charging ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1201 of 6020

Engine Control System (4JH1) 6E-167

DTC P0560 (Symptom Code 2) (Flash Code 35)

Circuit Description

The engine control module (ECM) monitors the system

voltage on the ECM main relay load supply voltage

terminal to make sure that the voltage stays within the

proper range. If the ECM detects an excessively lo

w

system voltage, this DTC will set.

Condition for Setting the DTC

• The ECM detects that the battery voltage feed

circuit voltage is less than 7 volts.

Action Taken When the DTC Sets

• The ECM does not illuminate the malfunction

indicator lamp (MIL) when the diagnostic runs and

fails.

Condition for Clearing the DTC

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

• A charging system problem may set this DTC.

DTC P0560 (Symptom Code 2) (Flash Code 35)

Schematic Reference: Engine Controls Schematics &

Starting and Charging Schematics

Connector End View Reference: Engine Control

Module (ECM) Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Start the engine and let idle for 30 seconds. 2. Load the electrical system by turning ON the headlights, A/C, etc.

3. Observe the System Voltage parameter with the scan tool.

Is the System Voltage parameter more than the

specified value? 10 volts

Go to Diagnostic Aids Go to Step 4

4 Test the charging system. Refer to Diagnosis of The Charging System in the Charging System Section.

Did you find a charging system problem?

Go to Step 5 Go to Step 6

5 Repair the charging system. Refer to Diagnosis of The Charging System in the Charging System

Section.

Did you complete the repair?

Go to Step 8

6 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent, for a poor connection and corrosion on the battery voltage feed at the

harness connector of the ECM (pin 3 of C-56

connector).

4. Repair or clean the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 8 Go to Step 7

7 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1203 of 6020

Engine Control System (4JH1) 6E-169

DTC P0560 (Symptom Code A) (Flash Code 35)

Circuit Description

The fuel injection pump control unit (PCU) monitors the

system voltage on the engine control module (ECM)

main relay load supply voltage terminal to make sure

that the voltage stays within the proper range. If the

ECM detects an excessively high or low system voltage,

this DTC will set.

Condition for Setting the DTC

• The PCU battery voltage feed circuit voltage is

less than 4.5 volts or more than 27 volts.

Action Taken When the DTC Sets

• The ECM does not illuminate the malfunction

indicator lamp (MIL) when the diagnostic runs and

fails.

Condition for Clearing the DTC

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

• A charging system problem may set this DTC.

• Jump starting the vehicle or a battery charger may

have set this DTC.

Notice:

• PCU is part of the fuel injection pump assembly.

DTC P0560 (Symptom Code A) (Flash Code 35)

Schematic Reference: Engine Controls Schematics &

Starting and Charging Schematics

Connector End View Reference: Engine Controls

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Is DTC P0560 (Symptom Code 1 or 2) set?

Go to Applicable DTC Go to Step 3

3 1. Start the engine and let idle for 30 seconds. 2. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 4 Go to Diagnostic

Aids

4 1. Turn OFF the ignition. 2. Disconnect the fuel injection pump control unit (PCU) harness connector.

3. Inspect for an intermittent, for poor connections and corrosion on the voltage feed or ground at

the harness connector of the PCU (pins 6 and 7

of E-6 connector).

4. Repair or clean the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 6 Go to Step 5

5 Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section.

Did you complete the replacement?

Go to Step 6

6 1. Reconnect all previously disconnected harness connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and let idle for 30 seconds.

5. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 2 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1310 of 6020

6E-276 Engine Control System (4JH1)

1. Connect the scan tool to the vehicle DLC, with theengine and the scan tool OFF.

2. Turn ON the scan tool.

3. Select Diagnostic > appropriate vehicle identification > Powertrain > 4JH1-TC >

Programming > Program VIN.

4. Input correct VIN reading from stamped VIN o

r

affixed VIN plate on the vehicle.

Select Lock ECU and lock the programmed VIN.

Service Programming System (SPS)

Description

The service programming system (SPS) allows a

technician to program a control module through the data

link connector (DLC). The information transfer circuit that

is used at the DLC is the same serial data circuit used be

the scan tool for retrieving diagnostic trouble codes

(DTCs), displaying data, clearing DTCs etc. This

procedure offers the ability to install software/calibrations

matched to a particular vehicle.

