vacuum ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 68 of 6020

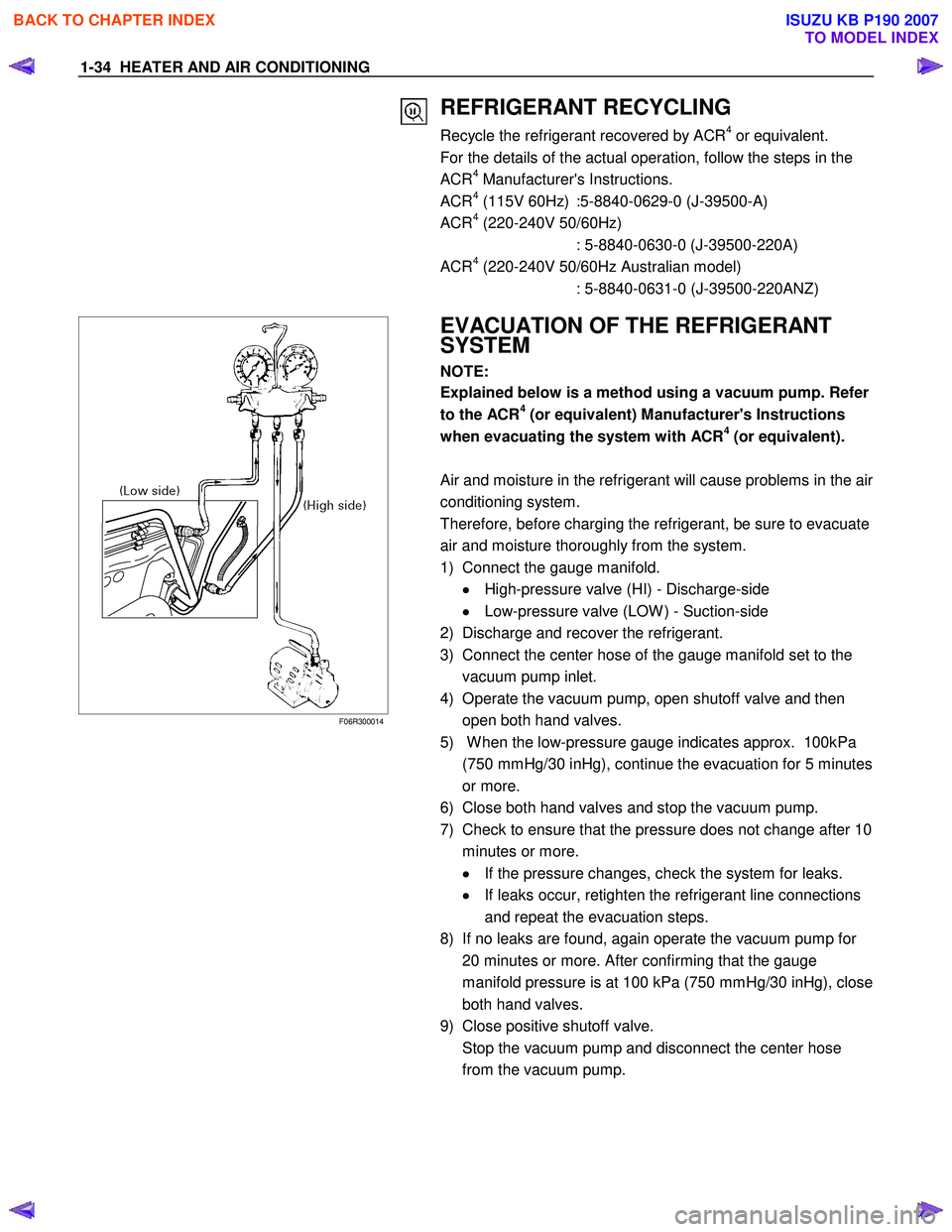

1-34 HEATER AND AIR CONDITIONING

REFRIGERANT RECYCLING

Recycle the refrigerant recovered by ACR4 or equivalent.

For the details of the actual operation, follow the steps in the

ACR

4 Manufacturer's Instructions.

ACR4 (115V 60Hz) :5-8840-0629-0 (J-39500-A)

ACR4 (220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

F06R300014

EVACUATION OF THE REFRIGERANT

SYSTEM

NOTE:

Explained below is a method using a vacuum pump. Refer

to the ACR

4 (or equivalent) Manufacturer's Instructions

when evacuating the system with ACR4 (or equivalent).

Air and moisture in the refrigerant will cause problems in the air

conditioning system.

Therefore, before charging the refrigerant, be sure to evacuate

air and moisture thoroughly from the system.

1) Connect the gauge manifold. •

••

•

High-pressure valve (HI) - Discharge-side

•

••

•

Low-pressure valve (LOW ) - Suction-side

2) Discharge and recover the refrigerant.

3) Connect the center hose of the gauge manifold set to the vacuum pump inlet.

4) Operate the vacuum pump, open shutoff valve and then open both hand valves.

5) W hen the low-pressure gauge indicates approx. 100kPa (750 mmHg/30 inHg), continue the evacuation for 5 minutes

or more.

6) Close both hand valves and stop the vacuum pump.

7) Check to ensure that the pressure does not change after 10

minutes or more. •

••

•

If the pressure changes, check the system for leaks.

•

••

•

If leaks occur, retighten the refrigerant line connections

and repeat the evacuation steps.

8) If no leaks are found, again operate the vacuum pump for 20 minutes or more. After confirming that the gauge

manifold pressure is at 100 kPa (750 mmHg/30 inHg), close

both hand valves.

9) Close positive shutoff valve.

