ignition ISUZU TF SERIES 2004 Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 127 of 4264

RESTRAINT CONTROL 9A1-57

DTC Will Clear When

The malfunction is no longer occurring and the ignition

is turned “OFF”.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2.

This test determines whether the SRS control unit is

malfunctioning

3.

This test isolates the malfunction to one side of the

pretensioner assembly yellow connector at the base

of the driver seat.

4.

This test determines whether the malfunction is in

“Driver Pretensioner High” circuit.

5.

This test determines whether the malfunction is in

“Driver Pretensioner Low” circuit.

6.

This test determines whether the malfunction is in

“Driver Pretensioner High” circuit.

7.

This test determines whether the malfunction is in

“Driver Pretensioner Low” circuit.

8.

This test determines whether the malfunction is in

the driver pretensioner assembly.

Diagnostic Aids

An intermittent condition is likely to be caused by a short

to ground/+B in the driver pretensioner circuit. Inspect

circuits “Driver Pretensioner High” and “Driver

Pretensioner Low” carefully for cutting or chafing.

DTC B0066 (Flash Code 66) Driver Pretensioner Squib Circuit Voltage Range/Performance

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2

1. When measurements are requested in this chart use 5-8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch “OFF.”

3. Ignition switch “ON.”

4. Check the driver pretensioner squib circuit for short to

voltage, short to ground and open.

Was a problem found? Verify repair Go to Step 3

3

1. Ignition switch “OFF.”

2. Disconnect pretensioner yellow connector located at base of

the driver seat. leave passenger pretensioner assembly

connected.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 and

appropriate adapter to pretensioner harness connector.

4. ignition switch “ON.”

Is DTC B0066 current? Go to Step 4 Go to Step 8

4

1. Ignition switch “OFF.”

2. Disconnect SRS control unit.

3. Disconnect SRS driver / passenger load tool.

4. Measure resistance on SRS control unit harness connector

“42” to terminal “40” (ground).

Does 5-8840-0285-0 display “OL” (infinite)? Go to Step 5 Replace SRS

harness or repair

chassis harness.

Go to Step 9

Page 128 of 4264

9A1-58 RESTRAINT CONTROL SYSTEM

Step Action Yes No

5 Measure resistance on SRS control unit harness connector from

terminal “41” to terminal “40” (ground).

Does 5-8840-0285-0 display “OL” (infinite)? Go to Step 6

Replace SRS

harness.

Go to Step 9

6 Measure resistance on SRS control unit harness connector from

terminal “42” to terminal “35” (ignition).

Does 5-8840-0285-0 display “OL” (infinite)? Go to Step 7

Replace SRS

harness or repair

chassis harness.

Go to Step 9

7 Measure resistance on SRS control unit harness connector from

terminal “41” to terminal “35” (ignition).

Does 5-8840-0285-0 display “OL” (infinite)? Go to Chart A

Replace SRS

harness or repair

chassis harness.

Go to Step 9

8

1. Ignition switch “OFF.”

2. Disconnect SRS driver / passenger load tool 5-8840-2421-0

from pretensioner assembly harness connector.

3. Connect SRS driver / passenger load tool 5-8840-2421-0 and

appropriate adapter to driver pretensioner assembly harness

connector.

4. Reconnect pretensioner harness connector as the base of the

driver seat.

5. Ignition switch “ON.”

Is DTC B0066 current? Go to Step 9

Ignition switch

“OFF.”

Replace driver

pretensioner

assembly.

Go to Step 9

9

1. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished? Go to the “SRS

Diagnostic System

Check” Go to Step 9

Page 129 of 4264

RESTRAINT CONTROL 9A1-59

DTC B0670 (Flash Code 63) Airbag Telltale Circuit Malfunction

RTW49JLF000101

Circuit Description

When the ignition switch is turned “ON”, battery voltage

is applied to the “AIR BAG” warning lamp and to the

“Ignition 1” input terminal “35”. The SRS control unit

responds by flashing the “AIR BAG” warning lamp

seven times. The SRS control unit monitors the lamp

driver output by comparing the output state at “SRS

Warning Lamp” terminal “39” to the microprocesso

r

commanded state. When “Ignition 1” is in the specified

value, and the output state does not match the

commanded state of the lamp driver for 500

milliseconds, DTC B0670 is set.