Most control modules have two types of memory. The

software/calibrations reside in the flash memory. The two

types of memory are listed below: • Electrically Erasable Programmable Read Onl

y

Memory (EEPROM).

This type of memory allows selected portions o

f

memory to be programmed while other portions

remain unchanged.

Certain learned values reside in the EEPROM, such as:

- The vehicle identification number (VIN)

- The software/calibrations identification numbers

- The control module security information

• Flash Read Only Memory-Flash Memory

Flash memory has increased memory storage capacity. During programming, all information within

this type of memory is erased, and then replaced

with entirely new information.

Service Programming Methods

The two methods of programming an engine control

module (ECM) are listed below: • Remote Programming

• Pass Thru Programming

For information on programming an ECM using one o

f

the methods listed above, refer to Service Programming

System (SPS) (Remote Procedure) or Service

Programming System (SPS) (Pass-Thru Procedure).

Before Programming a Control Module

Important:

DO NOT program an existing ECM with the identical

software/calibration package. This procedure is not a

short cut to correct the driveability condition. This is an

ineffective repair. An ECM should only be programmed

when the following occurs: • W hen a service procedure instructs you to replace

the ECM. W hen the ECM from another vehicle is

installed, VIN must be changed. And change

vehicle information as necessary such as type o

f

transmission.

• An updated software/calibrations is released.

Ensure that the following conditions are met before

programming an ECM: • The scan tool PCMCIA card is programmed with

the latest software.

• The TIS 2000 is installed with the latest software.

• The hardware key is plugged into the compute

r

port.

• Vehicle system voltage:

- There are no charging system concerns. All charging system concerns must be repaired

before programming the ECM.

- The battery voltage is greater than 12 volts bu

t

less than 16 volts. The battery must be fully

charged before programming the ECM.

-

A battery charger is NOT connected to the

vehicles battery. Incorrect system voltage o

r

voltage fluctuations from a battery charger may

cause programming failure or ECM damage.

- Turn OFF or disable any system that may put a load on the vehicles battery. Turn OFF o

r

disable systems such as:

◊ Heating, ventilation, and air conditioning

(HVAC) systems

◊ Headlights

◊ Room lights

◊ Accessory equipment

• The ignition switch is in the proper position. The

scan tool prompts you to turn ON the ignition, with

the engine OFF. DO NOT change the position o

f

the ignition switch during the programming

procedure unless instructed to do so.

• All tool connections are secure:

