engine mount ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1487 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-127

Removal

1. Demount the engine assembly.

Refer to "Engine Assembly".

2. Remove the cylinder head cover.

Refer to "Cylinder Head Cover".

3. Remove the camshaft.

Refer to "Camshaft Assembly".

4. Remove the cylinder head.

Refer to "Cylinder Head".

5. Remove the fuel supply pump and fuel rail.

Refer to "Fuel Supply Pump" and "Fuel Rail" in the fuel system section.

6. Remove the front cover.

Refer to "Front Cover".

7. Remove the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

8. Remove the water pump.

Refer to "W ater Pump" in Cooling System Section.

9. Remove the timing gear train.

Refer to "Timing Gear Train".

10.Remove the oil pump.

Refer to "Oil Pump".

11. Remove the gear case assembly.

Refer to “Gear Case Assembly”.

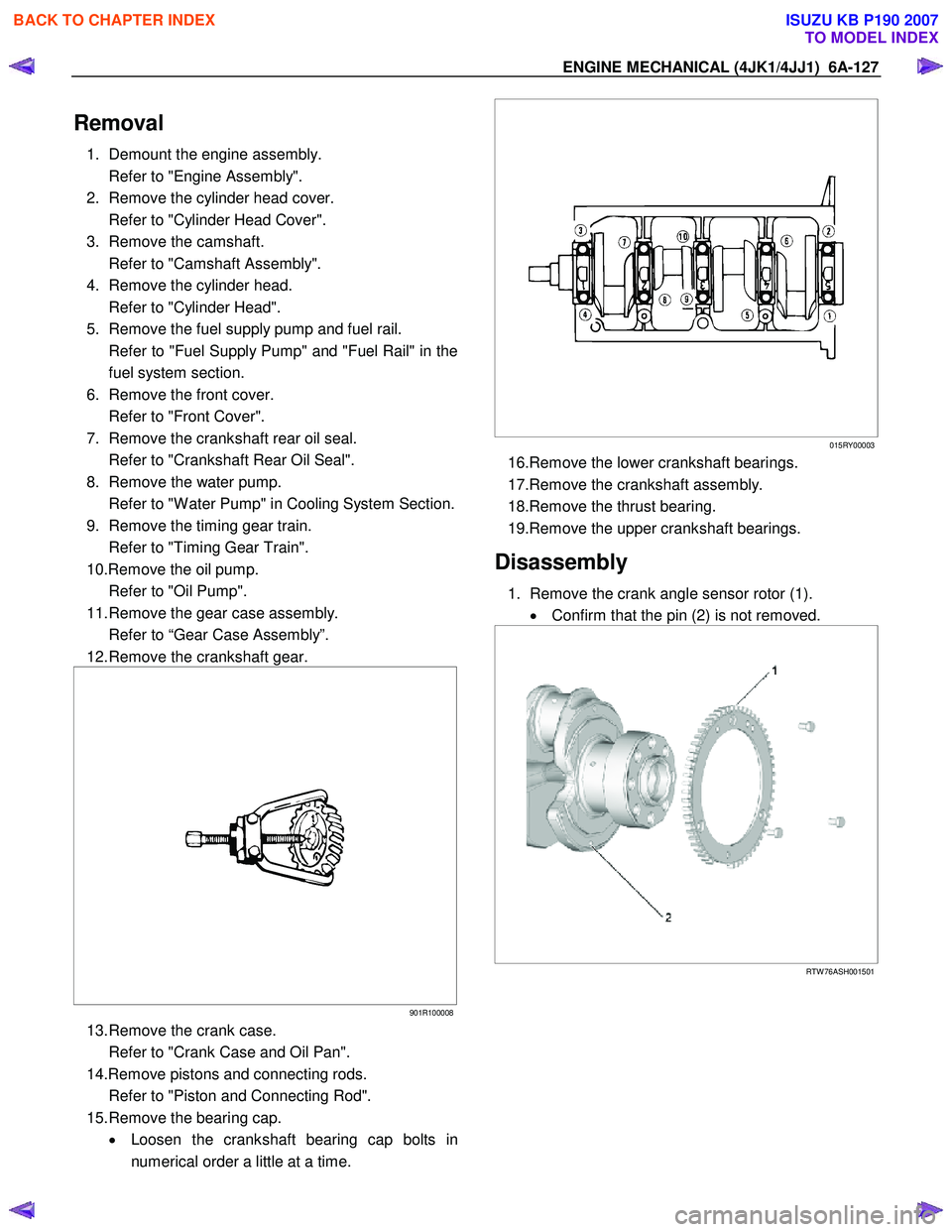

12. Remove the crankshaft gear.

901R100008

13. Remove the crank case.

Refer to "Crank Case and Oil Pan".

14.Remove pistons and connecting rods.

Refer to "Piston and Connecting Rod".

15. Remove the bearing cap. • Loosen the crankshaft bearing cap bolts in

numerical order a little at a time.

015RY00003

16.Remove the lower crankshaft bearings.

17.Remove the crankshaft assembly.

18.Remove the thrust bearing.

19.Remove the upper crankshaft bearings.