Stop the vacuum pump and disconnect the center hose from the vacuum pump.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 125 of 6020

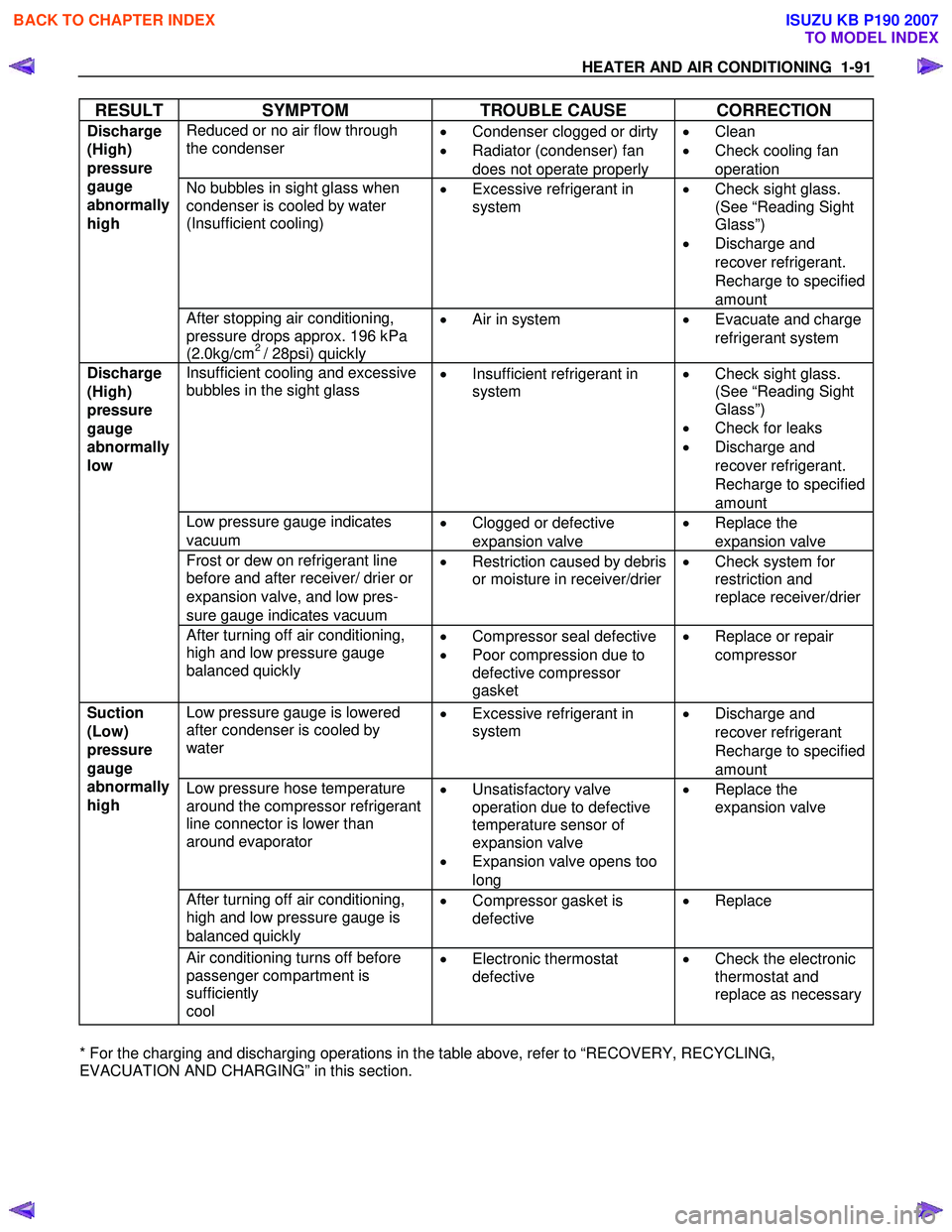

HEATER AND AIR CONDITIONING 1-91

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Reduced or no air flow through

the condenser

•

Condenser clogged or dirty

• Radiator (condenser) fan

does not operate properly •

Clean

• Check cooling fan

operation

No bubbles in sight glass when

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Discharge

(High)

pressure

gauge

abnormally

high

After stopping air conditioning,

pressure drops approx. 196 kPa

(2.0kg/cm

2 / 28psi) quickly •

Air in system

•

Evacuate and charge

refrigerant system

Insufficient cooling and excessive

bubbles in the sight glass

•

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Low pressure gauge indicates

vacuum •

Clogged or defective

expansion valve •

Replace the

expansion valve

Frost or dew on refrigerant line

before and after receiver/ drier or

expansion valve, and low pres-

sure gauge indicates vacuum •

Restriction caused by debris

or moisture in receiver/drier

•

Check system for

restriction and

replace receiver/drier

Discharge

(High)

pressure

gauge

abnormally

low

After turning off air conditioning,

high and low pressure gauge

balanced quickly

•

Compressor seal defective

• Poor compression due to

defective compressor

gasket •

Replace or repair

compressor

Low pressure gauge is lowered

after condenser is cooled by

water

•

Excessive refrigerant in

system

•

Discharge and

recover refrigerant

Recharge to specified

amount

Low pressure hose temperature

around the compressor refrigerant

line connector is lower than

around evaporator

•

Unsatisfactory valve

operation due to defective

temperature sensor of

expansion valve

• Expansion valve opens too

long •

Replace the

expansion valve

After turning off air conditioning,

high and low pressure gauge is

balanced quickly •

Compressor gasket is

defective

•

Replace

Suction

(Low)

pressure

gauge

abnormally

high

Air conditioning turns off before

passenger compartment is

sufficiently

cool •

Electronic thermostat

defective

•

Check the electronic

thermostat and

replace as necessary

* For the charging and discharging operations in the table above, refer to “RECOVERY, RECYCLING,

EVACUATION AND CHARGING” in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 126 of 6020