DTC Will Set When

“Ignition 1” voltage is in the specified value and the

output state at the “SRS Warning Lamp” terminal does

not match the commanded state of the lamp driver for

500 milliseconds. This test is run every 100

milliseconds during “Continuous Monitoring” tests and

once per each ignition cycle at the beginning.

Action Taken

SRS control unit attempts to turn “ON” the “AIR BAG”

warning lamp and sets a diagnostic trouble code.

DTC Will Clear When

The ignition switch is turned “OFF.”

Page 130 of 4264

9A1-60 RESTRAINT CONTROL SYSTEM

DTC Chart Test Description

Refer to Charts B and C to diagnose warning lamp

circuit malfunctions.

DTC B0670 (Flash Code 63) Airbag Telltale Circuit Malfunction

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2

1. Malfunctions within the “AIR BAG” warning lamp circuitry will

set this diagnostic trouble code.

2. These malfunctions are addressed in the “SRS Diagnostic

System Check” via Chart B and Chart C.

3. Failure to properly perform the “SRS Diagnostic System

Check” may result in misdiagnosis.

4. Ignition switch “ON.”

5. Clear SRS diagnostic trouble codes.

Is DTC B0670 set? Ignition switch

“OFF.”

Go to Chart A Repeat the “SRS

Diagnostic System

Check”

Page 131 of 4264

RESTRAINT CONTROL 9A1-61

DTC B1000 (Flash Code 72) SDM Internal Fault (SDM=SRS control unit)

RTW49JLF000101

Circuit Description

DTC B1000 is an indication of a potential internal SRS

control unit malfunction and will set if any of the

following conditions are detected:

1) Microprocessor energy reverse time failure.

2) EEPROM read / write failure.

3) ROM check sum.

4) Calibration check sum fault.

5) Inflators reserve voltage low.

6) Inflators electronic sensor active signal not detected

during commanded deployment.

7) QSDD (High-side/Low-side) FET failure.

8) Frontal accelerometer failure.

9) Phase lock loop lost lock.

10) QSDD communication fault.

DTC Will Set When

Any of the above indicated malfunctions are detected by

the SRS control unit. The malfunctions described

above are tested mainly during “Continuous Monitoring”

and some ones run each ignition cycle.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

SRS control unit is replaced.

Page 132 of 4264

9A1-62 RESTRAINT CONTROL SYSTEM

DTC B1000 (Flash Code 72) SDM Internal Fault (SDM=SRS control unit)

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SRS CONTROL

UNIT. NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS

CONTROL UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SRS CONTROL UNIT AND MOUNTING

BRACKET FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD

THE FRONT OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT

COULD BE ACTIVATED WHEN POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH

COULD CAUSE DEPLOYMENT AND RESULT IN PERSONAL INJURY.

CAUTION: If DTC B1000 can not clear by Tech2, it is necessary to replace the SRS control unit.

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Ignition switch

“OFF.”

Replace SRS

control unit.

Repeat the “SRS

Diagnostic System

Check” Go to the “SRS

Diagnostic System

Check”