Disassembly

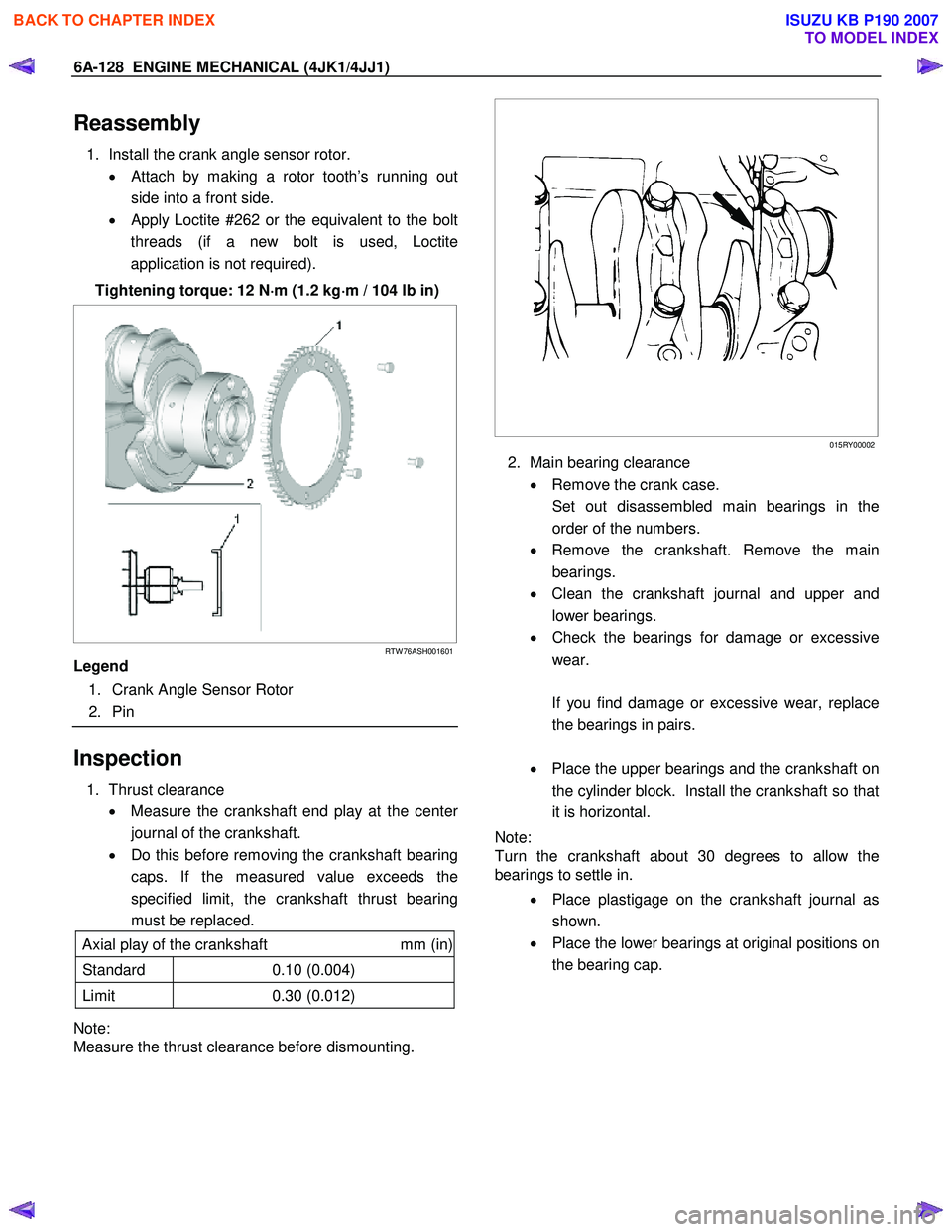

1. Remove the crank angle sensor rotor (1). • Confirm that the pin (2) is not removed.

RTW 76ASH001501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1488 of 6020

6A-128 ENGINE MECHANICAL (4JK1/4JJ1)

Reassembly

1. Install the crank angle sensor rotor.

• Attach by making a rotor tooth’s running out

side into a front side.

•

Apply Loctite #262 or the equivalent to the bolt

threads (if a new bolt is used, Loctite

application is not required).

Tightening torque: 12 N ⋅

⋅⋅

⋅

m (1.2 kg ⋅

⋅⋅

⋅

m / 104 lb in)

RTW 76ASH001601

Legend

1. Crank Angle Sensor Rotor

2. Pin

Inspection

1. Thrust clearance

• Measure the crankshaft end play at the cente

r

journal of the crankshaft.

• Do this before removing the crankshaft bearing

caps. If the measured value exceeds the

specified limit, the crankshaft thrust bearing

must be replaced.

Axial play of the crankshaft mm (in)

Standard 0.10 (0.004)

Limit 0.30 (0.012)

Note:

Measure the thrust clearance before dismounting.

015RY00002

2. Main bearing clearance

• Remove the crank case.

Set out disassembled main bearings in the order of the numbers.

• Remove the crankshaft. Remove the main

bearings.

• Clean the crankshaft journal and upper and

lower bearings.

• Check the bearings for damage or excessive

wear.

If you find damage or excessive wear, replace the bearings in pairs.

• Place the upper bearings and the crankshaft on

the cylinder block. Install the crankshaft so that

it is horizontal.

Note:

Turn the crankshaft about 30 degrees to allow the

bearings to settle in.

• Place plastigage on the crankshaft journal as

shown.

• Place the lower bearings at original positions on

the bearing cap.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1494 of 6020

6A-134 ENGINE MECHANICAL (4JK1/4JJ1)

