service indicator ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4404 of 6020

7A2-120 TRANSMISSION CONTROL SYSTEM (JR405E)

Z7: Shift Indicator is Faulty

Z8: Transmission Fluid is Splashed During Running

Z9: Abnormal Smell

Z10: Transmission Fluid Quantity is Low or High

Z11: Abnormal Transmission Fluid Pressure

Checks Action

Definition:

Shift indicator does not change even though the selector lever is moved.

Diagnosis Hints Inspect the transmission range switch and selector lever cable for

misadjusting or disordering. Refer to On-Vehicle Service section.

Checks Action

Definition:

Transmission Fluid is splashed during running.

Diagnosis Hints Transmission fluid quantity is excessively high.

Checks Action

Definition:

Abnormal smell.

Diagnosis Hints A trouble in the transmission main unit.

Checks Action

Definition:

Transmission fluid quantity is low or high.

Diagnosis Hints • If the fluid level is high, level check might be performed at low

temperature.

• If the fluid level is low, fluid leak is suspected.

Checks Action

Definition:

Transmission fluid pressure (TFP) is low or high.

Diagnosis Hints • Faulty pressure control (PC) solenoid valve or hydraulic circuits.

• If pressure is low, faulty oil pump is suspected.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4464 of 6020

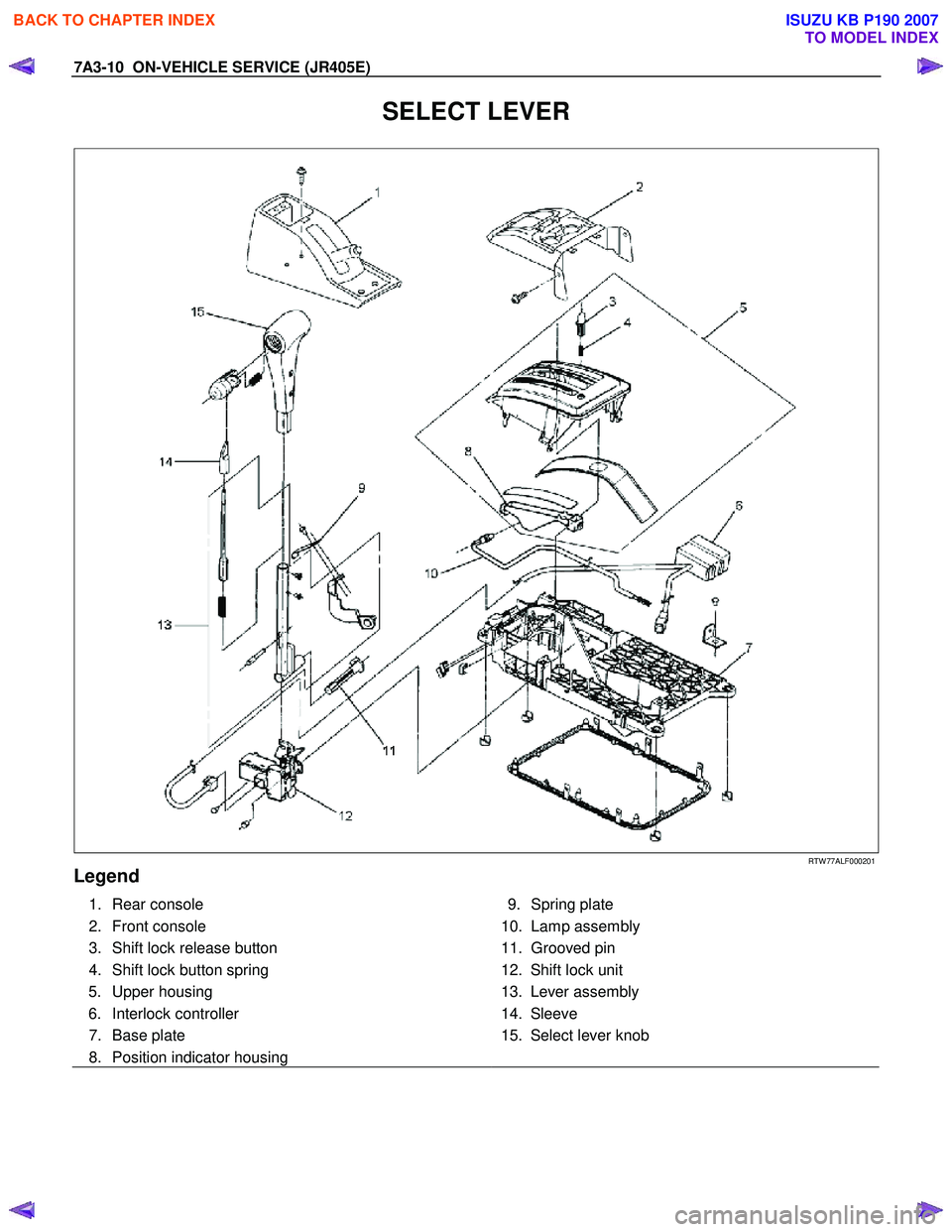

7A3-10 ON-VEHICLE SERVICE (JR405E)

