ECO mode ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2609 of 6020

Engine Mechanical – V6 Page 6A1–130

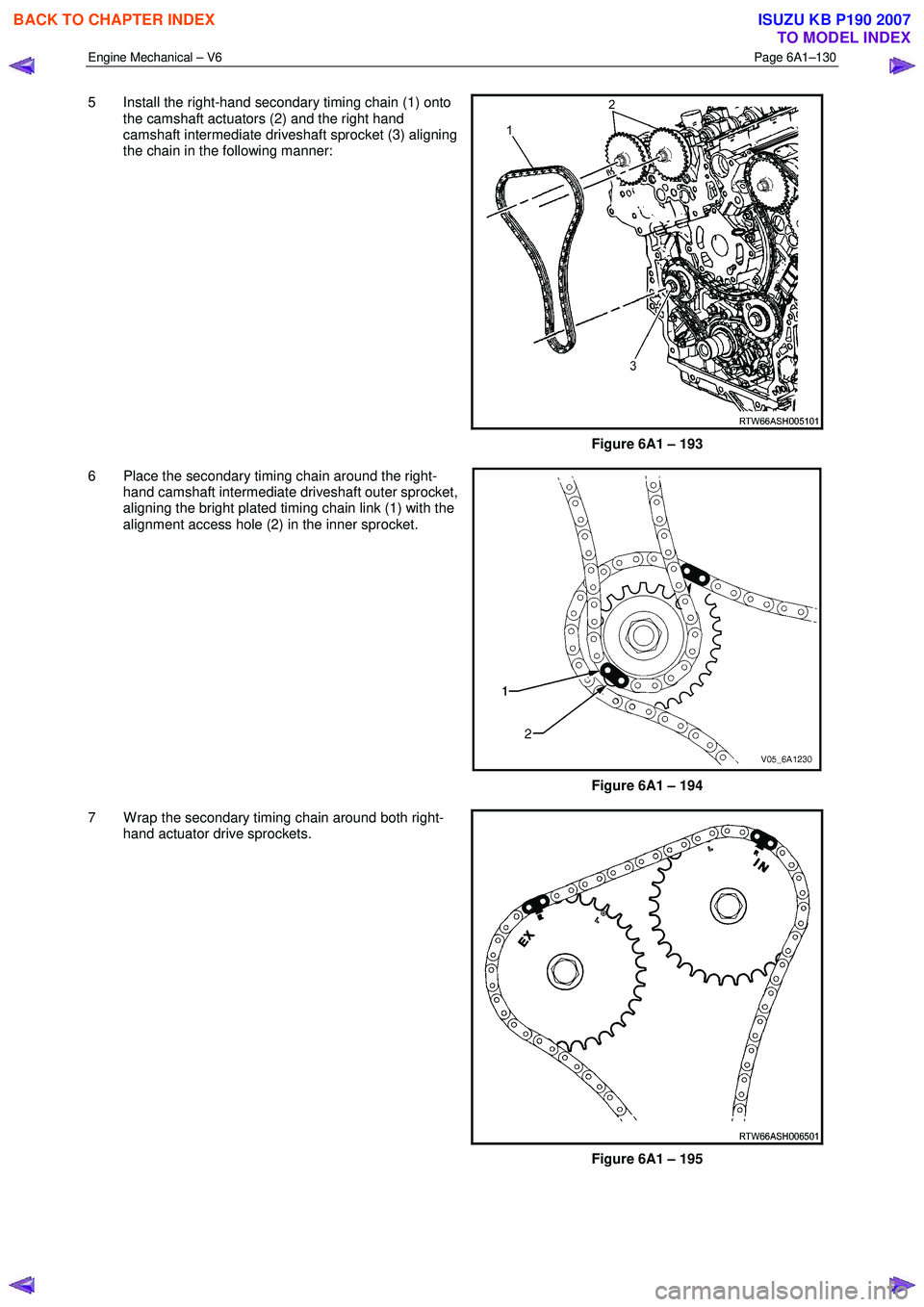

5 Install the right-hand secondary timing chain (1) onto

the camshaft actuators (2) and the right hand

camshaft intermediate driveshaft sprocket (3) aligning

the chain in the following manner:

Figure 6A1 – 193

6 Place the secondary timing chain around the right- hand camshaft intermediate driveshaft outer sprocket,

aligning the bright plated timing chain link (1) with the

alignment access hole (2) in the inner sprocket.