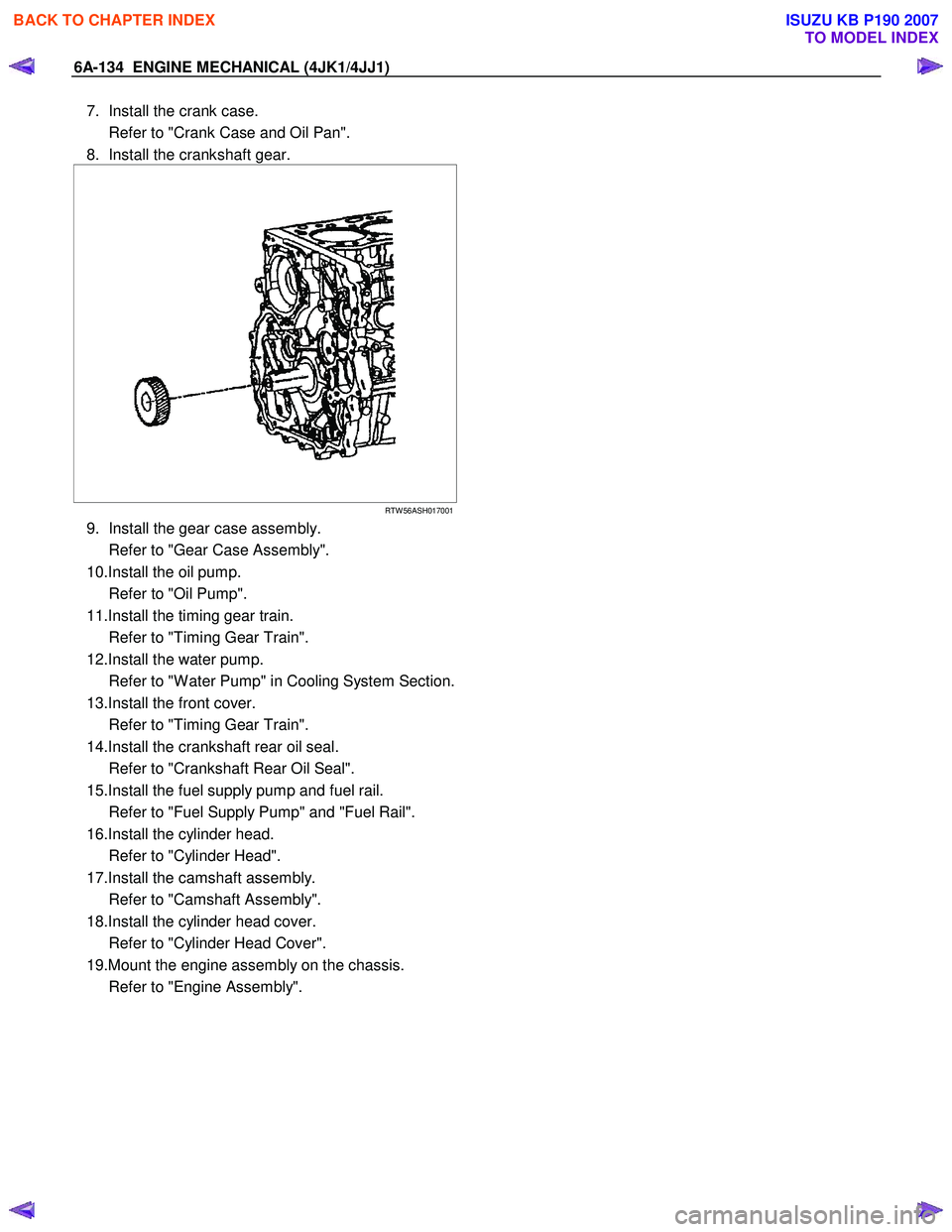

7. Install the crank case.

Refer to "Crank Case and Oil Pan".

8. Install the crankshaft gear.

RTW 56ASH017001

9. Install the gear case assembly.

Refer to "Gear Case Assembly".

10.Install the oil pump.

Refer to "Oil Pump".

11.Install the timing gear train.

Refer to "Timing Gear Train".

12.Install the water pump.

Refer to "W ater Pump" in Cooling System Section.

13.Install the front cover.

Refer to "Timing Gear Train".

14.Install the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

15.Install the fuel supply pump and fuel rail.

Refer to "Fuel Supply Pump" and "Fuel Rail".

16.Install the cylinder head.

Refer to "Cylinder Head".

17.Install the camshaft assembly.

Refer to "Camshaft Assembly".

18.Install the cylinder head cover.

Refer to "Cylinder Head Cover".

19.Mount the engine assembly on the chassis.

Refer to "Engine Assembly".

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1496 of 6020

6A-136 ENGINE MECHANICAL (4JK1/4JJ1)

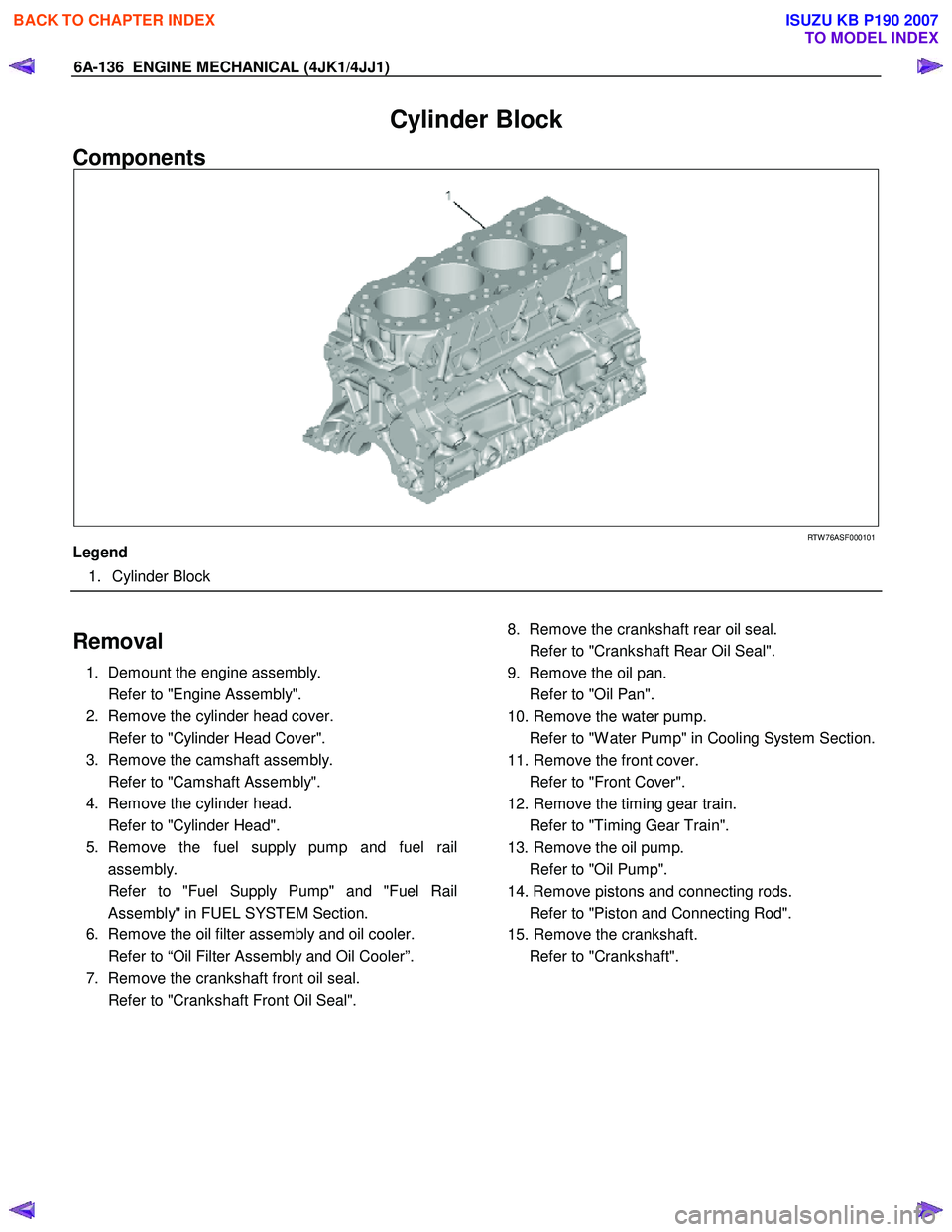

Cylinder Block

Components

RTW 76ASF000101

Legend

1. Cylinder Block

Removal

1. Demount the engine assembly.

Refer to "Engine Assembly".