Page 329 of 4264

BRAKE CONTROL SYSTEM 5A-13

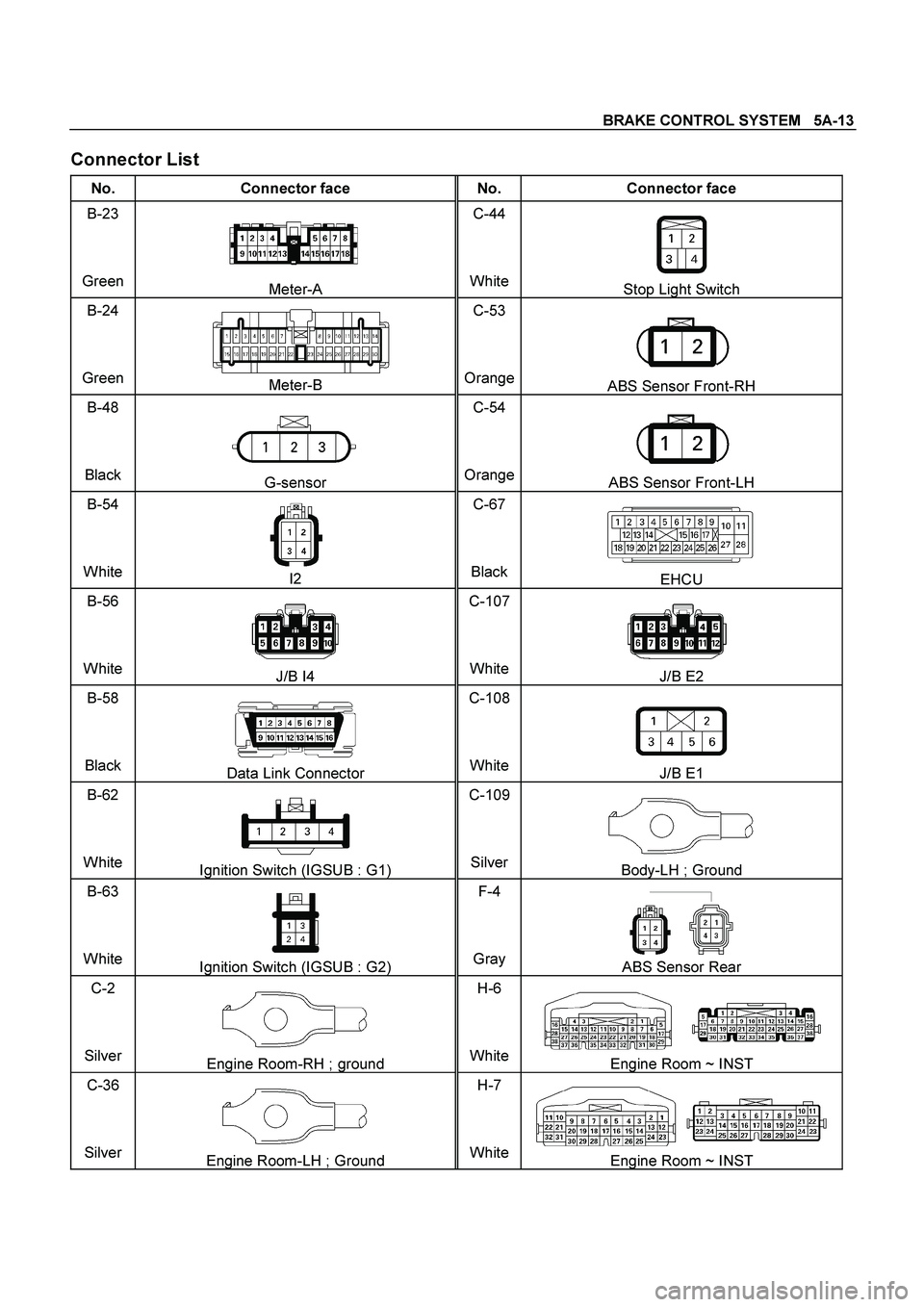

Connector List

No. Connector face No. Connector face

B-23

Green

Meter-A C-44

WhiteStop Light Switch

B-24

Green

Meter-B C-53

OrangeABS Sensor Front-RH

B-48

Black

G-sensor C-54

OrangeABS Sensor Front-LH

B-54

White

I2 C-67

BlackEHCU

B-56

White

J/B I4 C-107

WhiteJ/B E2

B-58

Black

Data Link Connector C-108

WhiteJ/B E1

B-62

White

Ignition Switch (IGSUB : G1) C-109

SilverBody-LH ; Ground

B-63

White

Ignition Switch (IGSUB : G2) F-4

Gray ABS Sensor Rear

C-2

Silver

Engine Room-RH ; ground H-6

WhiteEngine Room ~ INST

C-36

Silver

Engine Room-LH ; Ground H-7

WhiteEngine Room ~ INST

Page 335 of 4264

BRAKE CONTROL SYSTEM 5A-19

System Components

Electronic Hydraulic Control Unit (EHCU), four Wheel

Speed Sensors, two Warning Lamps, and G-sensor.

