Seat JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1764 of 2490

Clima

te Control System - General Inform

ation - Manifold Gauge Set Connection

Ge

neral Procedures

Mani

fol

d.

Low Side Pressure Gauge.

High Side Pressure Gauge.

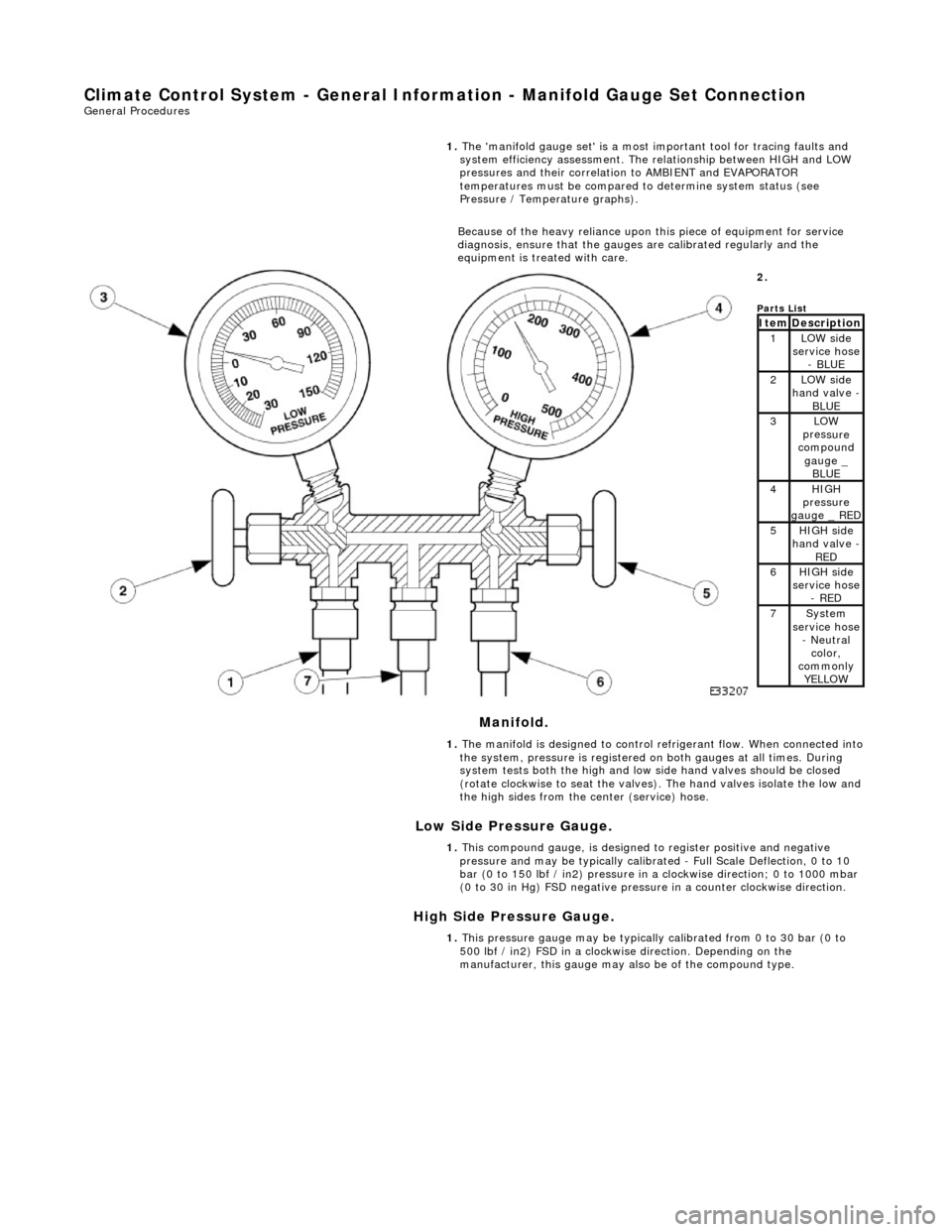

1.

The 'ma

nifold gauge set' is a most important tool for tracing faults and

system efficiency assessment. The relationship between HIGH and LOW

pressures and their correlation to AMBIENT and EVAPORATOR

temperatures must be compared to determine system status (see

Pressure / Temperature graphs).

Because of the heavy reliance upon this piece of equipment for service

diagnosis, ensure that the gauges are calibrated regularly and the

equipment is treated with care.

2.

Parts

List

ItemDescri

ption1LOW side

serv

ice hose

- BLUE

2LOW side

ha

nd valve -

BL

UE3LOW

pres

sure

compound

gauge _ BLUE

4HI GH

pressure

gauge _ RED

5HI GH

side

hand valve -

RED6HI GH

side

service hose

- RED

7Sys t

em

service hose

- Neutral color,

commonly YELLOW

1. The manifold is designed to control refrigerant flow. When connected into

the system, pressure is registered on both gauges at all times. During

system tests both the high and low side hand valves should be closed

(rotate clockwise to seat the valves). The hand valves isolate the low and

the high sides from the center (service) hose.

1. This compound gauge, is designed to register positive and negative

pressure and may be typically calibrate d - Full Scale Deflection, 0 to 10

bar (0 to 150 lbf / in2) pressure in a clockwise direction; 0 to 1000 mbar

(0 to 30 in Hg) FSD negative pressu re in a counter clockwise direction.

1. This pressure gauge may be typically calibrated from 0 to 30 bar (0 to

500 lbf / in2) FSD in a clockwise direction. Depending on the

manufacturer, this gauge may also be of the compound type.