Figure 6A1 – 194

7 W rap the secondary timing chain around both right- hand actuator drive sprockets.

Figure 6A1 – 195

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2610 of 6020

Engine Mechanical – V6 Page 6A1–131

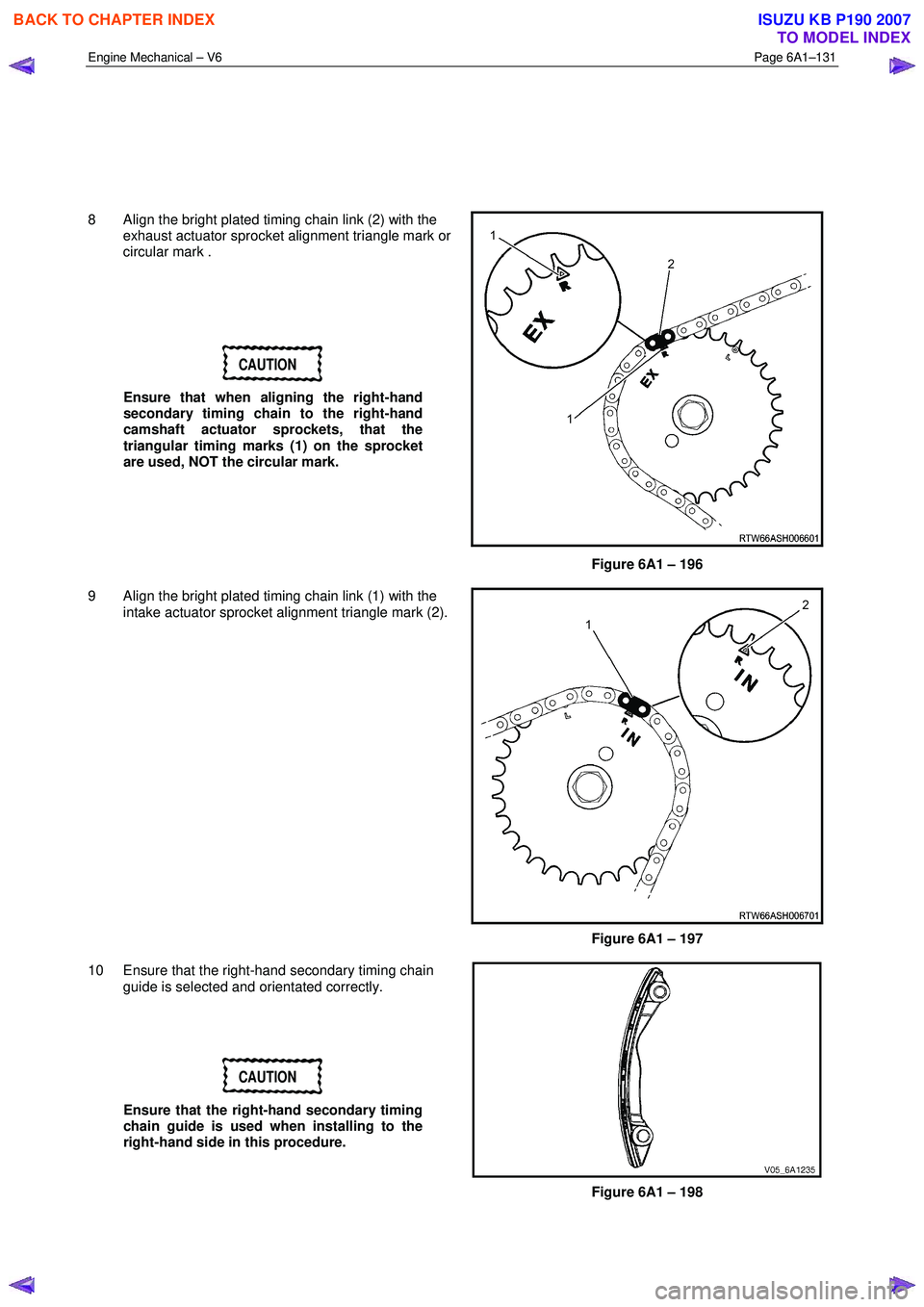

8 Align the bright plated timing chain link (2) with the exhaust actuator sprocket alignment triangle mark or

circular mark .

CAUTION

Ensure that when aligning the right-hand

secondary timing chain to the right-hand

camshaft actuator sprockets, that the

triangular timing marks (1) on the sprocket

are used, NOT the circular mark.

Figure 6A1 – 196

9 Align the bright plated timing chain link (1) with the intake actuator sprocket alignment triangle mark (2).

Figure 6A1 – 197

10 Ensure that the right-hand secondary timing chain guide is selected and orientated correctly.

CAUTION

Ensure that the right-hand secondary timing

chain guide is used when installing to the

right-hand side in this procedure.