Electronic Hydraulic Control Unit (EHCU)

The EHCU consists of ABS control circuits, fault

detector, and a fail-safe. It drives the EHCU according

to the signal from each sensor, cancelling ABS to return

to normal braking when a malfunction has occurred in

the ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment rear

left side. It consists of a motor, solenoid valves fail safe

relay.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front brake or both rear brakes

according to the signal sent from the EHCU.

Buffer chamber: Temporarily holds the brake fluid that

returns from the front and rear brake so that pressure

of front brake can be reduced smoothly.

Motor: Drives the pump according to the signal from

EHCU.

Fail safe Relay: When failure occurs in ABS.

The power supply to solenoid Valve is cut.

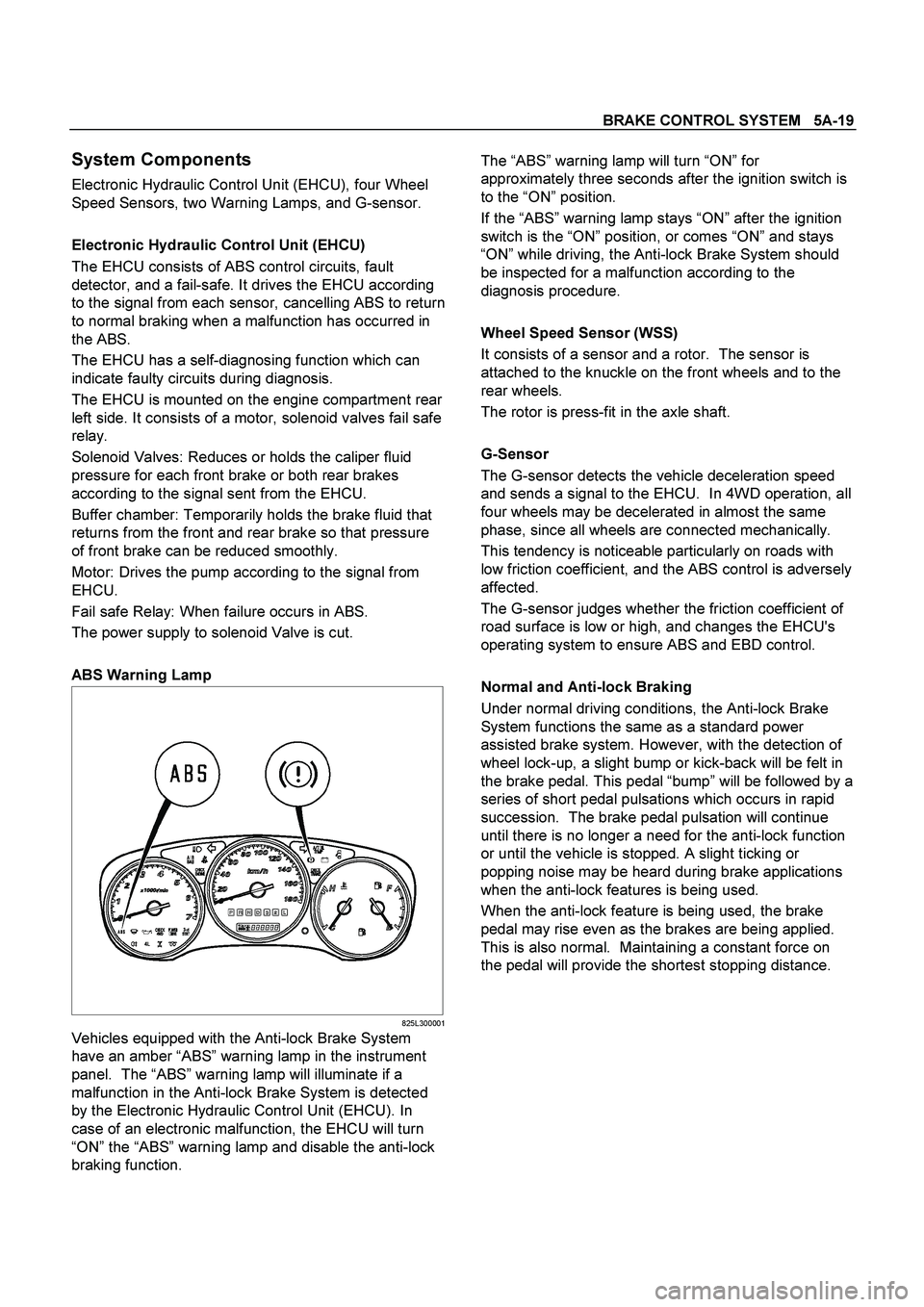

ABS Warning Lamp

825L300001

Vehicles equipped with the Anti-lock Brake System

have an amber “ABS” warning lamp in the instrument

panel. The “ABS” warning lamp will illuminate if a

malfunction in the Anti-lock Brake System is detected

by the Electronic Hydraulic Control Unit (EHCU). In

case of an electronic malfunction, the EHCU will turn

“ON” the “ABS” warning lamp and disable the anti-lock

braking function.

The “ABS” warning lamp will turn “ON” for

approximately three seconds after the ignition switch is

to the “ON” position.

If the “ABS” warning lamp stays “ON” after the ignition

switch is the “ON” position, or comes “ON” and stays

“ON” while driving, the Anti-lock Brake System should

be inspected for a malfunction according to the

diagnosis procedure.

Wheel Speed Sensor (WSS)

It consists of a sensor and a rotor. The sensor is

attached to the knuckle on the front wheels and to the

rear wheels.

The rotor is press-fit in the axle shaft.

G-Sensor

The G-sensor detects the vehicle deceleration speed

and sends a signal to the EHCU. In 4WD operation, all

four wheels may be decelerated in almost the same

phase, since all wheels are connected mechanically.