2. Remove the cylinder head cover.

Refer to "Cylinder Head Cover".

3. Remove the camshaft assembly.

Refer to "Camshaft Assembly".

4. Remove the cylinder head.

Refer to "Cylinder Head".

5. Remove the fuel supply pump and fuel rail assembly.

Refer to "Fuel Supply Pump" and "Fuel Rail Assembly" in FUEL SYSTEM Section.

6. Remove the oil filter assembly and oil cooler.

Refer to “Oil Filter Assembly and Oil Cooler”.

7. Remove the crankshaft front oil seal.

Refer to "Crankshaft Front Oil Seal".

8. Remove the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

9. Remove the oil pan.

Refer to "Oil Pan".

10. Remove the water pump.

Refer to "W ater Pump" in Cooling System Section.

11. Remove the front cover.

Refer to "Front Cover".

12. Remove the timing gear train.

Refer to "Timing Gear Train".

13. Remove the oil pump.

Refer to "Oil Pump".

14. Remove pistons and connecting rods.

Refer to "Piston and Connecting Rod".

15. Remove the crankshaft.

Refer to "Crankshaft".

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1497 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-137

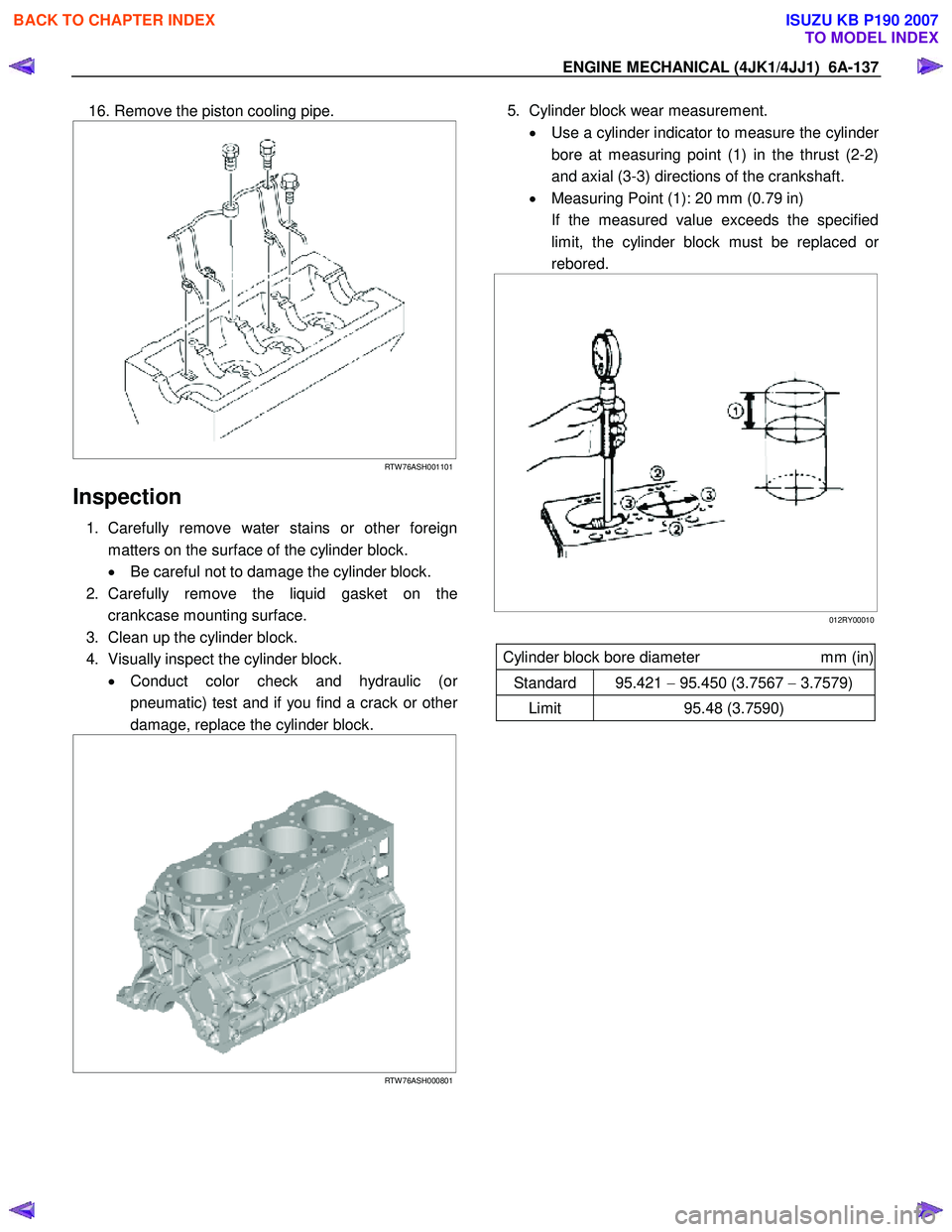

16. Remove the piston cooling pipe.

RTW 76ASH001101

Inspection

1. Carefully remove water stains or other foreign

matters on the surface of the cylinder block.

• Be careful not to damage the cylinder block.

2. Carefully remove the liquid gasket on the crankcase mounting surface.

3. Clean up the cylinder block.

4. Visually inspect the cylinder block. • Conduct color check and hydraulic (o

r

pneumatic) test and if you find a crack or other

damage, replace the cylinder block.

