torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3772 of 6020

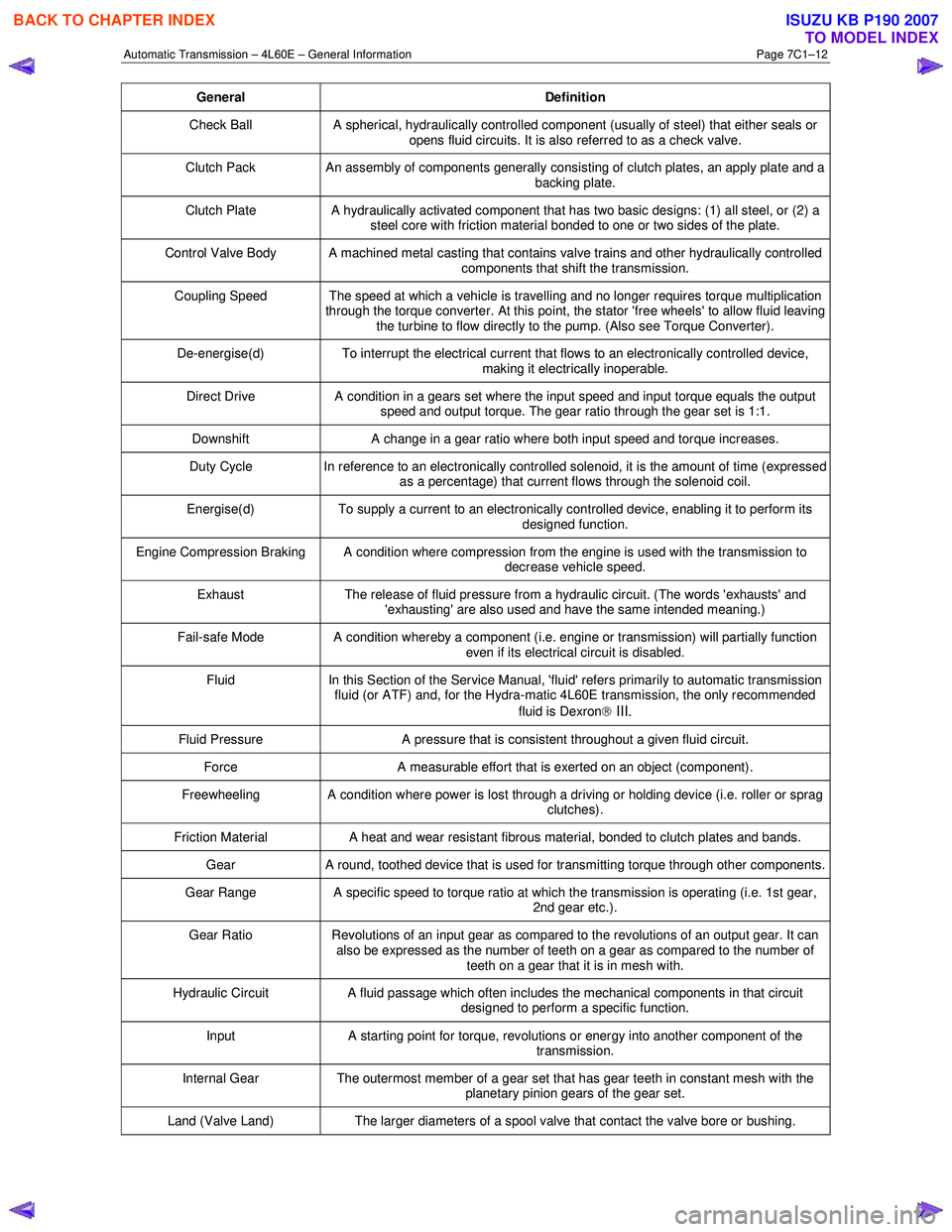

Automatic Transmission – 4L60E – General Information Page 7C1–12

General Definition

Check Ball A spherical, hydraulically controlled component (usually of steel) that either seals or

opens fluid circuits. It is also referred to as a check valve.

Clutch Pack An assembly of components generally consisting of clutch plates, an apply plate and a

backing plate.

Clutch Plate A hydraulically activated component that has two basic designs: (1) all steel, or (2) a

steel core with friction material bonded to one or two sides of the plate.

Control Valve Body A machined metal casting that contains valve trains and other hydraulically controlled components that shift the transmission.

Coupling Speed The speed at which a vehicle is travelling and no longer requires torque multiplication through the torque converter. At this point, the stator 'free wheels' to allow fluid leaving

the turbine to flow directly to the pump. (Also see Torque Converter).

De-energise(d) To interrupt the electrical current that flows to an electronically controlled device,

making it electrically inoperable.

Direct Drive A condition in a gears set where the input speed and input torque equals the output

speed and output torque. The gear ratio through the gear set is 1:1.

Downshift A change in a gear ratio where both input speed and torque increases.

Duty Cycle In reference to an electronically controlled solenoid, it is the amount of time (expressed

as a percentage) that current flows through the solenoid coil.

Energise(d) To supply a current to an electronically controlled device, enabling it to perform its

designed function.

Engine Compression Braking A condition where compression from the engine is used with the transmission to decrease vehicle speed.

Exhaust The release of fluid pressure from a hydraulic circuit. (The words 'exhausts' and

'exhausting' are also used and have the same intended meaning.)

Fail-safe Mode A condition whereby a component (i.e. engine or transmission) will partially function even if its electrical circuit is disabled.

Fluid In this Section of the Service Manual, 'fluid' refers primarily to automatic transmission

fluid (or ATF) and, for the Hydra-matic 4L60E transmission, the only recommended

fluid is Dexron

III.

