ISUZU TFS SERIES 1997 Workshop Manual

TFS SERIES 1997

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57182/w960_57182-0.png

ISUZU TFS SERIES 1997 Workshop Manual

Trending: low oil pressure, maintenance, differential, ESP, brake, clock setting, suspension

Page 101 of 1600

4C1-38 FRONT WHEEL DRIVE

(2) Insert the differential cage assembly with bearing outer

races into the side bearing bores of the carrier.

(3) Using two sets of feeler gauges, insert a feeler stock of

sufficient thickness between each bearing outer race and

the carrier to remove all end plat. Make certain the feeler

stock is pushed to the bottom of the bearing bores.

Mount the dial indicator on the carrier so that the indicator

stem is at right angles to a tooth on the ring gear.

Dial indicator : 5884-0126-0

(J-8001)

(4) Adjust feeler gauge thickness from side to side until ring

gear backlash is in the specified range.

Backlash mm(in)

0.13 - 0.18 (0.005 - 0.007)

W ith zero end play and correct backlash established,

remove the feeler gauge packs, determine the thickness of

the shims required and add 0.05 mm (0.002 in) to each

shim pack to provide side bearing preload. Always use new

shims.

(5) Remove side bearing

Remover : 5-8840-0013-0

(J-22888)

Pilot : 5-8521-0019-0 (167 mm)

9-8521-1743-0 (194 mm)

(J-8107-2)

14.Side Bearing

Install the side bearings together with the selected shims.

For 167 mm

1Installer : 5-8840-0138-0 (J-29036)

2Drive handle : 5-8840-0007-0 (J-8092)

3Pilot : 5-8521-0019-0

For 194 mm

1Installer : 9-8521-1164-0 (J-24244)

2Drive handle : 5-8840-0007-0 (J-8092)

3Pilot : 9-8521-1743-0 (J-8107-2)

