lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4646 of 6020

7B1-40 MANUAL TRANSMISSION

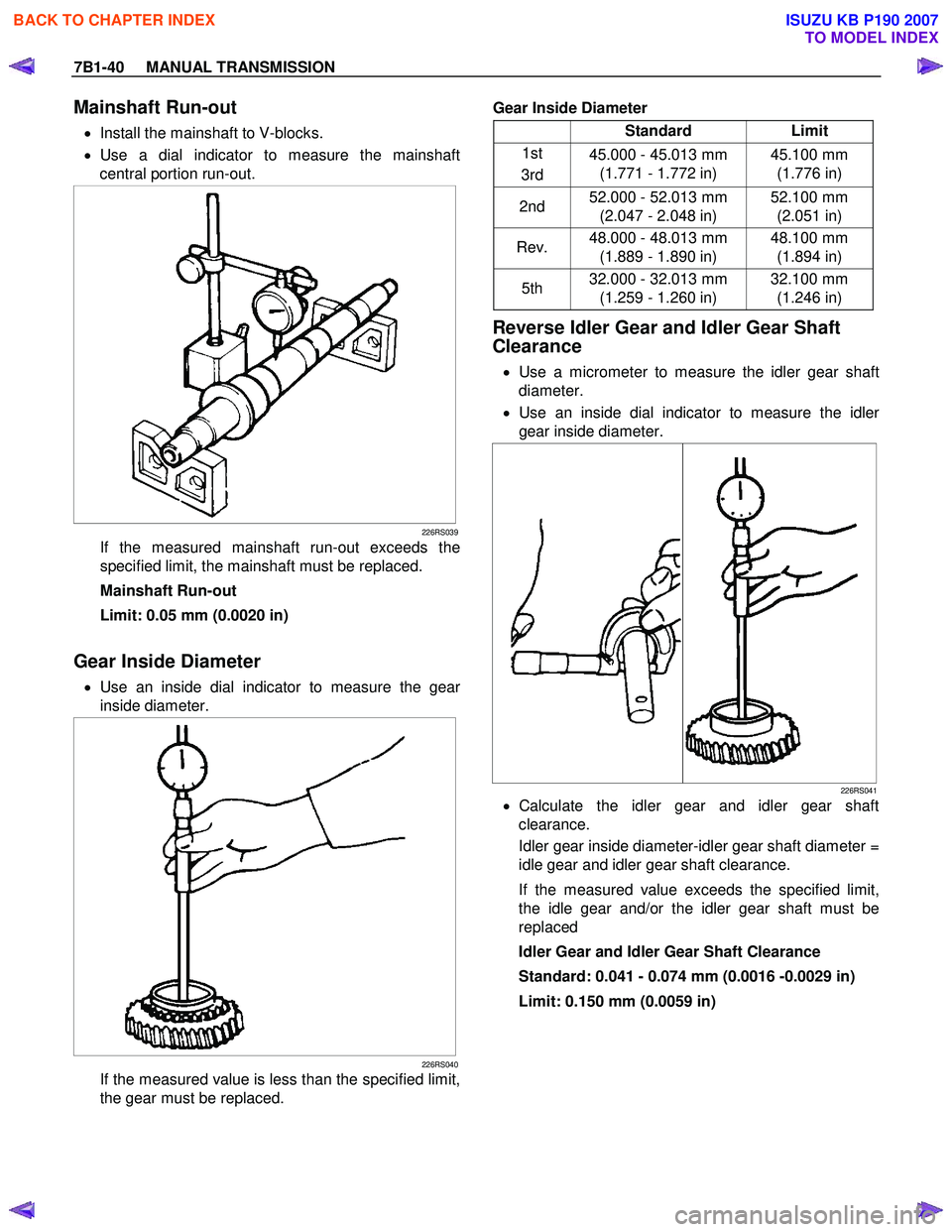

Mainshaft Run-out

• Install the mainshaft to V-blocks.

• Use a dial indicator to measure the mainshaft

central portion run-out.

226RS039

If the measured mainshaft run-out exceeds the

specified limit, the mainshaft must be replaced.

Mainshaft Run-out

Limit: 0.05 mm (0.0020 in)

Gear Inside Diameter

• Use an inside dial indicator to measure the gear

inside diameter.

226RS040

If the measured value is less than the specified limit,

the gear must be replaced.