Figure 6A1 – 198

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2611 of 6020

Engine Mechanical – V6 Page 6A1–132

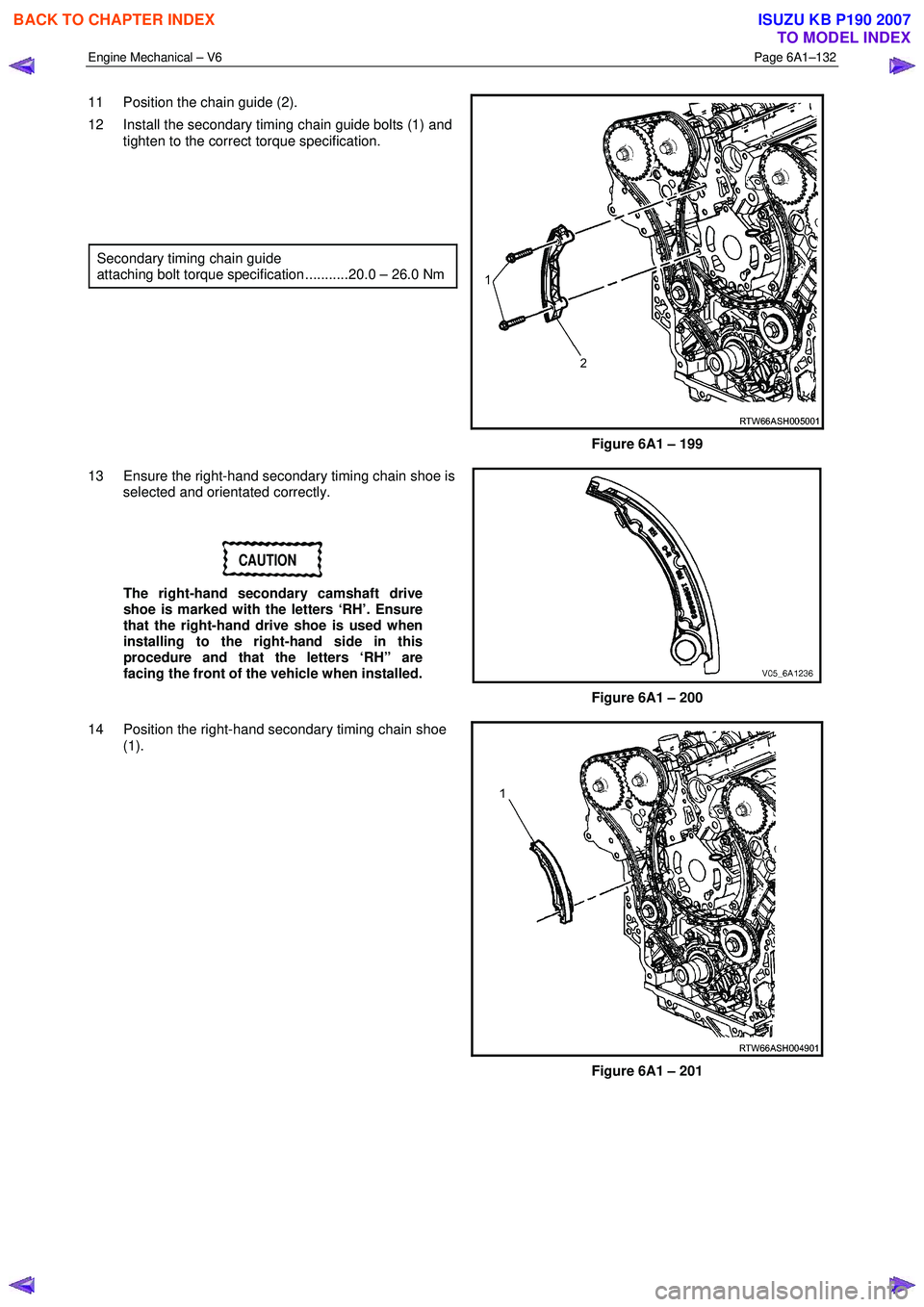

11 Position the chain guide (2).

12 Install the secondary timing chain guide bolts (1) and tighten to the correct torque specification.

Secondary timing chain guide

attaching bolt torque specification ...........20.0 – 26.0 Nm

Figure 6A1 – 199

13 Ensure the right-hand secondary timing chain shoe is selected and orientated correctly.

CAUTION

The right-hand secondary camshaft drive

shoe is marked with the letters ‘RH’. Ensure

that the right-hand drive shoe is used when

installing to the right-hand side in this

procedure and that the letters ‘RH” are

facing the front of the vehicle when installed.

Figure 6A1 – 200

14 Position the right-hand secondary timing chain shoe (1).

Figure 6A1 – 201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2612 of 6020

Engine Mechanical – V6 Page 6A1–133

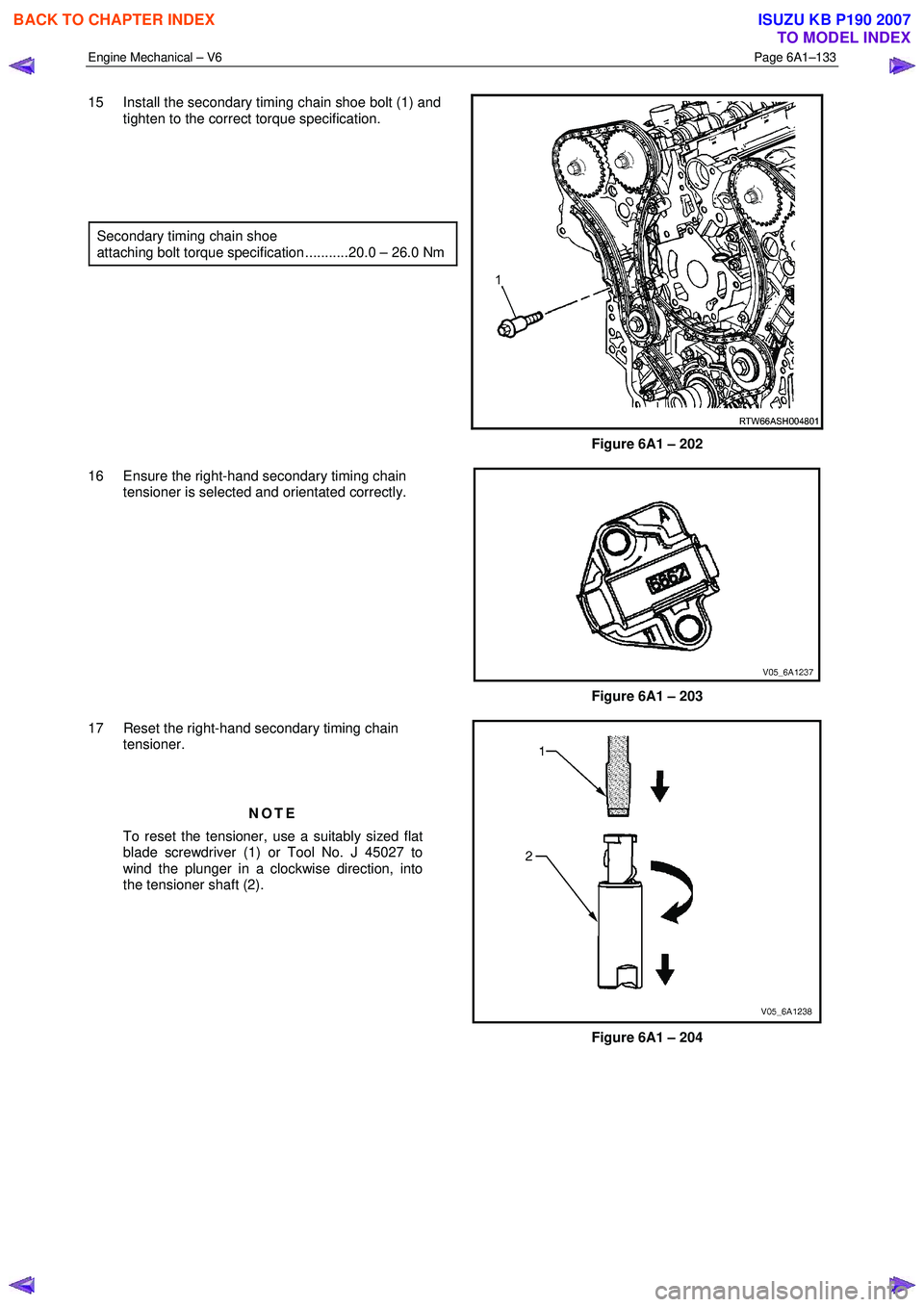

15 Install the secondary timing chain shoe bolt (1) and

tighten to the correct torque specification.

Secondary timing chain shoe

attaching bolt torque specification ...........20.0 – 26.0 Nm

Figure 6A1 – 202

16 Ensure the right-hand secondary timing chain tensioner is selected and orientated correctly.

Figure 6A1 – 203

17 Reset the right-hand secondary timing chain tensioner.

NOTE

To reset the tensioner, use a suitably sized flat

blade screwdriver (1) or Tool No. J 45027 to

wind the plunger in a clockwise direction, into

the tensioner shaft (2).

