exhaust JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1238 of 2490

El

ectronic Engine Controls -

Catalyst Monitor Sensor RH

Remo

val and Installation

General Equipment

Remov a

l

Installation

Snap -

on tool S6176

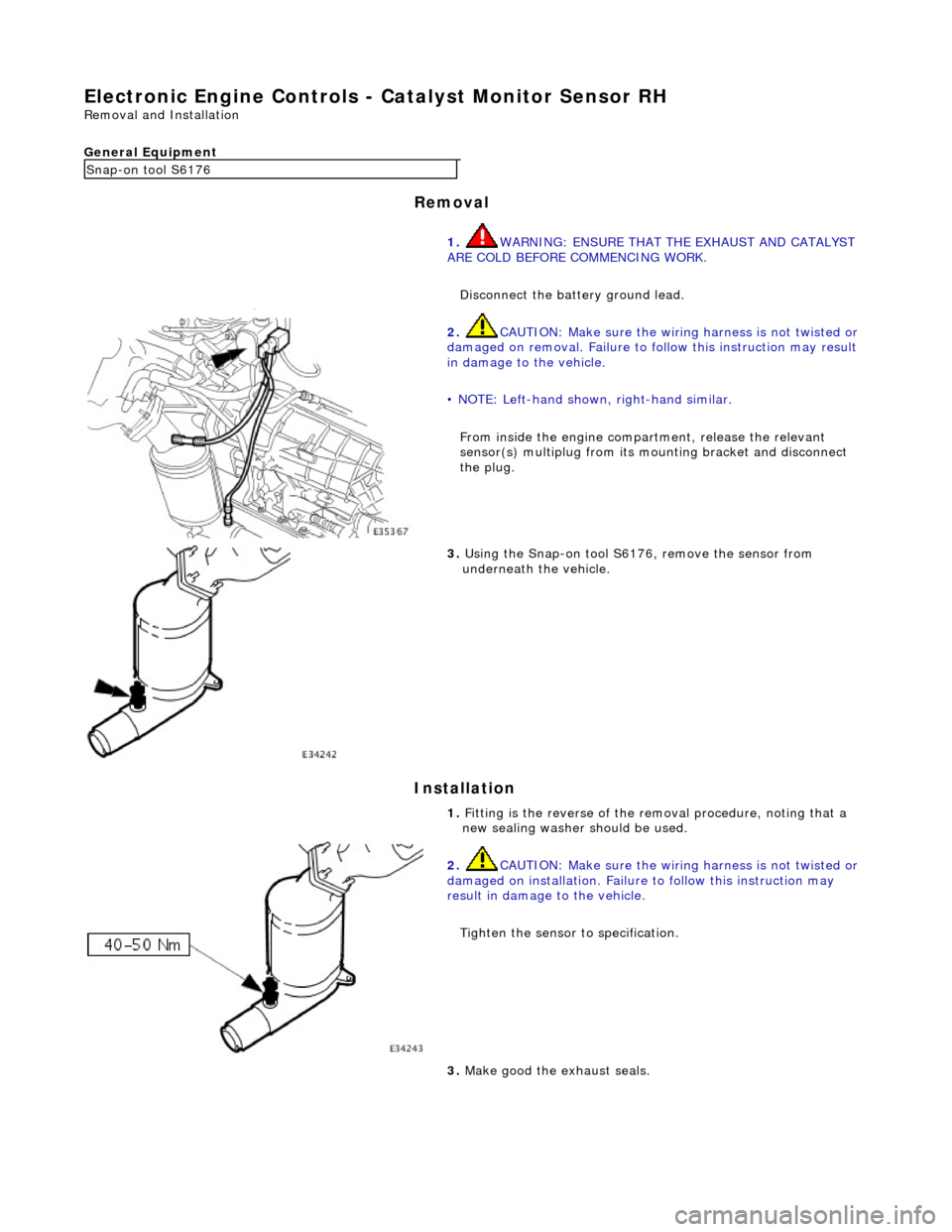

1. WARNING: ENSURE THAT THE EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK.

Disconnect the battery ground lead.

2. CAUTIO

N: Make sure the wiring harness is not twisted or

damaged on removal. Failure to fo llow this instruction may result

in damage to the vehicle.

• NOTE: Left-hand shown, right-hand similar.

From inside the engine compartment, release the relevant

sensor(s) multiplug from its mounting bracket and disconnect

the plug.