This tendency is noticeable particularly on roads with

low friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU's

operating system to ensure ABS and EBD control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power

assisted brake system. However, with the detection of

wheel lock-up, a slight bump or kick-back will be felt in

the brake pedal. This pedal “bump” will be followed by a

series of short pedal pulsations which occurs in rapid

succession. The brake pedal pulsation will continue

until there is no longer a need for the anti-lock function

or until the vehicle is stopped. A slight ticking or

popping noise may be heard during brake applications

when the anti-lock features is being used.

When the anti-lock feature is being used, the brake

pedal may rise even as the brakes are being applied.

This is also normal. Maintaining a constant force on

the pedal will provide the shortest stopping distance.

Page 337 of 4264

BRAKE CONTROL SYSTEM 5A-21

Computer System Service Precautions

The Anti-lock Brake System and Electronic Brake-force

Distribution interfaces directly with the Electronic

Hydraulic Control Unit (EHCU) which is a control

computer that is similar in some regards to the Engine

Control Module. These modules are designed to

withstand normal current draws associated with vehicle

operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for

opens or shorts, do not ground or apply voltage to any

of the circuits unless instructed to do so by the

appropriate diagnostic procedure. These circuits should

only be tested with a high impedance multimeter

5-8840-0366-0 or special tools as described in this

section. Power should never be removed or applied to

any control module with the ignition in the “ON”

position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock Brake

System and Electronic Brake-force Distribution

damage.

If welding work is to be performed on the vehicle

using an electric arc welder, the EHCU and valve

block connectors should be disconnected before

the welding operation begins.