Fluid Pressure A pressure that is consistent throughout a given fluid circuit.

Force A measurable effort that is exerted on an object (component).

Freewheeling A condition where power is lost through a driving or holding device (i.e. roller or sprag

clutches).

Friction Material A heat and wear resistant fibrous material, bonded to clutch plates and bands.

Gear A round, toothed device that is used for transmitting torque through other components.

Gear Range A specific speed to torque ratio at which the transmission is operating (i.e. 1st gear,

2nd gear etc.).

Gear Ratio Revolutions of an input gear as compared to the revolutions of an output gear. It can

also be expressed as the number of teeth on a gear as compared to the number of

teeth on a gear that it is in mesh with.

Hydraulic Circuit A fluid passage which often includes the mechanical components in that circuit

designed to perform a specific function.

Input A starting point for torque, revolutions or energy into another component of the

transmission.

Internal Gear The outermost member of a gear set that has gear teeth in constant mesh with the

planetary pinion gears of the gear set.

Land (Valve Land) The larger diameters of a spool valve that contact the valve bore or bushing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3773 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–13

General Definition

Line Pressure The main fluid pressure in a hydraulic system created by the pump and pressure

regulator valve.

Manual Valve A spool valve that distributes fluid to various hydraulic circuits and is mechanically

linked to the gear selector lever.

Orifice A restricting device (usually a hole in the spacer plate) for controlling pressure build up

into another circuit.

Overdrive An operating condition in the gear set allowing output speed to be higher than input

speed and output torque to be lower than input torque.

Overrunning The function of a one-way mechanical clutch that allows the clutch to freewheel during certain operating conditions of the transmission.

Pedal Position The percentage angle of the accelerator pedal as displayed by Tech 2.

Pinion Gears Pinion gears (housed in a carrier) that are in constant mesh with a circumferential

internal gear and centralised sun gear.

Planetary Gear Set An assembly of gears that consists of an internal gear, planet pinion gears with a carrier, and a sun gear.

Pressure A measurable force that is exerted on an area and expressed as kilopascals (kPa).

Pulse Width Modulated (PW M) An electronic signal that continuously cycles the On and Off time of a device (such as

a solenoid) while varying the amount of On time.

Race (Inner or Outer) A highly polished steel surface that contacts bearings or sprag or roller elements.

Reduction (Gear Reduction) An operating condition in the gear set allowing output speed to be lower than input speed and output torque to be higher than input torque.

Residual Fluid Pressure Excess pressure contained within an area after the supply pressure has been terminated.

Roller Clutch A mechanical clutch (holding device) consisting of roller bearings assembled between inner and outer races.

Servo A spring loaded device consisting of a piston in a bore that is operated (stroked) by

hydraulic pressure to apply or release a band.

Spool Valve A round hydraulic control valve often containing a variety of land and valley diameters.

Sprag Clutch A mechanical clutch (holding device consisting of "figure eight" like elements

assembled between inner and outer races.

Staking The effect of deforming, peening over or riveting a shaft to provide a solid mounting.

Throttle Position The travel of the throttle plate that is expressed in percentages and measured by

Tech 2.

Torque A measurable twisting force expressed in terms of Newton metres (Nm).

Torque Converter A component of an automatic transmission, (attached to the engine flex plate) that

transfers torque from the engine to the transmission through a fluid coupling.

Torx Plus Bit A special tool used for the removal of the bell housing. Precision tip fit means that cam

out of the bolt head is virtually eliminated.

NOTE

Torx

Plus Bits are different from normal Torx

Bits

Transmission Control Module

(TCM) An electronic device that manages the vehicle's engine and automatic transmission

functions.

Variable Capacity Pump The device that provides fluid for operating the hydraulic circuits in the transmission. The amount of fluid supplied varies depending on vehicle operating conditions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3774 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–14