- The RS-232 cable

- The connection at the DLC

- The voltage supply circuits

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1317 of 6020

Engine Control System (4JH1) 6E-283

Description And Operation

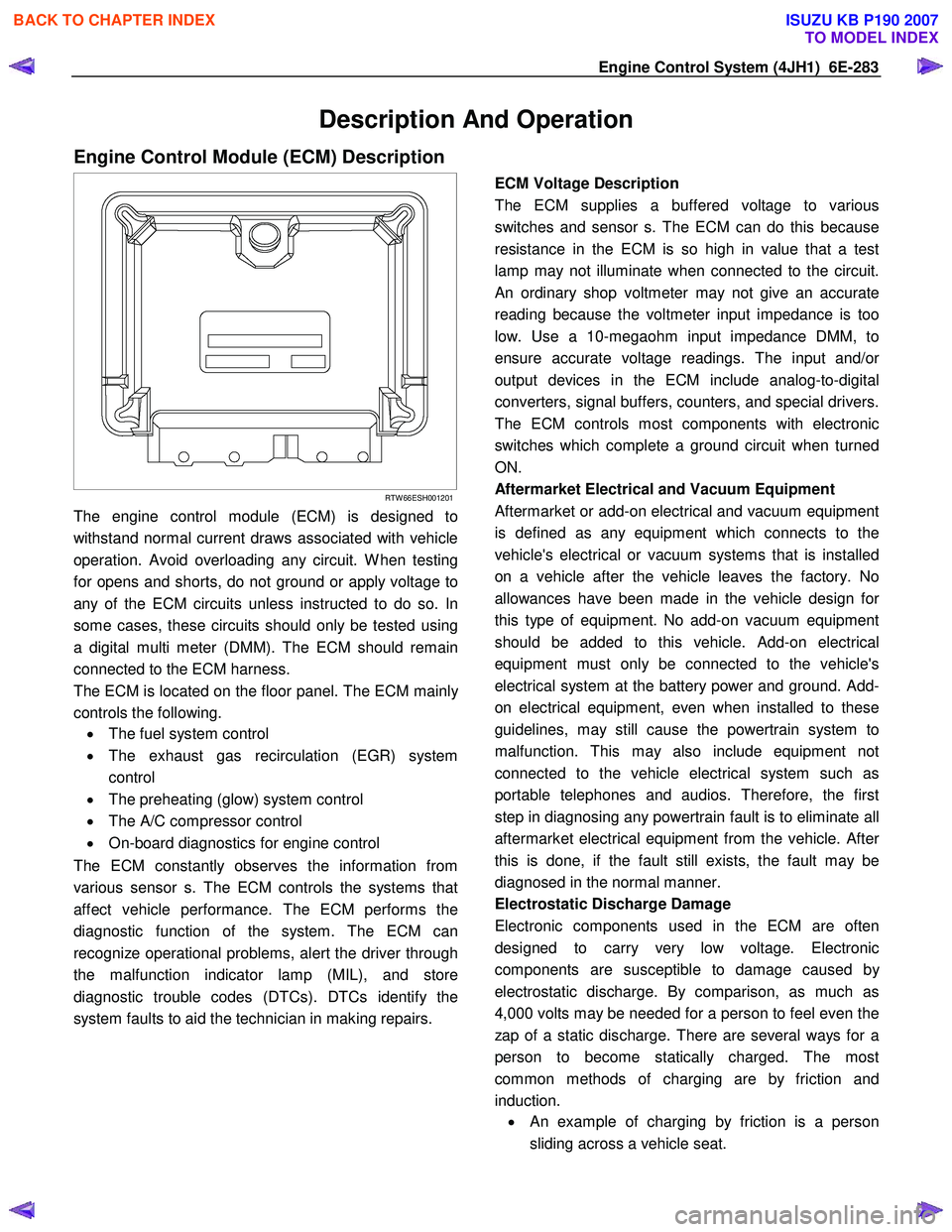

Engine Control Module (ECM) Description

RTW 66ESH001201

The engine control module (ECM) is designed to

withstand normal current draws associated with vehicle

operation. Avoid overloading any circuit. W hen testing

for opens and shorts, do not ground or apply voltage to

any of the ECM circuits unless instructed to do so. In

some cases, these circuits should only be tested using

a digital multi meter (DMM). The ECM should remain

connected to the ECM harness.

The ECM is located on the floor panel. The ECM mainl

y

controls the following.

• The fuel system control

• The exhaust gas recirculation (EGR) system

control

• The preheating (glow) system control

• The A/C compressor control

• On-board diagnostics for engine control

The ECM constantly observes the information from

various sensor s. The ECM controls the systems that

affect vehicle performance. The ECM performs the

diagnostic function of the system. The ECM can

recognize operational problems, alert the driver through

the malfunction indicator lamp (MIL), and store

diagnostic trouble codes (DTCs). DTCs identify the

system faults to aid the technician in making repairs.

ECM Voltage Description

The ECM supplies a buffered voltage to various

switches and sensor s. The ECM can do this because

resistance in the ECM is so high in value that a test

lamp may not illuminate when connected to the circuit.

An ordinary shop voltmeter may not give an accurate

reading because the voltmeter input impedance is too

low. Use a 10-megaohm input impedance DMM, to

ensure accurate voltage readings. The input and/o

r

output devices in the ECM include analog-to-digital

converters, signal buffers, counters, and special drivers.

The ECM controls most components with electronic

switches which complete a ground circuit when turned

ON.

Aftermarket Electrical and Vacuum Equipment

Aftermarket or add-on electrical and vacuum equipment

is defined as any equipment which connects to the

vehicle's electrical or vacuum systems that is installed

on a vehicle after the vehicle leaves the factory. No

allowances have been made in the vehicle design fo

r

this type of equipment. No add-on vacuum equipment

should be added to this vehicle. Add-on electrical

equipment must only be connected to the vehicle's

electrical system at the battery power and ground. Add-

on electrical equipment, even when installed to these

guidelines, may still cause the powertrain system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such as

portable telephones and audios. Therefore, the first

step in diagnosing any powertrain fault is to eliminate all

aftermarket electrical equipment from the vehicle. Afte

r

this is done, if the fault still exists, the fault may be

diagnosed in the normal manner.