Page 1777 of 2490

Air Distribution and Filtering - Center Registers

Removal and Installation

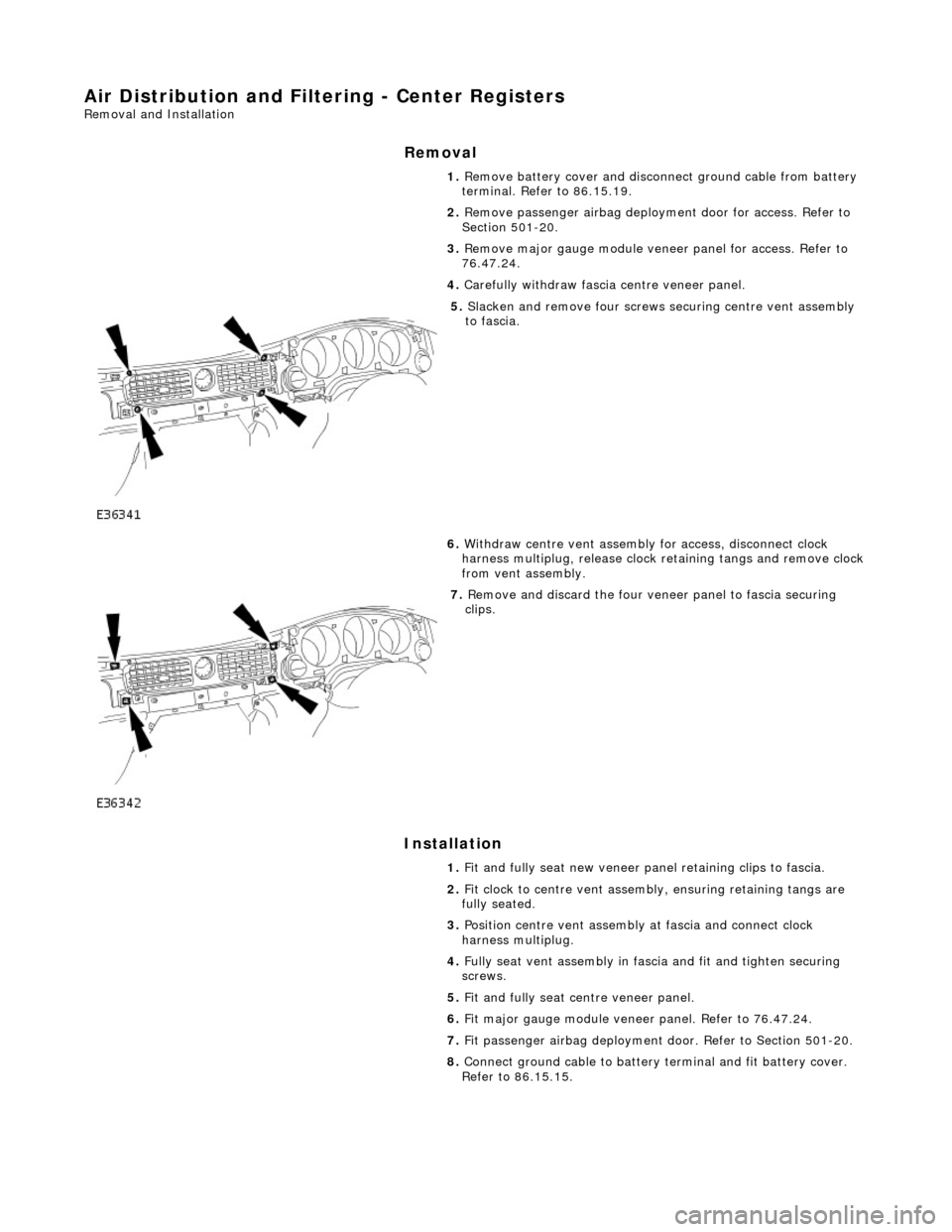

Removal

Installation

1.

Remove battery cover and disconnect ground cable from battery

terminal. Refer to 86.15.19.

2. Remove passenger airbag deployment door for access. Refer to

Section 501-20.

3. Remove major gauge module veneer panel for access. Refer to

76.47.24.

4. Carefully withdraw fascia centre veneer panel.

5. Slacken and remove four screws securing centre vent assembly

to fascia.

6. Withdraw centre vent assembly for access, disconnect clock

harness multiplug, release clock retaining tangs and remove clock

from vent assembly.

7. Remove and discard the four veneer panel to fascia securing

clips.

1. Fit and fully seat new veneer panel retaining clips to fascia.

2. Fit clock to centre vent assemb ly, ensuring retaining tangs are

fully seated.

3. Position centre vent assembly at fascia and connect clock

harness multiplug.

4. Fully seat vent assembly in fascia and fit and tighten securing

screws.