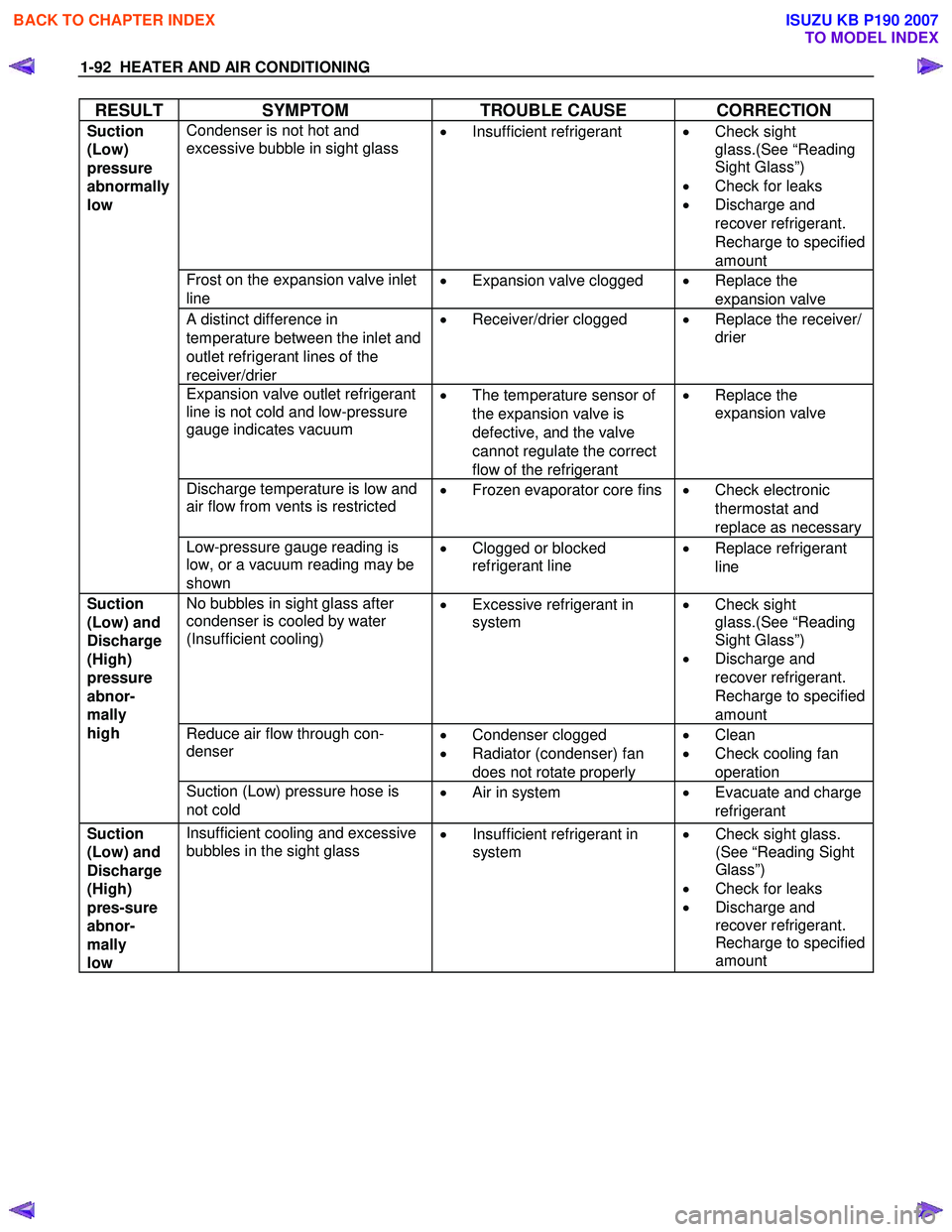

1-92 HEATER AND AIR CONDITIONING

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Condenser is not hot and

excessive bubble in sight glass

•

Insufficient refrigerant

•

Check sight

glass.(See “Reading

Sight Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Frost on the expansion valve inlet

line •

Expansion valve clogged

•

Replace the

expansion valve

A distinct difference in

temperature between the inlet and

outlet refrigerant lines of the

receiver/drier •

Receiver/drier clogged

•

Replace the receiver/

drier

Expansion valve outlet refrigerant

line is not cold and low-pressure

gauge indicates vacuum

•

The temperature sensor of

the expansion valve is

defective, and the valve

cannot regulate the correct

flow of the refrigerant •

Replace the

expansion valve

Discharge temperature is low and

air flow from vents is restricted

•

Frozen evaporator core fins

•

Check electronic

thermostat and

replace as necessary

Suction

(Low)

pressure

abnormally

low

Low-pressure gauge reading is

low, or a vacuum reading may be

shown •

Clogged or blocked

refrigerant line

•

Replace refrigerant

line

No bubbles in sight glass after

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight

glass.(See “Reading

Sight Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Reduce air flow through con-

denser

•

Condenser clogged

• Radiator (condenser) fan

does not rotate properly •

Clean

• Check cooling fan

operation

Suction

(Low) and

Discharge

(High)

pressure

abnor-

mally

high

Suction (Low) pressure hose is

not cold •

Air in system • Evacuate and charge

refrigerant

Suction

(Low) and

Discharge

(High)