Electrostatic Discharge Damage

Electronic components used in the ECM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused b

y

electrostatic discharge. By comparison, as much as

4,000 volts may be needed for a person to feel even the

zap of a static discharge. There are several ways for a

person to become statically charged. The most

common methods of charging are by friction and

induction. •

An example of charging by friction is a person

sliding across a vehicle seat.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1367 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-7

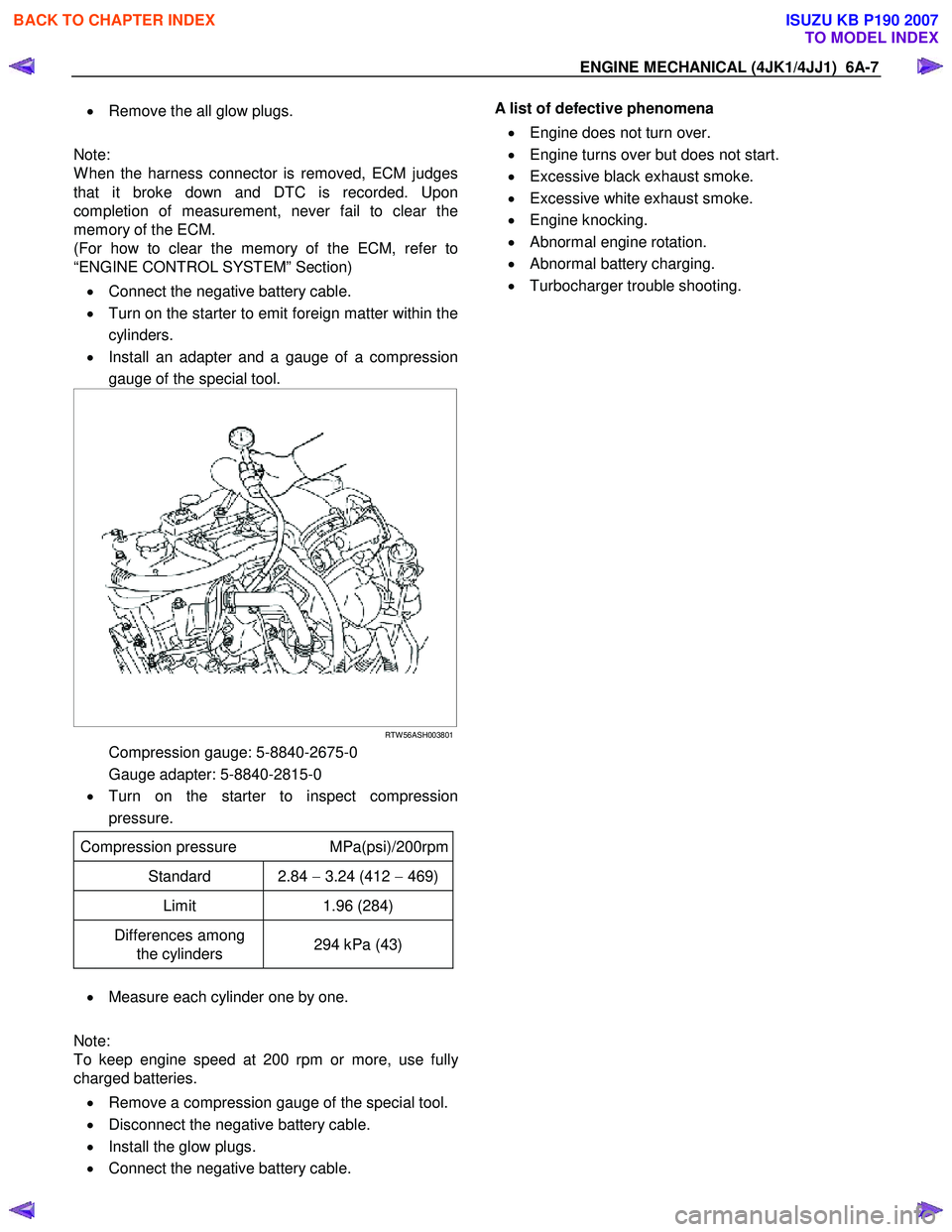

• Remove the all glow plugs.