Figure 6A1 – 204

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2613 of 6020

Engine Mechanical – V6 Page 6A1–134

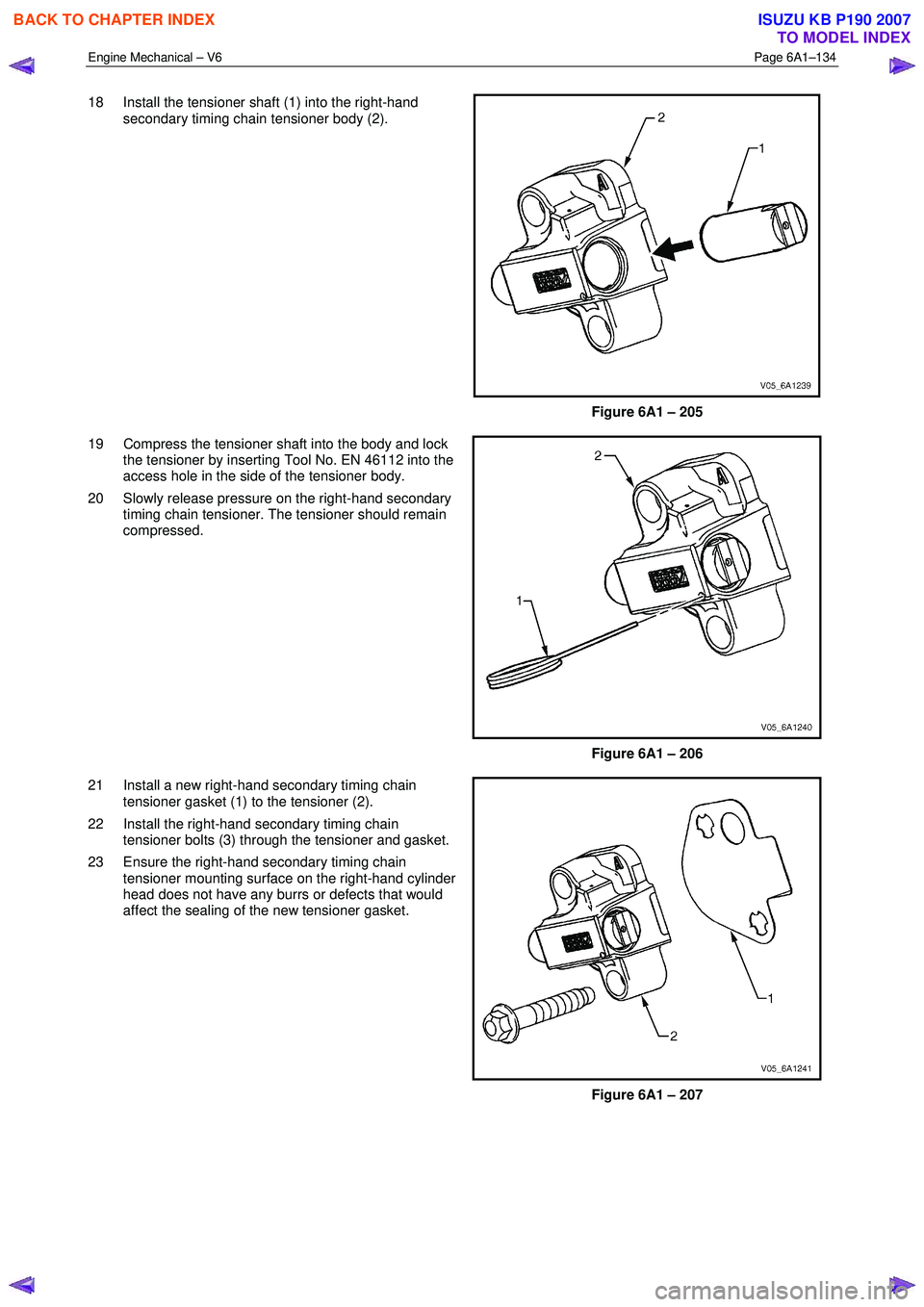

18 Install the tensioner shaft (1) into the right-hand

secondary timing chain tensioner body (2).

Figure 6A1 – 205

19 Compress the tensioner shaft into the body and lock the tensioner by inserting Tool No. EN 46112 into the

access hole in the side of the tensioner body.

20 Slowly release pressure on the right-hand secondary timing chain tensioner. The tensioner should remain

compressed.

Figure 6A1 – 206

21 Install a new right-hand secondary timing chain tensioner gasket (1) to the tensioner (2).

22 Install the right-hand secondary timing chain tensioner bolts (3) through the tensioner and gasket.

23 Ensure the right-hand secondary timing chain tensioner mounting surface on the right-hand cylinder

head does not have any burrs or defects that would

affect the sealing of the new tensioner gasket.