3. Us

ing the Snap-on tool S6176, remove the sensor from

underneath the vehicle.

1. Fitting is the reverse of the removal procedure, noting that a

new sealing washer should be used.

2. CAUTI

O

N: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may

result in damage to the vehicle.

Tighten the sensor to specification.

3. Make good th e exh

aust seals.

Page 1249 of 2490

Electron

ic Engine Controls -

Heated Oxygen Sensor (HO2S) LH

Rem

oval and Installation

General Equipment

Remov

al

Installation

Snap

-on tool S6176

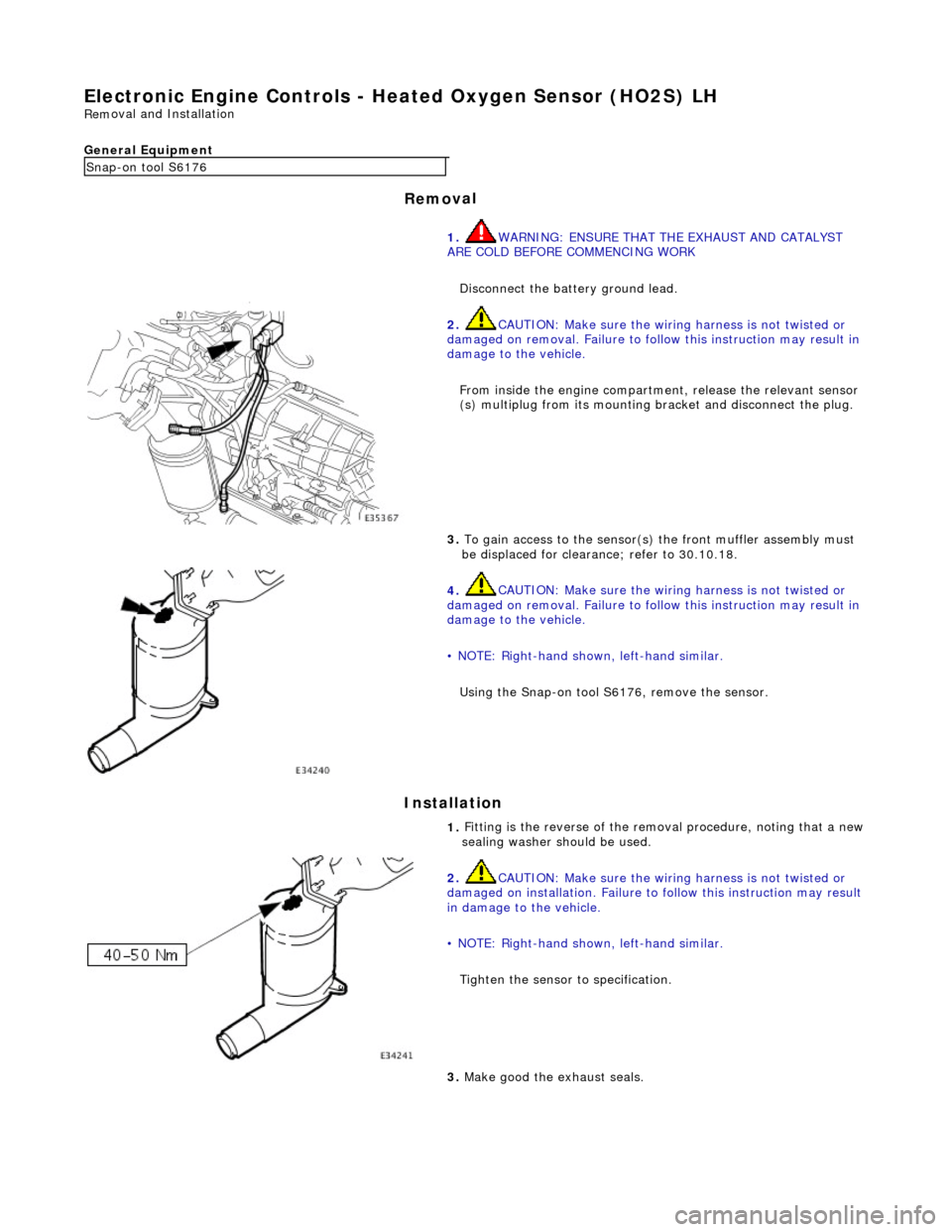

1. WARNING: ENSURE THAT TH E EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK

Disconnect the battery ground lead.

2.