Note:

W hen the harness connector is removed, ECM judges

that it broke down and DTC is recorded. Upon

completion of measurement, never fail to clear the

memory of the ECM.

(For how to clear the memory of the ECM, refer to

“ENGINE CONTROL SYSTEM” Section)

• Connect the negative battery cable.

• Turn on the starter to emit foreign matter within the

cylinders.

• Install an adapter and a gauge of a compression

gauge of the special tool.

RTW 56ASH003801

Compression gauge: 5-8840-2675-0

Gauge adapter: 5-8840-2815-0

• Turn on the starter to inspect compression

pressure.

Compression pressure MPa(psi)/200rpm

Standard 2.84 − 3.24 (412 − 469)

Limit 1.96 (284)

Differences among

the cylinders 294 kPa (43)

•

Measure each cylinder one by one.

Note:

To keep engine speed at 200 rpm or more, use full

y

charged batteries.

• Remove a compression gauge of the special tool.

• Disconnect the negative battery cable.

• Install the glow plugs.

• Connect the negative battery cable.

A list of defective phenomena

• Engine does not turn over.

• Engine turns over but does not start.

• Excessive black exhaust smoke.

• Excessive white exhaust smoke.

• Engine knocking.

• Abnormal engine rotation.

• Abnormal battery charging.

• Turbocharger trouble shooting.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1371 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-11