Figure 6A1 – 207

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2614 of 6020

Engine Mechanical – V6 Page 6A1–135

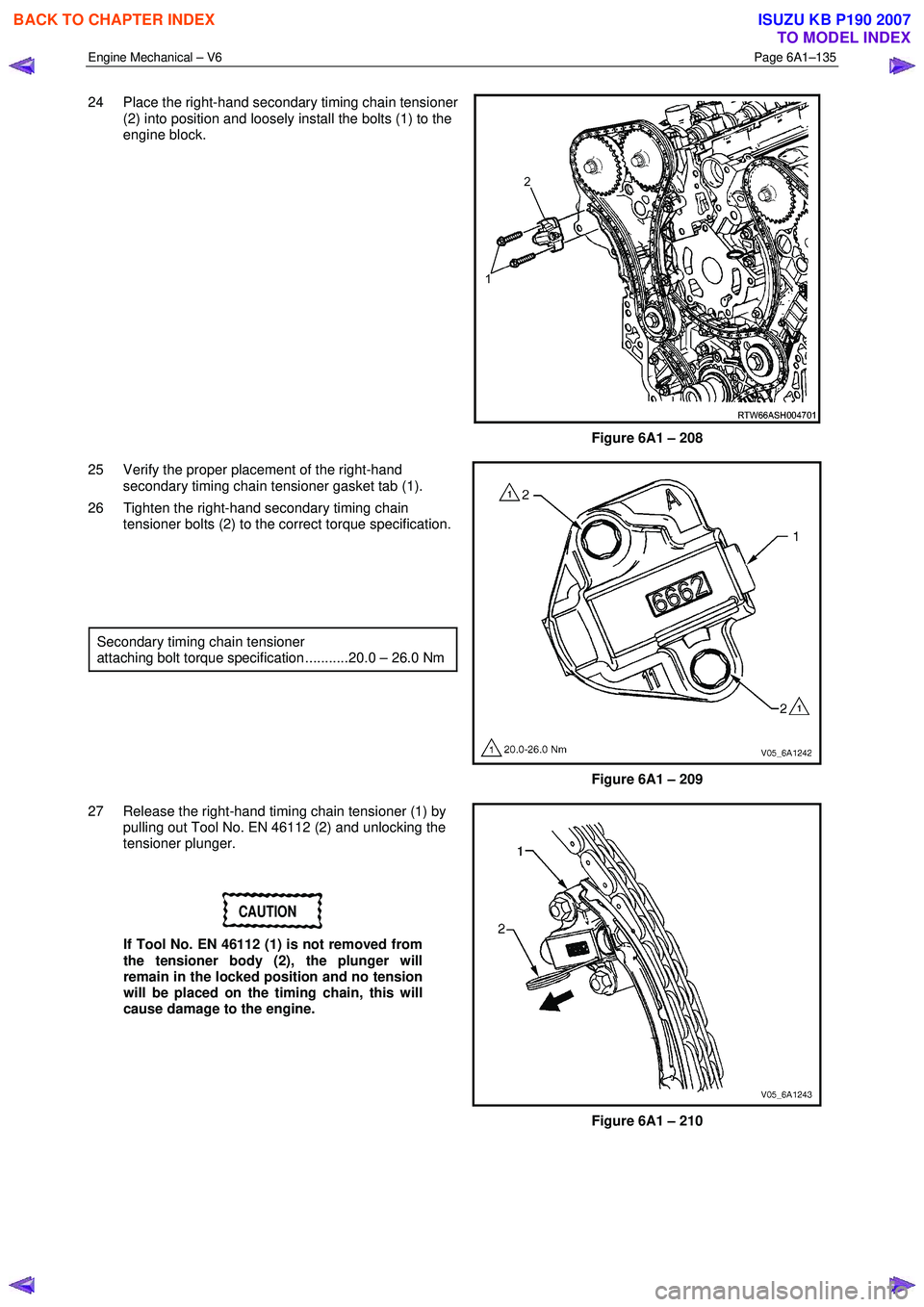

24 Place the right-hand secondary timing chain tensioner

(2) into position and loosely install the bolts (1) to the

engine block.

Figure 6A1 – 208

25 Verify the proper placement of the right-hand secondary timing chain tensioner gasket tab (1).

26 Tighten the right-hand secondary timing chain tensioner bolts (2) to the correct torque specification.

Secondary timing chain tensioner

attaching bolt torque specification ...........20.0 – 26.0 Nm

Figure 6A1 – 209

27 Release the right-hand timing chain tensioner (1) by pulling out Tool No. EN 46112 (2) and unlocking the

tensioner plunger.

CAUTION

If Tool No. EN 46112 (1) is not removed from

the tensioner body (2), the plunger will

remain in the locked position and no tension

will be placed on the timing chain, this will

cause damage to the engine.