The EHCU and valve block connectors should

never be connected or disconnected with the

ignition “ON”.

Note:

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS and Brake” warning lamp

will illuminate. But actually no trouble exists. When

the DTC is not detected and the ABS and BRAKE

warning lamp is on, “How to erase code” is

performed and a ABS and BRAKE warning lamp

are off.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS) and

Electronic Brake-force Distribution (EBD) System

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS and EBD

to a non-operative state by removing the fuse for the

ABS. After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning Lamp does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case

duplicating the system malfunction during a test drive or

a good description of vehicle behavior from the

customer may be helpful in locating a “most likely”

failed component or circuit. The symptom diagnosis

chart may also be useful in isolating the failure. Most

intermittent problems are caused by faulty electrical

connections or wiring. When an intermittent failure is

encountered, check suspect circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not

fully seated in the connector body (backed out).

Improperly formed or damaged terminals.

Test Driving ABS Complaint Vehicles

In case that there has been an abnormality in the

lighting pattern of “ABS” warning lamp, the fault can be

located in accordance with the “DIAGNOSIS BY “ABS”

WARNING LAMP ILLUMINATION PATTERN”. In case

of such trouble as can be detected by the driver as a

vehicle symptom, however, it is necessary to give a test

drive following the test procedure mentioned below,

thereby reproducing the symptom for trouble diagnosis

on a symptom basis:

1.

Start the engine and make sure that the “ABS” W/L

goes OFF. If the W/L remains ON, it means that

the Diagnostic Trouble Code (DTC) is stored.

Therefore, read the code and locate the fault.

Note: The DTC cannot be cleared if the vehicle speed

does not exceed about 6km/h (4mph) at DTC, even

though the repair operation is completed.

2. Start the vehicle and accelerate to about 30 km/h

(19 mph) or more.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40

km/h (25 mph) or more.

5. Brake at a time so as to actuate the ABS and stop

the vehicle.

6. Be cautious of abnormality during the test. If the

W/L is actuated while driving, read the DTC and

locate the fault.

7. If the abnormality is not reproduced by the test,

make best efforts to reproduce the situation

reported by the customer.

8. If the abnormality has been detected, repair in

accordance with the “SYMPTOM DIAGNOSIS” .

Note:

Be sure to give a test drive on a wide, even road

with a small traffic.

If an abnormality is detected, be sure to suspend

the test and start trouble diagnosis at once.

Page 338 of 4264

5A-22 BRAKE CONTROL SYSTEM

“ABS” Warning Lamp

When ABS and trouble occurs to actuate “ABS”

warning lamp, the trouble code corresponding to the

trouble is stored in the EHCU. Only ordinary brake is

available with ABS being unactuated. Even when

“ABS” warning lamp is actuated, if the starter switch is

set ON after setting it OFF once, the EHCU checks up

on the entire system and, if there is no abnormality,

judges ABS to work currently and the warning lamp is lit

normally even though the trouble code is stored.

NOTE: Illumination of the “ABS” warning lamp indicates

that anti-lock braking is no longer available. Power

assisted braking without anti-lock control is still

available.

Normal Operation

“ABS ” Warning Lamp

When the ignition is first moved from “OFF” to “RUN”,

the amber “ABS” warning lamp will turn “ON”. The

“ABS” warning lamp will turn “ON” during engine

starting and will usually stay “ON” for approximately

three seconds after the ignition switch is returned to the

“ON” position. The warning lamp should remain “OFF”

at all other times.