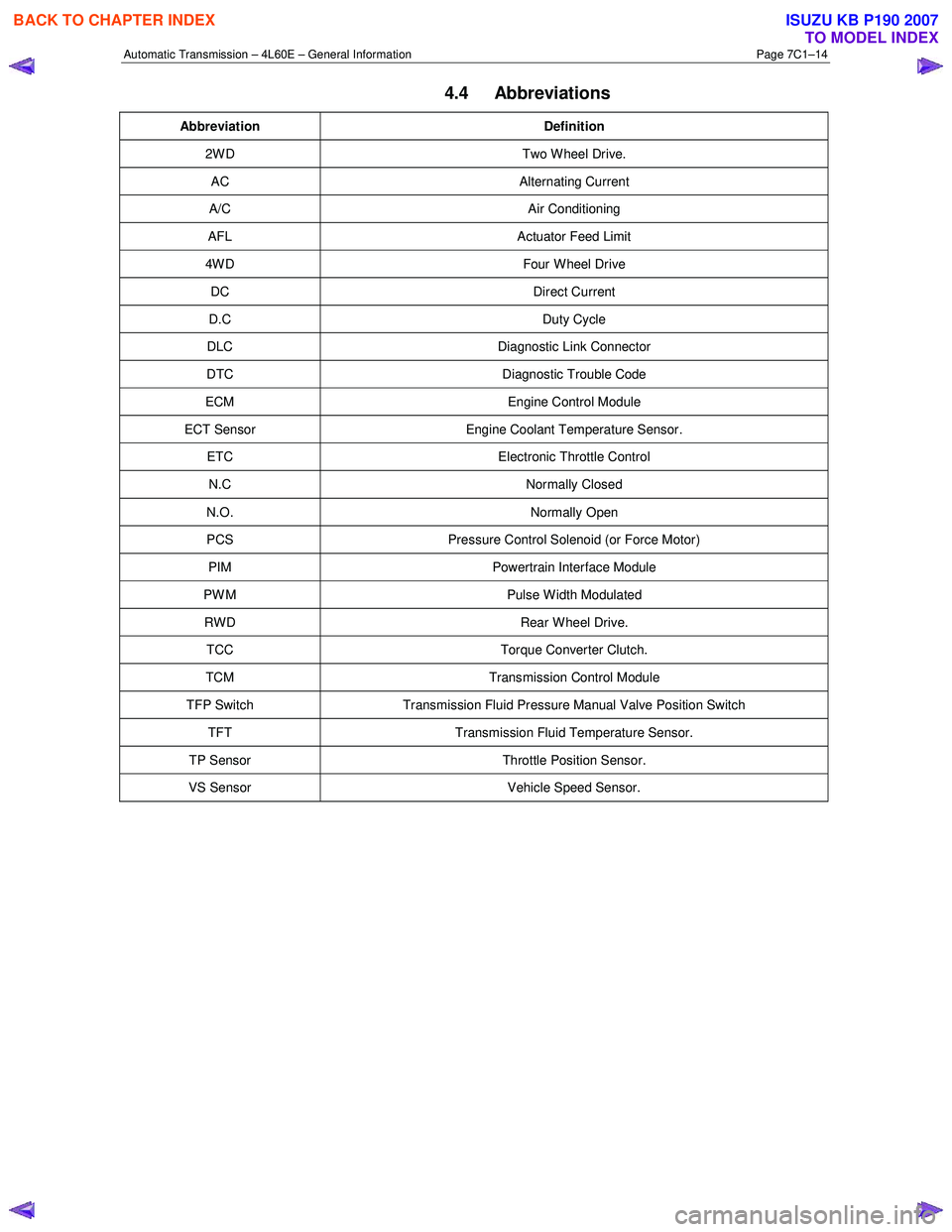

4.4 Abbreviations

Abbreviation Definition

2W D Two W heel Drive.

AC Alternating Current

A/C Air Conditioning

AFL Actuator Feed Limit

4W D Four W heel Drive

DC Direct Current

D.C Duty Cycle

DLC Diagnostic Link Connector

DTC Diagnostic Trouble Code

ECM Engine Control Module

ECT Sensor Engine Coolant Temperature Sensor.

ETC Electronic Throttle Control

N.C Normally Closed

N.O. Normally Open

PCS Pressure Control Solenoid (or Force Motor)

PIM Powertrain Interface Module

PW M Pulse W idth Modulated

RWD Rear Wheel Drive.

TCC Torque Converter Clutch.

TCM Transmission Control Module

TFP Switch Transmission Fluid Pressure Manual Valve Position Switch

TFT Transmission Fluid Temperature Sensor.

TP Sensor Throttle Position Sensor.

VS Sensor Vehicle Speed Sensor.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3775 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–15