5. Fit and fully seat centre veneer panel.

6. Fit major gauge module veneer panel. Refer to 76.47.24.

7. Fit passenger airbag deployment door. Refer to Section 501-20.

8. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 1797 of 2490

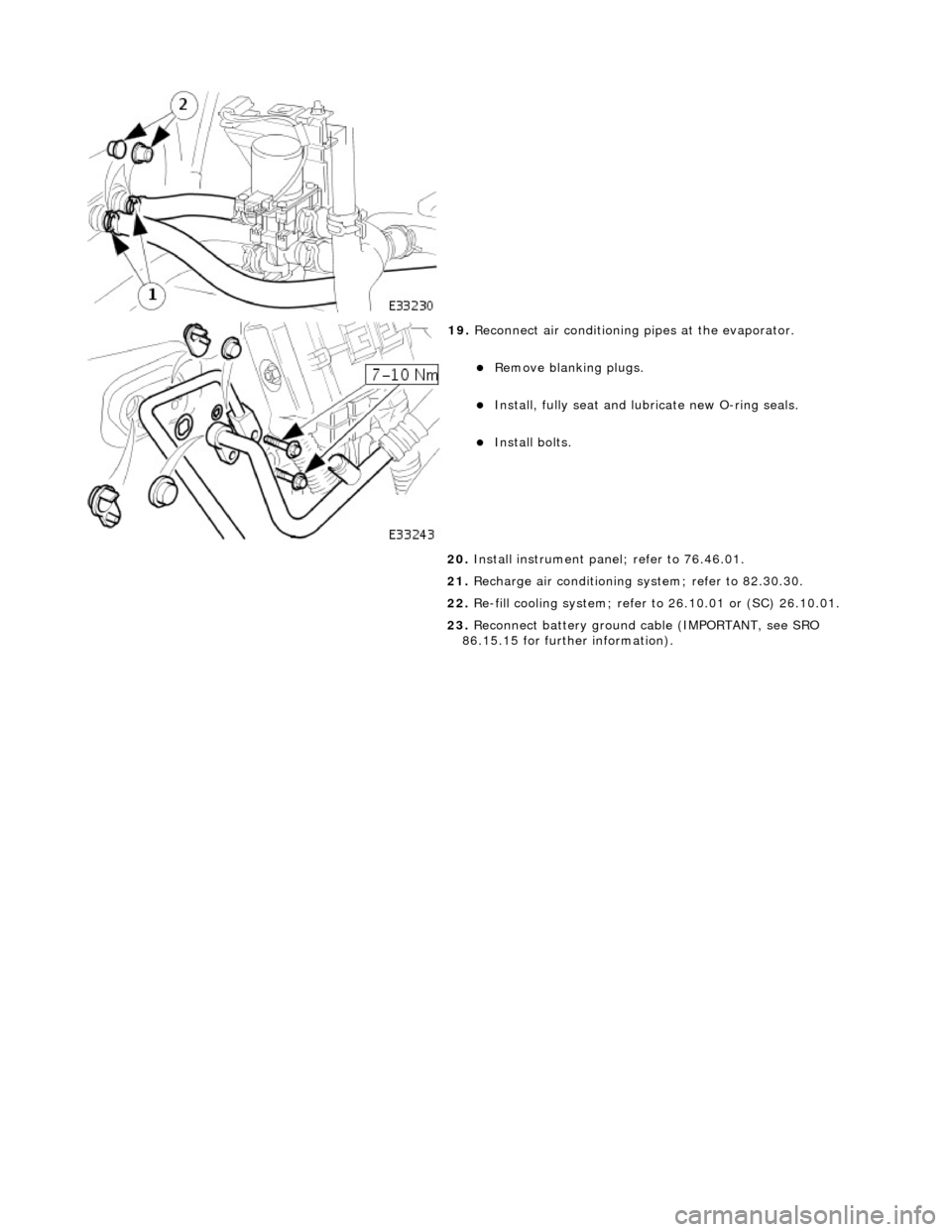

19. Reconnect air conditioning pipes at the evaporator.

Remove blanking plugs.

Install, fully seat and lubr icate new O-ring seals.

Install bolts.

20. Install instrument pane l; refer to 76.46.01.

21. Recharge air conditioning system; refer to 82.30.30.

22. Re-fill cooling system; refer to 26.10.01 or (SC) 26.10.01.

23. Reconnect battery ground cable (IMPORTANT, see SRO

86.15.15 for further information).