pres-sure

abnor-

mally

low Insufficient cooling and excessive

bubbles in the sight glass •

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 700 of 6020

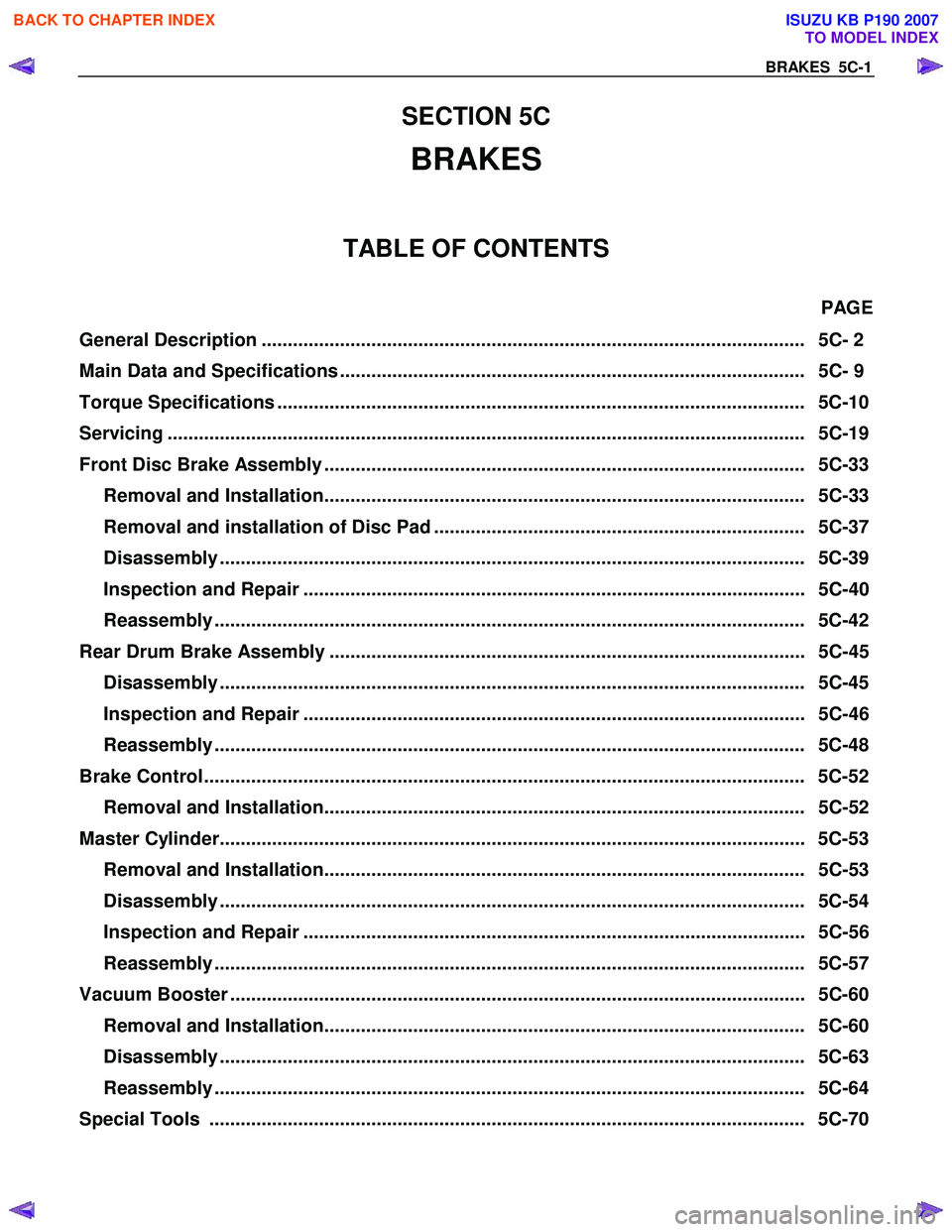

BRAKES 5C-1

SECTION 5C

BRAKES

TABLE OF CONTENTS

PAGE

General Description ........................................................................................................ 5C- 2

Main Data and Specifications ......................................................................................... 5C- 9

Torque Specifications ..................................................................................................... 5C-1 0

Servicing ...................................................................................................................... .... 5C-19

Front Disc Brake Assembly ............................................................................................ 5C-33 Removal and Installation............................................................................................ 5C-33

Removal and installation of Disc Pad ....................................................................... 5C-37

Disassembly ................................................................................................................ 5C- 39

Inspection and Repair ................................................................................................ 5C-40

Reassembly ................................................................................................................. 5C- 42

Rear Drum Brake Assembly ........................................................................................... 5C-45 Disassembly ................................................................................................................ 5C- 45

Inspection and Repair ................................................................................................ 5C-46

Reassembly ................................................................................................................. 5C- 48

Brake Control.................................................................................................................. . 5C-52

Removal and Installation............................................................................................ 5C-52

Master Cylinder................................................................................................................ 5C-53

Removal and Installation............................................................................................ 5C-53

Disassembly ................................................................................................................ 5C- 54

Inspection and Repair ................................................................................................ 5C-56

Reassembly ................................................................................................................. 5C- 57

Vacuum Booster .............................................................................................................. 5C -60

Removal and Installation............................................................................................ 5C-60

Disassembly ................................................................................................................ 5C- 63

Reassembly ................................................................................................................. 5C- 64

Special Tools ................................................................................................................. . 5C-70