SELECT LEVER

RTW 77ALF000201

Legend

1. Rear console

2. Front console

3. Shift lock release button

4. Shift lock button spring 5. Upper housing

6. Interlock controller

7. Base plate

8. Position indicator housing

9. Spring plate

10. Lamp assembly

11. Grooved pin

12. Shift lock unit

13. Lever assembly

14. Sleeve

15. Select lever knob

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4465 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-11

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Remove the rear console and the front console.

4. Remove the 2 screws fixing the select lever knob.

5. Remove the knob together with the knob button and spring from the lever.

6. Turn the sleeve counterclockwise to remove it. Make a note of the number of turns required to free

the sleeve.

7. Remove the harness connectors from the base plate.

8. Remove the upper housing (held in place by 4 latched fasteners).

9. Remove the lamp assembly by turning it counterclockwise.

10. Remove the spring plate.

11. Remove the grooved pin.

12. Disconnect the shift cable from the select lever.

13. Remove the lever assembly by pressing the rod down (lever in N position).

14. Remove the harness connectors from the shift lock unit, then remove the shift lock unit.

15. Remove the interlock controller.

16. If the replacement of shift lock release button o

r

shift lock button spring is required, remove the

position indicator housing, the shift lock button

spring and shift lock release button can be

removed.

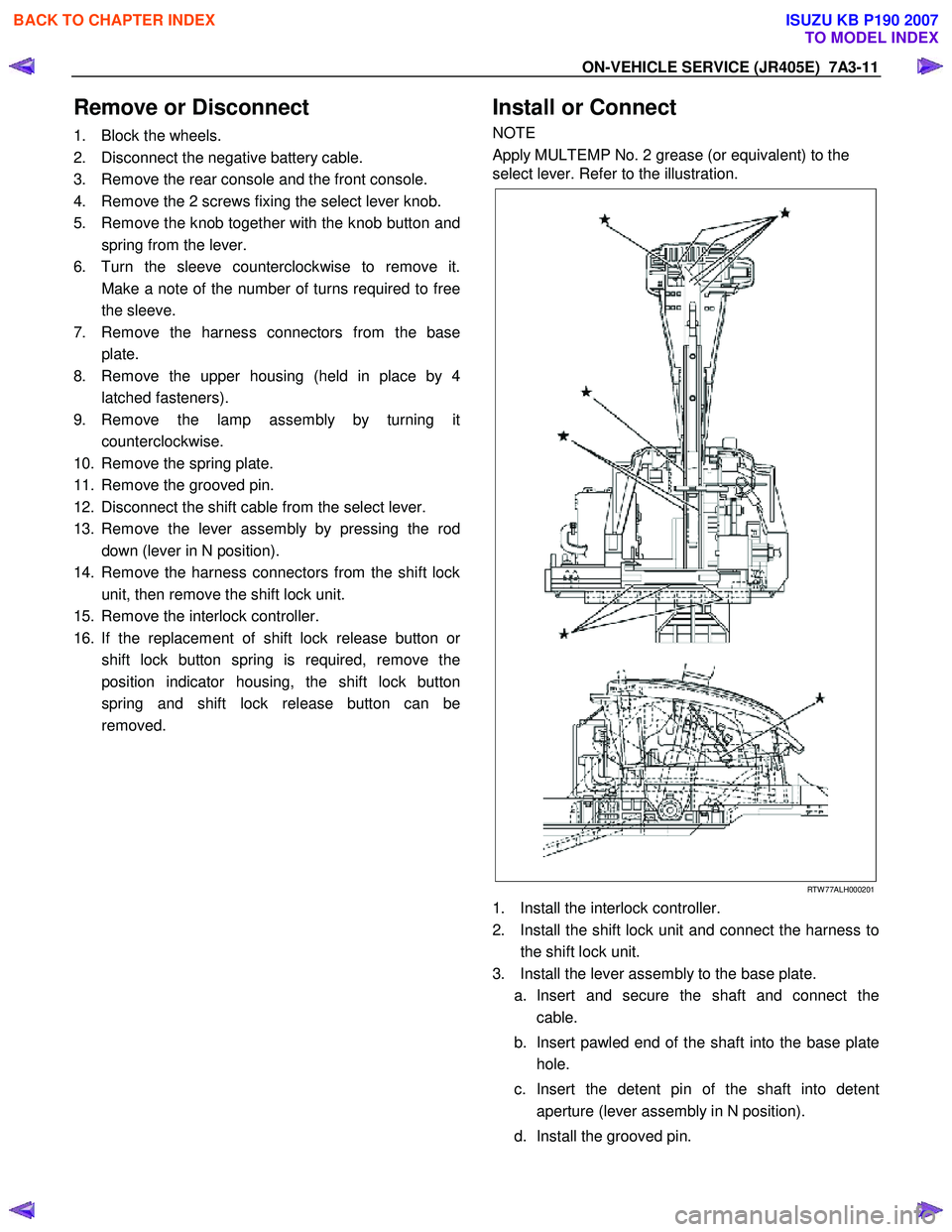

Install or Connect

NOTE

Apply MULTEMP No. 2 grease (or equivalent) to the

select lever. Refer to the illustration.

RTW 77ALH000201

1. Install the interlock controller.

2. Install the shift lock unit and connect the harness to the shift lock unit.

3. Install the lever assembly to the base plate. a. Insert and secure the shaft and connect the cable.

b. Insert pawled end of the shaft into the base plate hole.

c. Insert the detent pin of the shaft into detent aperture (lever assembly in N position).

d. Install the grooved pin.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4875 of 6020

TRANSFER CONTROL SYSTEM 7D1-1

SECTION 7D1

TRANSFER CONTROL SYSTEM

TABLE OF CONTENTS

PAGE

Service Precaution ..................................................................................................... 7D1 - 2

General Description ................................................................................................... 7D1 - 3

System Components .................................................................................................. 7D1 - 5 Parts Location ....................................................................................................... 7D1 - 5

Functions of Switch and Indicator Lamp ................................................................. 7D1 - 12

Parts Location ............................................................................................................ 7D1 - 24

Circuit Diagram ........................................................................................................... 7D1 - 33

Connector List ............................................................................................................ 7D1 - 41

Diagnosis .................................................................................................................... 7D1 - 46

Before determining a trouble (Non-trouble mode) ............................................ 7D1 - 46

Memory erasing procedure ....................................................................................... 7D1 - 52

Diagnosis from symptom ........................................................................................... 7D1 - 54