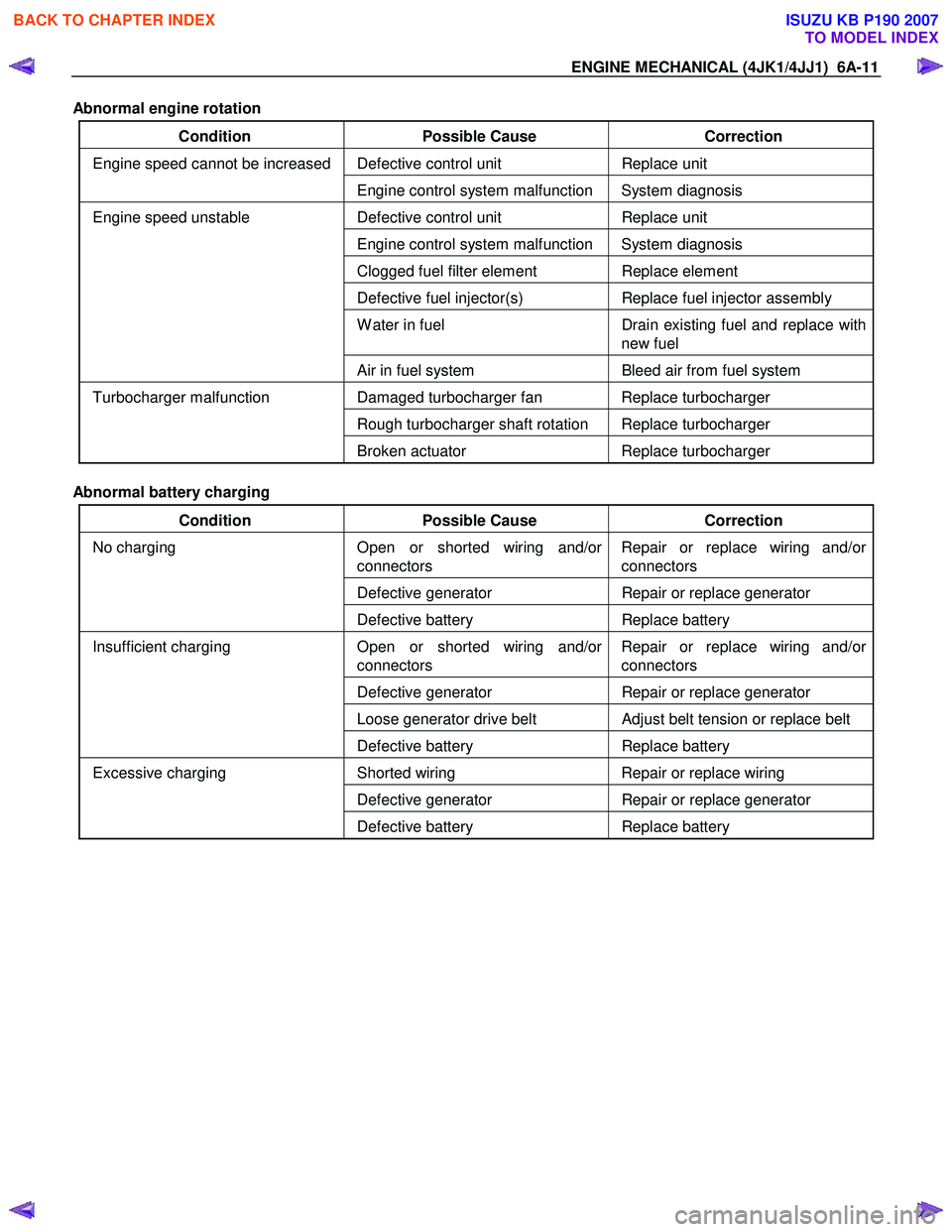

Abnormal engine rotation

Condition Possible Cause Correction

Defective control unit Replace unit Engine speed cannot be increased

Engine control system malfunction System diagnosis

Defective control unit Replace unit

Engine control system malfunction System diagnosis

Clogged fuel filter element Replace element

Defective fuel injector(s) Replace fuel injector assembly

W ater in fuel Drain existing fuel and replace with

new fuel

Engine speed unstable

Air in fuel system Bleed air from fuel system

Damaged turbocharger fan Replace turbocharger

Rough turbocharger shaft rotation Replace turbocharger

Turbocharger malfunction

Broken actuator Replace turbocharger

Abnormal battery charging

Condition Possible Cause Correction

Open or shorted wiring and/or

connectors Repair or replace wiring and/or

connectors

Defective generator Repair or replace generator

No charging

Defective battery Replace battery

Open or shorted wiring and/or

connectors Repair or replace wiring and/or

connectors

Defective generator Repair or replace generator

Loose generator drive belt Adjust belt tension or replace belt

Insufficient charging

Defective battery Replace battery

Shorted wiring Repair or replace wiring

Defective generator Repair or replace generator

Excessive charging

Defective battery Replace battery

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1373 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-13

Main Data and specifications

Item Engine model 4JK1 Engine model 4JJ1

Type Diesel/4-cycle/water cooling-type in-line DOHC

Combustion chamber type Direct injection type

Cylinder liner type Liner less

Number of cylinders -cylinder

bore × strokes mm (in) 4-95.4 (3.76) × 87.4 (3.44) 4-95.4(3.76) × 104.9(4.13)

Displacement

cc (cu.in) 2499 (152) 2999 (183)

Compression ratio 18.3 17.5

Compression pressure MPa (psi)/rpm 3 (435)/200

Idling speed rpm 700 ± 25

Valve clearance Intake 0.15 (0.006) (cold)

mm (in) Exhaust 0.15 (0.006) (cold)

Ignition type Compressed ignition

Injection order 1 - 3 - 4 - 2

Lubricating system

Lubricating type Pressure delivery type

Oil pump type Gear type

Volume of lubricating oil L (qts) 8.0 (8.5)

Oil filter type Full flow filter (cartridge type)

Oil cooling type Built-in-type, water cooling

Cooling system

Cooling type W ater cooling type

Radiator type Corrugated fin (pressure type)

W ater pump type Centrifugal, belt drive type

Thermostat type W ax-type units

Thermostat valve-opening temperature °C ( °F) 85 (185)

Volume of coolant L (qts) M/T8.7 (9.2) A/T 8.6 (9.1) (incl. radiator)

Fuel system

Injection pump type Fuel supply pump fuel rail type

Fuel injector type Electronic control injector

6-hole

Fuel pump type Into the fuel tank type

Charging system

Generator type AC type

Power output V-A 12 - 90

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1547 of 6020

6C-6 FUEL SYSTEM (4JK1/4JJ1)