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 707 of 6020

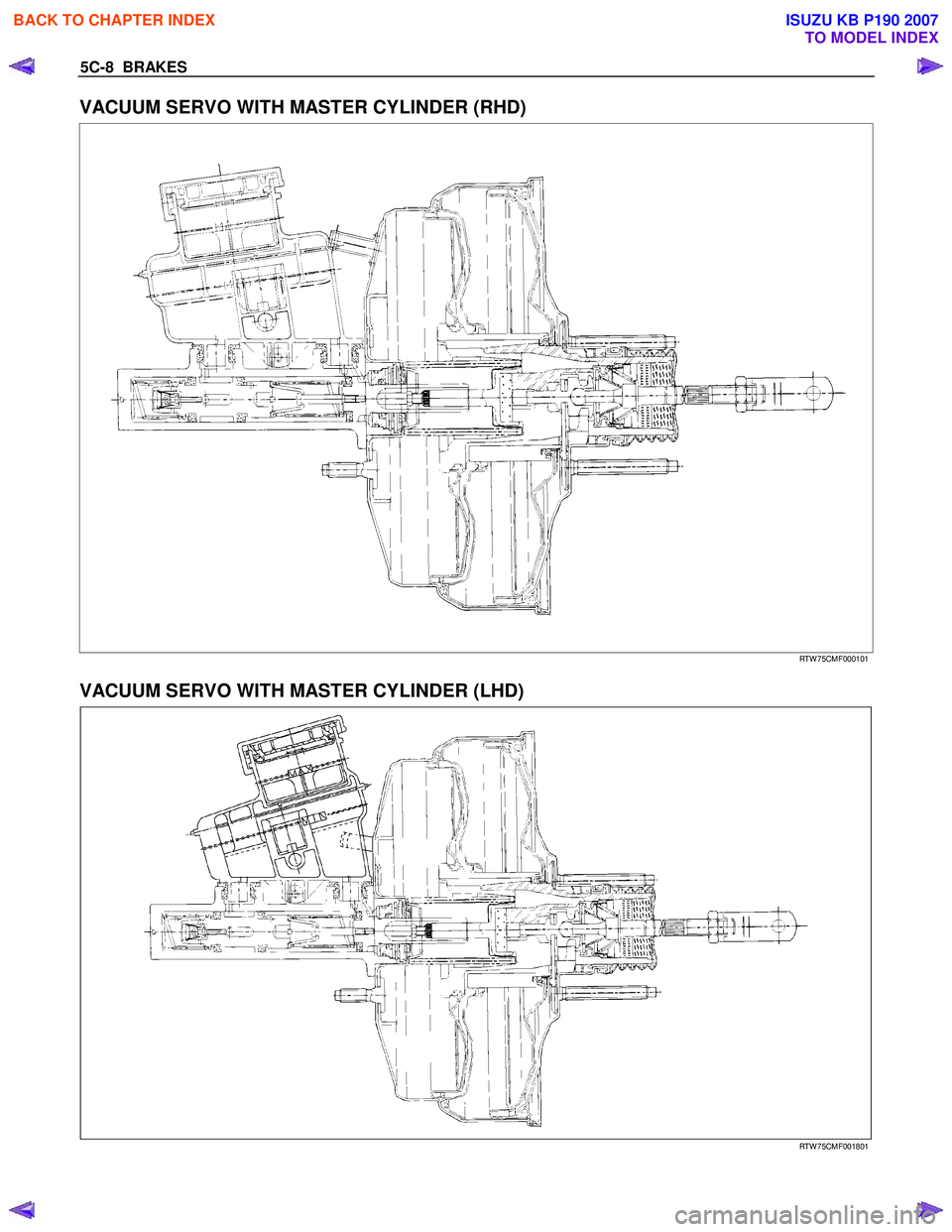

5C-8 BRAKES

VACUUM SERVO WITH MASTER CYLINDER (RHD)

RTW 75CMF000101

VACUUM SERVO WITH MASTER CYLINDER (LHD)