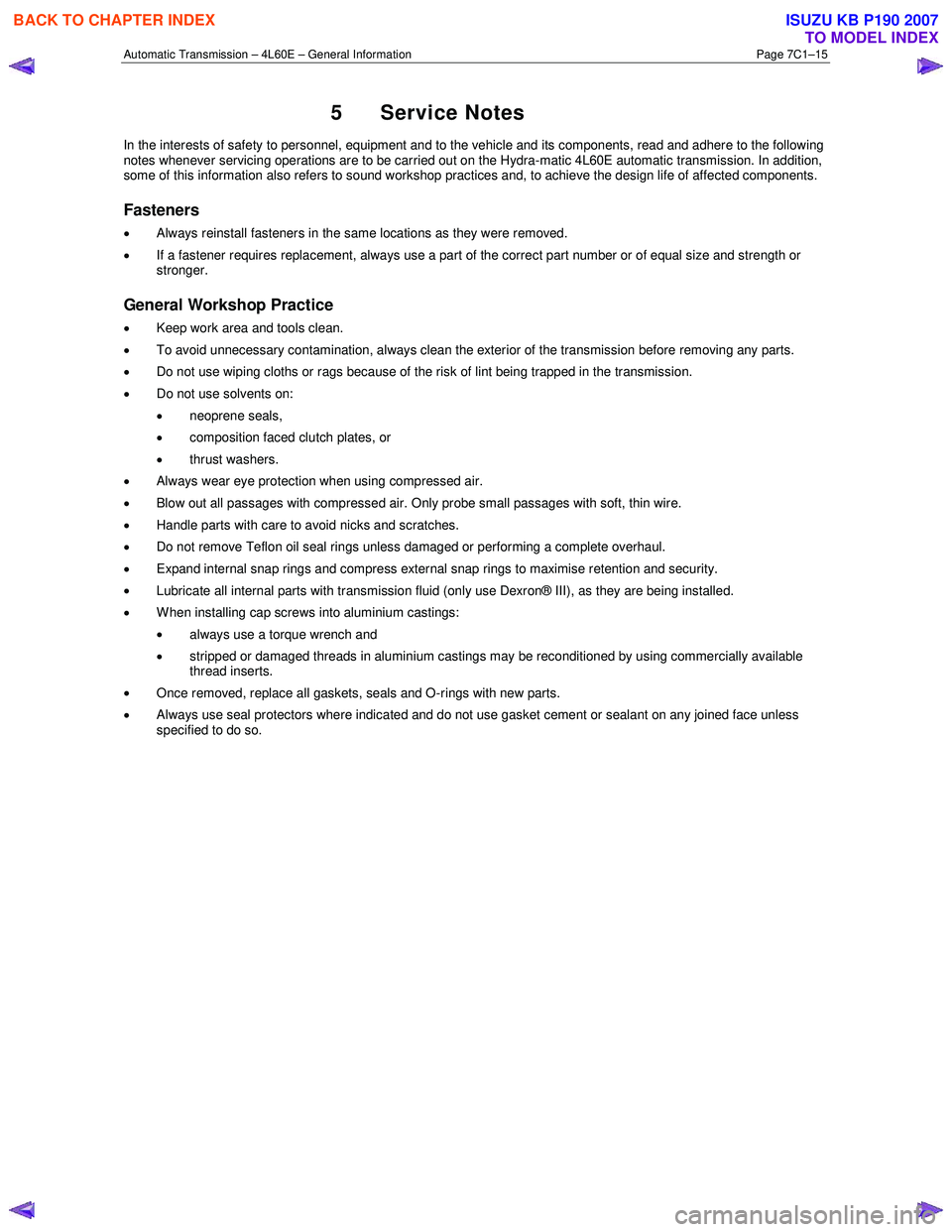

5 Service Notes

In the interests of safety to personnel, equipment and to the vehicle and its components, read and adhere to the following

notes whenever servicing operations are to be carried out on the Hydra-matic 4L60E automatic transmission. In addition,

some of this information also refers to sound workshop practices and, to achieve the design life of affected components.

Fasteners

• Always reinstall fasteners in the same locations as they were removed.

• If a fastener requires replacement, always use a part of the correct part number or of equal size and strength or

stronger.

General Workshop Practice

• Keep work area and tools clean.

• To avoid unnecessary contamination, always clean the exterior of the transmission before removing any parts.

• Do not use wiping cloths or rags because of the risk of lint being trapped in the transmission.

• Do not use solvents on:

• neoprene seals,

• composition faced clutch plates, or

• thrust washers.

• Always wear eye protection when using compressed air.

• Blow out all passages with compressed air. Only probe small passages with soft, thin wire.

• Handle parts with care to avoid nicks and scratches.

• Do not remove Teflon oil seal rings unless damaged or performing a complete overhaul.

• Expand internal snap rings and compress external snap rings to maximise retention and security.

• Lubricate all internal parts with transmission fluid (only use Dexron® III), as they are being installed.

• When installing cap screws into aluminium castings:

• always use a torque wrench and

• stripped or damaged threads in aluminium castings may be reconditioned by using commercially available

thread inserts.

• Once removed, replace all gaskets, seals and O-rings with new parts.

• Always use seal protectors where indicated and do not use gasket cement or sealant on any joined face unless

specified to do so.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3776 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–16

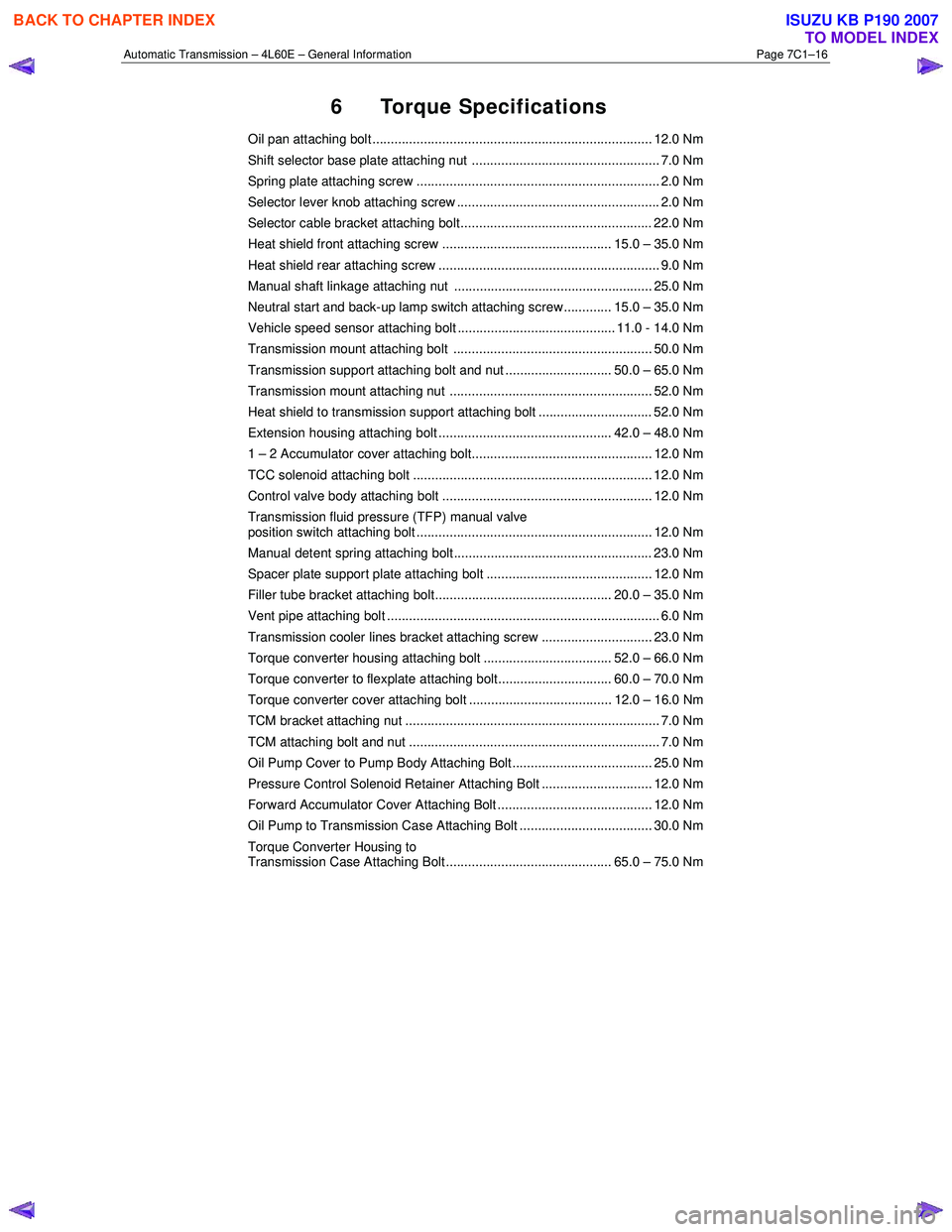

6 Torque Specifications

Oil pan attaching bolt ............................................................................ 12.0 Nm