CAUTION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

From inside the engine compartm ent, release the relevant sensor

(s) multiplug from its mounting bracket and disconnect the plug.

3.

To gain access to the sensor(s) the front muffler assembly must

be displaced for clearance; refer to 30.10.18.

4.

CAUTION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

• NOTE: Right-hand shown, left-hand similar.

Using the Snap-on tool S6176, remove the sensor.

1.

Fitting is the reverse of the remo val procedure, noting that a new

sealing washer should be used.

2.

CAUTION: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may result

in damage to the vehicle.

• NOTE: Right-hand shown, left-hand similar.

Tighten the sensor to specification.

3.

Make good the exhaust seals.

Page 1250 of 2490

Electronic

Engine Controls -

Heated Oxygen Sensor (HO2S) RH

Remo

val and Installation

General Equipment

Remov a

l

Installation

Snap -on to

ol S6176

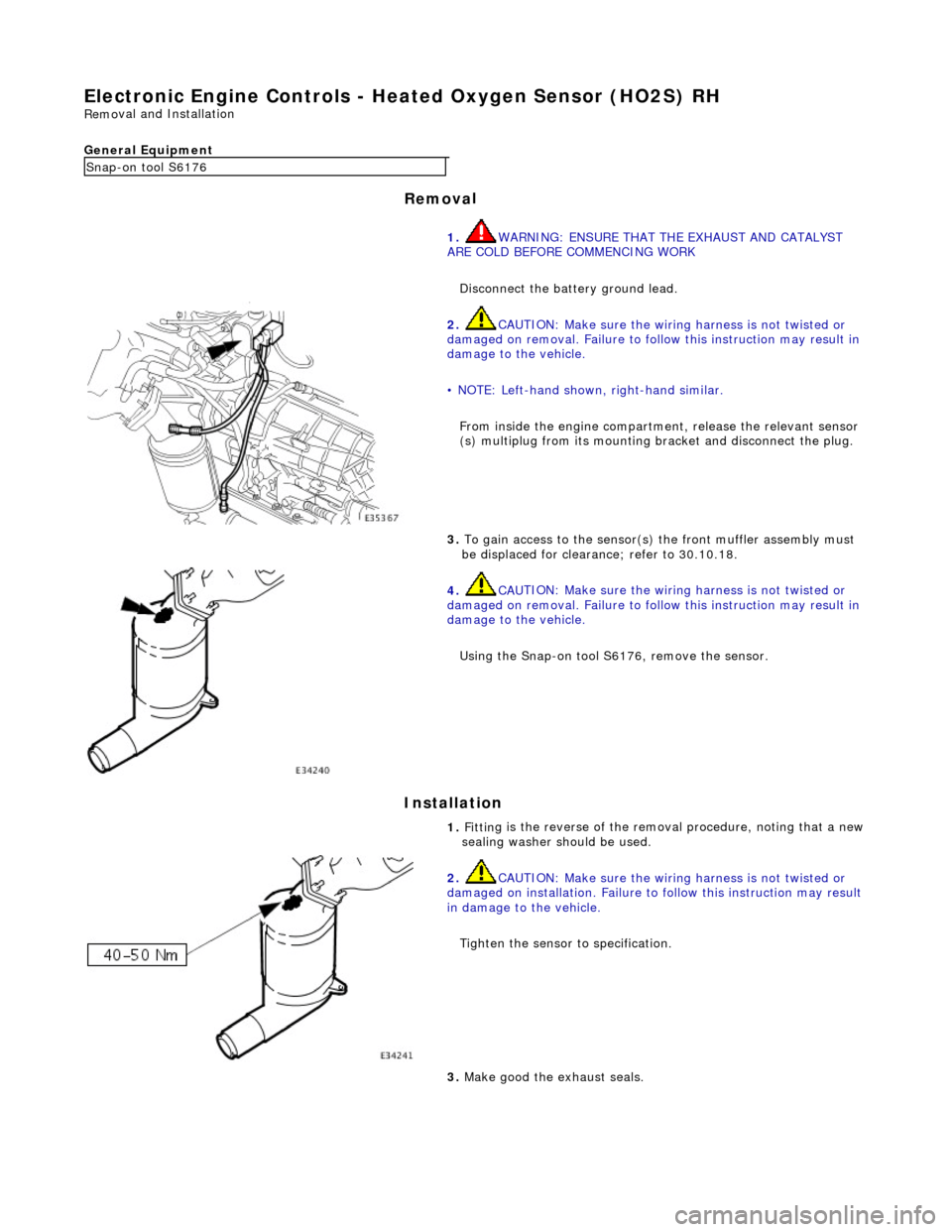

1. WARNING: ENSURE THAT TH E EXHAUST AND CATALYST

ARE COLD BEFORE COMMENCING WORK

Disconnect the battery ground lead.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

• NOTE: Left-hand shown, right-hand similar.

