ECO mode ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2514 of 6020

Engine Mechanical – V6 Page 6A1–35

2.11 Engine Noise Under Load

NOTE

A cold piston knock which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when the specific cylinder’s

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Low oil pressure. 1 Perform an oil pressure test, refer to 2.19

Engine Oil Pressure Diagnosis.

2 Repair or replace the engine oil pump as required, refer to 3.17 Oil Pump Assembly.

Detonation or spark knock. Confirm the correct operation of the ignition system, refer to

6C1-2 Engine Management – V6 – Diagnostics.

Loose torque converter bolts. Inspect and tighten the torque converter bolts to the correct

torque specification, refer to 7C1 Automatic – 4L60E –

General Information – 4L60E – General Information.

Cracked flexplate. Replace the flywheel/flex-plate as required, refer to 4.3

Flexplate Assembly.

Excessive connecting rod bearing clearance. Inspect the connecting rod, crankshaft and bearings and

repair/replace components as required, refer to 4.5

Pistons, Pins, Rings, Connecting Rods and Big-

end Bearings and 4.6 Crankshaft and Main Bearings.

Excessive crankshaft bearing clearance Inspect the crankshaft, cylinder block journals, main

bearings and main bearing caps and repair/replace

components as required, refer to 4.6 Crankshaft

and Main Bearings and 4.7Cylinder Block.

2.12 Engine Will Not Crank – Crankshaft Will Not Rotate

Cause Correction

Seized accessory drive system component. 1 Remove the accessory drive belt, refer to 3.5

Accessory Drive Belt.

2 Rotate the crankshaft by hand at the balancer pulley or flywheel.

3 Repair or replace accessory drive system components as required.

Hydraulically locked cylinder caused by:

• coolant in cylinder,

• oil in cylinder, or

• fuel in cylinder. 1 Remove the spark plugs and check for fluid, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect for broken head gasket/s.

3 Inspect for cracked engine block or cylinder head.

4 Inspect for sticking fuel injector.

5 Repair or replace components as required.

Seized torque converter. 1 Remove the torque converter bolts, refer to 7C1

Automatic – 4L60E – General Information – 4L60E –

General Information.

2 Rotate the crankshaft by hand at the balancer pulley or flywheel.

3 Repair or replace torque converter as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2517 of 6020

Engine Mechanical – V6 Page 6A1–38

2.15 Engine Compression Test

A compression pressure test of the engine cylinders determines the condition of the rings, the valves and the head

gasket.

Preliminary Steps

1 Ensure the battery is fully charged.

2 Remove the spark plugs from all cylinders, refer to 6C1-3 Engine Management – V6 – Service Operations.

NOTE

DTCs will set when the fuel system or the ignition

system is disabled and the engine is cranked.

Disregard DTCs that set under this condition.

3 Disable the fuel system by removing the fuel pump relay, refer to 8A Electrical Body & Chassis.

4 Start the engine to use any residual fuel from the fuel lines.

4 Disable the ignition coils by removing fuses 34 and 35, refer to 8A Electrical Body & Chassis .

5 Using Tech 2, command the throttle plate to wide open throttle.

Engine Cylinder Compression Test

1 Install the compression tester to cylinder number 1.

2 W hile observing the compression tester reading, turn the ignition to the START position for several seconds and then allow the ignition to return to the ON position.

3 Record the highest compression reading obtained.

4 Repeat the engine compression test for each cylinder.

Test Result Evaluation

Normal engine compression pressure builds quickly and evenly to over 965 kPa. In addition, the lowest reading of an

engine cylinder should not be less than 70 percent of the highest reading. If any cylinder fails the compression test,

adding 15 ml of engine oil to the suspected cylinder may help isolate the following fault condition.

1 A fault condition in the piston rings will produce the following result:

• A low compression on the first engine cycle

• The compression tends to build-up with the succeeding engine rotation.

• The compression improves with the addition of engine oil.

2 A fault condition in an intake or exhaust valve will produce the following result:

• A low compression on the first engine cycle

• The compression does not build with the succeeding engine rotation.