Page 102 of 1600

FRONT WHEEL DRIVE 4C1-39

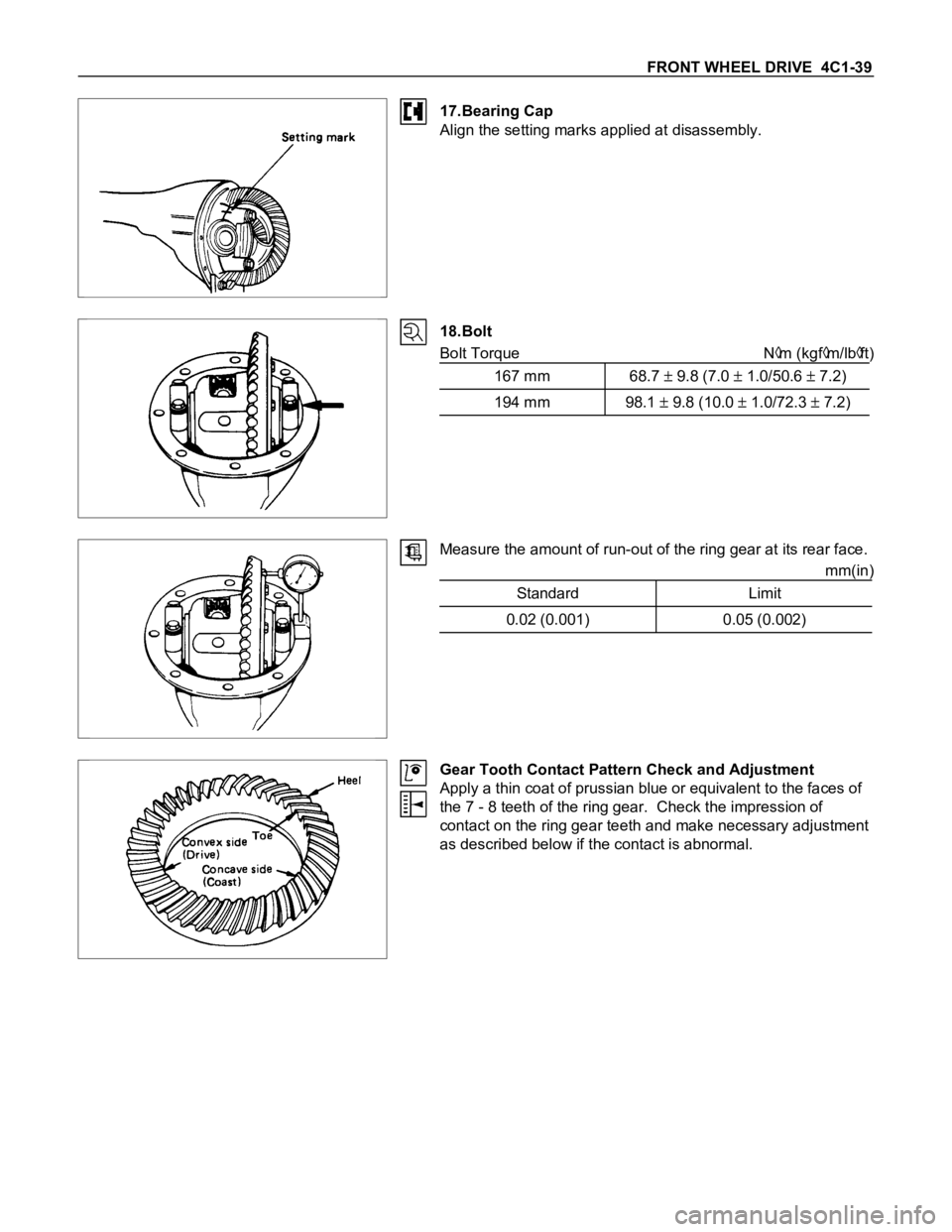

17.Bearing Cap

Align the setting marks applied at disassembly.

18.Bolt

Bolt Torque N

m (kgfm/lbft)

167 mm 68.7

9.8 (7.0 1.0/50.6 7.2)

194 mm 98.1 9.8 (10.0 1.0/72.3 7.2)

Measure the amount of run-out of the ring gear at its rear face.

mm(in)

Standard Limit

0.02 (0.001) 0.05 (0.002)

Gear Tooth Contact Pattern Check and Adjustment

Apply a thin coat of prussian blue or equivalent to the faces of

the 7 - 8 teeth of the ring gear. Check the impression of

contact on the ring gear teeth and make necessary adjustment

as described below if the contact is abnormal.

Page 103 of 1600

4C1-40 FRONT WHEEL DRIVE

20.Differential Assembly

(1) Clean the faces of the front axle case and differential

carrier.

Apply the recommended liquid gasket or its equivalent to

the sealing side of the axle case and the carrier.

(2) Attach the differential case and the carrier assembly to the

front axle case and tighten the nuts and bolts. The axle

case bolt is used for drainage.

Torque N

m (kgfm/lbft)

25.5

5 (2.6 0.5/18.8 3.6)

(3) Install the axle shaft assemblies as instructed earlier in this

section under “Axle Shaft Replacement”.

(4) Fill the axle case with hypoid gear lubricant, to just below

the filler hole.

Lubricant capacity liter (US/UK gal)

167 mm 1.0 (0.26/0.22)

194 mm 1.4 (0.37/0.31)

Page 104 of 1600

FRONT WHEEL DRIVE 4C1-41

FRONT HUB AND DISC (42 model)

DISASSEMBLY

Refer to SECTION 3E “WHEEL AND TIRE” for wheel removal procedure.

Disassembly Steps

1. Bolt

2. Brake caliper

3. Hub cap

4. Split pin

5. Nut retainer

6. Hub nut

7. Lock washer8. Outer bearing

9. Hub and disc assembly

10. Oil seal

11. Inner bearing and outer race

12. Bolt

13. Wheel pin

Page 105 of 1600

4C1-42 FRONT WHEEL DRIVE

Important Operations

Before removal, jack up the front of vehicle and support frame

with jack stands.

2. Brake Caliper

(1) Remove the two bolts from the rear side of the knuckle arm,

then remove the brake caliper, with the brake hose

attached.