Gear Inside Diameter

Standard Limit

1st

3rd 45.000 - 45.013 mm

(1.771 - 1.772 in) 45.100 mm

(1.776 in)

2nd 52.000 - 52.013 mm

(2.047 - 2.048 in) 52.100 mm

(2.051 in)

Rev. 48.000 - 48.013 mm

(1.889 - 1.890 in) 48.100 mm

(1.894 in)

5th 32.000 - 32.013 mm

(1.259 - 1.260 in) 32.100 mm

(1.246 in)

Reverse Idler Gear and Idler Gear Shaft

Clearance

• Use a micrometer to measure the idler gear shaft

diameter.

• Use an inside dial indicator to measure the idle

r

gear inside diameter.

226RS041

• Calculate the idler gear and idler gear shaft

clearance.

Idler gear inside diameter-idler gear shaft diameter =

idle gear and idler gear shaft clearance.

If the measured value exceeds the specified limit,

the idle gear and/or the idler gear shaft must be

replaced

Idler Gear and Idler Gear Shaft Clearance

Standard: 0.041 - 0.074 mm (0.0016 -0.0029 in)

Limit: 0.150 mm (0.0059 in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4648 of 6020

7B1-42 MANUAL TRANSMISSION

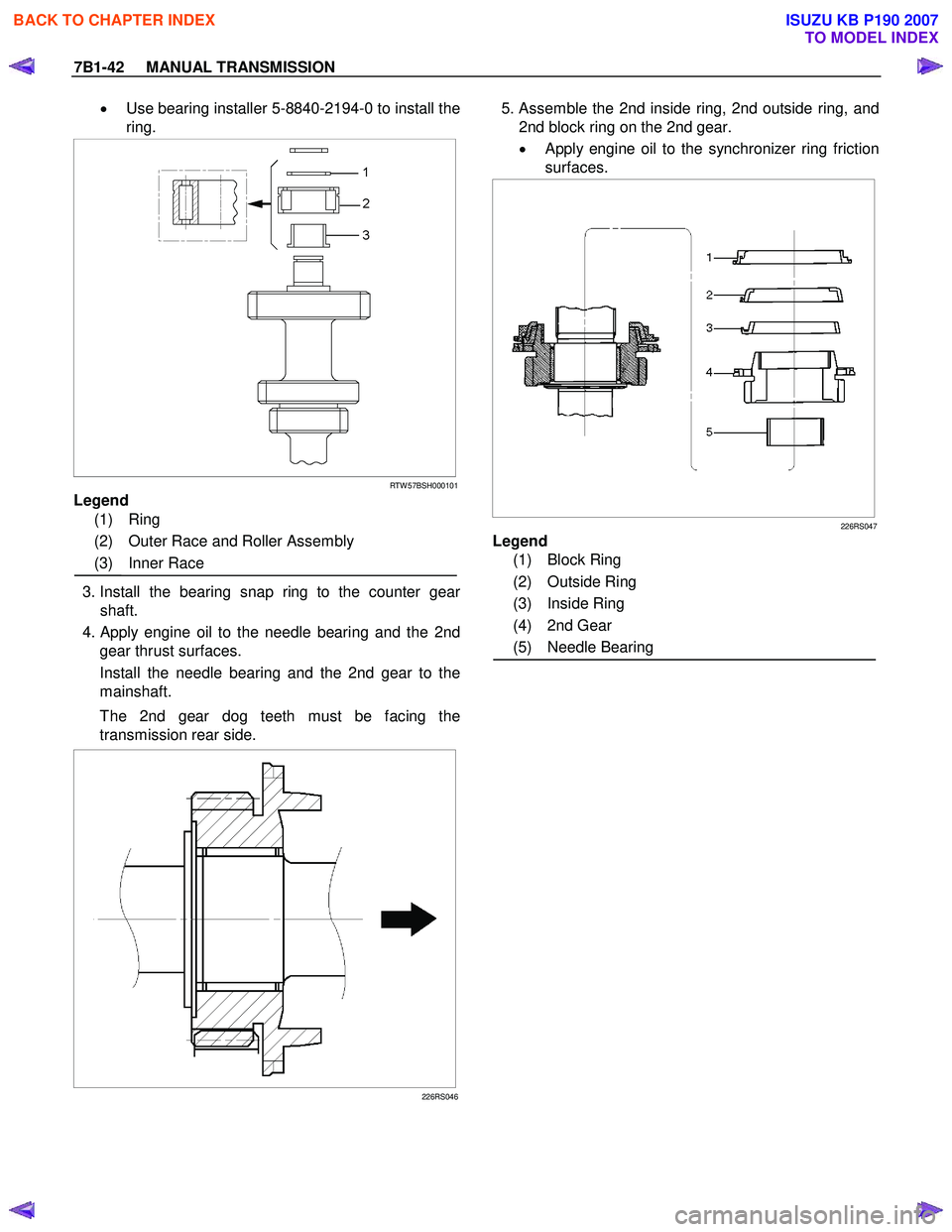

• Use bearing installer 5-8840-2194-0 to install the

ring.