Figure 6A1 – 210

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2615 of 6020

Engine Mechanical – V6 Page 6A1–136

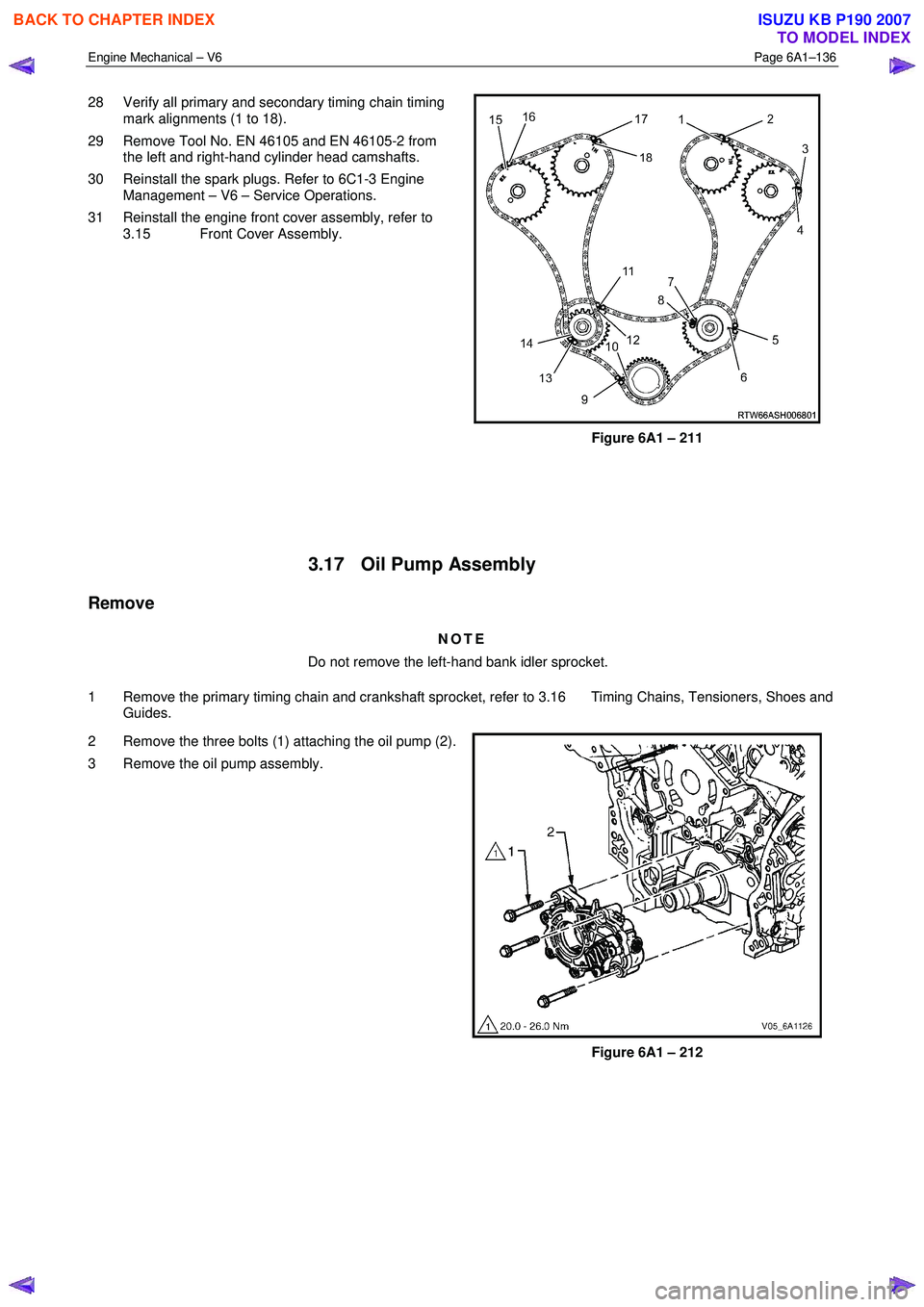

28 Verify all primary and secondary timing chain timing

mark alignments (1 to 18).

29 Remove Tool No. EN 46105 and EN 46105-2 from the left and right-hand cylinder head camshafts.

30 Reinstall the spark plugs. Refer to 6C1-3 Engine Management – V6 – Service Operations.

31 Reinstall the engine front cover assembly, refer to 3.15 Front Cover Assembly.

Figure 6A1 – 211

3.17 Oil Pump Assembly

Remove

NOTE

Do not remove the left-hand bank idler sprocket.

1 Remove the primary timing chain and crankshaft sprocket, refer to 3.16 Timing Chains, Tensioners, Shoes and Guides.

2 Remove the three bolts (1) attaching the oil pump (2).

3 Remove the oil pump assembly.

Figure 6A1 – 212

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2620 of 6020

Engine Mechanical – V6 Page 6A1–141

Reassemble

CAUTION

As there are no serviceable components

within the oil pump, a disassembled oil pump

must be replaced.