Shift selector base plate attaching nut ................................................... 7.0 Nm

Spring plate attaching screw .................................................................. 2.0 Nm

Selector lever knob attaching screw ....................................................... 2.0 Nm

Selector cable bracket attaching bolt.................................................... 22.0 Nm

Heat shield front attaching screw .............................................. 15.0 – 35.0 Nm

Heat shield rear attaching screw ............................................................ 9.0 Nm

Manual shaft linkage attaching nut ...................................................... 25.0 Nm

Neutral start and back-up lamp switch attaching screw............. 15.0 – 35.0 Nm

Vehicle speed sensor attaching bolt ........................................... 11.0 - 14.0 Nm

Transmission mount attaching bolt ...................................................... 50.0 Nm

Transmission support attaching bolt and nut ............................. 50.0 – 65.0 Nm

Transmission mount attaching nut ....................................................... 52.0 Nm

Heat shield to transmission support attaching bolt ............................... 52.0 Nm

Extension housing attaching bolt ............................................... 42.0 – 48.0 Nm

1 – 2 Accumulator cover attaching bolt................................................. 12.0 Nm

TCC solenoid attaching bolt ................................................................. 12.0 Nm

Control valve body attaching bolt ......................................................... 12.0 Nm

Transmission fluid pressure (TFP) manual valve

position switch attaching bolt ................................................................ 12.0 Nm

Manual detent spring attaching bolt ...................................................... 23.0 Nm

Spacer plate support plate attaching bolt ............................................. 12.0 Nm

Filler tube bracket attaching bolt................................................ 20.0 – 35.0 Nm

Vent pipe attaching bolt .......................................................................... 6.0 Nm

Transmission cooler lines bracket attaching screw .............................. 23.0 Nm

Torque converter housing attaching bolt ................................... 52.0 – 66.0 Nm

Torque converter to flexplate attaching bolt............................... 60.0 – 70.0 Nm

Torque converter cover attaching bolt ....................................... 12.0 – 16.0 Nm

TCM bracket attaching nut ..................................................................... 7.0 Nm

TCM attaching bolt and nut .................................................................... 7.0 Nm

Oil Pump Cover to Pump Body Attaching Bolt...................................... 25.0 Nm

Pressure Control Solenoid Retainer Attaching Bolt .............................. 12.0 Nm

Forward Accumulator Cover Attaching Bolt .......................................... 12.0 Nm

Oil Pump to Transmission Case Attaching Bolt .................................... 30.0 Nm

Torque Converter Housing to

Transmission Case Attaching Bolt............................................. 65.0 – 75.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3777 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–17

7 Transmission Specifications

7.1 General

Type

Hydra-matic 4L60E

Special Features

Electronically controlled shift pattern, feel and torque

Converter clutch operation

Overdrive 4th speed range

Selector Location ..................................................................................Floor mounted console

Gear Ratios Park (P) ....................................................................................................................... ........... –

Reverse (R) .................................................................................................................... ... 2.29

Neutral (N) .............................................................................................................................. –

Drive (D – 4) .................................................................................................................. ...... 0.7

Drive (D – 3) .................................................................................................................. ...... 1.0

Second (2) ......................................................................................................................... 1.63

First (1) ...................................................................................................................... ........ 3.06

Shift Speeds Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Oil Pressure

Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Torque Converter

Number of Elements .................................................................. 3 plus torque converter clutch

Torque Converter Diameter and End Play

HFV6 ........................................................................................................................... 258 mm

End Play .............................................................................................................. 0.1 – 0.5 mm

Lubricant

Type recommended ................................................................................................ Dexron

® III

Capacity......................... Nominal only. Check when transmission is at operating temperature

Service Refill ............................................................................................................... 4. 8 litres

Total (Dry)................................................................................................................... 8 .8 litres

Fluid Cooling.....................................Transmission fluid to engine coolant in one radiator tank

Clutches and Band 2 – 4 Band:

Type........................................................................................... Composition lined, steel band

Operation: ..................................................................................................................... .. Servo

Adjustment: ................................................................................................ Selective Apply Pin

Pin Size and Identification.

65.82 – 66.12 mm ...................................................................................................... 1 Groove

67.23 – 67.53 mm ...................................................................................................... 2 Groove

68.64 – 68.94 mm ....................................................................................................No Groove

Reverse Input Clutch Type................................................................................................................Multiple we t disc

Backing plate ........................................................................................................ (1) Select ive

Clutch plate (numbers):

Steel ....................................................................................................................................... 4

Composition............................................................................................................................ 4

Belleville ..................................................................................................................... ............ 1

Backing Plate ........................................................................................................ 1 (Selecti ve)

Backing plate, identification and thickness:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3783 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–23