RTW 57BSH000101

Legend

(1) Ring

(2) Outer Race and Roller Assembly

(3) Inner Race

3. Install the bearing snap ring to the counter gear

shaft.

4.

Apply engine oil to the needle bearing and the 2nd

gear thrust surfaces.

Install the needle bearing and the 2nd gear to the

mainshaft.

The 2nd gear dog teeth must be facing the

transmission rear side.

226RS046

5. Assemble the 2nd inside ring, 2nd outside ring, and

2nd block ring on the 2nd gear.

•

Apply engine oil to the synchronizer ring friction

surfaces.

226RS047

Legend

(1) Block Ring

(2) Outside Ring

(3) Inside Ring

(4) 2nd Gear

(5) Needle Bearing

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4650 of 6020

7B1-44 MANUAL TRANSMISSION

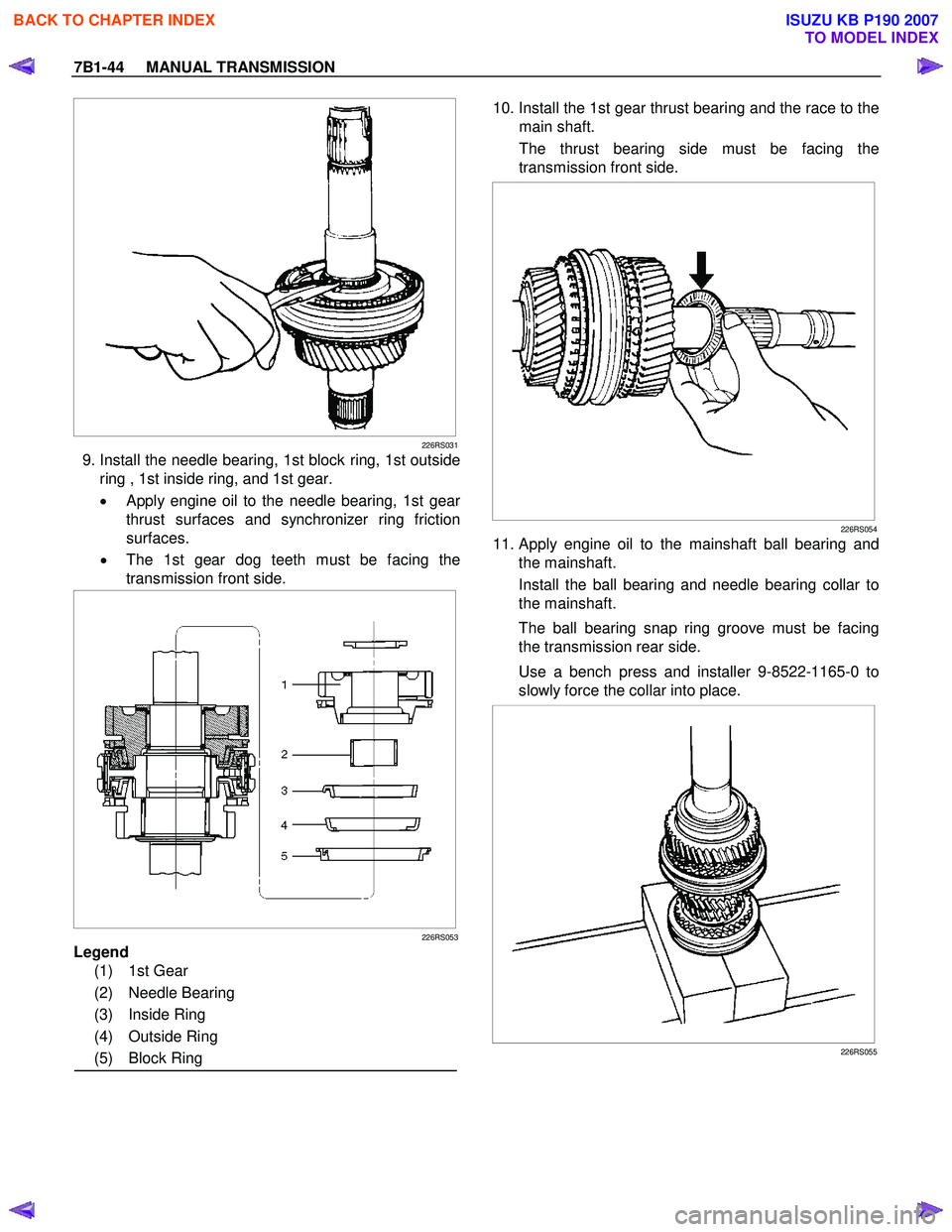

226RS031

9. Install the needle bearing, 1st block ring, 1st outside

ring , 1st inside ring, and 1st gear.