RTW 76ASH000801

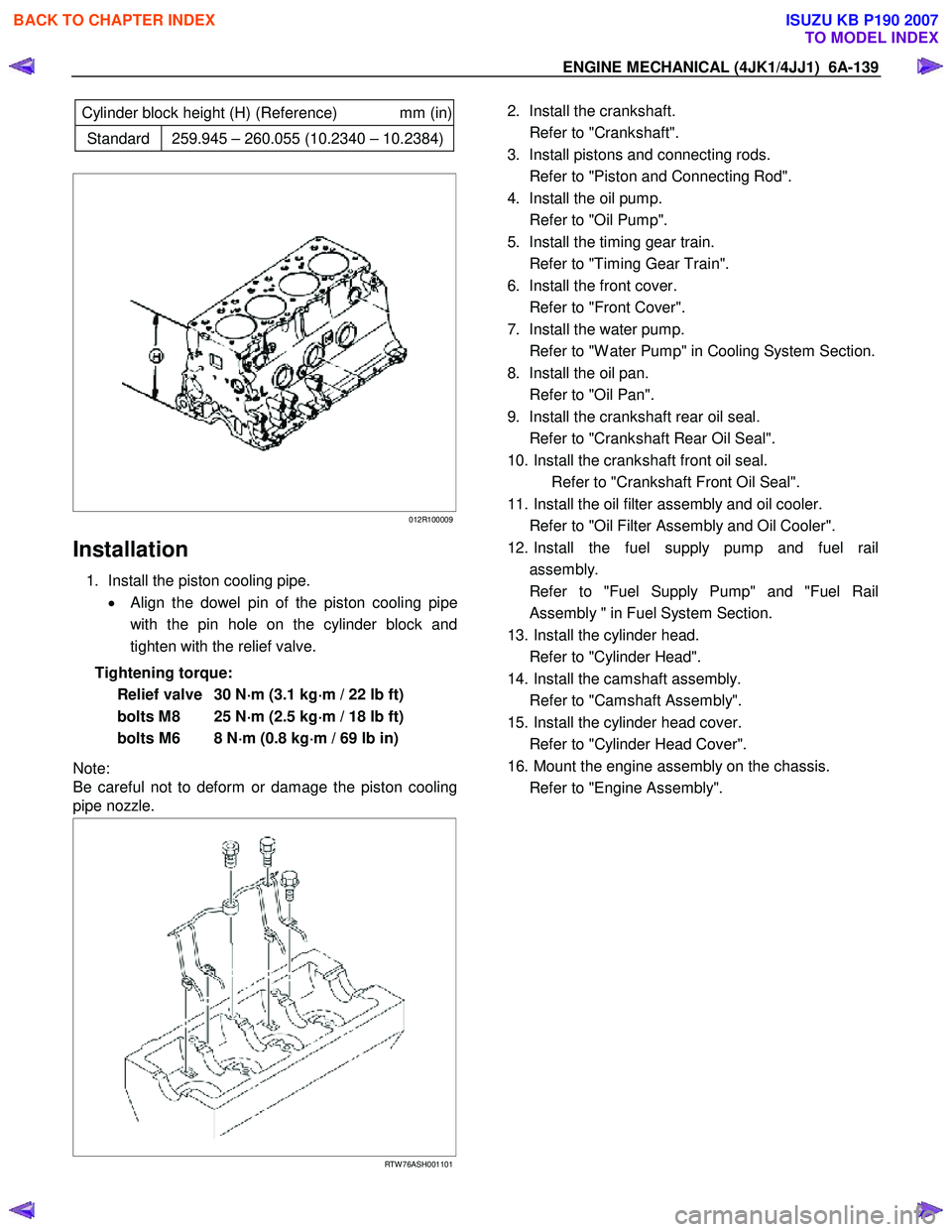

5. Cylinder block wear measurement.

• Use a cylinder indicator to measure the cylinde

r

bore at measuring point (1) in the thrust (2-2)

and axial (3-3) directions of the crankshaft.

• Measuring Point (1): 20 mm (0.79 in)

If the measured value exceeds the specified limit, the cylinder block must be replaced o

r

rebored.

012RY00010

Cylinder block bore diameter mm (in)

Standard 95.421 − 95.450 (3.7567 − 3.7579)

Limit 95.48 (3.7590)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1499 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-139

Cylinder block height (H) (Reference) mm (in)

Standard 259.945 – 260.055 (10.2340 – 10.2384)

012R100009

Installation

1. Install the piston cooling pipe.

• Align the dowel pin of the piston cooling pipe

with the pin hole on the cylinder block and

tighten with the relief valve.

Tightening torque: Relief valve 30 N ⋅

⋅⋅

⋅

m (3.1 kg ⋅

⋅⋅

⋅

m / 22 lb ft)

bolts M8 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

bolts M6 8 N ⋅

⋅⋅

⋅

m (0.8 kg ⋅

⋅⋅

⋅

m / 69 lb in)

Note:

Be careful not to deform or damage the piston cooling

pipe nozzle.

RTW 76ASH001101

2. Install the crankshaft.

Refer to "Crankshaft".

3. Install pistons and connecting rods.

Refer to "Piston and Connecting Rod".

4. Install the oil pump.

Refer to "Oil Pump".

5. Install the timing gear train.

Refer to "Timing Gear Train".

6. Install the front cover.

Refer to "Front Cover".

7. Install the water pump.

Refer to "W ater Pump" in Cooling System Section.

8. Install the oil pan.

Refer to "Oil Pan".

9. Install the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

10. Install the crankshaft front oil seal. Refer to "Crankshaft Front Oil Seal".

11. Install the oil filter assembly and oil cooler.

Refer to "Oil Filter Assembly and Oil Cooler".

12. Install the fuel supply pump and fuel rail assembly.

Refer to "Fuel Supply Pump" and "Fuel Rail Assembly " in Fuel System Section.

13. Install the cylinder head.

Refer to "Cylinder Head".

14. Install the camshaft assembly.

Refer to "Camshaft Assembly".

15. Install the cylinder head cover.

Refer to "Cylinder Head Cover".