Page 1803 of 2490

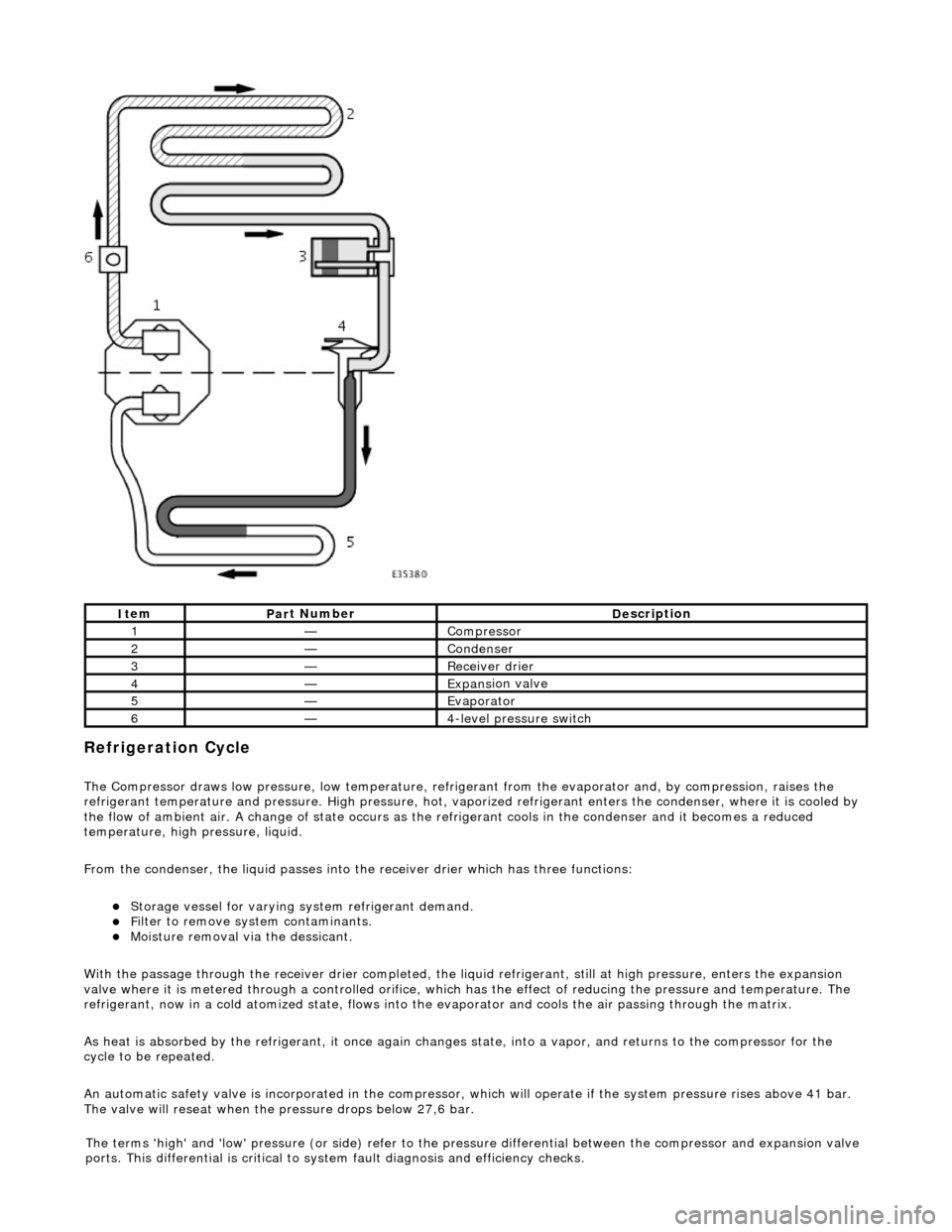

Refrigeration Cycle

The Compressor draws low pressure, lo

w te

mperature, refrigerant from the evaporat or and, by compression, raises the

refrigerant temperature and pressure. High pressure, hot, vaporized refr igerant enters the condenser, where it is cooled by

the flow of ambient air. A change of state occurs as the refrigerant cools in the condense r and it becomes a reduced

temperature, high pressure, liquid.

From the condenser, the liquid passes into the receiver drier which has three functions:

Storage vessel

for varying sy

stem refrigerant demand.

F

ilter to remove sy

stem contaminants.

Mo

isture removal via the dessicant.

With the passage through the receiver drie r completed, the liquid refrigerant, still at high pressure, enters the expansion

valve where it is metered through a contro lled orifice, which has the effect of reducing the pres sure and temperature. The

refrigerant, now in a cold atomized st ate, flows into the evaporator and cools the air passing through the matrix.

As heat is absorbed by the refrigerant, it once again changes state, into a vapor, and returns to the compressor for the

cycle to be repeated.

An automatic safety valve is incorporated in the compressor, which will operate if the system pressure rises above 41 bar.

The valve will reseat when the pressure drops below 27,6 bar.

It

em

Par

t Number

De

scription

1—Compre

ssor

2—Conden

ser

3—Re

ceiver drier

4—Expans

ion valve

5—Evaporator

6—4

-level pressure switch

The terms 'high' and 'low'

pressure (or si

de) refer to the pres sure differential betw een the compressor and expansion valve

ports. This differential is critical to sy stem fault diagnosis and efficiency checks.