•

Apply engine oil to the needle bearing, 1st gear

thrust surfaces and synchronizer ring friction

surfaces.

• The 1st gear dog teeth must be facing the

transmission front side.

226RS053

Legend

(1) 1st Gear

(2) Needle Bearing

(3) Inside Ring

(4) Outside Ring

(5) Block Ring

10. Install the 1st gear thrust bearing and the race to the

main shaft.

The thrust bearing side must be facing the

transmission front side.

226RS054

11. Apply engine oil to the mainshaft ball bearing and the mainshaft.

Install the ball bearing and needle bearing collar to

the mainshaft.

The ball bearing snap ring groove must be facing

the transmission rear side.

Use a bench press and installer 9-8522-1165-0 to

slowly force the collar into place.

226RS055

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4651 of 6020

MANUAL TRANSMISSION 7B1-45

12. Apply engine oil to the needle bearing and the 3rd

gear thrust surfaces.

Install the needle bearing and the 3rd gear to the

mainshaft.

The 3rd gear dog teeth must be facing the

transmission front side.

226RS056

13. Install the 3rd block ring.

14. Check and install the 3rd-4th synchronizer assembl

y

using the following steps:

1. Check that the inserts (3) fit snugly into the clutch hub insert grooves.

2. Check that the insert springs (4) are fitted to the inserts, as shown in the illustration.

3. Check that the clutch hub (5) and the sleeve (6) slide smoothly.

4. Install the synchronizer assembly to the mainshaft.

The clutch hub face with the heavy boss must be facing the 3rd gear side.

226RS049

226RW 221

15. Select and install mainshaft snap ring using the

following instructions:

Select the snap ring which will provide the minimum

clearance between the 3rd-4th clutch hub and the

snap ring.

226RS058

There are three snap ring sizes available.

The snap rings are color-coded to indicate thei

r

thickness as shown in the figure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4652 of 6020