(2) Use a wire etc., for attaching the brake caliper to the upper

link.

3. Hub Cap

When removing hub cap, exercise care so as not to scratch or

distort hub fitting face.

9. Hub and Disc Assembly

Using a brass bar to remove the outer bearing outer race (1),

oil seal, inner bearing and inner bearing outer race (2) from the

hug.

If necessary, replace the wheel pin in the following manner.

12.Bolt

13.Wheel Pin ; Front Hub

(1) Scribe mark on hub to disc before disassembly to insure

proper assembly.

Page 106 of 1600

FRONT WHEEL DRIVE 4C1-43

(2) Clamp hub and disc assembly in vise using protective pads

and remove six (6) disc to hub retaining bolts.

(3) Place hub on a suitable work surface and remove wheel

studs, as required, using a hammer.

Page 107 of 1600

4C1-44 FRONT WHEEL DRIVE

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear, damage or any other abnormal conditions are found

through inspection.

Hub

Hub bearing

Bearing outer race

Disc

Oil seal

Visual Check

Check the following parts for wear, damage or other abnormal

conditions.

Page 108 of 1600

FRONT WHEEL DRIVE 4C1-45

REASSEMBLY

Refer to SECTION 3E “WHEEL AND TIRE” for wheel removal procedure.

Reassembly Steps

1. Wheel pin

2. Bolt

3. Inner bearing and outer race

4. Oil seal

5. Hub and disc assembly

6. Outer bearing

7. Lock washer

8. Hub nut

9. Nut retainer

10. Split pin

11. Hub cap

12. Brake caliper

13. Bolt

Page 109 of 1600

4C1-46 FRONT WHEEL DRIVE

Important Operations

1. Wheel Pin

(1) Place hub on a wood workbench or a block of wood,

approx. 6” by 6” to protect the wheel stud ends and threads.

(2) Install wheel stud using a hammer.

Be sure wheel stud is started squarely and seats

completely.

(3) Align index marks and install hub to disc.

2. Bolt

Torque N

m (kgfm/lbft)

103

5 (10.5 1/75.9 7.2)

3. Inner Bearing and Outer Race

4. Oil Seal

Outer Bearing Outer Race

(1) Install the bearing outer race by driving into the hub.

Installer (Outer) : 5-8822-0053-0 (J-29016)

Installer (Inner) : 5-8822-0054-0 (J-29015)

Drive handle : 5-8840-0007-0 (J-8092)

(2) Install the outer and inner bearing into the hub with fingers.

Page 110 of 1600

FRONT WHEEL DRIVE 4C1-47

(3) Install oil seal using special tools.

Installer : 5-8522-0051-0

(J-33161)

Grip : 5-8840-0007-0

(J-8092)

5. Hub and Disc Assembly

11. Hub Cap

Apply grease in the hub and hub cap.

Description Amount g(oz)

Hub 50 (1.76)

Hub cap 20 (0.70)

Outer bearing 6.5 (0.23)

Inner bearing 12 (0.42)

8. Hub nut

Adjustment of front wheel hub bearing preload

1. Tighten spindle nut to 3.0 kg

m (21.7 lb.ft/29.4 Nm) torque.

2. Turn the hub 2-3 turns and loosen the nut just enough so

that it can be turned with the fingers.

3. Turn the nut all the way in with the fingers and check to be

sure the hub has no free play.

4. Measure the bearing preload by pulling one of the wheel hub

studs with a spring scale.

5. Tighten the spindle nut until specified bearing preload Is

obtained.

After reassembling, install the disc brake caliper assembly.

Bearing Preload kg(lb)

New bearing and New oil seal 0.8 - 1.0(1.8 - 2.2)

Reuse bearing and New oil seal 0.8 - 1.0 (1.8 - 2.2)

13.Bolt

Torque N

m (kgfm/lbft)

155

15.7 (15.8 1.6/114.3 11.6)

Trending: inflation pressure, rear view mirror, compression ratio, transmission, driver seat adjustment, brake fluid, check oil