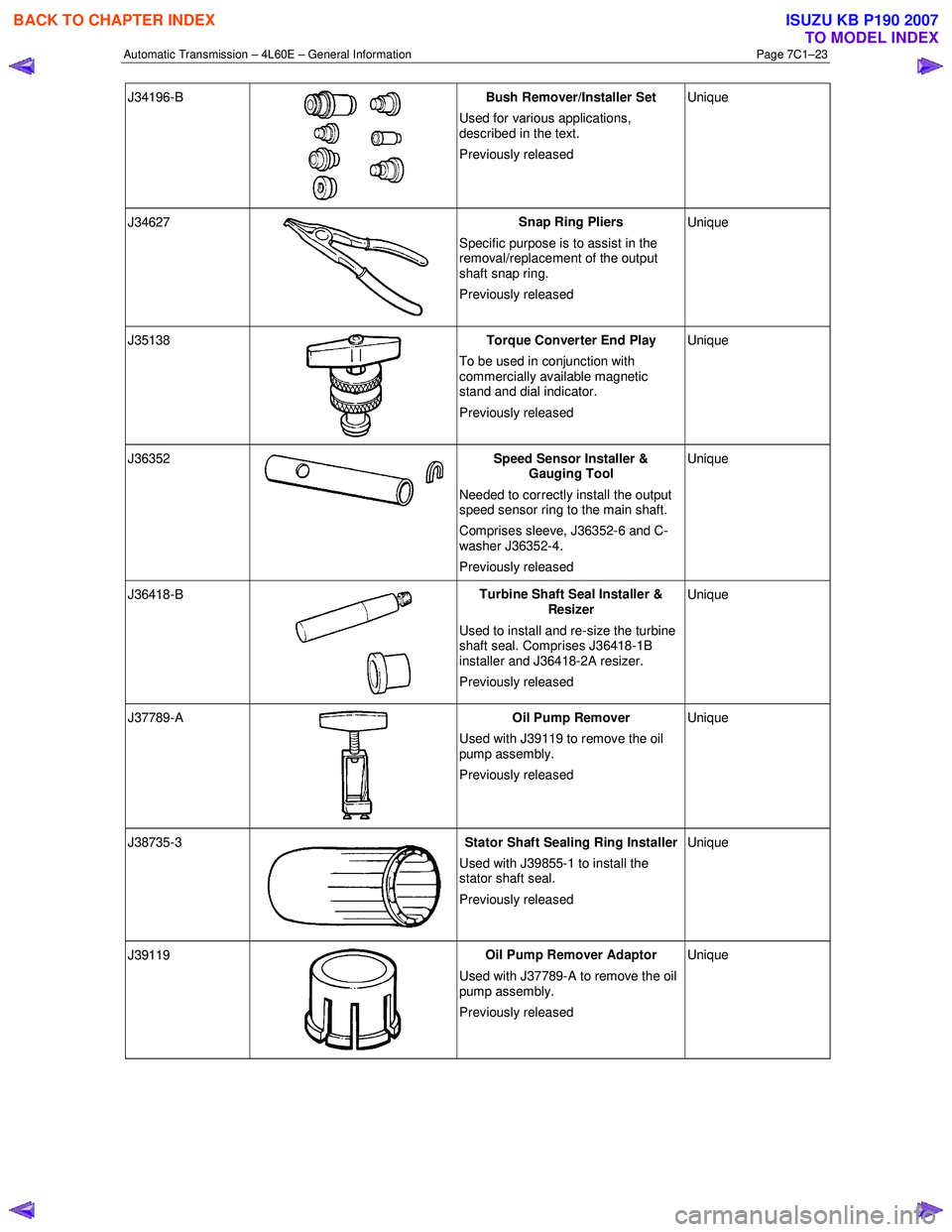

J34196-B

Bush Remover/Installer Set

Used for various applications,

described in the text.

Previously released Unique

J34627

Snap Ring Pliers

Specific purpose is to assist in the

removal/replacement of the output

shaft snap ring.

Previously released Unique

J35138

Torque Converter End Play

To be used in conjunction with

commercially available magnetic

stand and dial indicator.

Previously released Unique

J36352 Speed Sensor Installer &

Gauging Tool

Needed to correctly install the output

speed sensor ring to the main shaft.

Comprises sleeve, J36352-6 and C-

washer J36352-4.

Previously released Unique

J36418-B

Turbine Shaft Seal Installer &

Resizer

Used to install and re-size the turbine

shaft seal. Comprises J36418-1B

installer and J36418-2A resizer.

Previously released Unique

J37789-A

Oil Pump Remover

Used with J39119 to remove the oil

pump assembly.

Previously released Unique

J38735-3 Stator Shaft Sealing Ring Installer

Used with J39855-1 to install the

stator shaft seal.

Previously released Unique

J39119

Oil Pump Remover Adaptor

Used with J37789-A to remove the oil

pump assembly.

Previously released Unique

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3784 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–24