7B1-46 MANUAL TRANSMISSION

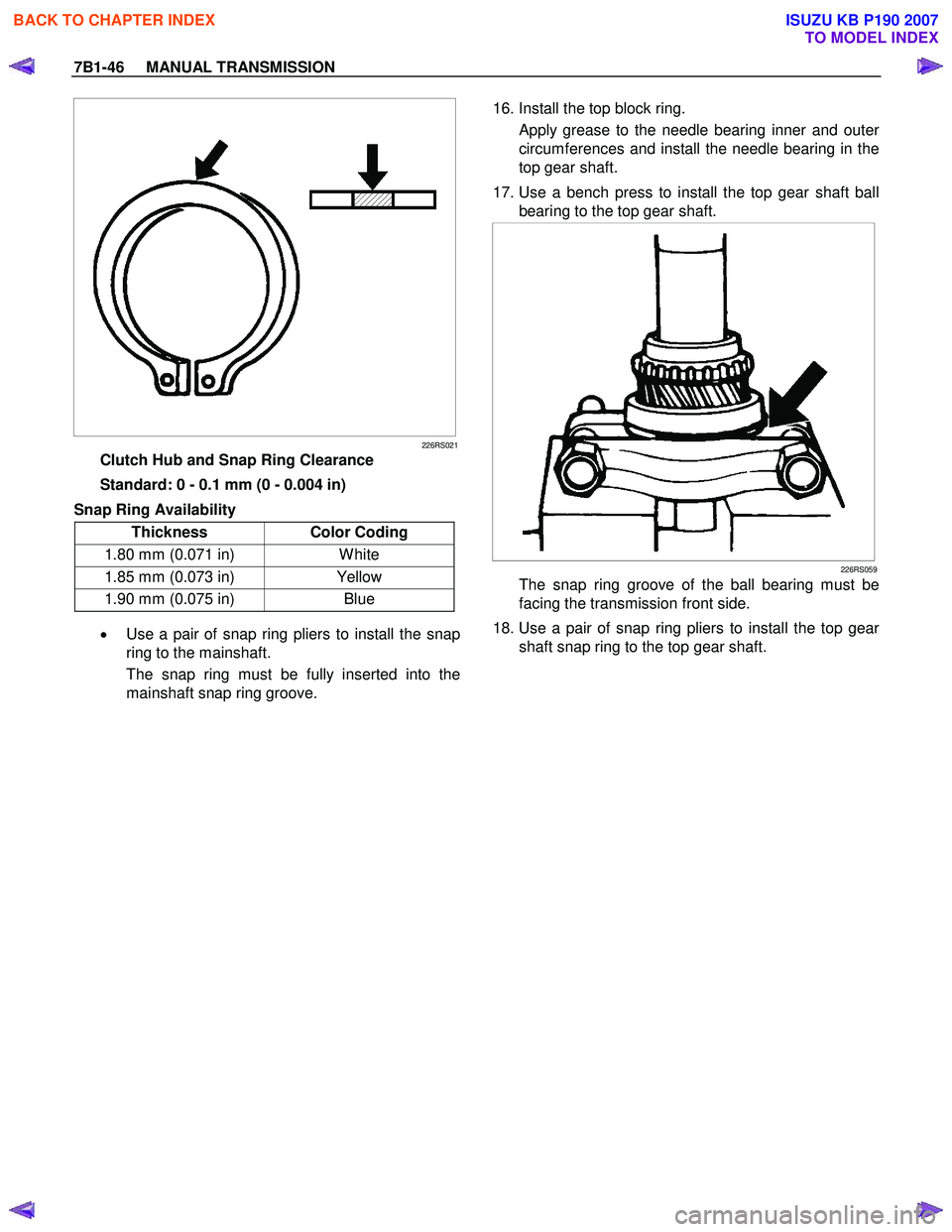

226RS021

Clutch Hub and Snap Ring Clearance

Standard: 0 - 0.1 mm (0 - 0.004 in)

Snap Ring Availability

Thickness Color Coding

1.80 mm (0.071 in) W hite

1.85 mm (0.073 in) Yellow

1.90 mm (0.075 in) Blue

• Use a pair of snap ring pliers to install the snap

ring to the mainshaft.

The snap ring must be fully inserted into the

mainshaft snap ring groove.

16. Install the top block ring.

Apply grease to the needle bearing inner and oute

r

circumferences and install the needle bearing in the

top gear shaft.

17. Use a bench press to install the top gear shaft ball bearing to the top gear shaft.

226RS059

The snap ring groove of the ball bearing must be

facing the transmission front side.

18. Use a pair of snap ring pliers to install the top gea

r

shaft snap ring to the top gear shaft.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4659 of 6020

MANUAL TRANSMISSION 7B1-53

2. HARD SHIFTING

Checkpoint Trouble Cause Countermeasure

Change lever play

Clutch pedal free play

Repair or replace the

applicable parts and regrease

Readjust the clutch pedal free

play

W orn change lever sliding

portions

Improper clutch pedal free

play

Change lever operationRepair or regrease the change

lever assembly

Replenish or replace the

engine oil

Hard operating change lever

caused insufficient grease

Insufficient or improper gear

oil

OK

OK NG

NG

NG

NG

OK

OKGear oil

Continued on the next page

Shift rod and quadrant box

sliding faces, and other partsReplace the shidt rod and/or

the quadrant boxW orn shift rod and/or sliding

faces

Repair or replace the sleeveSleeve movement failure

NG

NG

OKShift block sleeve movement

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4665 of 6020

MANUAL TRANSMISSION 7B1-59

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLE MENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNECESSARY SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require a