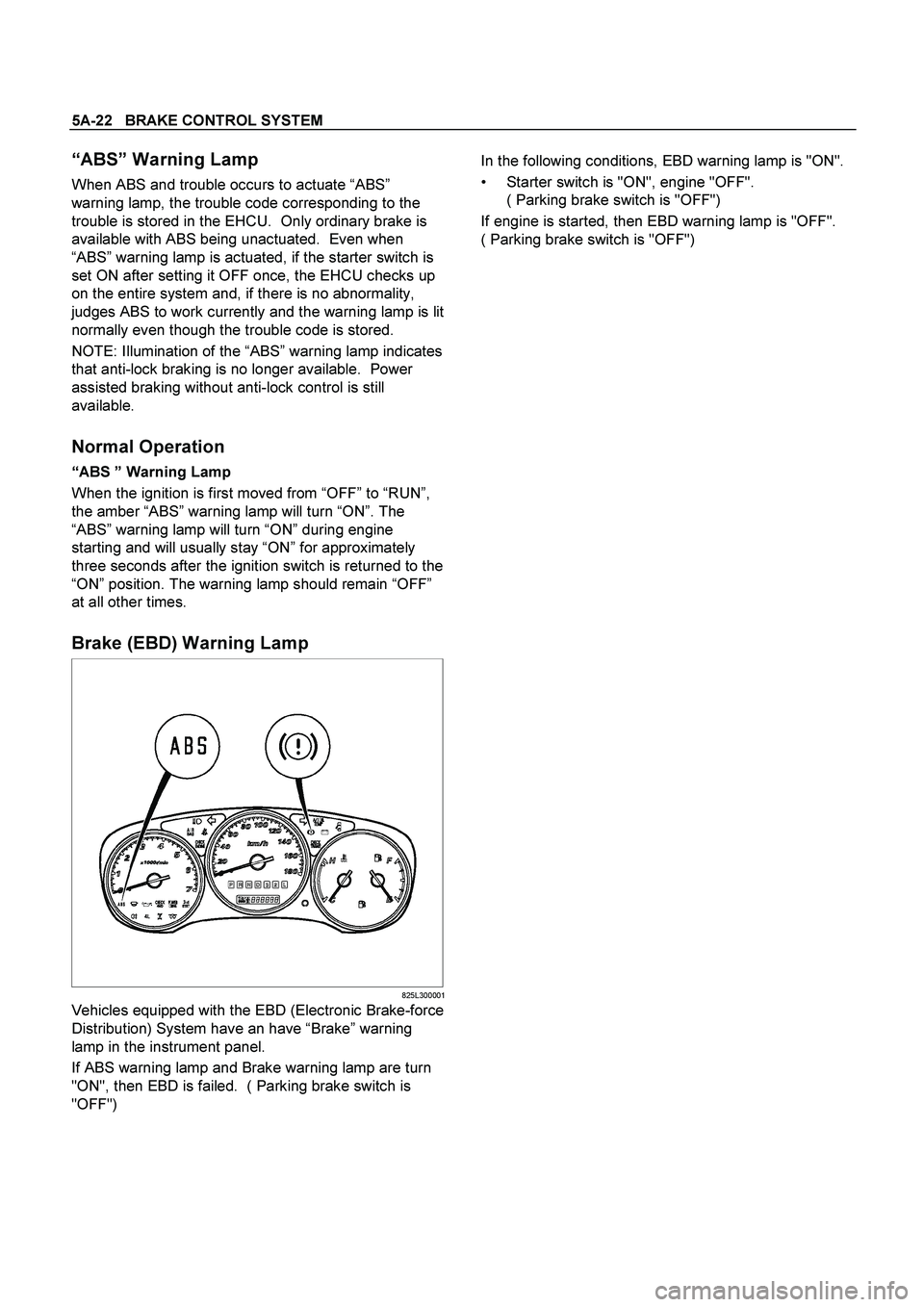

Brake (EBD) Warning Lamp

825L300001

Vehicles equipped with the EBD (Electronic Brake-force

Distribution) System have an have “Brake” warning

lamp in the instrument panel.

If ABS warning lamp and Brake warning lamp are turn

"ON", then EBD is failed. ( Parking brake switch is

"OFF")

In the following conditions, EBD warning lamp is "ON".

Starter switch is "ON", engine "OFF".

( Parking brake switch is "OFF")

If engine is started, then EBD warning lamp is "OFF".

( Parking brake switch is "OFF")