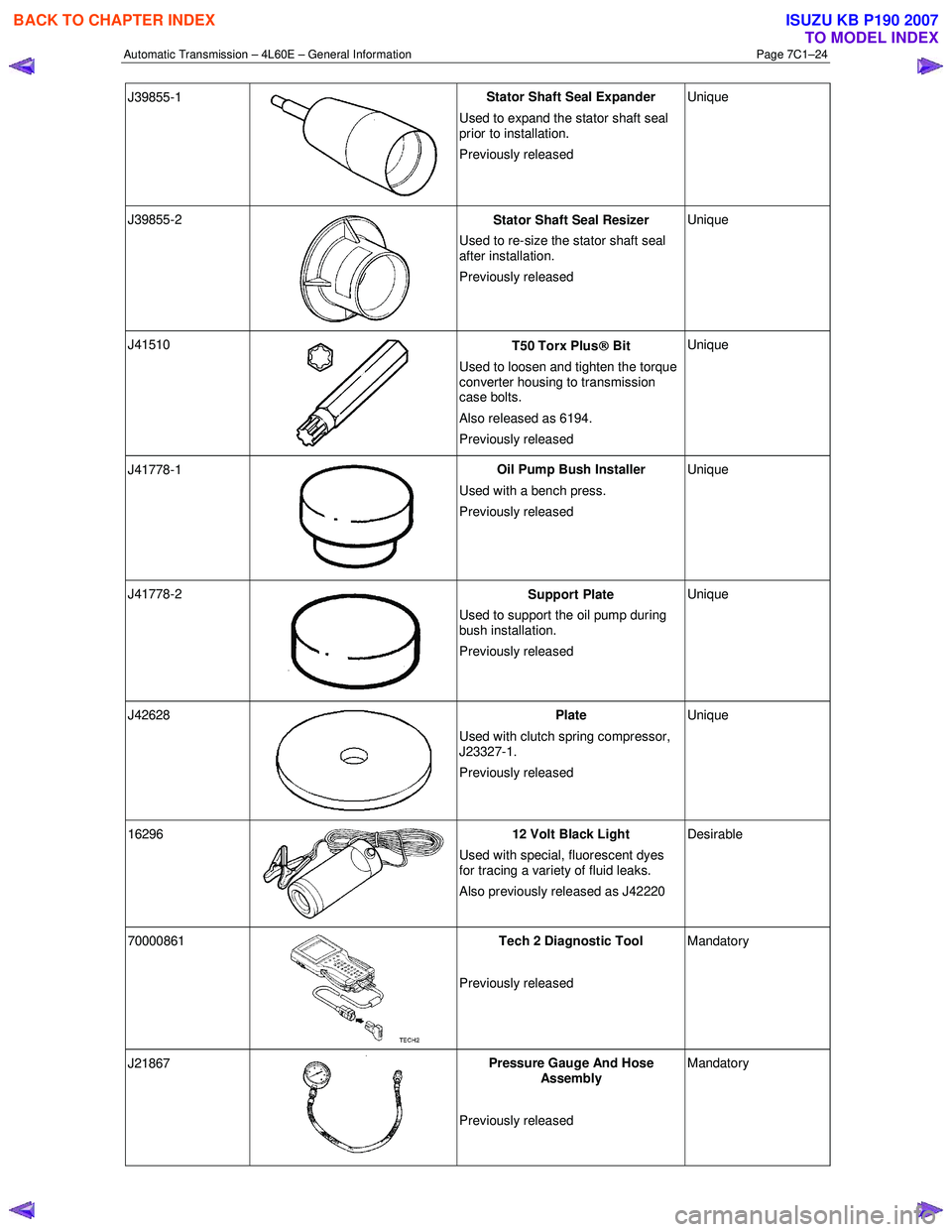

J39855-1

Stator Shaft Seal Expander

Used to expand the stator shaft seal

prior to installation.

Previously released Unique

J39855-2

Stator Shaft Seal Resizer

Used to re-size the stator shaft seal

after installation.

Previously released Unique

J41510

T50 Torx Plus

Bit

Used to loosen and tighten the torque

converter housing to transmission

case bolts.

Also released as 6194.

Previously released Unique

J41778-1

Oil Pump Bush Installer

Used with a bench press.

Previously released Unique

J41778-2

Support Plate

Used to support the oil pump during

bush installation.

Previously released Unique

J42628

Plate

Used with clutch spring compressor,

J23327-1.

Previously released Unique

16296 12 Volt Black Light

Used with special, fluorescent dyes

for tracing a variety of fluid leaks.

Also previously released as J42220 Desirable

70000861

Tech 2 Diagnostic Tool

Previously released Mandatory

J21867

Pressure Gauge And Hose

Assembly

Previously released Mandatory

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3789 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–3

Circuit Description ............................................................................................................................................... 43

Conditions for Running the DTC ........................................................................................................................ 43

DTC P0711 ...................................................................................................................................................... 43

DTC P0712 ...................................................................................................................................................... 43

DTC P0713 ...................................................................................................................................................... 44

Conditions for Setting the DTC................................................................................................. .......................... 44

DTC P0711 ...................................................................................................................................................... 44

DTC P0712 ...................................................................................................................................................... 44

DTC P0713 ...................................................................................................................................................... 44

Action Taken When the DTC Sets ................................................................................................. ..................... 44

Conditions for Clearing the DTC ........................................................................................................................ 44

Diagnostic Aids .................................................................................................................................................... 45

Test Description ................................................................................................................................................... 45

DTC P0711 to P0713 Diagnostic Table ............................................................................................ ................... 45

4.14 DTC P0719 – Brake Switch Circuit High Input (Stuck On) ......................................................................... ....... 47

DTC Description ................................................................................................................................................... 47

Circuit Description ............................................................................................................................................... 47

Conditions for Running the DTC ................................................................................................. ....................... 47

Conditions for Setting the DTC........................................................................................................................... 47

Action Taken When the DTC Sets ................................................................................................. ..................... 47

Conditions for Clearing the DTC ........................................................................................................................ 47

Diagnostic Aids .................................................................................................................................................... 48

Test Description ................................................................................................................................................... 48

DTC P0719 Diagnostic Table..................................................................................................... .......................... 48

4.15 DTC P0722 – Vehicle Speed Sensor Circuit Low Voltage........................................................................... ...... 49

DTC Description ................................................................................................................................................... 49

Circuit Description ............................................................................................................................................... 49

Conditions for Running the DTC ................................................................................................. ....................... 49

Conditions for Setting the DTC........................................................................................................................... 49

Action Taken When the DTC Sets ................................................................................................. ..................... 50

Conditions for Clearing the DTC ........................................................................................................................ 50

Diagnostic Aids .................................................................................................................................................... 50

Test Description ................................................................................................................................................... 50

DTC P0722 Diagnostic Table..................................................................................................... .......................... 50