16. Mount the engine assembly on the chassis.

Refer to "Engine Assembly".

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1506 of 6020

6A-146 ENGINE MECHANICAL (4JK1/4JJ1)

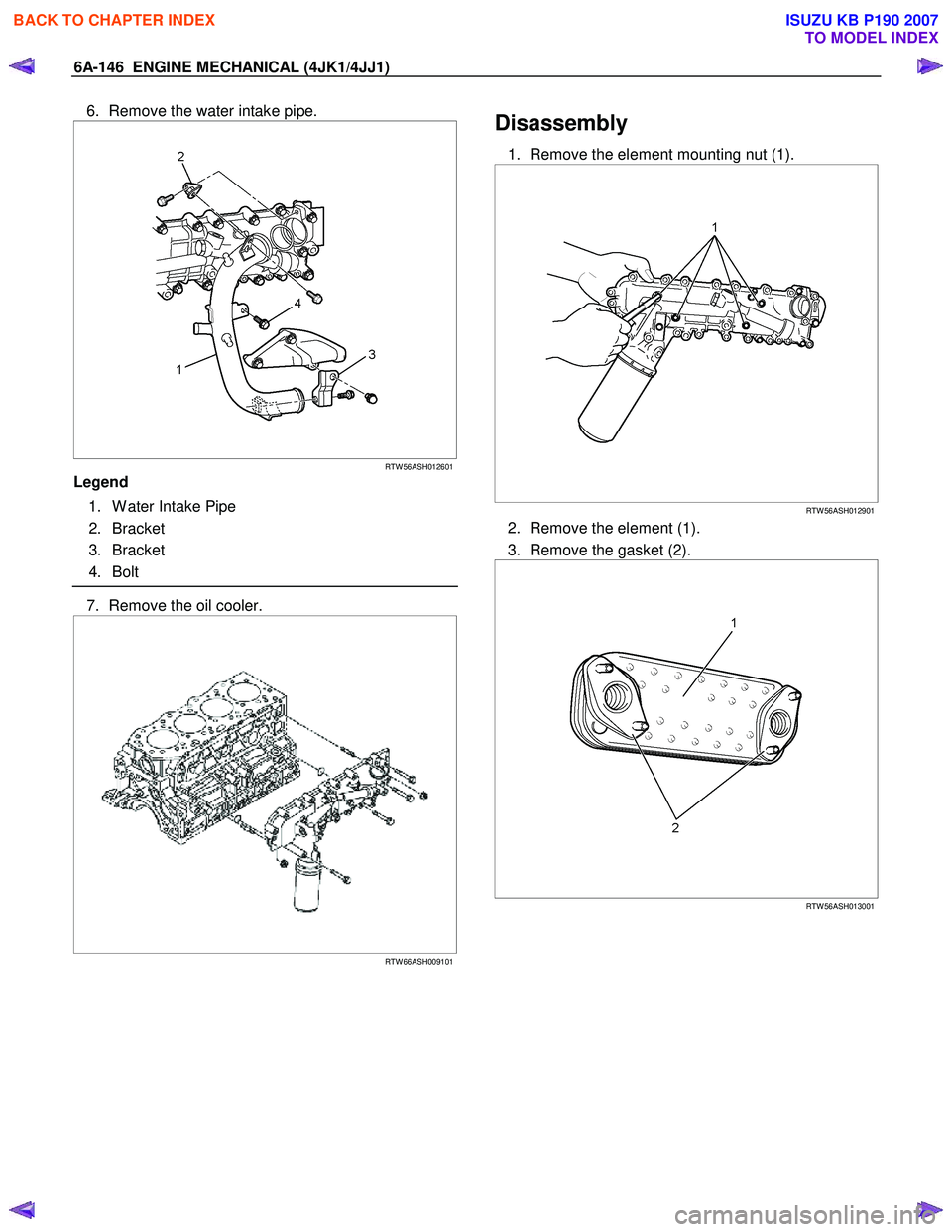

6. Remove the water intake pipe.

RTW 56ASH012601

Legend

1. W ater Intake Pipe

2. Bracket

3. Bracket

4. Bolt

7. Remove the oil cooler.

RTW 66ASH009101

Disassembly

1. Remove the element mounting nut (1).

RTW 56ASH012901

2. Remove the element (1).

3. Remove the gasket (2).

RTW 56ASH013001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1507 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-147