• The compression does not improve with the addition of engine oil.

3 A fault condition in the cylinder head gasket will produce the following result:

• A low compression on the first engine cycle

• The compression does not build with the succeeding engine rotation.

• The compression does not improve with the addition of engine oil.

• The suspected cylinders are positioned adjacent to each other.

• The engine oil may be contaminated with engine coolant.

• The engine coolant may be contaminated with engine oil.

Once the fault has been identified, refer to the relevant service procedure and reinstall the removed components.

Using Tech 2, clear DTCs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2518 of 6020

Engine Mechanical – V6 Page 6A1–39

2.16 Cylinder Leakage Test

A leakage test may be performed to measure cylinder/combustion chamber leakage. High cylinder leakage may indicate

one or more of the following:

• worn or burnt valves,

• broken valve springs,

• stuck valve lifters,

• incorrect valve lash/adjustment,

• damaged piston,

• worn piston rings,

• worn or scored cylinder bore,

• damaged cylinder head gasket,

• cracked or damaged cylinder head, or

• cracked or damaged engine block.

1 Disconnect the battery ground negative cable.

2 Remove the spark plugs from all cylinders, refer to 6C1-3 Engine Management – V6 – Service Operations.

3 Rotate the crankshaft to place the piston in the cylinder being tested at top dead centre (TDC) of the compression stroke.

4 Install a commercially available cylinder head leak down tester into the spark plug hole.

NOTE

If required, hold the crankshaft balancer bolt to

prevent the engine from rotating.

5 Apply shop air pressure to the cylinder head leak down tester and adjust according to the manufacturers instructions.

6 Record the cylinder leakage value. Cylinder leakage that exceeds 25 percent is considered excessive and may require component service. In excessive leakage situations, inspect for the following conditions:

• air leakage sounds at the throttle body or air inlet duct that may indicate a worn or burnt intake valve or a

broken valve spring,

• air leakage sounds at the exhaust system tailpipe that may indicate a worn or burnt exhaust valve or a broken

valve spring,

• air leakage sounds from the crankcase, oil level indicator tube, or oil fill tube that may indicate worn piston

rings, a damaged piston, a worn or scored cylinder bore, a damaged engine block or a damaged cylinder

head, or

• air bubbles in the cooling system may indicate a damaged cylinder head or a damaged cylinder head gasket.

7 Perform the leakage test on the remaining cylinders and record the values.

2.17 Engine Oil Consumption Diagnosis

Definition

Excessive oil consumption (not due to leaks) is the use of 3 litres or more of engine oil within 10,000 kilometres. Prior to

performing oil pressure testing, a preliminary inspection of the vehicle should be performed. During the preliminary visual

inspection, the following likely causes of excessive oil usage should be investigated.

Cause Correction

External oil leaks. Refer to 2.18 Engine Oil Leak Diagnosis.

Incorrect oil level or reading of the oil level indicator. Check for the correct oil level, refer to 3.1 Engine Oil.

Incorrect oil viscosity. Replace the engine oil, using the recommended SAE grade

of engine oil, refer to 3.1 Engine Oil.

Continuous high-speed driving or severe usage. Service vehicle more frequently, refer to 0B Lubrication and

Service.

Crankcase ventilation system restricted or malfunctioning. Repair or replace crankcase ventilation system components as required, refer to 6C1-3 Engine Management – V6 –

Service Operations.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2519 of 6020

Engine Mechanical – V6 Page 6A1–40

Cause Correction

W orn valve guides and or valve stems. Inspect and repair valves and valve guides as required,

refer to 3.22 Cylinder Head Assembly.

W orn or damaged valve stem oil seal. Replace valve stem oil seals as required, refer to 3.22

Cylinder Head Assembly.