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5897 of 6020

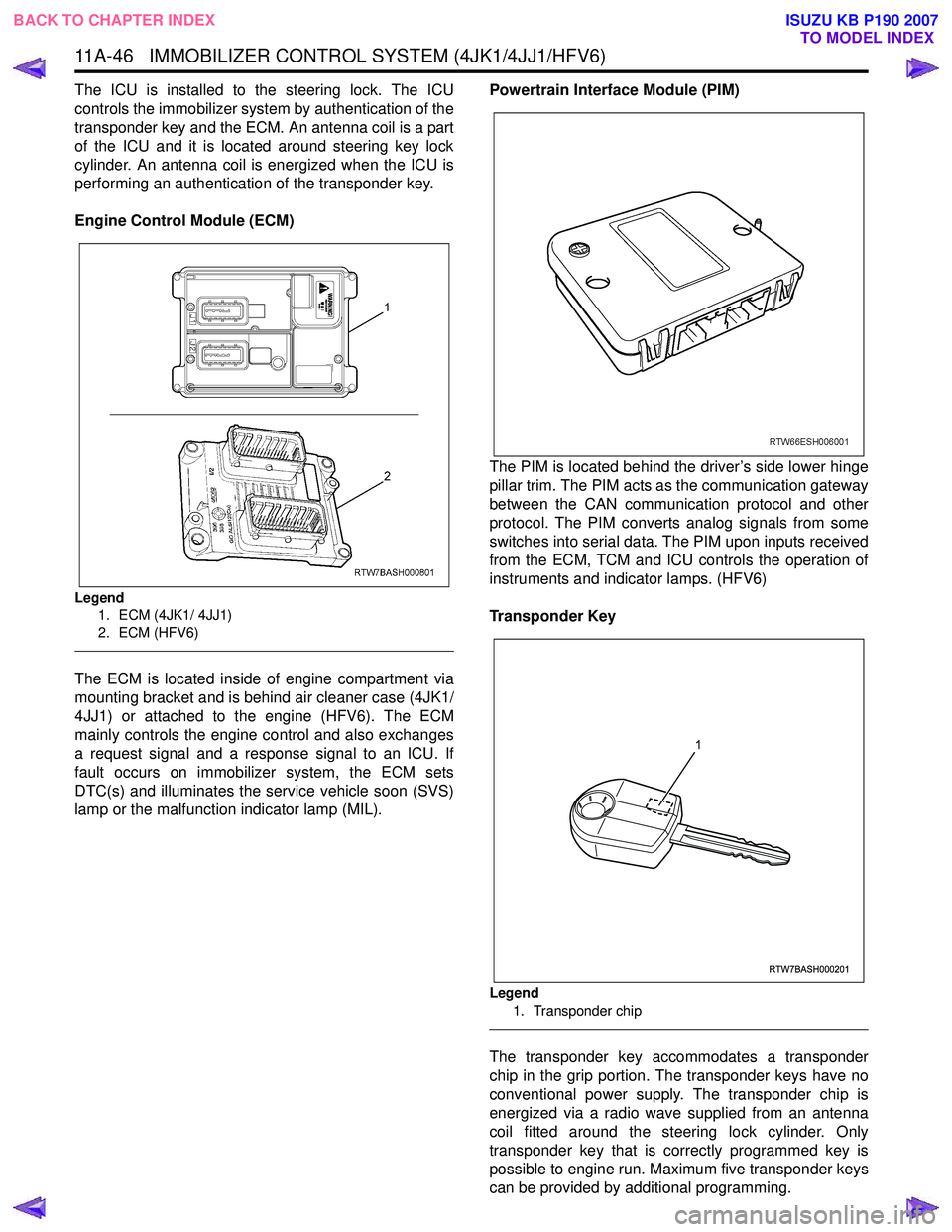

11A-46 IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6)

The ICU is installed to the steering lock. The ICU

controls the immobilizer system by authentication of the

transponder key and the ECM. An antenna coil is a part

of the ICU and it is located around steering key lock

cylinder. An antenna coil is energized when the ICU is

performing an authentication of the transponder key.

Engine Control Module (ECM)

Legend 1. ECM (4JK1/ 4JJ1)

2. ECM (HFV6)

The ECM is located inside of engine compartment via

mounting bracket and is behind air cleaner case (4JK1/

4JJ1) or attached to the engine (HFV6). The ECM

mainly controls the engine control and also exchanges

a request signal and a response signal to an ICU. If

fault occurs on immobilizer system, the ECM sets

DTC(s) and illuminates the service vehicle soon (SVS)

lamp or the malfunction indicator lamp (MIL). Powertrain Interface Module (PIM)

The PIM is located behind the driver’s side lower hinge

pillar trim. The PIM acts as the communication gateway

between the CAN communication protocol and other

protocol. The PIM converts analog signals from some

switches into serial data. The PIM upon inputs received

from the ECM, TCM and ICU controls the operation of

instruments and indicator lamps. (HFV6)

Transponder Key

Legend 1. Transponder chip

The transponder key accommodates a transponder

chip in the grip portion. The transponder keys have no

conventional power supply. The transponder chip is

energized via a radio wave supplied from an antenna

coil fitted around the steering lock cylinder. Only

transponder key that is correctly programmed key is

possible to engine run. Maximum five transponder keys

can be provided by additional programming.

RTW7BASH000201

1

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5956 of 6020

11B-2 ANTITHEFT SYSTEM

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

The Antitheft system consists of the four major