From inside the engine compartm ent, release the relevant sensor

(s) multiplug from its mounting bracket and disconnect the plug.

3. To

gain access to the sensor(s)

the front muffler assembly must

be displaced for clearance; refer to 30.10.18.

4. CAU

TION: Make sure the wiring harness is not twisted or

damaged on removal. Failure to follow this instruction may result in

damage to the vehicle.

Using the Snap-on tool S6176, remove the sensor.

1. Fittin

g is the reverse of the remo

val procedure, noting that a new

sealing washer should be used.

2. CAU

TION: Make sure the wiring harness is not twisted or

damaged on installation. Failure to follow this instruction may result

in damage to the vehicle.

Tighten the sensor to specification.

3. M

ake good the exhaust seals.

Page 1522 of 2490

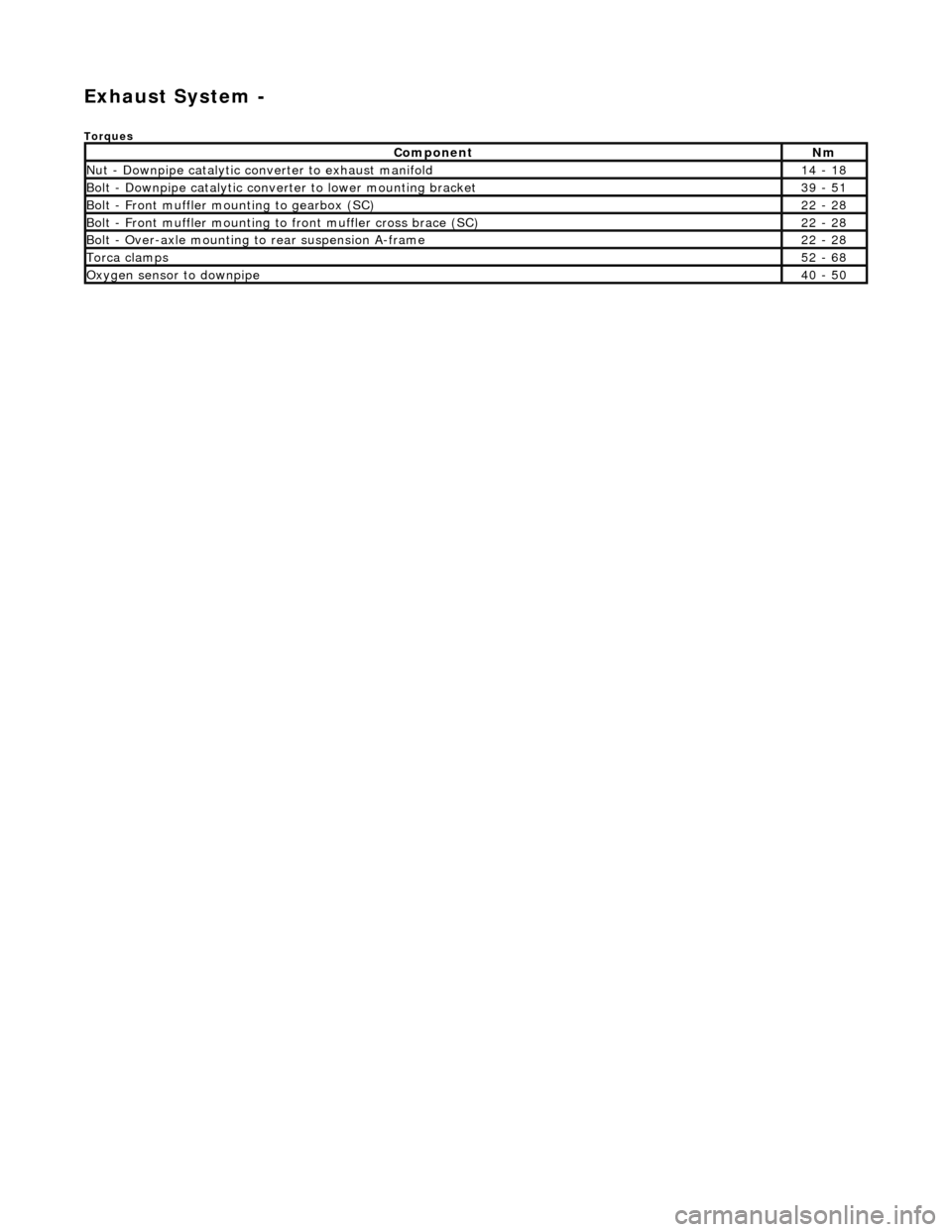

Exhaust System -

Torques

ComponentNm

Nut - Downpipe catalytic converter to exhaust manifold14 - 18

Bolt - Downpipe catalytic converter to lower mounting bracket39 - 51

Bolt - Front muffler mounting to gearbox (SC)22 - 28

Bolt - Front muffler mounting to front muffler cross brace (SC)22 - 28

Bolt - Over-axle mounting to rear suspension A-frame22 - 28

Torca clamps52 - 68

Oxygen sensor to downpipe40 - 50

Page 1523 of 2490

Exhaust System - Exhaust System

Description and Operation

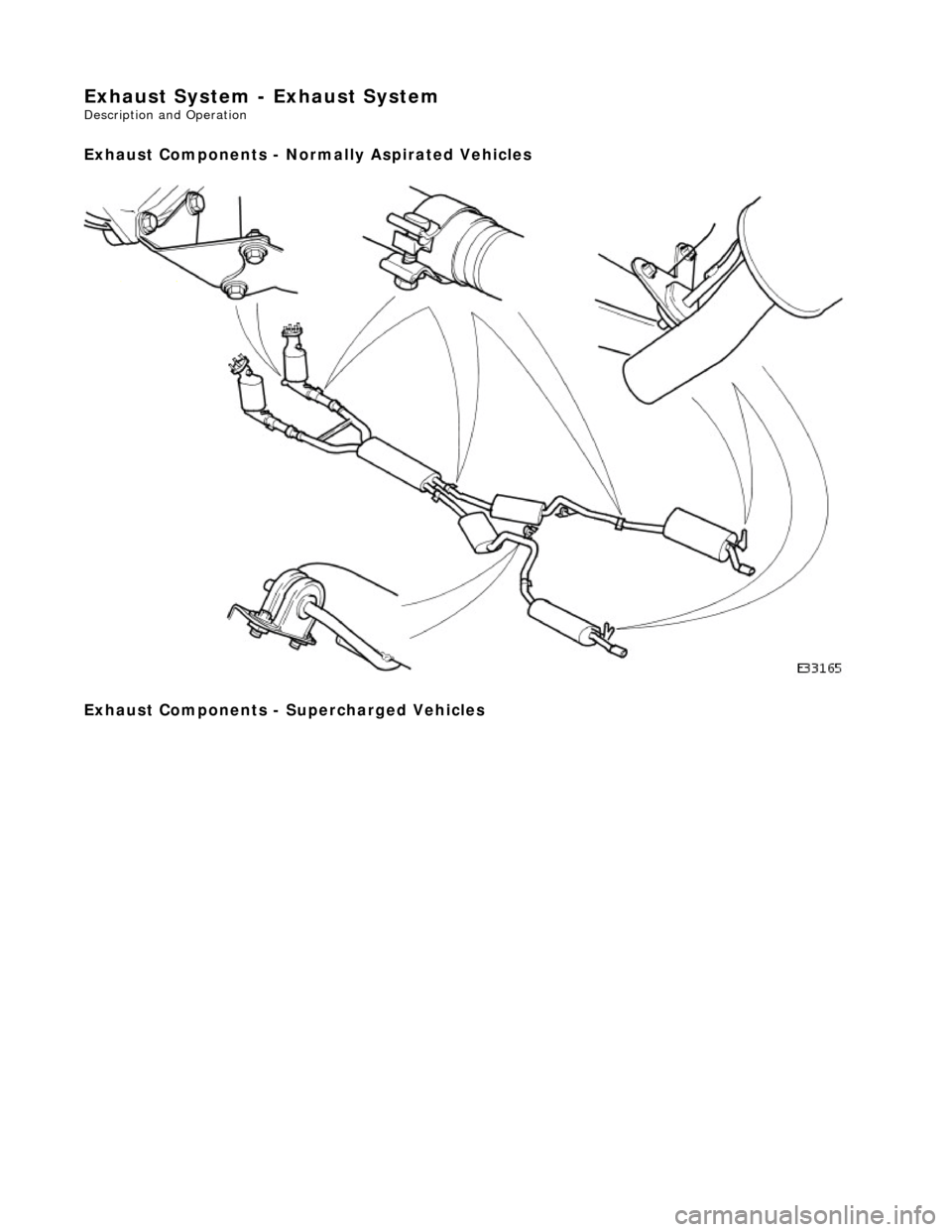

Exhaust Components - Normally Aspirated Vehicles

Exhaust Components - Supercharged Vehicles

Page 1524 of 2490

All vehicles are fitted with a stainless steel exhaust system which features:

Low back-pressure gas flow. Catalytic converters for mark ets having unleaded fuel. Front muffler common to the left-hand and right-hand engine cylinder banks.

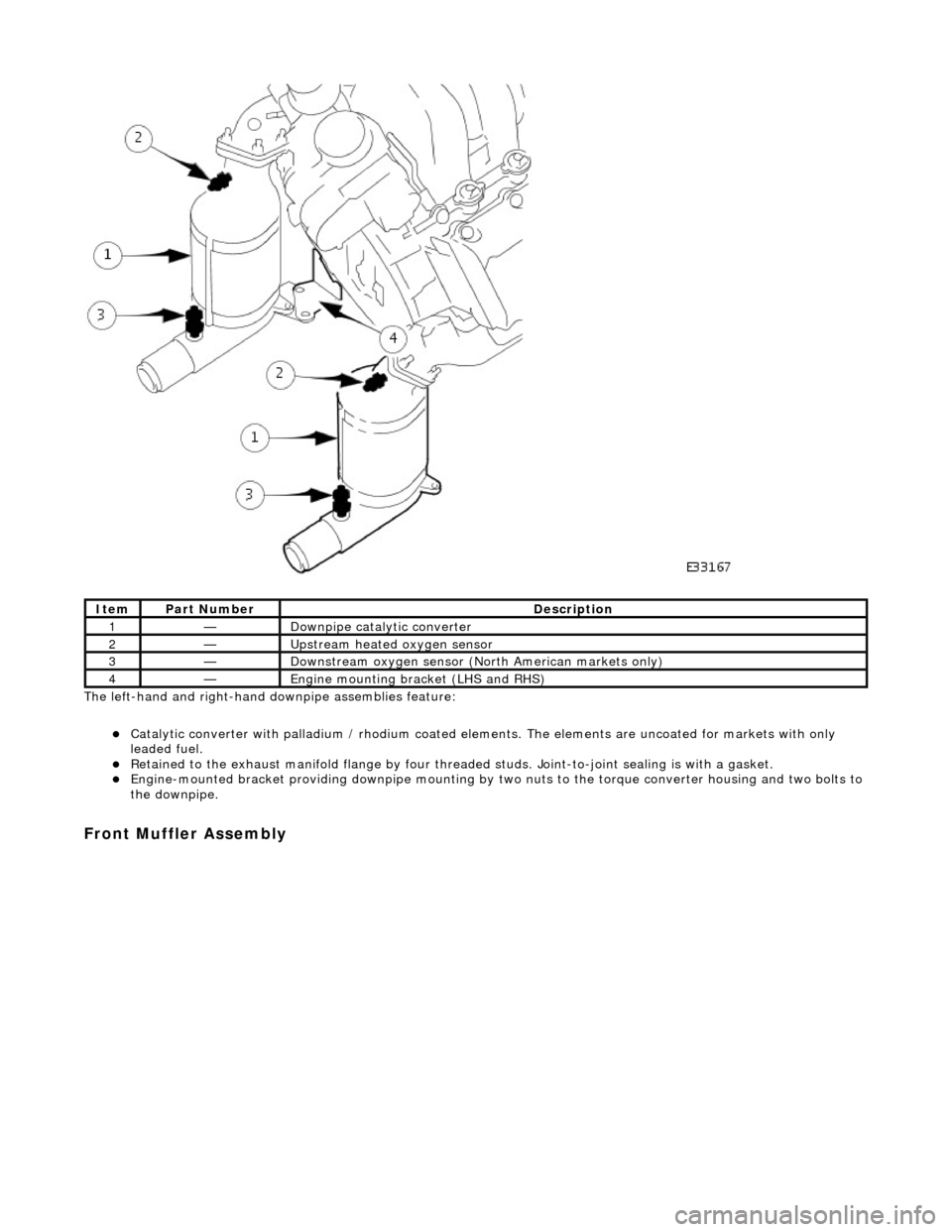

Downpipe Catalytic Converter Assembly

Page 1525 of 2490

The left-hand and right-hand do wnpipe assemblies feature:

Catalytic converter with palladium / rhodium coated elem ents. The elements are uncoated for markets with only

leaded fuel.