Piston rings broken, worn or not seated correctly. Allowing adequate time for the piston rings to seat correctly,

replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

Piston rings incorrectly installed or not matched to cylinder

bore oversize. Replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

2.18 Engine Oil Leak Diagnosis

Introduction

It is important to correctly identify the source of an engine oil leak. For example, a power steering fluid leak or spillage

during servicing can travel across the valley area of the engine and run-out the weep hole, which is located at the back of

the cylinder block. Failure to correctly identify the source of an engine oil leak can lead to unnecessary replacement of

engine components.

Most fluid leaks can be repaired by repairing or replacing the faulty component or resealing the gasket surface. However,

once a leak is identified it is important to determine and repair the cause as well as the leak itself.

Locating and Identifying the Leak

Inspect the leaking fluid and determine whether it is engine oil, transmission fluid, power steering fluid, brake fluid or

some other fluid. If unsure of the source of the leaking lubricant, a quick check of fluid levels should indicate where the

fluid is coming from, as one or more fluid level should be low.

Visual Inspection

Once the type of leaking fluid has been determined, a visual inspection of the affected system should be performed.

W hen performing the visual inspection:

1 Bring the vehicle to the normal operating temperature.

2 Park the vehicle over a large sheet of paper or other clean surface.

3 Leave the vehicle idling for 2-3 minutes, then check for dripping fluid.

4 If required, identify the type of fluid leaking and the approximate location of the leak.

5 Visually inspect the suspected area. A small mirror may assist viewing areas that are difficult to see normally.

6 Check for leaks at all sealing surfaces and fittings.

7 Check for any cracked or damaged components.

8 If the leak cannot be located, completely clean the entire engine and surrounding components, drive the vehicle at normal operating temperature for several kilometres and then repeat Steps 3 to 8.

9 If the leak still cannot be located, proceed with either the Powder Method or Black Light and Dye Method as outlined below.

Powder Method

1 Completely clean the entire engine and surrounding components.

2 Apply an aerosol type powder (e.g. foot powder) to the suspected area.

3 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

4 Identify the source of the leak from the discoloration of the powder around the suspect components.

5 If required, use a small mirror to assist in viewing areas that are difficult to see normally.

6 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Black Light and Dye Method

A black light and die kit Tool No. J28428-E or a commercially available equivalent is available to technicians to aid in

engine oil leak diagnosis. W hen using a black light and die kit for the first time, it is recommended the technician read the

manufacturers instructions prior to using the kit.

1 Add the specified amount of dye, as per manufacturers instructions, into the engine or suspected source of the oil leak.

2 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2520 of 6020

Engine Mechanical – V6 Page 6A1–41

3 W ith the vehicle parked on a flat level surface, aim the black light at the suspected component/s. The dyed fluid will

appear as a yellow path leading to the oil leak source

4 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Possible Causes for Engine Oil Leaks

Common possible causes for engine oil leaks are:

• higher than recommended fluid levels,

• higher than recommended fluid pressures,

• blocked or faulty fluid filters or pressure relief valve,

• blocked or faulty engine ventilation system,

• incorrectly tightened or damaged fasteners,

• cracked or porous components,

• incorrect gaskets or sealants used,

• incorrect gaskets or sealant installation,

• damaged or worn gaskets or seals, and

• damaged or worn sealing surfaces.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2523 of 6020

Engine Mechanical – V6 Page 6A1–44

CAUTION

When running the engine with the accessory

drive belt removed, the coolant pump will not

be operating and the engine may overheat if

left unsupervised even for a short period.

NOTE

There may also be a number of DTCs set when

running the engine with the accessory drive belt

removed.

4 Inspect all drive pump pulleys for pilling. NOTE

Pilling is the small balls (pills) or strings of rubber

in the belt grooves caused by the accumulation of

rubber dust.

6 Misalignment of the accessory drive system pulleys may be caused by incorrect mounting of an accessory drive component (A/C compressor, generator etc.) or pulley. Misalignment may also be caused by incorrect installation of

a pulley during a previous repair. Test for a misaligned pulley using a straight edge in the pulley grooves across

two or three pulleys. If a misaligned pulley is found, refer to the relevant component service information for the

correct installation and removal procedures.