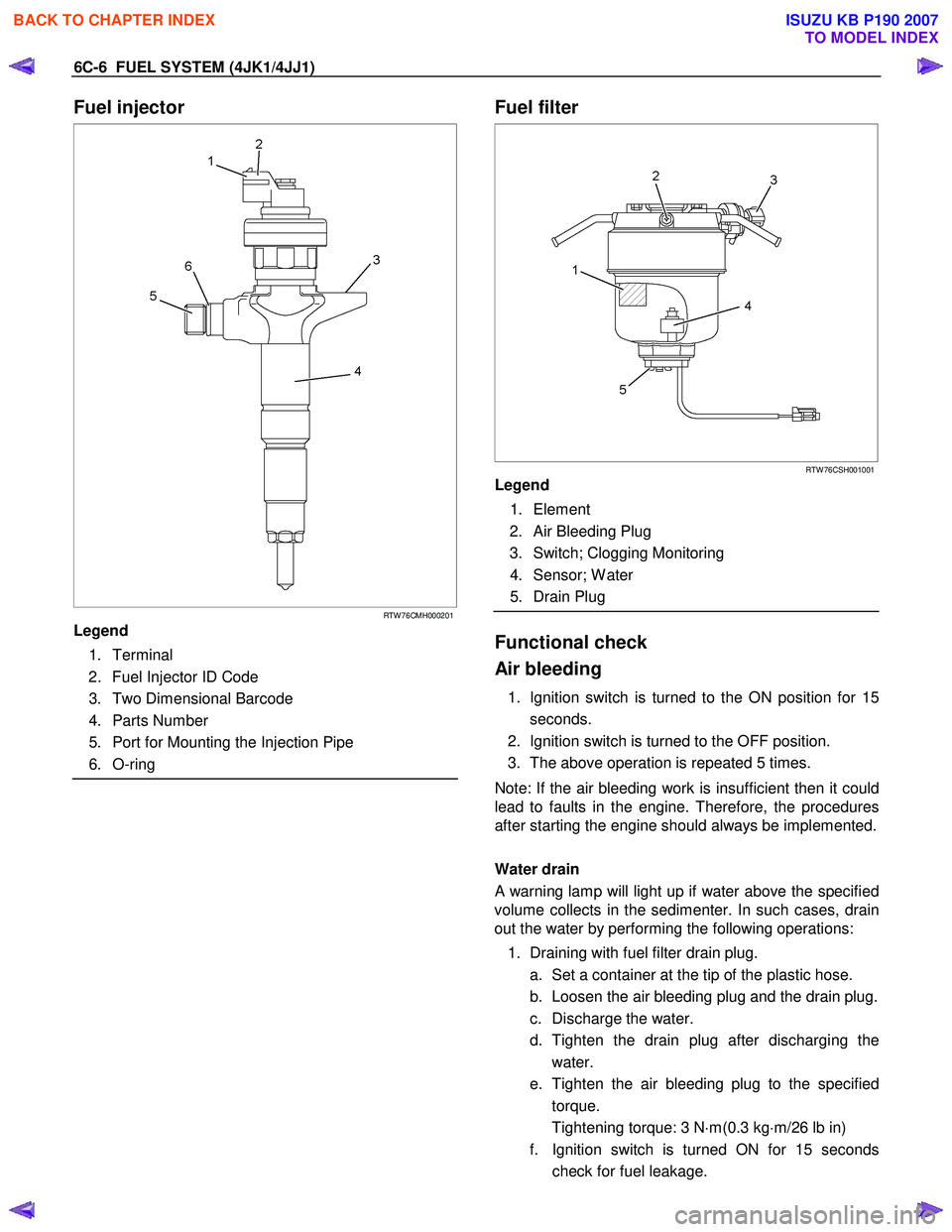

Fuel injector

RTW 76CMH000201

Legend

1. Terminal

2. Fuel Injector ID Code

3. Two Dimensional Barcode

4. Parts Number

5. Port for Mounting the Injection Pipe

6. O-ring

Fuel filter

RTW 76CSH001001

Legend

1. Element

2. Air Bleeding Plug

3. Switch; Clogging Monitoring

4. Sensor; W ater

5. Drain Plug

Functional check

Air bleeding

1. Ignition switch is turned to the ON position for 15 seconds.

2. Ignition switch is turned to the OFF position.

3. The above operation is repeated 5 times.

Note: If the air bleeding work is insufficient then it could

lead to faults in the engine. Therefore, the procedures

after starting the engine should always be implemented.