RTW 75CMF001801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 708 of 6020

BRAKES 5C-9

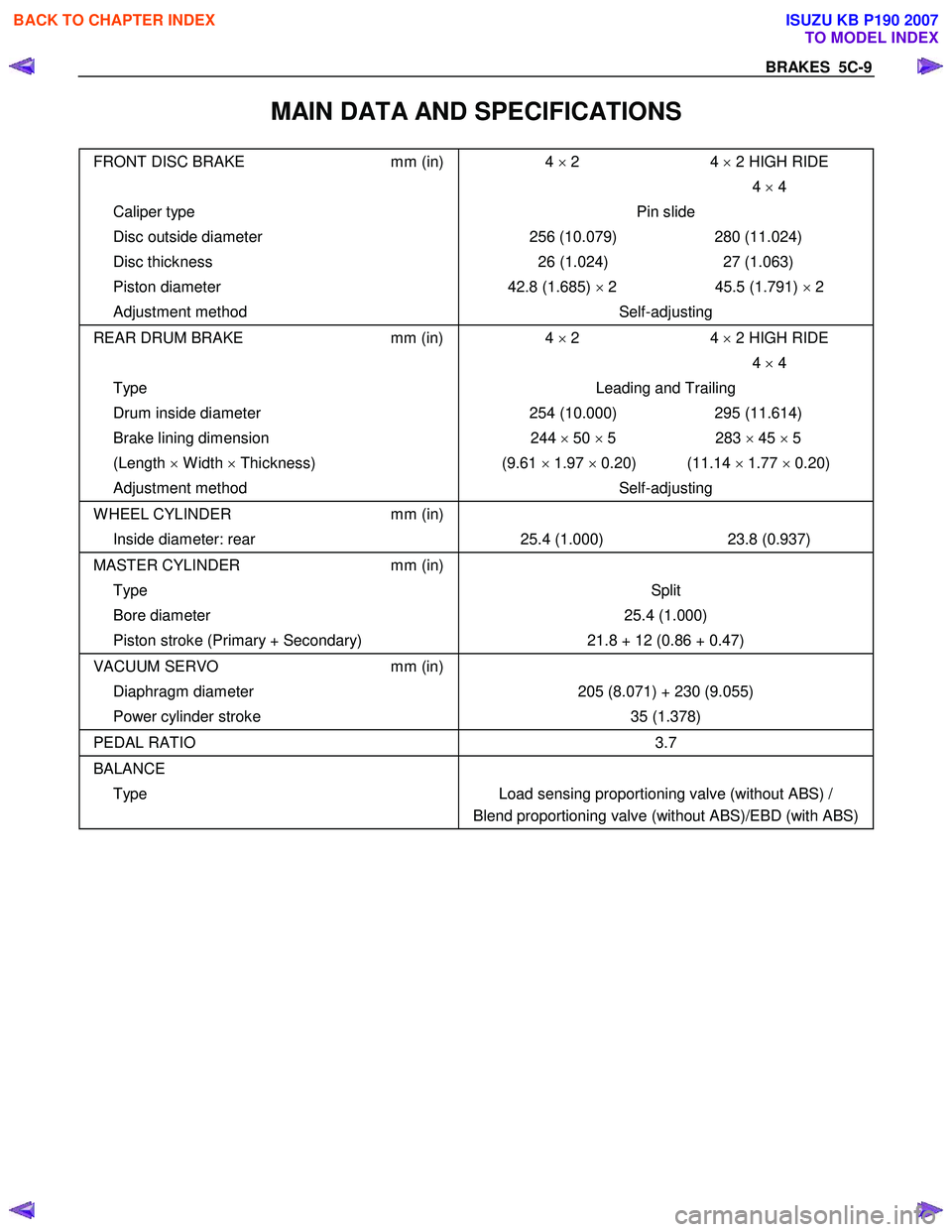

MAIN DATA AND SPECIFICATIONS

FRONT DISC BRAKE mm (in) 4 × 2 HIGH RIDE

4

× 2

4 × 4

Caliper type Pin slide

Disc outside diameter 256 (10.079) 280 (11.024)

Disc thickness 26 (1.024) 27 (1.063)

Piston diameter 42.8 (1.685) × 2 45.5 (1.791) × 2

Adjustment method Self-adjusting

REAR DRUM BRAKE mm (in) 4 × 2 HIGH RIDE

4

× 2

4 × 4

Type Leading and Trailing

Drum inside diameter 254 (10.000) 295 (11.614)

Brake lining dimension 244 × 50 × 5 283 × 45 × 5

(Length × W idth × Thickness) (9.61 × 1.97 × 0.20) (11.14 × 1.77 × 0.20)

Adjustment method Self-adjusting

W HEEL CYLINDER mm (in)

Inside diameter: rear 25.4 (1.000) 23.8 (0.937)

MASTER CYLINDER mm (in)

Type Split

Bore diameter 25.4 (1.000)

Piston stroke (Primary + Secondary) 21.8 + 12 (0.86 + 0.47)

VACUUM SERVO mm (in)

Diaphragm diameter 205 (8.071) + 230 (9.055)

Power cylinder stroke 35 (1.378)

PEDAL RATIO 3.7

BALANCE

Type Load sensing proportioning valve (without ABS) /

Blend proportioning valve (without ABS)/EBD (with ABS)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 711 of 6020

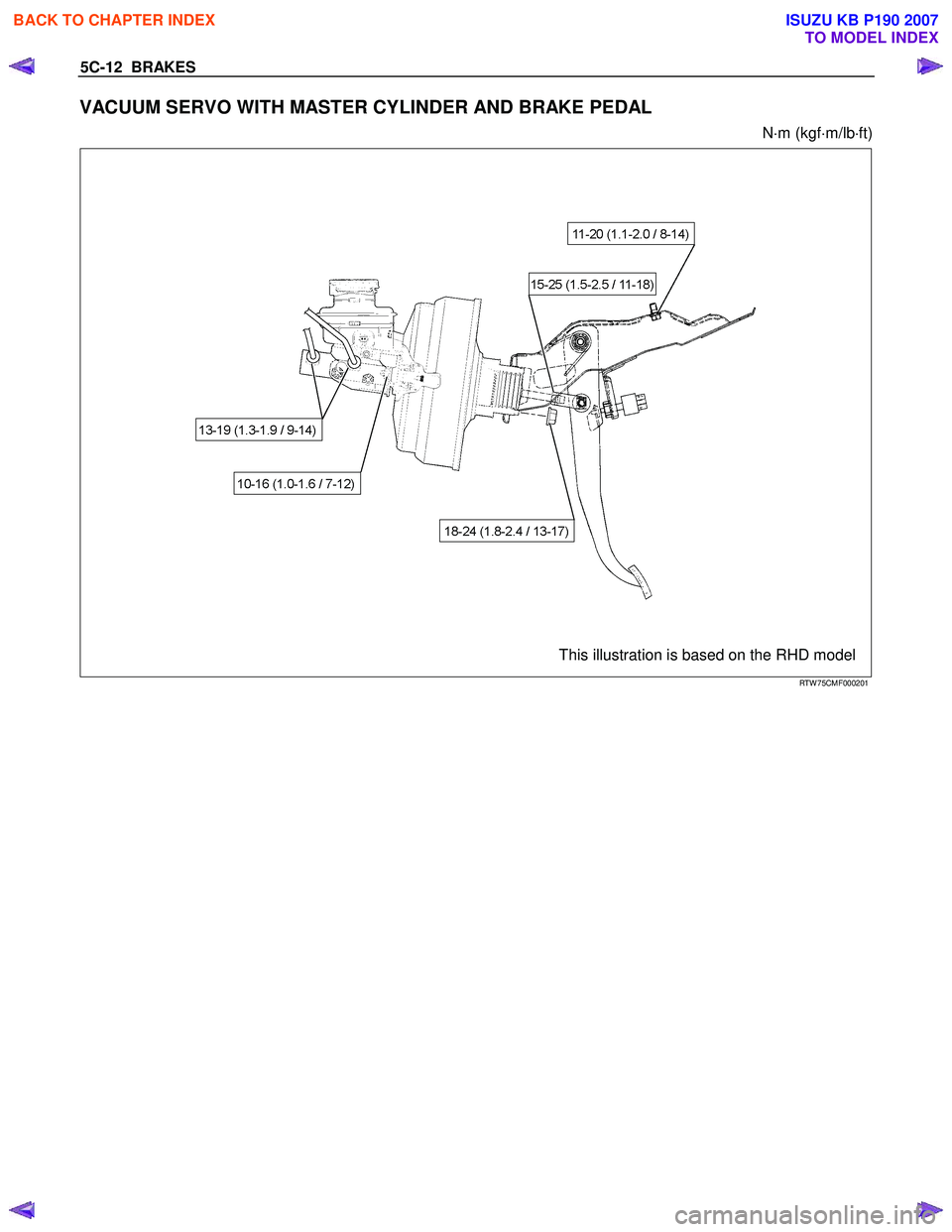

5C-12 BRAKES

VACUUM SERVO WITH MASTER CYLINDER AND BRAKE PEDAL

N ⋅m (kgf ⋅m/lb ⋅ft)