components which are Antitheft Control Unit (ACU),

Antitheft horn, key (remote key), and scan tool (Tech-2).

This system can be activated by a correctly

programmed key (remote key) and starter switch is set

to OFF.

This system can be deactivated by a correctly

programmed key (remote key) connected with a

correctly programmed ACU and a correctly

programmed lCU.

W hen the vehicle doors, and engine hood are locked,

the antitheft alarm system is designed to protect your

vehicle and valuables from theft.

Any attempt to forcibly open any door, the engine hood

without using the vehicle key (or remote control) will

cause the hazard lights to flash on and off and the horn

to sound intermittently. This will continue for 30 seconds

(Hazard lamp flash; For 5 minutes) before the system

automatically shuts itself off.

Please operate the door either the key lock or remote

key after closing all doors to arm the alarm system.

Miss waning will be detected when the passenger door

is opened with locked condition and then this door is

closed.

During the first 10 seconds:

• LED lights up; Test, switch - on delay

• LED rapidly flashes (2Hz); Door, bonnet, open or

system fault

After approx. 10 seconds:

• LED slowly flashes; System on (0.5Hz)

RTU7Z0SH019101

Activating the anti-theft system

1. W hen the key switch is turned to the ACC position or

removed from the starter switch.

2. Closing and locking all the doors by the keylock o

r

remote key, and the engine hood will cause the

indicator light to come on.

3. Approximately 10 seconds later, the indicator light will slow flash. The anti-theft system is now in

operation.

Antitheft system alarm operating

conditions

W hen the antitheft system is engaged, the alarm will

operate under the following condition;

1. W henever some forcibly attempts to open a door, the engine hood without using the key.

2. W henever someone unlocks a door with door lock knob.

3. W henever the engine hood release handle is operated.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007