replacement after removal. ISUZU/GM will also call

out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4681 of 6020

MANUAL TRANSMISSION 7B1-75

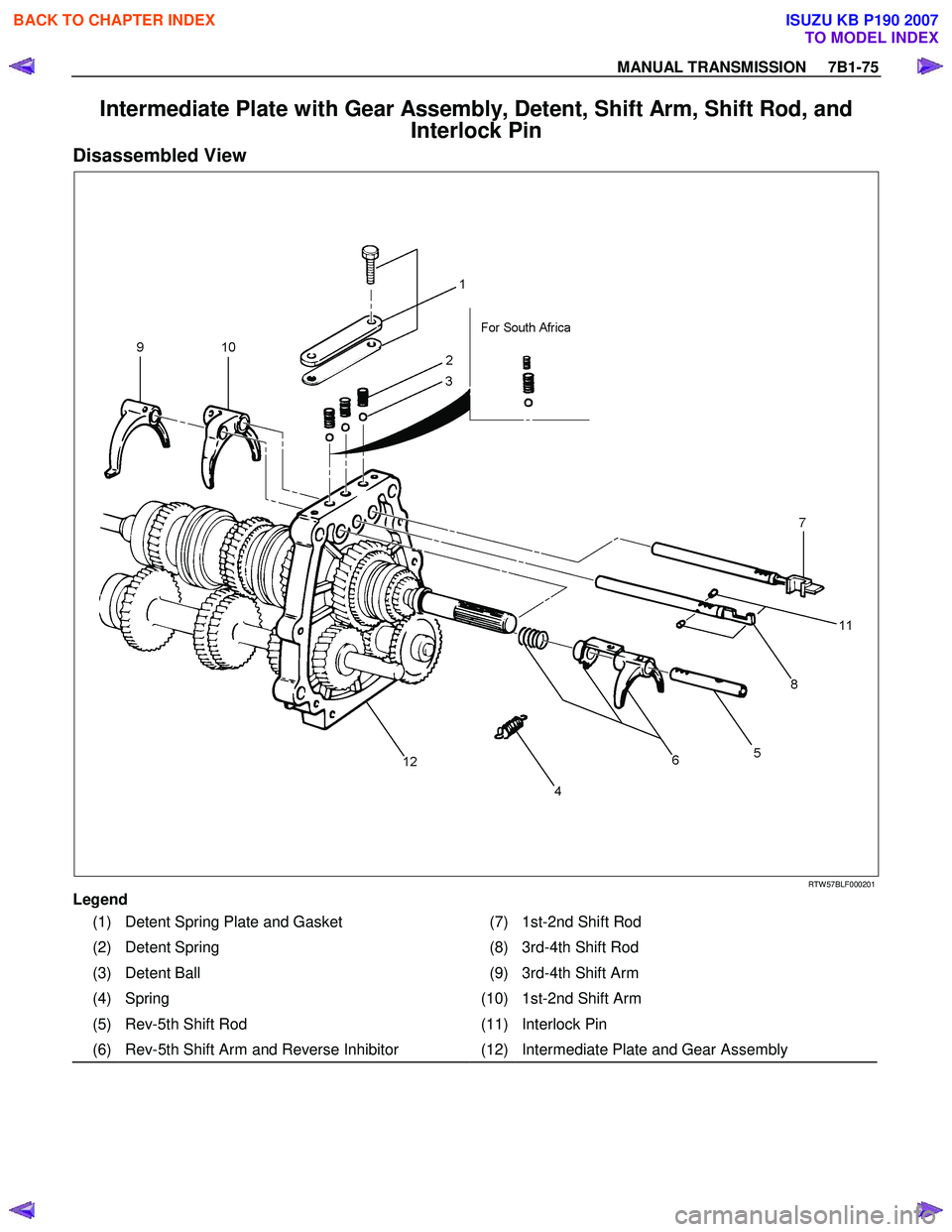

Intermediate Plate with Gear Assembly, Detent, Shift Arm, Shift Rod, and

Interlock Pin

Disassembled View

RTW 57BLF000201

Legend

(1) Detent Spring Plate and Gasket (7) 1st-2nd Shift Rod

(2) Detent Spring (8) 3rd-4th Shift Rod

(3) Detent Ball (9) 3rd-4th Shift Arm

(4) Spring (10) 1st-2nd Shift Arm

(5) Rev-5th Shift Rod (11) Interlock Pin

(6) Rev-5th Shift Arm and Reverse Inhibitor (12) Intermediate Plate and Gear Assembly