Page 1846 of 2490

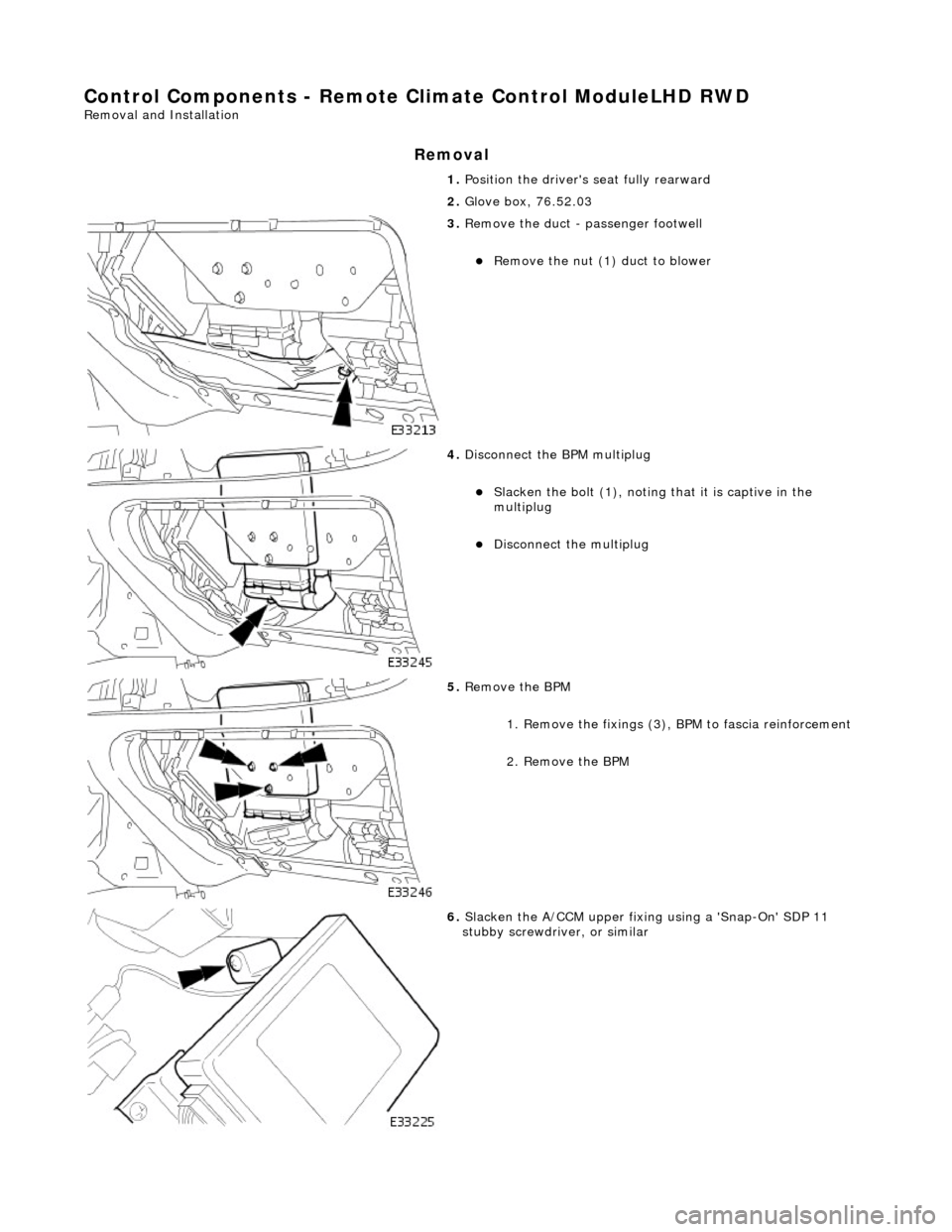

Control Components - Remote Climate Control ModuleLHD RWD

Removal and Installation

Removal

1. Position the driver's seat fully rearward

2. Glove box, 76.52.03

3. Remove the duct - passenger footwell

Remove the nut (1) duct to blower

4. Disconnect the BPM multiplug

Slacken the bolt (1), noting that it is captive in the

multiplug

Disconnect the multiplug

5. Remove the BPM

1. Remove the fixings (3), BPM to fascia reinforcement

2. Remove the BPM

6. Slacken the A/CCM upper fixing using a 'Snap-On' SDP 11

stubby screwdriver, or similar

Page 1848 of 2490

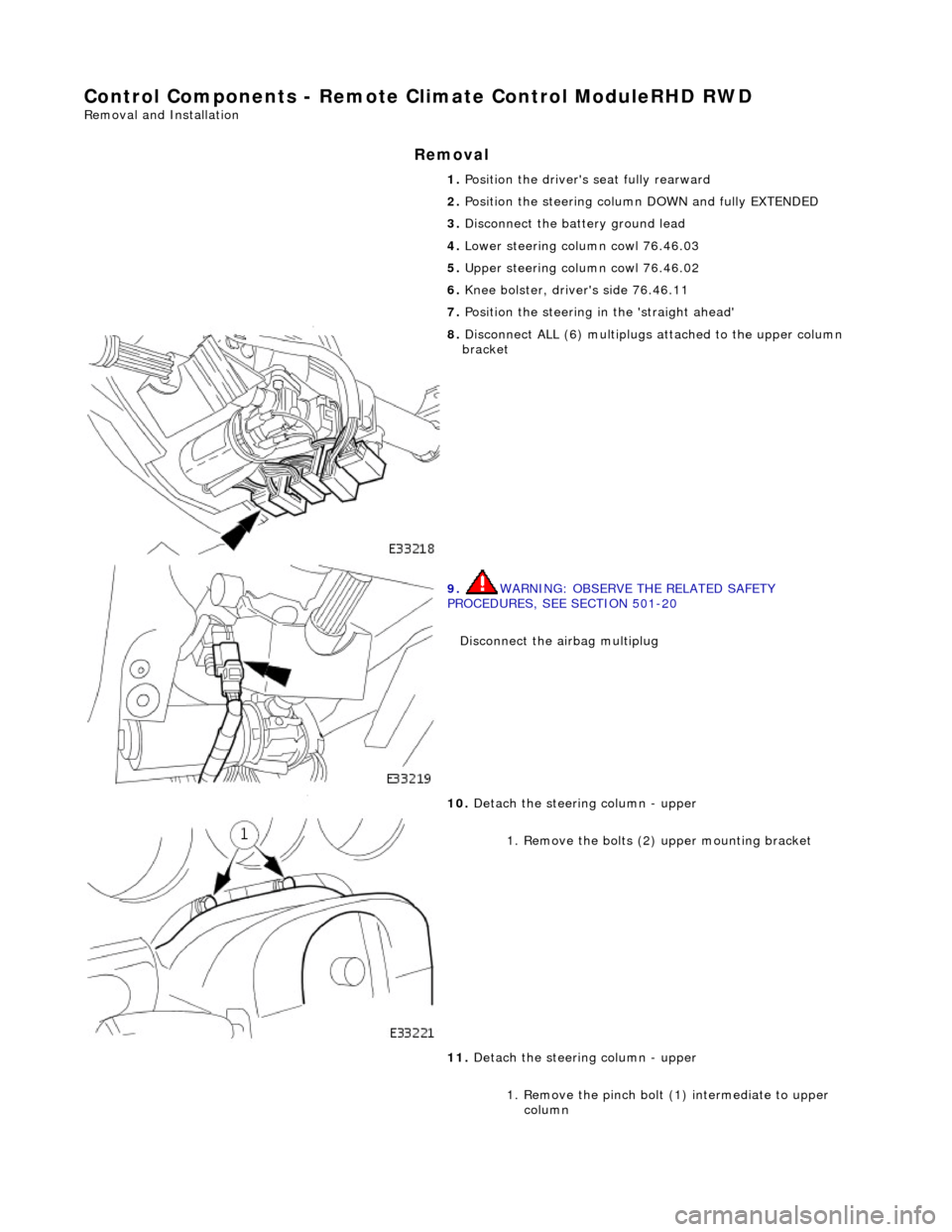

Control Components - Remote Climate Control ModuleRHD RWD

Removal and Installation

Removal

1. Position the driver's seat fully rearward