Water drain

A warning lamp will light up if water above the specified

volume collects in the sedimenter. In such cases, drain

out the water by performing the following operations:

1. Draining with fuel filter drain plug. a. Set a container at the tip of the plastic hose.

b. Loosen the air bleeding plug and the drain plug.

c. Discharge the water.

d. Tighten the drain plug after discharging the water.

e. Tighten the air bleeding plug to the specified torque.

Tightening torque: 3 N ⋅m(0.3 kg ⋅m/26 lb in)

f. Ignition switch is turned ON for 15 seconds check for fuel leakage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1589 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-1

SECTION 6D

ENGINE ELECTRICAL

TABLE OF CONTENTS

Charging System ................................................ 6D-2

Servicing Cautions .......................................... 6D-2

Important Generator Components and

Function.......................................................... 6D-2

Troubleshooting .............................................. 6D-5

Diagnosis......................................................... 6D-7

Specifications .................................................. 6D-8

Unit Se rv ic ing (4 JJ 1) ....................................... .... ..6D -9

Disassembly .................................................... 6D-10

Inspection and Repair ..................................... 6D-11 Rotor Assembly ........................................... 6D-11

Stator Coil .................................................... 6D-12

Brushes ....................................................... 6D-12

Rectifier ....................................................... 6D-13

Regulator Assembly..................................... 6D-13

Measuring Procedure .................................. 6D-13

Reassembly..................................................... 6D-14

Final Assembly ................................................ 6D-14

Starter Motor ...................................................... 6D-15 Starting Circuit Diagram .................................. 6D-15

Removal and Installation ................................. 6D-15 Important Operations – Removal................. 6D-15

Important Operations – Installation.............. 6D-15

Disassembly .................................................... 6D-16 Disassembly Steps ...................................... 6D-16

Important Operations ................................... 6D-17

Inspection and Repair ..................................... 6D-20 Armature ...................................................... 6D-20

Yoke............................................................. 6D-21

Brush and Brush Holder .............................. 6D-22

Overrunning Clutch...................................... 6D-22

Bearing ........................................................ 6D-23

Reassembly..................................................... 6D-24 Reassembly Steps ....................................... 6D-24

Important Operations ................................... 6D-25

Inspection After Assembly ........................... 6D-26

Magnetic Switch .............................................. 6D-27

Torque Specifications...................................... 6D-28

Pre-Heating System ........................................... 6D-29 Inspection and Repair ..................................... 6D-29 Visual Check................................................ 6D-29

Glow Relay .................................................. 6D-29

Glow Plug .................................................... 6D-29

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1590 of 6020

6D-2 ENGINE ELECTRICAL (4JK1/4JJ1)

Charging System

Servicing Cautions

• Battery polarity is important. If the battery cables

are reversed, the generator diodes will be

destroyed.

• Do not remove the battery cables or the charging

circuit wiring when the engine is running.

• Confirm that the terminal wires are connected to

the proper terminals by checking the terminal

numbers (the number on the terminal wire and the

terminal must be the same).

• Disconnect the battery negative cable (-) before

inspecting the generator.

• Do not open or close the battery relay switch when

the engine is running.

• Disconnect the battery negative cable (-) when

using external equipment (Quick-Charge) to

charge the battery.

• W hen steam cleaning or washing the engine, do

not allow steam or water to come in direct contact

with the battery and other electrical system

components.

• Be sure to read the item on belt tension

adjustment before beginning the procedure.

Important Generator Components

and Function

• The generator used on 4JK1 engine cannot be

disassembled.

• The generator uses a built-in solid-state IC voltage

regulator. The regulator and other important

components together with their connections are

shown in the illustration.

• The voltage regulator is installed to the rear cove

r

assembly of the generator together with the brush

holder and the rectifier. The generator requires no

additional voltage regulation.

• 9 diodes are connected to the stator coil to convert

AC to DC. The DC voltage is delivered to the

generator output terminal.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007