10 Inspecting the fasteners can eliminate the possibility that an incorrect fastener has been installed.

12 Inspecting the pulleys for being bent should include inspecting for a dent or other damage that would prevent the drive belt from not seating correctly in all of the pulley grooves or on the smooth surface when the back end of the

belt is used as the driving surface.

14 Replacing the drive belt when it is not damaged and there is no excessive pilling will only be a temporary repair.

Diagnostic Table

Step Action Yes No

1 Did you review the information provided in 2.2 Symptoms, and

perform the required inspections. Go to Step 2 Go to 2.2

Symptoms

2 Confirm the customer complaint. Is there a chirping noise? Go to Step 3 Refer to Diagnostic

Aids in this Section

3 1 Remove the drive belt, refer to 3.5 Accessory Drive Belt.

2 Operate the engine for no more than 40 seconds.

Does the chirping noise still exist? Accessory drive

system OK.

Go to 2.2

Symptoms, and restart the

diagnosis of the noise Go to Step 4

4 Inspect for severe pilling, i.e. in excess of 33% of the belt groove

depth.

Do the belt grooves have pilling? Go to Step 5 Go to Step 6

5 Clean the drive belt pulleys with a wire brush. Are the belt pulleys clean? Go to Step 15 Go to Step 6

6 Inspect for misalignment of the pulleys. Are the pulleys misaligned? Go to Step 7 Go to Step 8

7 Replace or repair misaligned pulleys. Did you complete the repair? Go to Step 15 —

8 Inspect for any bent or damaged accessory drive component mounting brackets.

Did you find any bent or damaged brackets? Go to Step 9 Go to Step 10

9 Replace or repair any bent or damaged Brackets. Did you complete the repairs? Go to Step 15 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2525 of 6020