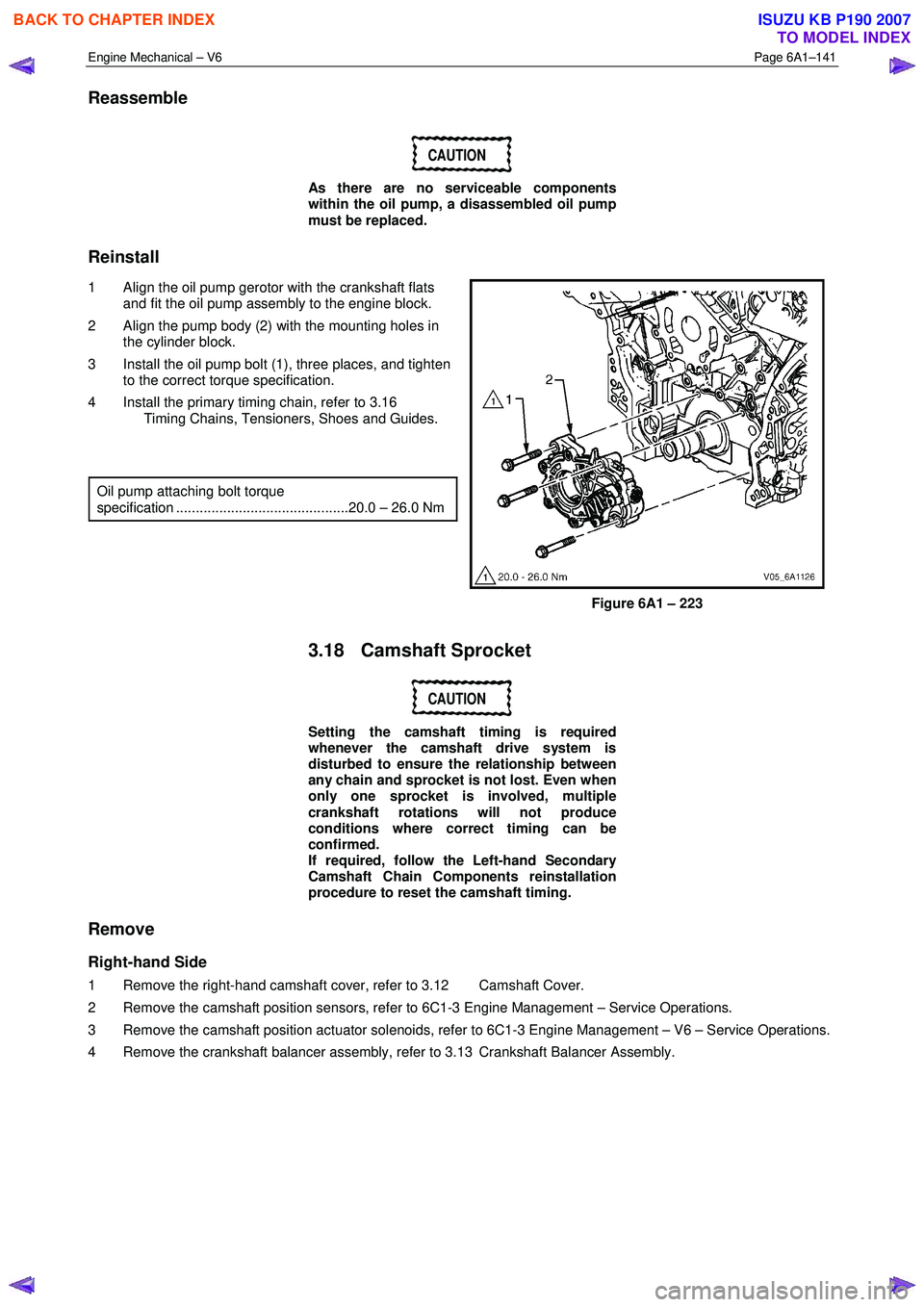

Reinstall

1 Align the oil pump gerotor with the crankshaft flats and fit the oil pump assembly to the engine block.

2 Align the pump body (2) with the mounting holes in the cylinder block.

3 Install the oil pump bolt (1), three places, and tighten to the correct torque specification.

4 Install the primary timing chain, refer to 3.16 Timing Chains, Tensioners, Shoes and Guides.

Oil pump attaching bolt torque

specification ............................................20.0 – 26.0 Nm

Figure 6A1 – 223

3.18 Camshaft Sprocket

CAUTION

Setting the camshaft timing is required

whenever the camshaft drive system is

disturbed to ensure the relationship between

any chain and sprocket is not lost. Even when

only one sprocket is involved, multiple

crankshaft rotations will not produce

conditions where correct timing can be

confirmed.

If required, follow the Left-hand Secondary

Camshaft Chain Components reinstallation

procedure to reset the camshaft timing.

Remove

Right-hand Side

1 Remove the right-hand camshaft cover, refer to 3.12 Camshaft Cover.

2 Remove the camshaft position sensors, refer to 6C1-3 Engine Management – Service Operations.

3 Remove the camshaft position actuator solenoids, refer to 6C1-3 Engine Management – V6 – Service Operations.

4 Remove the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2637 of 6020

Engine Mechanical – V6 Page 6A1–158

3.20 Rocker Arm

Remove

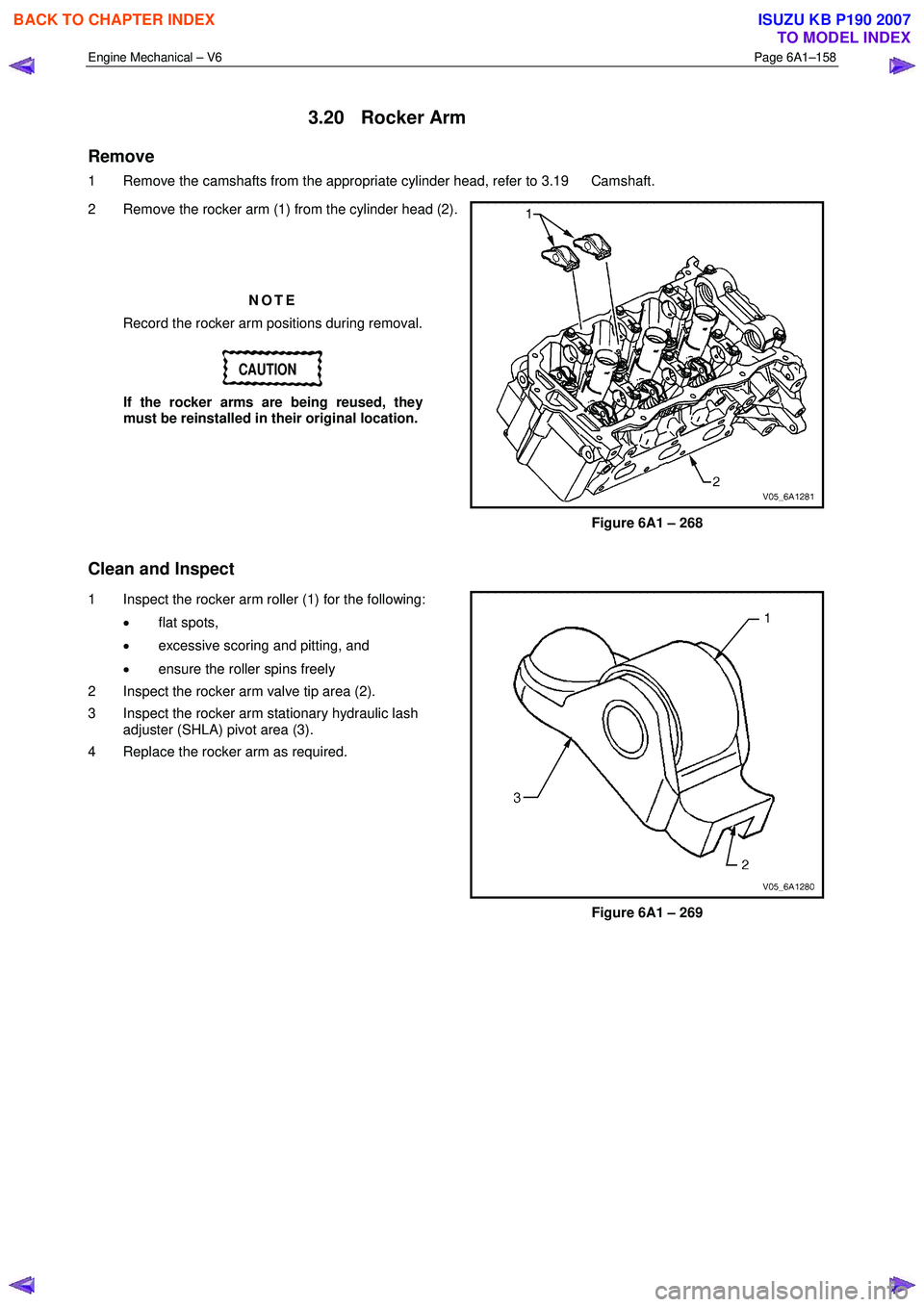

1 Remove the camshafts from the appropriate cylinder head, refer to 3.19 Camshaft.

2 Remove the rocker arm (1) from the cylinder head (2).

NOTE

Record the rocker arm positions during removal.

CAUTION

If the rocker arms are being reused, they

must be reinstalled in their original location.

