (M/T Only)

32 Not Used

33 GRN Thermo Relay Signal Input

34 Not Used

35 W HT Keyword 2000

36 Not Used

37 Not Used

38 W HT APP Sensor Signal

39 BLU/YEL Ignition Voltage Feed

40 Not Used

41 BRN/RED A/C Compressor Relay Control

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

42 BRN/YEL MIL Control

43 ORN/BLU Glow Indicator Lamp Control

44 Not Used

45 BLU Diag Request Switch

46 Not Used

47 Not Used

48 Not Used

49 RED APP Sensor Low Reference

50 Not Used

51 Not Used

52 Not Used

53 Not Used

54 Not Used

55 Not Used

56 Not Used

57 BLK APP Sensor 5 Volts reference

58 BLU/BLK ECM Main Relay Control

59 Not Used

60 Not Used

61 Not Used

62 Not Used

63 BLU/RED ECM Voltage Feed via ECM Fuse

64 Not Used

65 W HT/BLK Brake Pedal 2 Switch Signal

66 Not Used

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007