Retained to the exhaust manifold flange by four thread ed studs. Joint-to-joint sealing is with a gasket. Engine-mounted bracket providing downpipe mounting by two nuts to the torque converter housing and two bolts to

the downpipe.

Front Muffler Assembly

ItemPart NumberDescription

1—Downpipe catalytic converter

2—Upstream heated oxygen sensor

3—Downstream oxygen sensor (North American markets only)

4—Engine mounting bracket (LHS and RHS)

Page 1530 of 2490

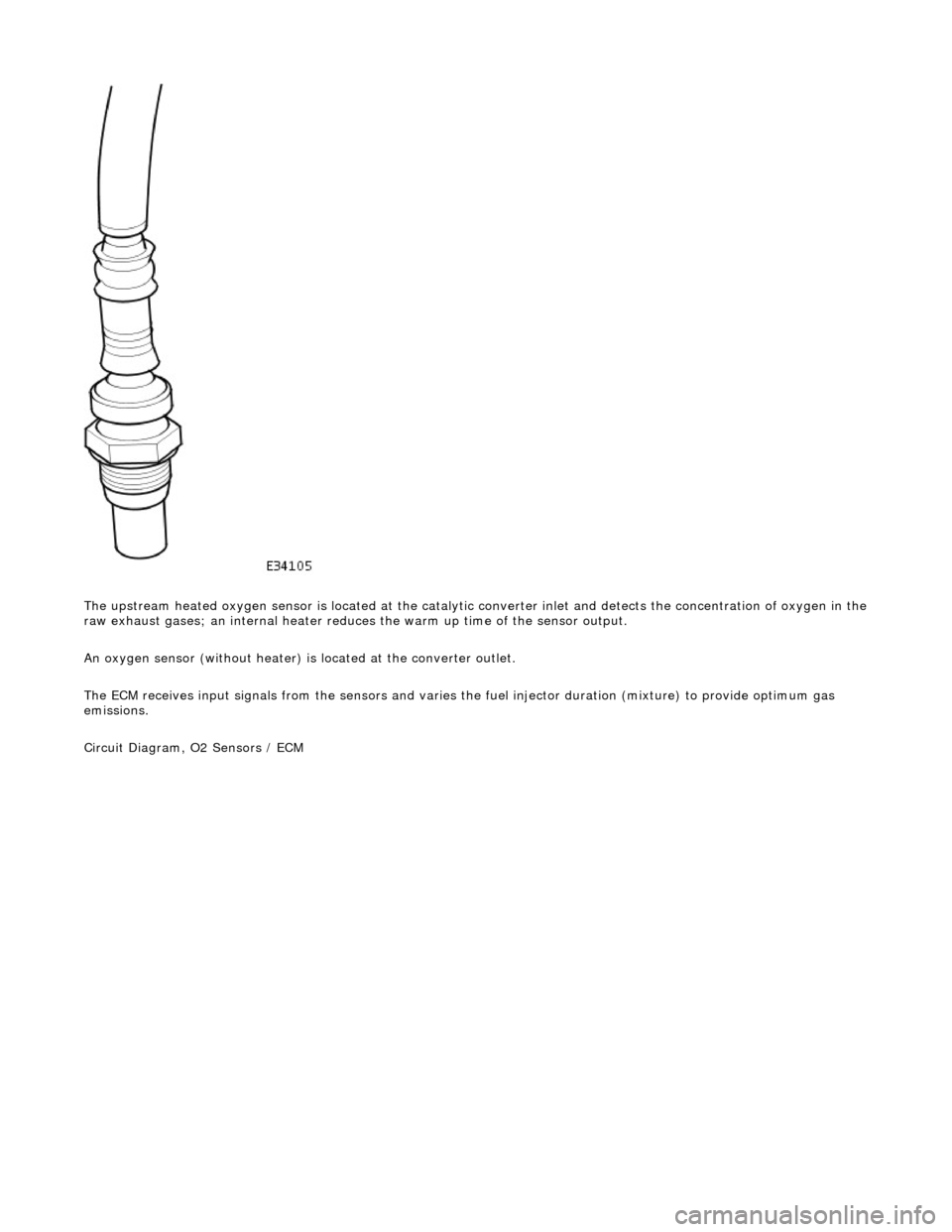

The upstream heated oxygen sensor is located at the catalytic converter inlet and detects the concentration of oxygen in the

raw exhaust gases; an internal heater reduces the warm up time of the sensor output.