Engine Mechanical – V6 Page 6A1–46

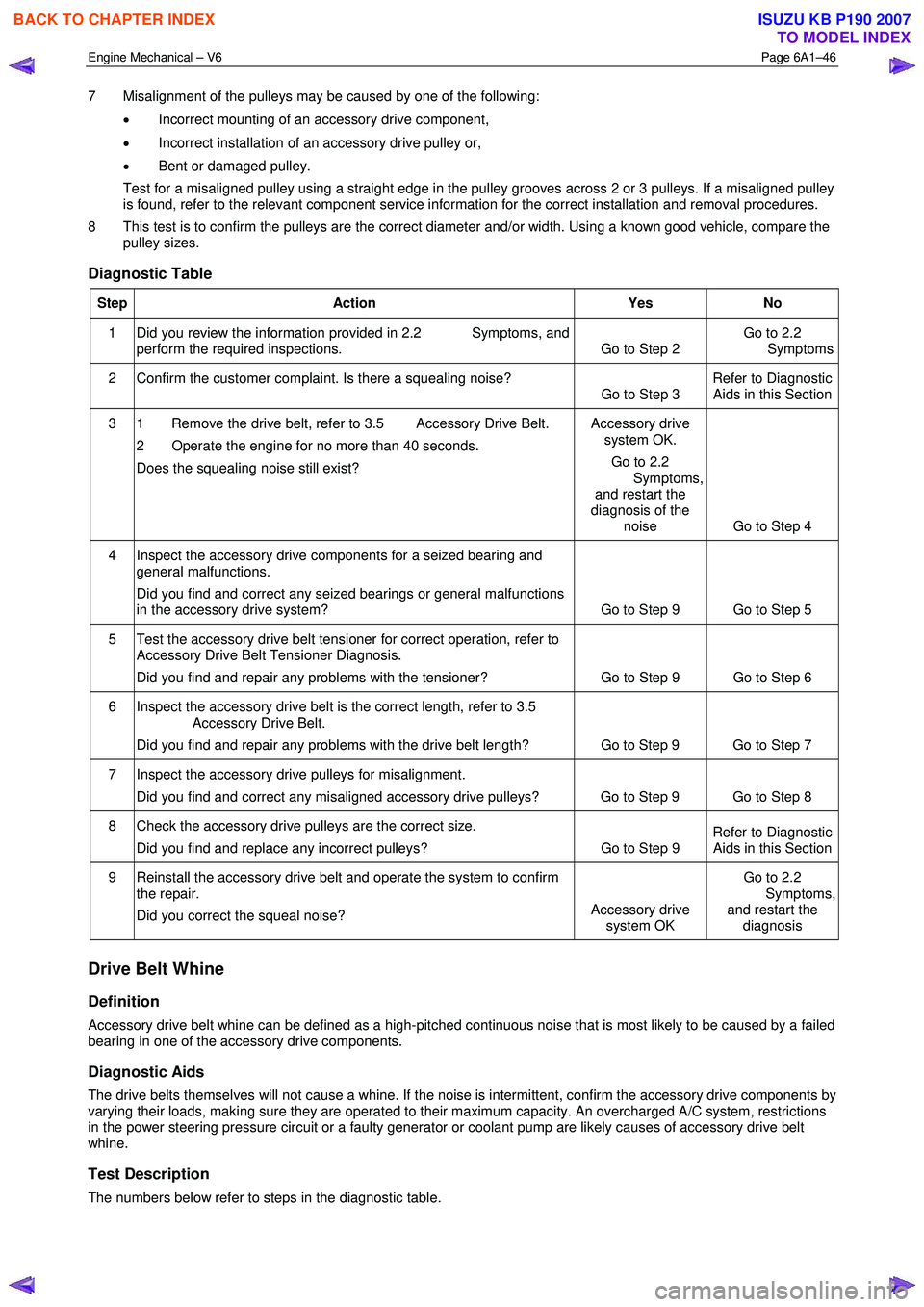

7 Misalignment of the pulleys may be caused by one of the following:

• Incorrect mounting of an accessory drive component,

• Incorrect installation of an accessory drive pulley or,

• Bent or damaged pulley.

Test for a misaligned pulley using a straight edge in the pulley grooves across 2 or 3 pulleys. If a misaligned pulley is found, refer to the relevant component service information for the correct installation and removal procedures.

8 This test is to confirm the pulleys are the correct diameter and/or width. Using a known good vehicle, compare the pulley sizes.

Diagnostic Table

Step Action Yes No

1 Did you review the information provided in 2.2 Symptoms, and

perform the required inspections. Go to Step 2 Go to 2.2

Symptoms

2 Confirm the customer complaint. Is there a squealing noise? Go to Step 3 Refer to Diagnostic

Aids in this Section

3 1 Remove the drive belt, refer to 3.5 Accessory Drive Belt.

2 Operate the engine for no more than 40 seconds.

Does the squealing noise still exist? Accessory drive

system OK.

Go to 2.2

Symptoms, and restart the

diagnosis of the noise Go to Step 4

4 Inspect the accessory drive components for a seized bearing and

general malfunctions.

Did you find and correct any seized bearings or general malfunctions

in the accessory drive system? Go to Step 9 Go to Step 5

5 Test the accessory drive belt tensioner for correct operation, refer to

Accessory Drive Belt Tensioner Diagnosis.

Did you find and repair any problems with the tensioner? Go to Step 9 Go to Step 6

6 Inspect the accessory drive belt is the correct length, refer to 3.5

Accessory Drive Belt.

Did you find and repair any problems with the drive belt length? Go to Step 9 Go to Step 7

7 Inspect the accessory drive pulleys for misalignment.

Did you find and correct any misaligned accessory drive pulleys? Go to Step 9 Go to Step 8

8 Check the accessory drive pulleys are the correct size. Did you find and replace any incorrect pulleys? Go to Step 9 Refer to Diagnostic

Aids in this Section

9 Reinstall the accessory drive belt and operate the system to confirm

the repair.

Did you correct the squeal noise? Accessory drive

system OK Go to 2.2

Symptoms, and restart the diagnosis

Drive Belt Whine

Definition

Accessory drive belt whine can be defined as a high-pitched continuous noise that is most likely to be caused by a failed

bearing in one of the accessory drive components.