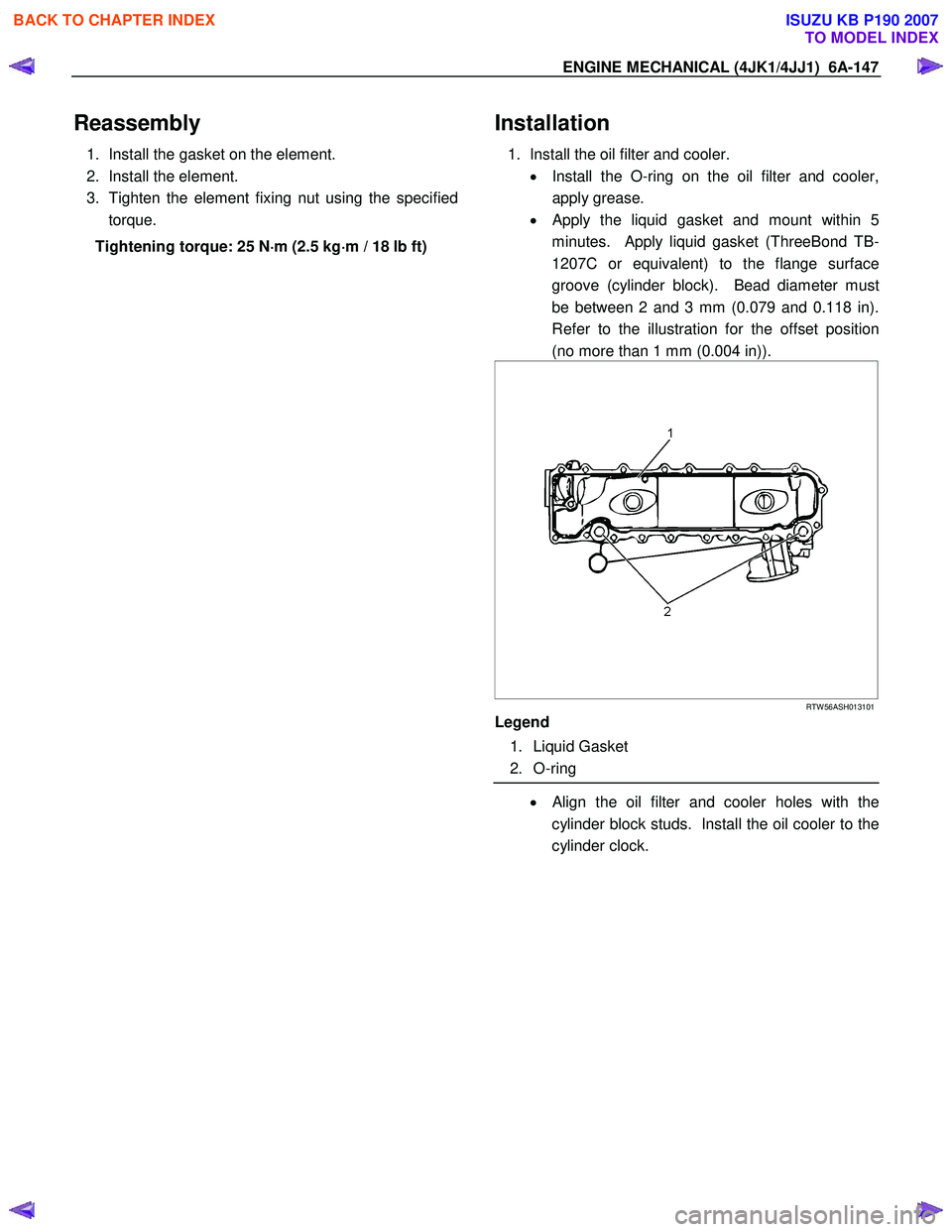

Reassembly

1. Install the gasket on the element.

2. Install the element.

3. Tighten the element fixing nut using the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

Installation

1. Install the oil filter and cooler.

• Install the O-ring on the oil filter and cooler,

apply grease.

•

Apply the liquid gasket and mount within 5

minutes. Apply liquid gasket (ThreeBond TB-

1207C or equivalent) to the flange surface

groove (cylinder block). Bead diameter must

be between 2 and 3 mm (0.079 and 0.118 in).

Refer to the illustration for the offset position

(no more than 1 mm (0.004 in)).

RTW 56ASH013101

Legend

1. Liquid Gasket

2. O-ring

• Align the oil filter and cooler holes with the

cylinder block studs. Install the oil cooler to the

cylinder clock.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1513 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-153

Installation

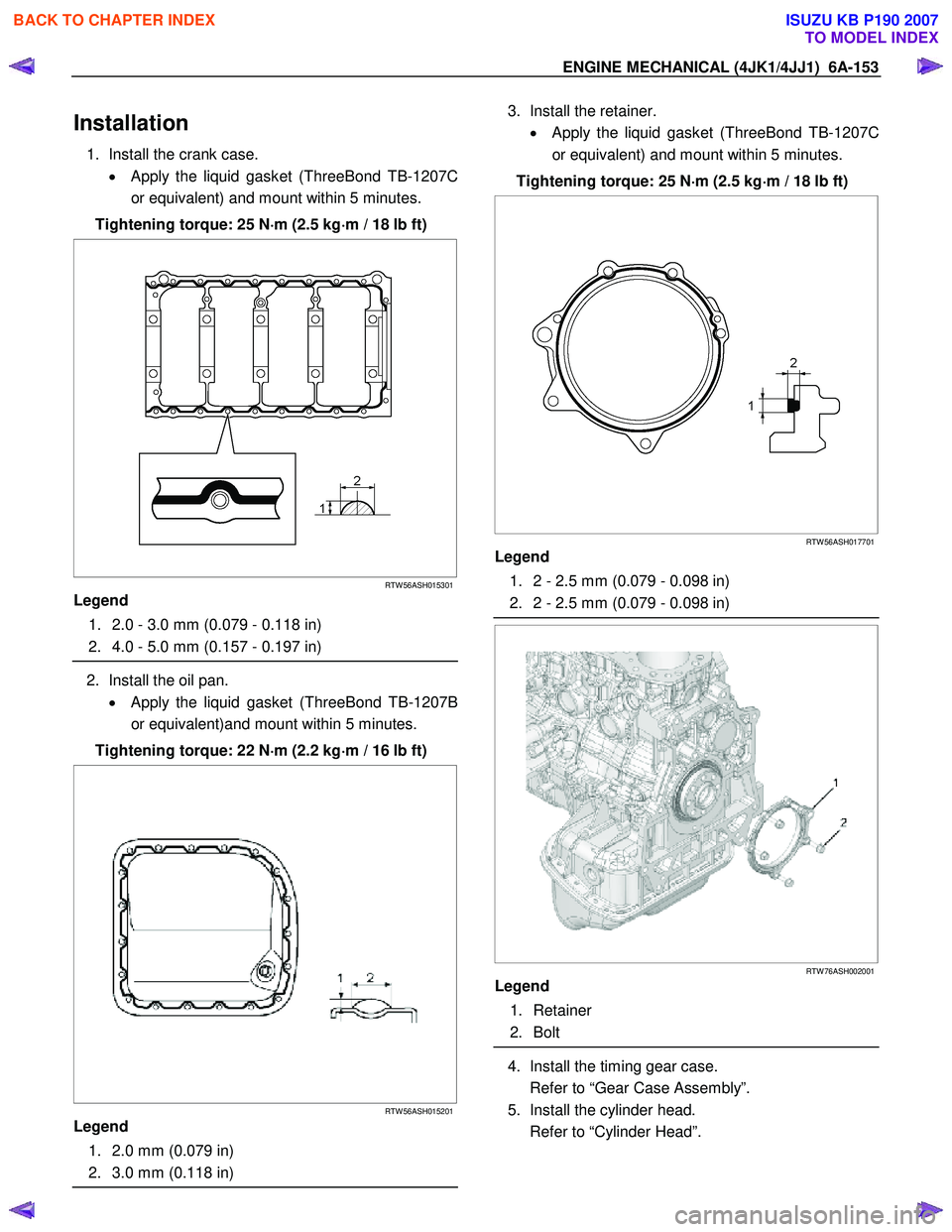

1. Install the crank case.

• Apply the liquid gasket (ThreeBond TB-1207C

or equivalent) and mount within 5 minutes.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

RTW 56ASH015301

Legend

1. 2.0 - 3.0 mm (0.079 - 0.118 in)

2. 4.0 - 5.0 mm (0.157 - 0.197 in)

2. Install the oil pan.

• Apply the liquid gasket (ThreeBond TB-1207B

or equivalent)and mount within 5 minutes.