Figure 6A1 – 268

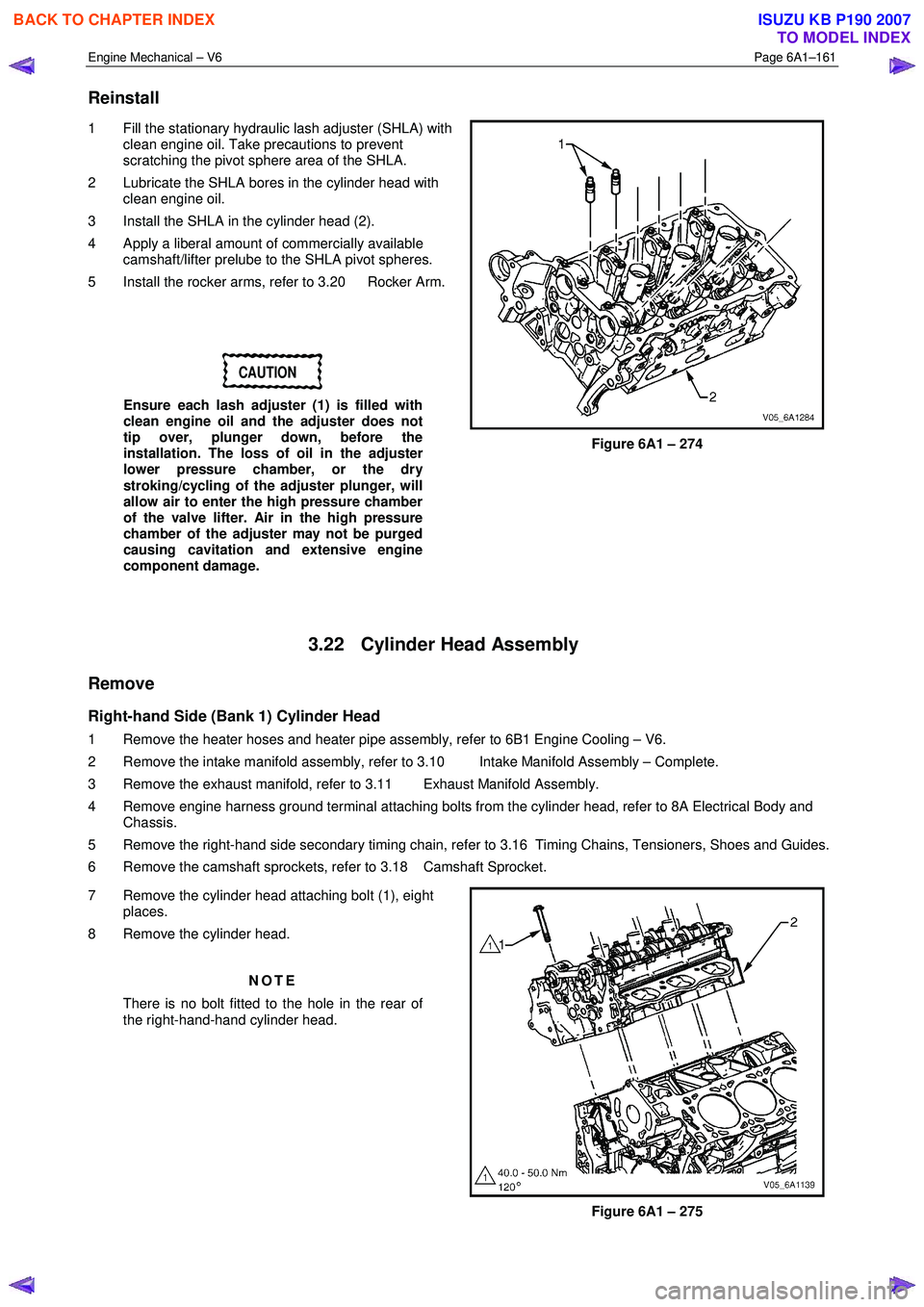

Clean and Inspect

1 Inspect the rocker arm roller (1) for the following:

• flat spots,

• excessive scoring and pitting, and

• ensure the roller spins freely

2 Inspect the rocker arm valve tip area (2).

3 Inspect the rocker arm stationary hydraulic lash adjuster (SHLA) pivot area (3).

4 Replace the rocker arm as required.

Figure 6A1 – 269

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2640 of 6020

Engine Mechanical – V6 Page 6A1–161

Reinstall

1 Fill the stationary hydraulic lash adjuster (SHLA) with

clean engine oil. Take precautions to prevent

scratching the pivot sphere area of the SHLA.

2 Lubricate the SHLA bores in the cylinder head with clean engine oil.

3 Install the SHLA in the cylinder head (2).

4 Apply a liberal amount of commercially available camshaft/lifter prelube to the SHLA pivot spheres.

5 Install the rocker arms, refer to 3.20 Rocker Arm.

CAUTION

Ensure each lash adjuster (1) is filled with

clean engine oil and the adjuster does not

tip over, plunger down, before the

installation. The loss of oil in the adjuster

lower pressure chamber, or the dry

stroking/cycling of the adjuster plunger, will

allow air to enter the high pressure chamber

of the valve lifter. Air in the high pressure

chamber of the adjuster may not be purged

causing cavitation and extensive engine

component damage.

Figure 6A1 – 274

3.22 Cylinder Head Assembly

Remove

Right-hand Side (Bank 1) Cylinder Head

1 Remove the heater hoses and heater pipe assembly, refer to 6B1 Engine Cooling – V6.

2 Remove the intake manifold assembly, refer to 3.10 Intake Manifold Assembly – Complete.

3 Remove the exhaust manifold, refer to 3.11 Exhaust Manifold Assembly.

4 Remove engine harness ground terminal attaching bolts from the cylinder head, refer to 8A Electrical Body and Chassis.

5 Remove the right-hand side secondary timing chain, refer to 3.16 Timing Chains, Tensioners, Shoes and Guides.

6 Remove the camshaft sprockets, refer to 3.18 Camshaft Sprocket.

7 Remove the cylinder head attaching bolt (1), eight places.

8 Remove the cylinder head.

NOTE

There is no bolt fitted to the hole in the rear of

the right-hand-hand cylinder head.

Figure 6A1 – 275

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007