4.16 DTC P0723 – Vehicle Speed Sensor Circuit Intermittent .......................................................................... ........ 52

DTC Description ................................................................................................................................................... 52

Circuit Description ............................................................................................................................................... 52

Conditions for Running the DTC ................................................................................................. ....................... 52

Conditions for Setting the DTC........................................................................................................................... 53

Action Taken When the DTC Sets ................................................................................................. ..................... 53

Conditions for Clearing the DTC ........................................................................................................................ 53

Diagnostic Aids .................................................................................................................................................... 53

Test Description ................................................................................................................................................... 53

DTC P0723 Diagnostic Table..................................................................................................... .......................... 54

4.17 DTC P0724 – Brake Switch Circuit Low Input (Stuck Off) ................................................................................ 55

DTC Description ................................................................................................................................................... 55

Circuit Description ............................................................................................................................................... 55

Conditions for Running the DTC ................................................................................................. ....................... 56

Conditions for Setting the DTC........................................................................................................................... 56

Action Taken When the DTC Sets ................................................................................................. ..................... 56

Conditions for Clearing the DTC ........................................................................................................................ 56

Diagnostic Aids .................................................................................................................................................... 56

Test Description ................................................................................................................................................... 56

DTC P0724 Diagnostic Table..................................................................................................... .......................... 56

4.18 DTC P0741 – Torque Converter Clutch System – Stuck Off......................................................................... .... 57

DTC Description ................................................................................................................................................... 57

Circuit Description ............................................................................................................................................... 57

Conditions for Running the DTC ................................................................................................. ....................... 58

Conditions for Setting the DTC........................................................................................................................... 58

Action Taken When the DTC Sets ................................................................................................. ..................... 58

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3790 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–4

Conditions for Clearing the DTC ........................................................................................................................ 58

Diagnostic Aids .................................................................................................................................................... 58

Test Description ................................................................................................................................................... 58

DTC P0741 Diagnostic Table..................................................................................................... .......................... 59

4.19 DTC P0742 – Torque Converter Clutch System – Stuck On .......................................................................... ... 60

DTC Description ................................................................................................................................................... 60

Circuit Description ............................................................................................................................................... 60

Conditions for Running the DTC ................................................................................................. ....................... 60

Conditions for Setting the DTC........................................................................................................................... 61

Action Taken When the DTC Sets ................................................................................................. ..................... 61

Conditions for Clearing the DTC ........................................................................................................................ 61

Diagnostic Aids .................................................................................................................................................... 61

Test Description ................................................................................................................................................... 61

DTC P0742 Diagnostic Table..................................................................................................... .......................... 61

4.20 DTC P0751 – 1-2 Shift Solenoid Valve Performance – No First or Fourth Gear ............................................. 63

DTC Description ................................................................................................................................................... 63

Circuit Description ............................................................................................................................................... 63

Conditions for Running the DTC ................................................................................................. ....................... 63

Conditions for Setting the DTC........................................................................................................................... 63

Action Taken When the DTC Sets ................................................................................................. ..................... 63

Conditions for Clearing the DTC ........................................................................................................................ 63

Diagnostic Aids .................................................................................................................................................... 64

Test Description ................................................................................................................................................... 64

DTC P0751 Diagnostic Table..................................................................................................... .......................... 64

4.21 DTC P0752 – 1-2 Shift Solenoid Valve Performance – No Second or Third Gear........................................... 65

DTC Description ................................................................................................................................................... 65

Circuit Description ............................................................................................................................................... 65

Conditions for Running the DTC ................................................................................................. ....................... 65

Conditions for Setting the DTC........................................................................................................................... 65

Action Taken When the DTC Sets ................................................................................................. ..................... 66

Conditions for Clearing the DTC ........................................................................................................................ 66

Diagnostic Aids .................................................................................................................................................... 66

Test Description ................................................................................................................................................... 66

DTC P0752 Diagnostic Table..................................................................................................... .......................... 66

4.22 DTC P0756 – 2-3 Shift Solenoid Valve Performance – No First or Second Gear ............................................ 68

DTC Description ................................................................................................................................................... 68

Circuit Description ............................................................................................................................................... 68

Conditions for Running the DTC ................................................................................................. ....................... 68

Conditions for Setting the DTC........................................................................................................................... 68

Action Taken When the DTC Sets ................................................................................................. ..................... 68

Conditions for Clearing the DTC ........................................................................................................................ 68

Diagnostic Aids .................................................................................................................................................... 69

Test Description ................................................................................................................................................... 69

DTC P0756 Diagnostic Table..................................................................................................... .......................... 69

4.23 DTC P0757 – 2-3 Shift Solenoid Valve Performance – No Third or Fourth Gear ............................................ 70

DTC Description ................................................................................................................................................... 70

Circuit Description ............................................................................................................................................... 70

Conditions for Running the DTC ................................................................................................. ....................... 71

Conditions for Setting the DTC........................................................................................................................... 71

Action Taken When the DTC Sets ................................................................................................. ..................... 71

Conditions for Clearing the DTC ........................................................................................................................ 71

Diagnostic Aids .................................................................................................................................................... 71

Test Description ................................................................................................................................................... 71

DTC P0757 Diagnostic Table..................................................................................................... .......................... 72

4.24 DTC P0787 – 3-2 Shift Solenoid Control Circuit Low Voltage .......................................................................... 73

DTC Description ................................................................................................................................................... 73

Circuit Description ............................................................................................................................................... 73

Conditions for Running the DTC ................................................................................................. ....................... 73

Conditions for Setting the DTC........................................................................................................................... 73

Action Taken When the DTC Sets ................................................................................................. ..................... 73

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007