2. Position the steering column DOWN and fully EXTENDED

3. Disconnect the battery ground lead

4. Lower steering column cowl 76.46.03

5. Upper steering column cowl 76.46.02

6. Knee bolster, driver's side 76.46.11

7. Position the steering in the 'straight ahead'

8. Disconnect ALL (6) multiplugs attached to the upper column

bracket

9. WARNING: OBSERVE THE RELATED SAFETY

PROCEDURES, SEE SECTION 501-20

Disconnect the airbag multiplug

10. Detach the steering column - upper

1. Remove the bolts (2 ) upper mounting bracket

11. Detach the steering column - upper

1. Remove the pinch bolt (1) intermediate to upper column

Page 1853 of 2490

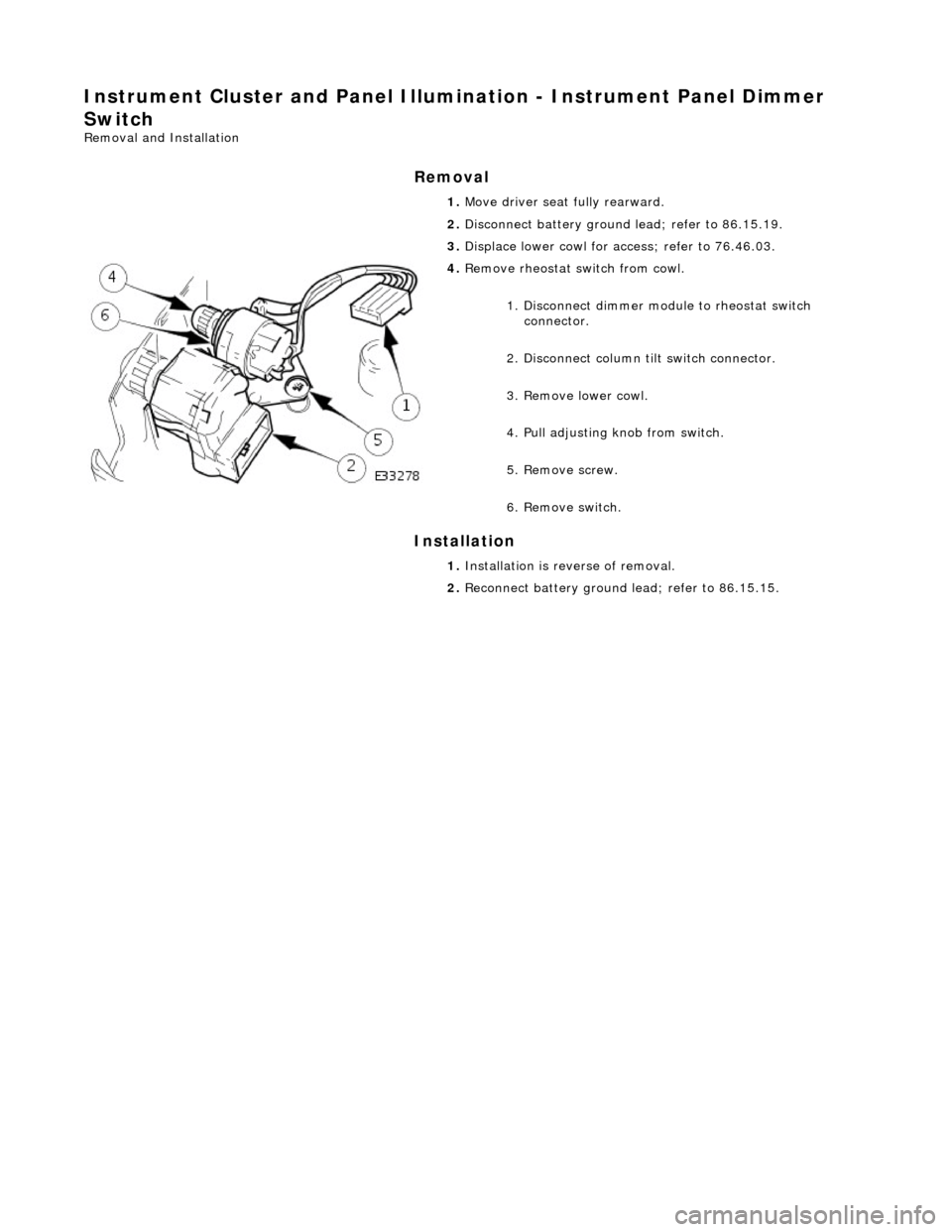

Instrument Cluster and Panel Illumination - Instrument Panel Dimmer

Switch

Removal and Installation

Removal

Installation

1.

Move driver seat fully rearward.