This illustration is based on the RHD model

RTW 75CMF000201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 725 of 6020

5C-26 BRAKES

A bleeding operation is necessary to remove air from the

hydraulic brake system whenever air is introduced into the

hydraulic system. It may be necessary to bleed the hydraulic

system at all four brakes if air has been introduced through a

low fluid level or by disconnecting brake pipes at the maste

r

cylinder. If a brake pipe is disconnected at one wheel, only that

wheel cylinder/caliper needs to be bled. If the pipes are

disconnected at any fitting located between the master cylinde

r

and brakes, then the brake system served by the disconnected

pipe must be bled.

1. Set the parking brake completely, then start the engine.

NOTE:

The vacuum booster will be damaged if the bleeding operation

is performed with the engine off.

2. Remove the master cylinder reservoir cap.

RTW 75CSH001701

3. Fill the master cylinder reservoir with brake fluid. Keep the

reservoir at least half full during the air bleeding operation.

4. Always use new brake fluid for replenishment.

5. In replenishing brake fluid, take care that air bubbles do not enter the brake fluid.

W hen the master cylinder is replaced or overhauled, first

bleed the air from the master cylinder, then from each

wheel cylinder and caliper following the procedures

described below.

RTW 75CSH001801

Bleeding the Master Cylinder

6. Disconnect the rear wheel brake pipe (1) from the master

cylinder.

Check the fluid level and replenish as necessary. I

f

replenished, leave the system for at least one minute.

7. Depress the brake pedal slowly once and hold it depressed.

8. Completely seal the delivery port of the master cylinder with your finger, where the pipe was disconnected, then release

the brake pedal slowly.

9. Release your finger from the delivery port when the brake pedal returns completely.

10. Repeat steps 7 through 9 until the brake fluid comes out o

f

the delivery port during step 7.

NOTE: Do not allow the fluid level in the reservoir to go belo

w

the half-way mark.

11. Reconnect the brake pipe (1) to the master cylinder and tighten the pipe.

12. Depress the brake pedal slowly once and hold it depressed.

13. Loosen the rear wheel brake pipe (1) at the master cylinder.

14. Retighten the brake pipe, then release the brake pedal slowly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 752 of 6020