Tightening torque: 22 N ⋅

⋅⋅

⋅

m (2.2 kg ⋅

⋅⋅

⋅

m / 16 lb ft)

RTW 56ASH015201

Legend

1. 2.0 mm (0.079 in)

2. 3.0 mm (0.118 in)

3. Install the retainer.

• Apply the liquid gasket (ThreeBond TB-1207C

or equivalent) and mount within 5 minutes.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

RTW 56ASH017701

Legend

1. 2 - 2.5 mm (0.079 - 0.098 in)

2. 2 - 2.5 mm (0.079 - 0.098 in)

RTW 76ASH002001

Legend

1. Retainer

2. Bolt

4. Install the timing gear case.

Refer to “Gear Case Assembly”.

5. Install the cylinder head.

Refer to “Cylinder Head”.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1519 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-159

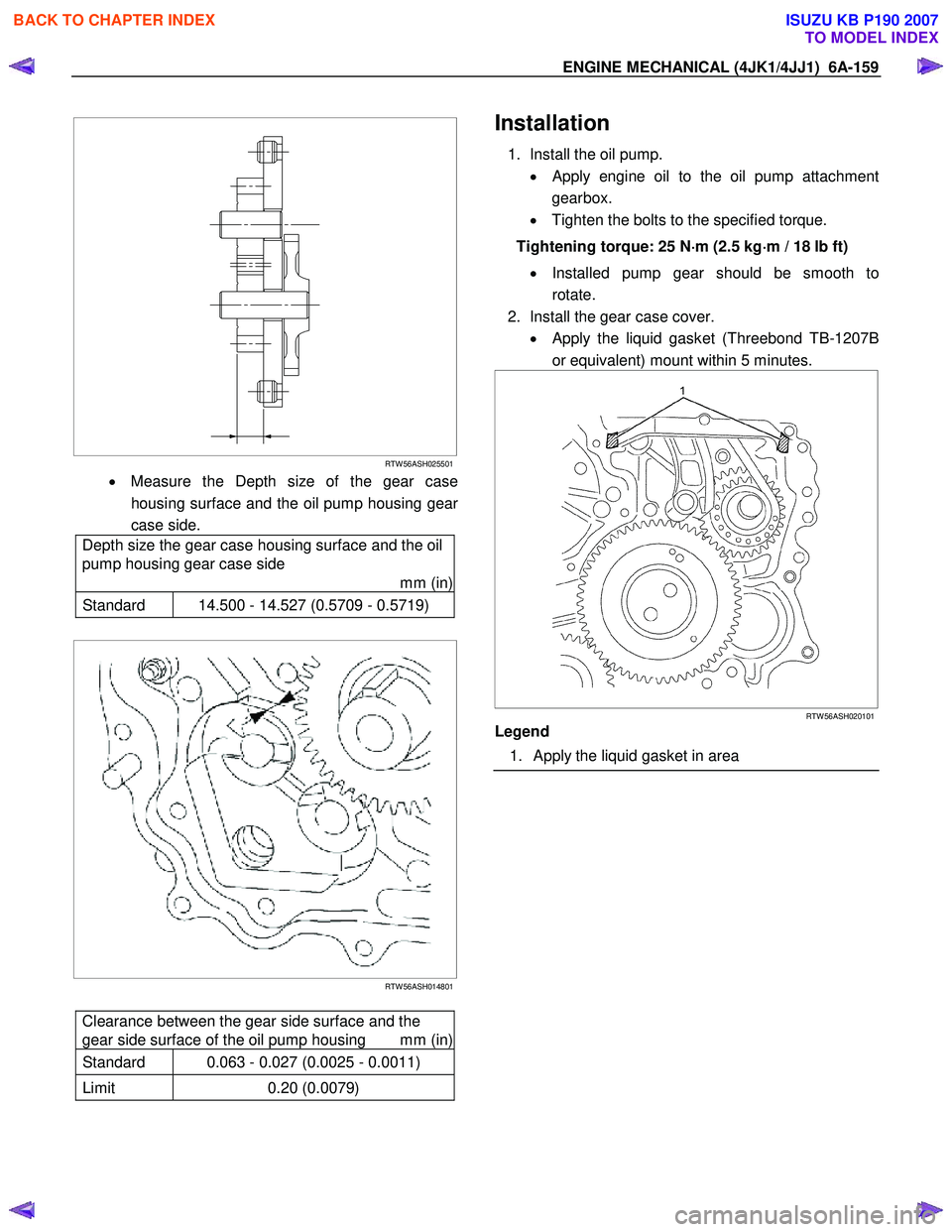

RTW 56ASH025501

• Measure the Depth size of the gear case

housing surface and the oil pump housing gea

r

case side.

Depth size the gear case housing surface and the oil

pump housing gear case side

mm (in)

Standard 14.500 - 14.527 (0.5709 - 0.5719)

RTW 56ASH014801

Clearance between the gear side surface and the

gear side surface of the oil pump housing mm (in)

Standard 0.063 - 0.027 (0.0025 - 0.0011)

Limit 0.20 (0.0079)

Installation

1. Install the oil pump.

•

Apply engine oil to the oil pump attachment

gearbox.

• Tighten the bolts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

• Installed pump gear should be smooth to

rotate.

2. Install the gear case cover. • Apply the liquid gasket (Threebond TB-1207B

or equivalent) mount within 5 minutes.

RTW 56ASH020101

Legend

1. Apply the liquid gasket in area

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007