2. Disconnect battery ground lead; refer to 86.15.19.

3. Displace lower cowl for access; refer to 76.46.03.

4. Remove rheostat sw itch from cowl.

1. Disconnect dimmer module to rheostat switch connector.

2. Disconnect column tilt switch connector.

3. Remove lower cowl.

4. Pull adjusting knob from switch.

5. Remove screw.

6. Remove switch.

1. Installation is reverse of removal.

2. Reconnect battery ground lead; refer to 86.15.15.

Page 1858 of 2490

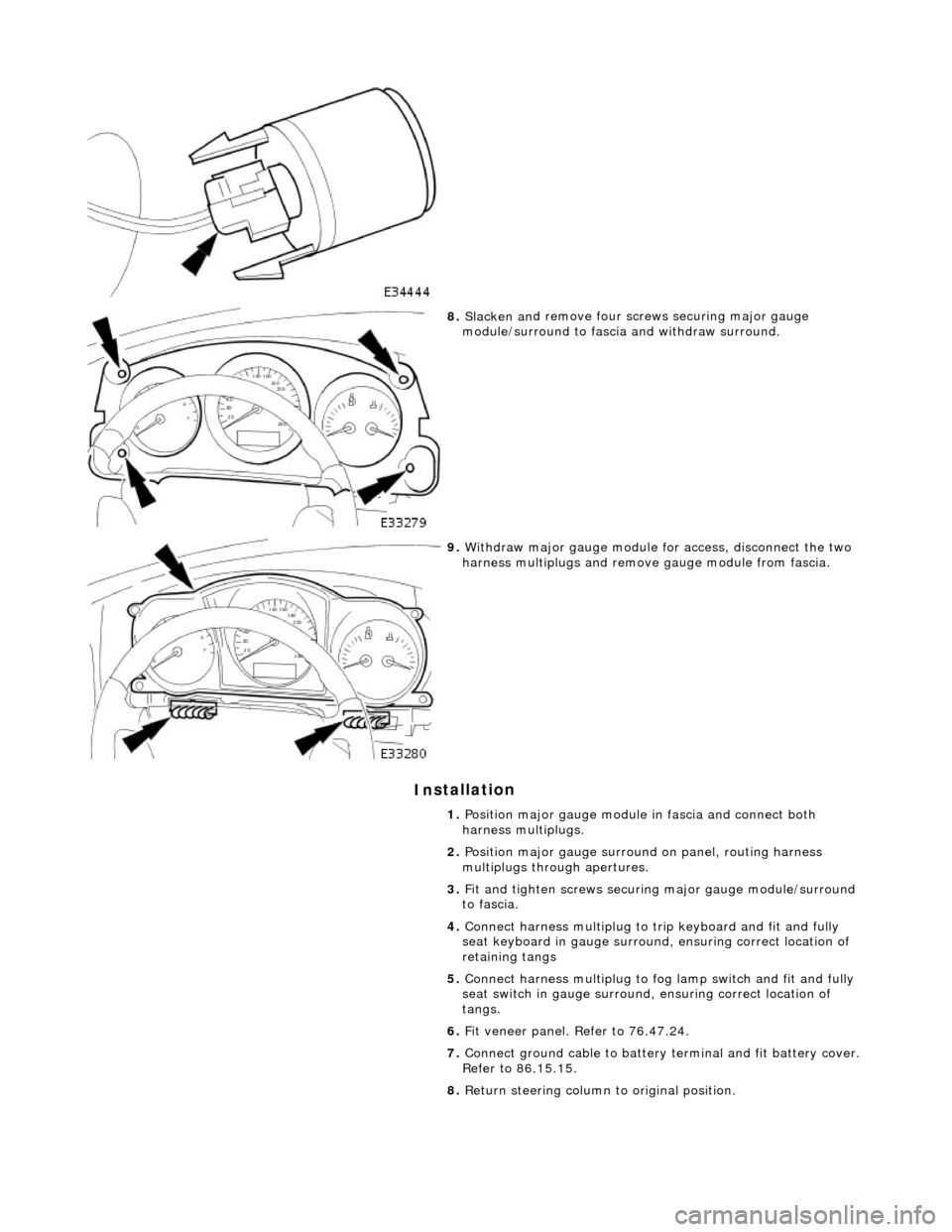

In

stallation

8.

Slac ken an

d remove four screws securing major gauge

module/surround to fascia and withdraw surround.

9. With draw major gau

ge module fo

r access, disconnect the two

harness multiplugs and remove gauge module from fascia.

1. Position major gauge module in fascia and connect both

harness multiplugs.

2. Position major gauge surround on panel, routing harness

multiplugs through apertures.

3. Fit and tighten screws securing major gauge module/surround

to fascia.

4. Connect harness multiplug to tr ip keyboard and fit and fully

seat keyboard in gauge surround, ensuring correct location of

retaining tangs

5. Connect harness multiplug to fog lamp switch and fit and fully

seat switch in gaug e surround, ensuring correct location of

tangs.

6. Fit veneer panel. Refer to 76.47.24.

7. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

8. Return steering column to original position.

Page 1925 of 2490

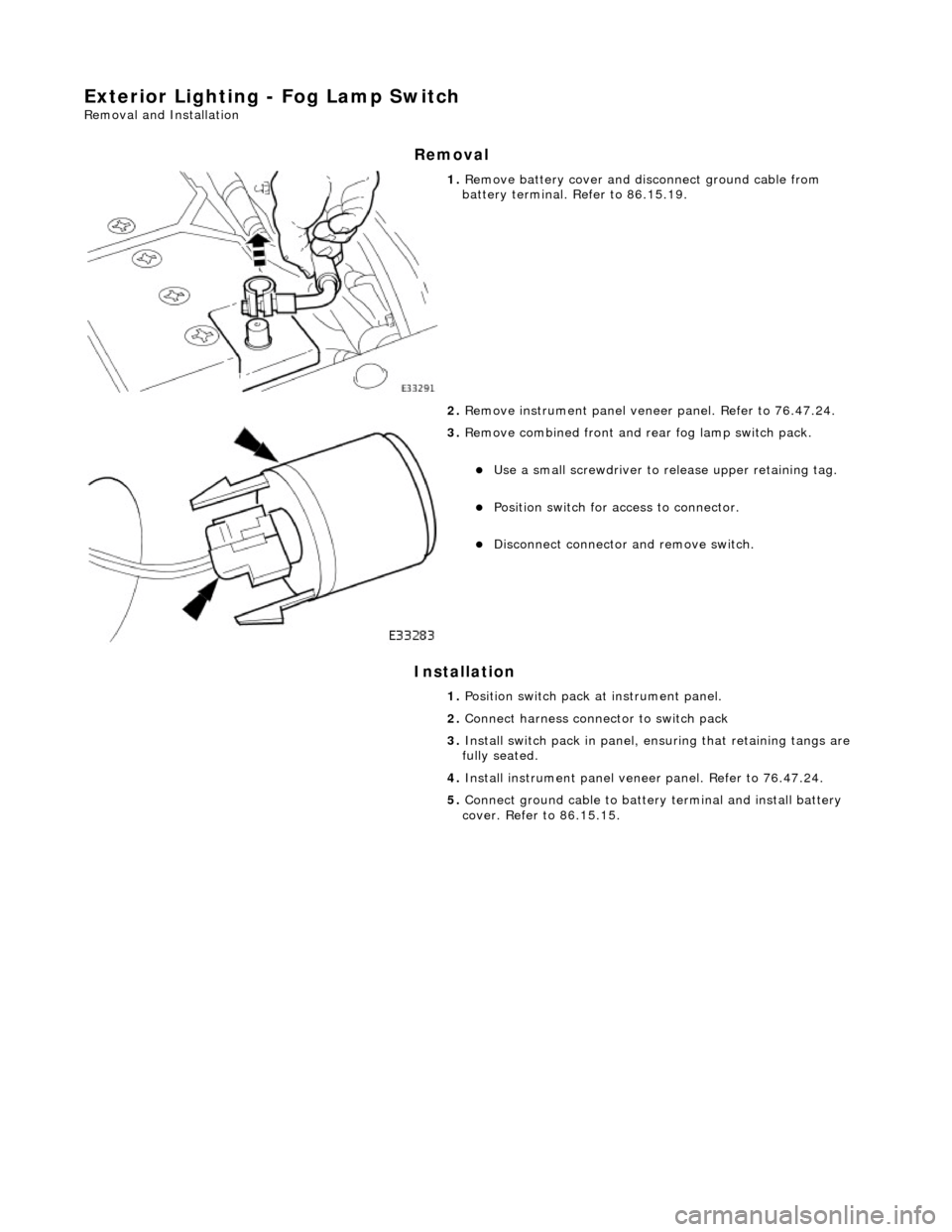

Exterior Lighting - Fog Lamp Switch

Removal and Installation

Removal

Installation

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove instrument pa nel veneer panel. Refer to 76.47.24.