Diagnostic Aids

The drive belts themselves will not cause a whine. If the noise is intermittent, confirm the accessory drive components by

varying their loads, making sure they are operated to their maximum capacity. An overcharged A/C system, restrictions

in the power steering pressure circuit or a faulty generator or coolant pump are likely causes of accessory drive belt

whine.

Test Description

The numbers below refer to steps in the diagnostic table.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2526 of 6020

Engine Mechanical – V6 Page 6A1–47

3 The noise may be an internal engine noise. Removing the drive belt and operating the engine briefly will confirm

whether or not the noise is related to the drive belt.

CAUTION

When running the engine with the accessory

drive belt removed, the coolant pump will not

be operating and the engine may overheat if

left unsupervised even for a short period.

NOTE

There may also be a number of DTCs set when

running the engine with the accessory drive belt

removed.

4 The inspection of bearings should include the following accessory drive components: • drive belt tensioners,

• drive belt idlers,

• generator,

• power steering pump,

• coolant pump, and

• A/C compressor.

The drive belt may need to be installed and the accessory drive components operated separately, at varying loads to confirm the location of the faulty bearing, refer to the relevant Sections for component inspection and repair

procedures.

Diagnostic Table

Step Action Yes No

1 Did you review the information provided in 2.2 Symptoms, and

perform the required inspections. Go to Step 2 Go to 2.2

Symptoms

2 Confirm the customer complaint. Is there a whining noise? Go to Step 3 Refer to Diagnostic

Aids in this Section

3 1 Remove the drive belt, refer to 3.5 Accessory Drive Belt.

2 Operate the engine for no more than 40 seconds.

Does the whining noise still exist? Accessory drive

system OK

Go to 2.2

Symptoms, and restart the diagnosis Go to Step 4

4 Inspect the accessory drive components for a faulty or seized

bearings and general malfunctions.

Did you find and correct any faulty/seized bearings or general

malfunctions in the accessory drive system? Go to Step 5 Refer to Diagnostic

Aids in this Section

5 Reinstall the accessory drive belt and operate the system to confirm the repair.

Did you correct the whine? Accessory drive

system OK Go to 2.2

Symptoms, and restart the diagnosis

Drive Belt Rumble

Definition

Accessory drive belt rumble can be defined as a low pitch tapping, knocking or thumping noise heard at or just above idle,

once per rotation of the drive belt or a specific component. Drive belt rumble is generally caused by one of the following:

• pilling or strings in the drive belt grooves,

• separation of the drive belt, or

• a damaged or faulty drive belt.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2527 of 6020

Engine Mechanical – V6 Page 6A1–48

NOTE

Pilling is the small balls (pills) or strings of rubber

in the belt grooves caused by the accumulation of

rubber dust.

Diagnostic Aids

Vibration from the engine may cause a body component or other parts to emit a rumbling noise.

The drive belt may have a condition that cannot be seen or felt. Sometimes the replacement of the belt may be the only

way to confirm the belt is faulty.

If the drive belt has been replaced and the diagnostic table completed, but the rumble is still present only when the drive

belt is installed, an accessory drive component such as the A/C compressor may be the cause. Varying the load to each

accessory drive component in turn, should help isolate which component is causing the noise.

Test Description

The numbers below refer to steps in the diagnostic table.

2 Confirms the symptom exists at the time of diagnosis. Other vehicle components may be causing the noise.

3 Confirms the accessory drive belt is the cause of the noise. Drive belt rumbling is often confused with an internal engine noise due to the similarity in the description. Removing the drive belt and operating the engine briefly will

confirm whether or not the noise is related to the drive belt.

CAUTION

When running the engine with the accessory

drive belt removed, the coolant pump will not

be operating and the engine may overheat if

left unsupervised even for a short period.

NOTE

There may also be a number of DTCs set when

running the engine with the accessory drive belt

removed.

4 Inspecting the drive belt is to ensure that it is not causing the noise. Small cracks across the ribs of the drive belt will not cause the noise and are not justification alone to replace the belt. Belt separation can be identified by the

ply of the belt separating and may be seen at the edge of the belt or felt as lumps under the belt.