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4682 of 6020

7B1-76 MANUAL TRANSMISSION

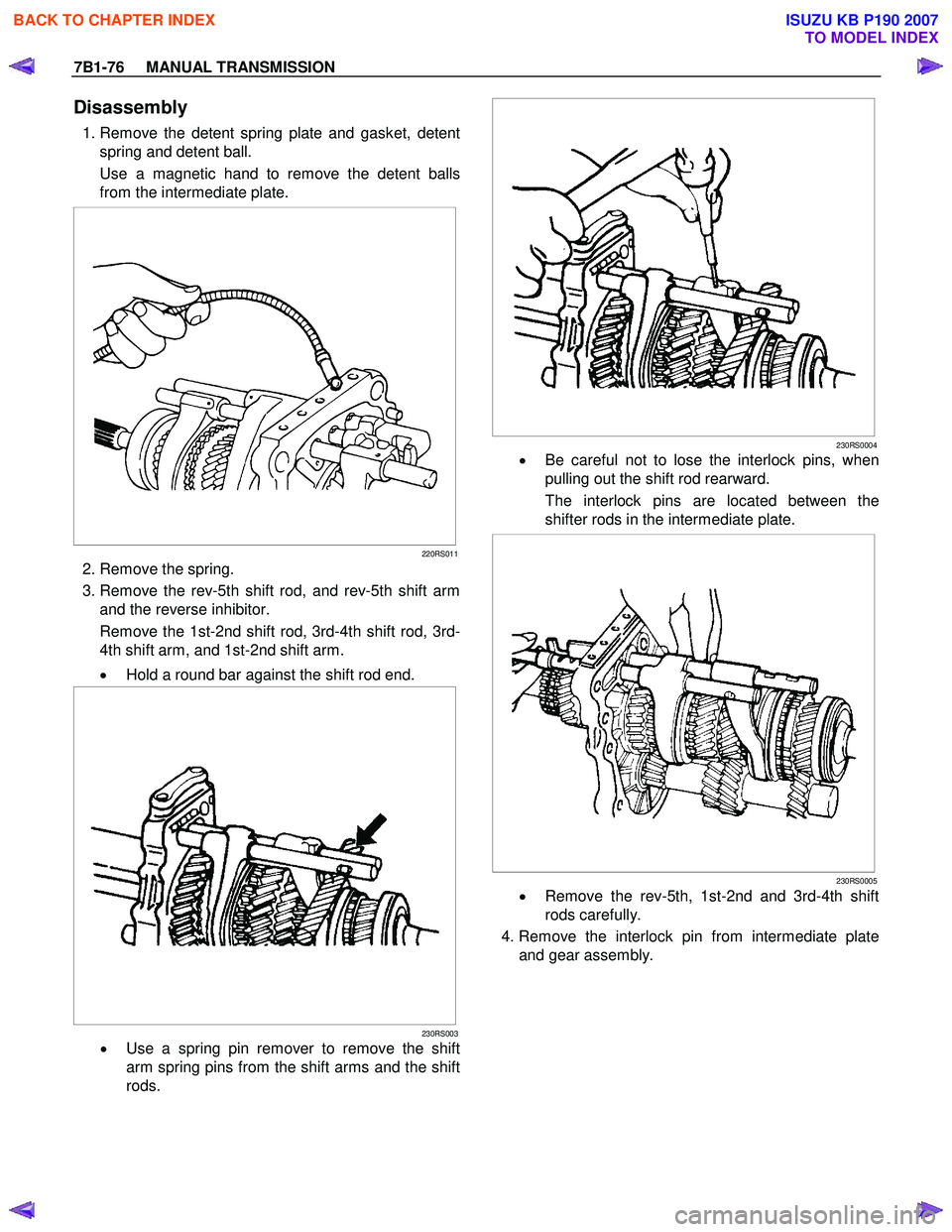

Disassembly

1. Remove the detent spring plate and gasket, detent

spring and detent ball.

Use a magnetic hand to remove the detent balls

from the intermediate plate.

220RS011

2. Remove the spring.

3. Remove the rev-5th shift rod, and rev-5th shift arm and the reverse inhibitor.

Remove the 1st-2nd shift rod, 3rd-4th shift rod, 3rd-

4th shift arm, and 1st-2nd shift arm.

• Hold a round bar against the shift rod end.

230RS003

• Use a spring pin remover to remove the shift

arm spring pins from the shift arms and the shift

rods.

230RS0004

•

Be careful not to lose the interlock pins, when

pulling out the shift rod rearward.

The interlock pins are located between the

shifter rods in the intermediate plate.

230RS0005

• Remove the rev-5th, 1st-2nd and 3rd-4th shift

rods carefully.

4. Remove the interlock pin from intermediate plate and gear assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4684 of 6020

7B1-78 MANUAL TRANSMISSION

Reassembly

1. Install the rev-5th shift arm and reverse inhibitor and

rev-5th shift rod.

• Apply oil to the reverse inhibitor inner surface.

• Install the shift rod in the intermediate plate.

• Hold a round bar against the shift rod end lowe

r

face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

• Install the interlock pin in the intermediate plate.

Do not allow the interlock pin to fall from the

intermediate plate.

2. Install the 1st-2nd shift arm and 3rd-4th shift arm to the intermediate plate and gear assembly.

3. Install the 3rd-4th shift rod and the 1st-2nd shift rod. • Install the interlock pin in the intermediate plate

and gear assembly.

• Install the 3rd-4th shift rod in the intermediate

plate.

Do not allow the interlock pin to fall from the

intermediate plate.

• Install the interlock pin and then the 1st-2nd shift

rod in the intermediate plate.