3. Remove combined front and rear fog lamp switch pack.

Use a small screwdriver to re lease upper retaining tag.

Position switch for access to connector.

Disconnect connector and remove switch.

1. Position switch pack at instrument panel.

2. Connect harness connector to switch pack

3. Install switch pack in panel, ensuring that retaining tangs are

fully seated.

4. Install instrument panel veneer panel. Refer to 76.47.24.

5. Connect ground cable to batter y terminal and install battery

cover. Refer to 86.15.15.

Page 1927 of 2490

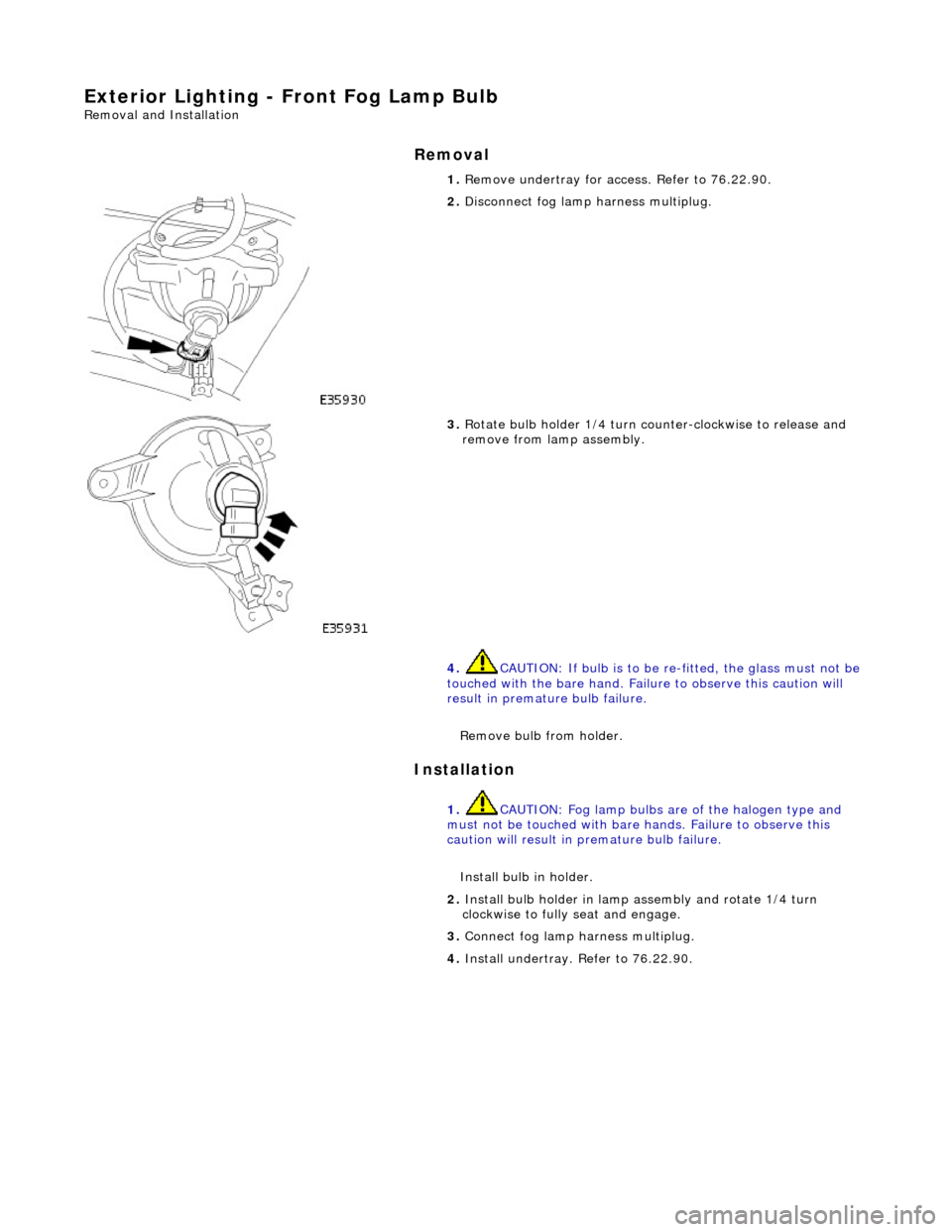

Exterior Lighting - Front Fog Lamp Bulb

Removal and Installation

Removal

Installation

1.

Remove undertray for ac cess. Refer to 76.22.90.

2. Disconnect fog lamp harness multiplug.

3. Rotate bulb holder 1/4 turn counter-clockwise to release and

remove from lamp assembly.

4. CAUTION: If bulb is to be re -fitted, the glass must not be

touched with the bare hand. Failure to observe this caution will

result in premature bulb failure.

Remove bulb from holder.

1. CAUTION: Fog lamp bulbs are of the halogen type and

must not be touched with bare hands. Failure to observe this

caution will result in premature bulb failure.

Install bulb in holder.

2. Install bulb holder in lamp assembly and rotate 1/4 turn

clockwise to fully seat and engage.

3. Connect fog lamp harness multiplug.

4. Install undertray. Refer to 76.22.90.