5 Small amounts of pilling is a normal condition and is deemed acceptable. W hen the pilling is severe (33% of the belt groove depth), the belt does not have a smooth surface to run on and should be replaced.

Diagnostic Table

Step Action Yes No

1 Did you review the information provided in 2.2 Symptoms, and

perform the required inspections. Go to Step 2 Go to 2.2

Symptoms

2 Confirm the customer complaint. Is there a rumbling noise? Go to Step 3 Refer to Diagnostic

Aids in this Section

3 1 Remove the drive belt, refer to 3.5 Accessory Drive Belt.

2 Operate the engine for no more than 40 seconds.

Does the rumbling noise still exist? Accessory drive

system OK

Go to 2.2

Symptoms,

and restart the diagnosis Go to Step 4

4 Inspect the accessory drive belt for damage, separation or sections of missing ribs.

Did you find any damaged, separated or missing ribs? Go to Step 7 Go to Step 5

5 Inspect the accessory drive belt for severe pilling (exceeding 33% of the belt groove depth).

Did you find sever pilling? Go to Step 6 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2529 of 6020

Engine Mechanical – V6 Page 6A1–50

Diagnostic Table

Step Action Yes No

1 Did you review the information provided in 2.2 Symptoms, and

perform the required inspections. Go to Step 2 Go to 2.2

Symptoms

2 Confirm the customer complaint. Is there a rumbling noise? Go to Step 3 Refer to Diagnostic

Aids in this Section

3 1 Remove the drive belt, refer to 3.5 Accessory Drive Belt.

2 Operate the engine for no more than 40 seconds.

Does the vibration noise still exist? Accessory drive

system OK.

Go to 4.2

Symptoms, and

restart the diagnosis Go to Step 4

4 Inspect the accessory drive belt for damage, wear, debris build-up or

sections of missing ribs.

Did you find any damage, wear, debris build-up or missing ribs? Go to Step 5 Go to Step 6

5 Install a new accessory drive belt, refer to 3.5 Accessory Drive Belt.

Did you replace the accessory drive belt? Go to Step 10 —

6 Inspect for incorrect, loose, missing or damaged fasteners. Did you find any incorrect, loose, missing or damaged fasteners? Go to Step 7 Go to Step 8

7 Tighten any loose fasteners to the correct torque specification, refer to

6 Torque W rench Specifications.

Replace any incorrect or missing fasteners.

Did you complete the repairs? Go to Step 10 —

8 Inspect the coolant pump for a bent shaft, refer to 6B1 Engine Cooling – V6.

Did you find and repair a bent coolant pump shaft? Go to Step 10 Go to Step 9

9 Inspect for bent, cracked or damaged accessory drive component mounting brackets.

Did you find and repair any bent brackets? Go to Step 10 Refer to Diagnostic

Aids in this Section

10 If required, reinstall the accessory drive belt and operate the system to

confirm the repair.

Did you correct the vibration? Accessory drive

system OK Refer to Diagnostic

Aids in this Section

Drive Belt Falls Off

Definition

The drive belt falls off during normal operation or does not ride correctly on the accessory drive pulleys.

Diagnostic Aids

If the accessory drive belt repeatedly falls off the drive pulleys, this is most likely due to pulley misalignment.

An extra load that is quickly applied and released by an accessory drive component (e.g. A/C compressor) may cause

the accessory drive belt to fall off. In this circumstance, confirm the fault by operating the accessory drive components in

turn, noting which one caused the belt to fall off.

Lack of drive belt tension may also cause the belt to fall off the pulleys. Low drive belt tension could be caused by one of

the following:

• an incorrect drive belt length,

• a faulty drive belt tensioner, or

• a stretched or faulty drive belt.

Test Description

The numbers below refer to steps in the diagnostic table.

2 Confirms the condition of the drive belt. Damage may have occurred to the drive belt when it first fell off or it may have been damaged which caused the belt to fall off.

4 Misalignment of the pulleys may be caused by:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007