An oxygen sensor (without heater) is located at the converter outlet.

The ECM receives input signals from the se nsors and varies the fuel injector duration (mixture) to provide optimum gas

emissions.

Circuit Diagram, O2 Sensors / ECM

Page 1533 of 2490

Exhaust System - Exhaust System

Diagnosis and Testing

Symptom Chart

Symptom Chart

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

DTC P0420 Catalyst system efficiency below

threshold (Bank 1)Catalyst failure

Upstream O2 sensor failure

Downstream O2 sensor failure

O2 sensor heater failure

Associated harness / connector failure

*

*

*

*

*See DTC P0137, P0138

and P0140

*

DTC P0430 Catalyst system efficiency below

threshold (Bank 2)Catalyst failure

Upstream O2 sensor failure

Downstream O2 sensor failure

O2 sensor heater failure

Associated harness / connector failure

*

*

*

*

*See DTC P0157, P0158

and P0160

*

DTC P0131 O2 sensor circuit low voltage (Bank 1

sensor 1)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test A

*

DTC P0132 O2 sensor circuit high voltage (Bank

1 sensor 1)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. O2 sensor failure

*

*

*

*

*GO to Pinpoint Test A

*

DTC P0133 O2 sensor circuit slow response

(Bank 1 sensor 1)O2 sensor heater failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

O2 sensor failure

*

*

*

*

*

*GO to Pinpoint Test B

*

DTC P0135 O2 sensor heater circuit malfunction

(Bank 1 sensor 1)O2 sensor failure

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*GO to Pinpoint Test A

*

DTC P0137 O2 sensor circuit low voltage (Bank 1

sensor 2)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test C

*

DTC P0138 O2 sensor circuit high voltage (Bank

1 sensor 2)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

*

*

*

*GO to Pinpoint Test C

*

Page 1534 of 2490

Pinpoint test A: P0131, P0132, P0135

between connections. ECM failure

*

DTC P0140 O2 sensor circuit no activity detected

(Bank 1 sensor 2)O2 sensor failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

*

*

*

*

*GO to Pinpoint Test D

*

DTC P0420 Catalyst system efficiency below

threshold (bank 1)Downstream O2 sensor failure

Catalyst failure

Catalyst low temperature caused by

water splash

*

*

*GO to Pinpoint Test C

GO to Pinpoint Test D

*

*

DTC P0151 O2 sensor circuit low voltage (Bank 2

sensor 1)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test E

*

DTC P0152 O2 sensor circuit high voltage (Bank

2 sensor 1)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. O2 sensor failure

*

*

*

*

*GO to Pinpoint Test E

*

DTC P0153 O2 sensor circuit slow response

(Bank 2 sensor 1)O2 sensor heater failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

O2 sensor failure

*

*

*

*

*

*GO to Pinpoint Test F

*

DTC P0155 O2 sensor heater circuit malfunction

(Bank 2 sensor 1)O2 sensor failure

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*GO to Pinpoint Test E

*

DTC P0157 O2 sensor circuit low voltage (Bank 2

sensor 2)O2 sensor failure

Sensor ground fault

Harness failure

Connector pin(s) bent, loose or corroded

*

*

*

*GO to Pinpoint Test G

*

DTC P0158 O2 sensor circuit high voltage (Bank

2 sensor 2)O2 sensor failure to B+

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. ECM failure

*

*

*

*

*GO to Pinpoint Test G

*

DTC P0160 O2 sensor circuit no activity detected

(Bank 2 sensor 2)O2 sensor failure / out of spec

Sensor ground fault

Harness failure

Connector pin(s) bent or tracking

between connections. Low exhaust temperature

*

*

*

*

*GO to Pinpoint Test H

*

DTC P0430 Catalyst system efficiency below

threshold (bank 2)Downstream O2 sensor failure

Catalyst failure

Catalyst low temperature caused by

water splash

*

*

*GO to Pinpoint Test G

GO to Pinpoint Test H

*

*

PINPOINT TEST A : P0131, P0132, P0135

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.