BRAKES 5C-53

MASTER CYLINDER

REMOVAL AND INSTALLATION

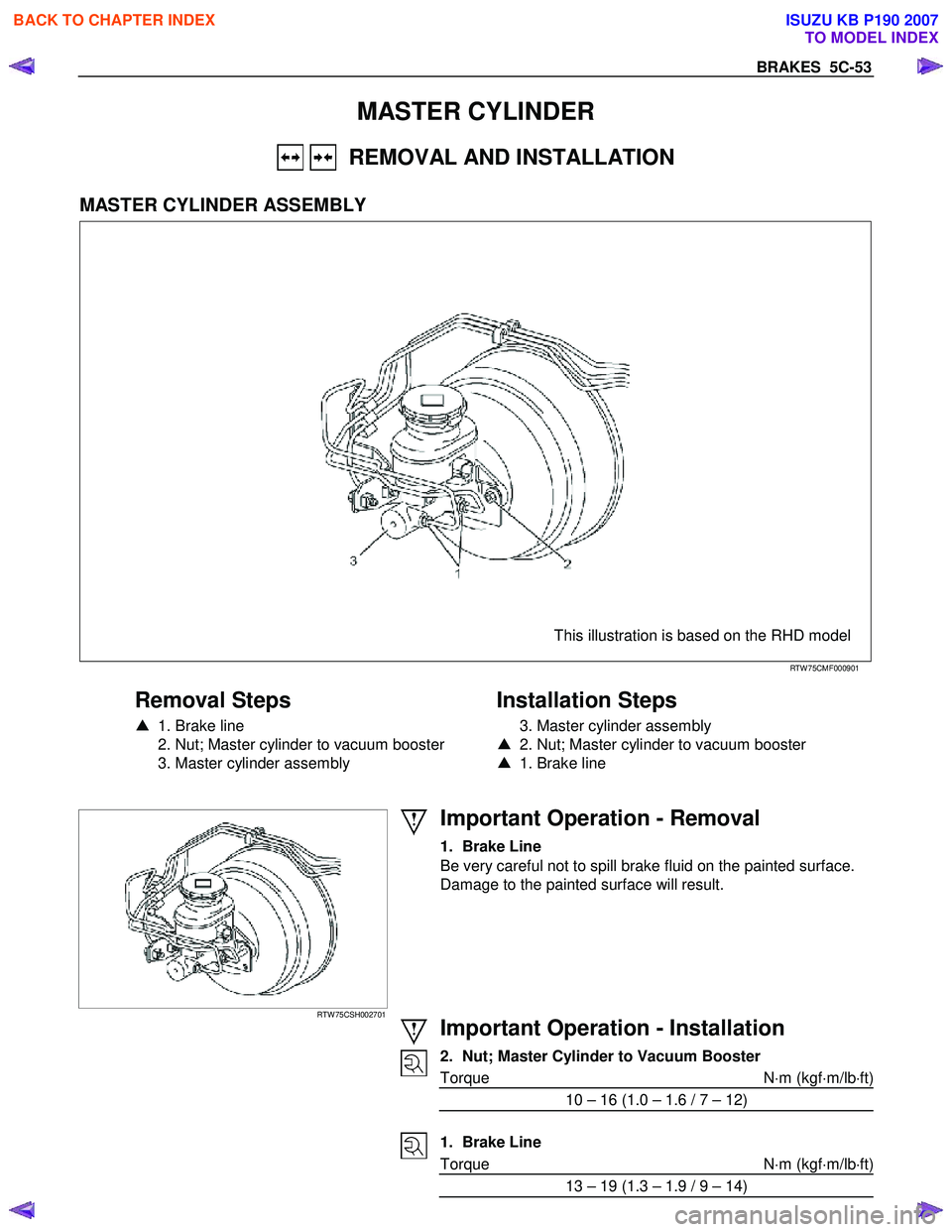

MASTER CYLINDER ASSEMBLY

This illustration is based on the RHD model

RTW 75CMF000901

Removal Steps

▲ 1. Brake line

2. Nut; Master cylinder to vacuum booster

3. Master cylinder assembly

Installation Steps

3. Master cylinder assembly

▲ 2. Nut; Master cylinder to vacuum booster

▲ 1. Brake line

RTW 75CSH002701

Important Operation - Removal

1. Brake Line

Be very careful not to spill brake fluid on the painted surface.

Damage to the painted surface will result.

Important Operation - Installation

2. Nut; Master Cylinder to Vacuum Booster

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

10 – 16 (1.0 – 1.6 / 7 – 12)

1. Brake Line

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

13 – 19 (1.3 – 1.9 / 9 – 14)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 754 of 6020

BRAKES 5C-55

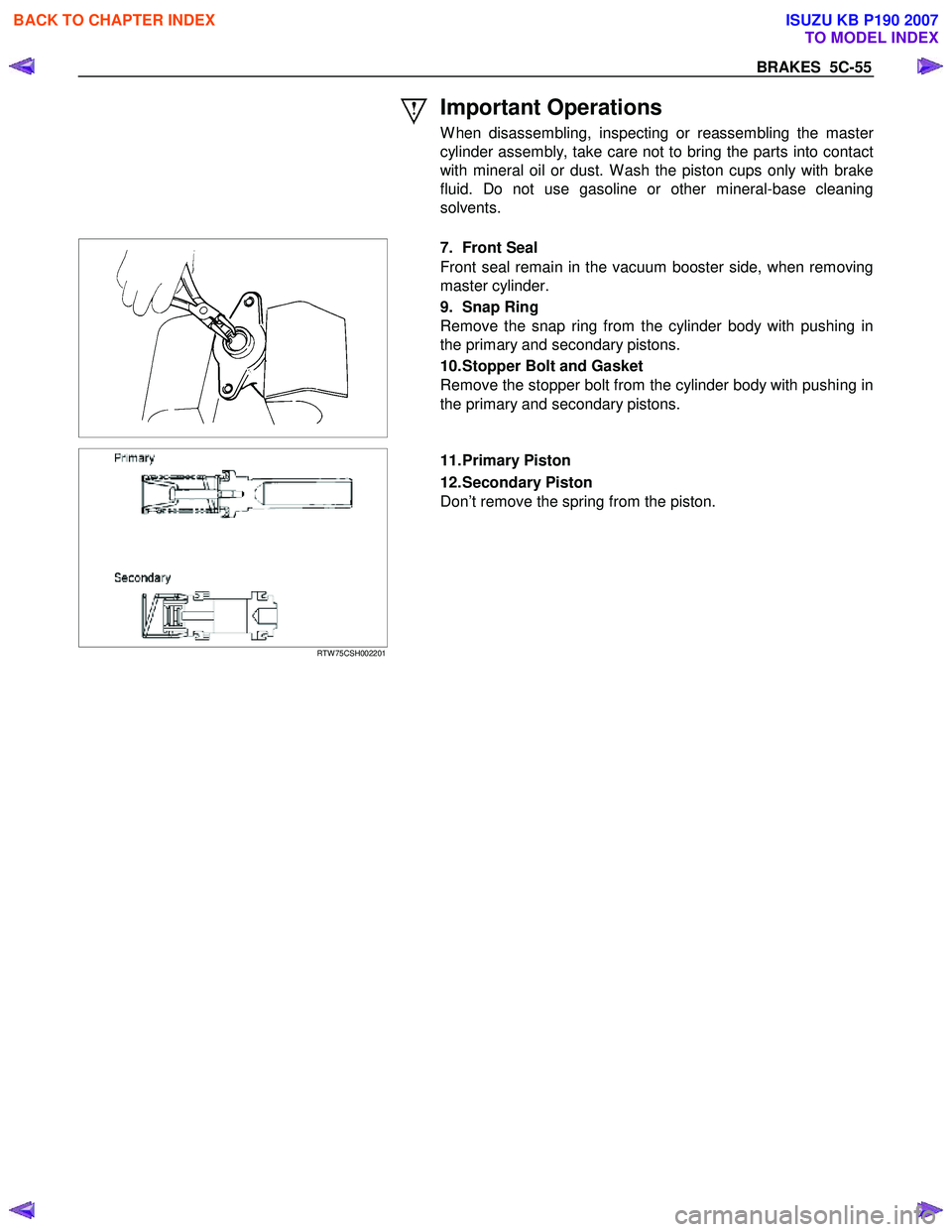

Important Operations

W hen disassembling, inspecting or reassembling the master

cylinder assembly, take care not to bring the parts into contact

with mineral oil or dust. W ash the piston cups only with brake

fluid. Do not use gasoline or other mineral-base cleaning

solvents.

7. Front Seal

Front seal remain in the vacuum booster side, when removing

master cylinder.

9. Snap Ring

Remove the snap ring from the cylinder body with pushing in

the primary and secondary pistons.

10. Stopper Bolt and Gasket

Remove the stopper bolt from the cylinder body with pushing in

the primary and secondary pistons.

RTW 75CSH002201

11. Primary Piston

12. Secondary Piston

Don’t remove the spring from the piston.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007