Do not allow the interlock pin to fall from the

intermediate plate.

• Hold a round bar against the shift rod end lowe

r

face to protect it against damage.

• Install a new spring pin.

Never reinstall the used spring pin.

230RS007

4. Install the spring.

5. Put the detent balls in the intermediate plate holes.• Apply oil to the detent balls.

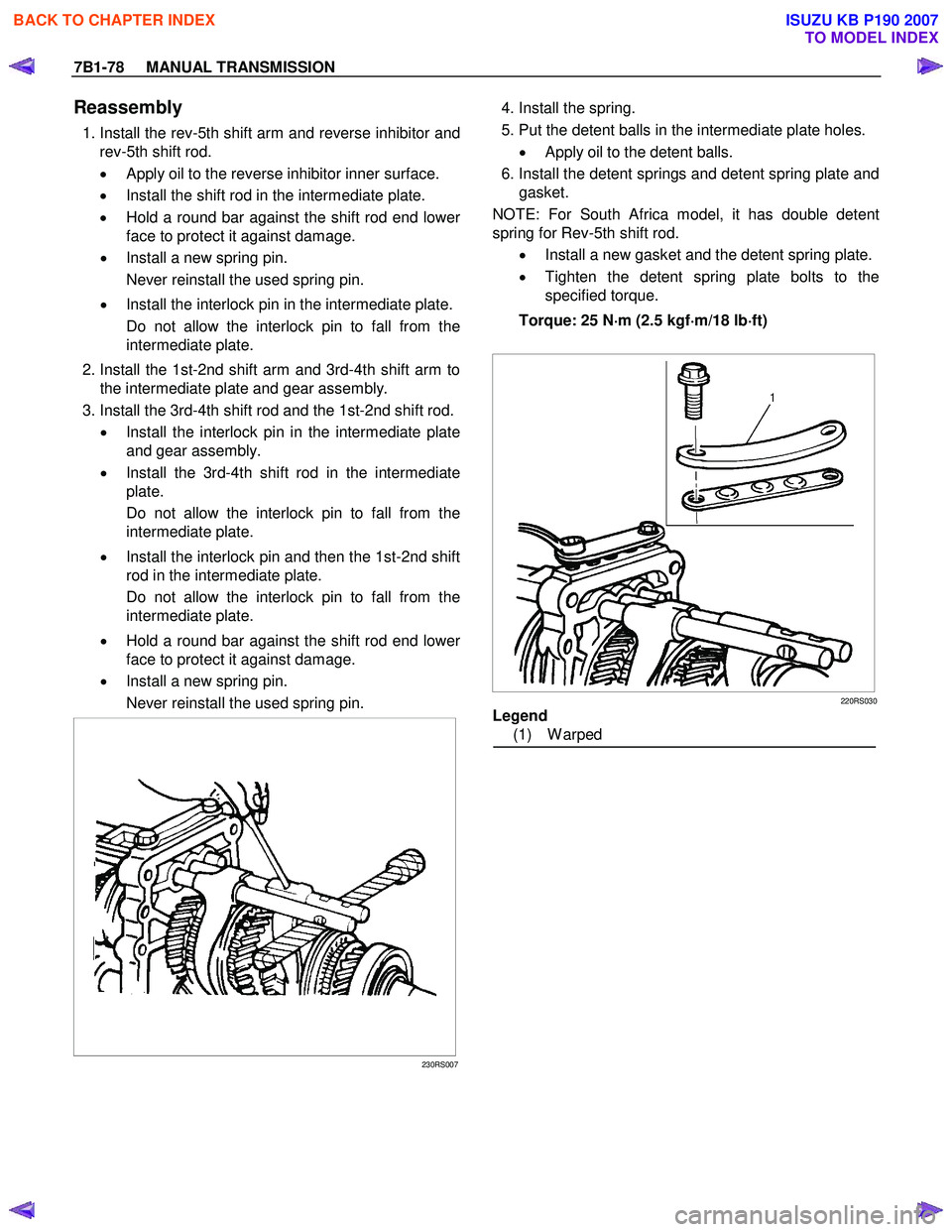

6. Install the detent springs and detent spring plate and gasket.

NOTE: For South Africa model, it has double detent

spring for Rev-5th shift rod.

• Install a new gasket and the detent spring plate.

• Tighten the detent spring plate bolts to the

specified torque.

Torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kgf ⋅

⋅⋅

⋅

m/18 lb ⋅

⋅⋅

⋅

ft)

220RS030

Legend

(1) W arped

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007