module JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2036 of 2490

The hinged fuel filler flap which is attached to the rear saddle panel by two nuts, incorporates a rubber buffer, snap-in

striker, hinge spring and fuel cap stowage magnet. The rubber fuel bowl moulding at tached via a steel armature to the body reinforcement panel, is retained at the filler neck by a clip. A mating drain tube is fitted with an internal filter. The filler flap

latch mechanism which is secured by nuts to the fuel bowl armature, comprises a locking pin and actuator. The actuator,

driven directly by the security and lock ing control module, operates independently from the central locking system. Locking

of the fuel filler flap can only be achieved by operation of the key or the remote rf transmitter.

Page 2121 of 2490

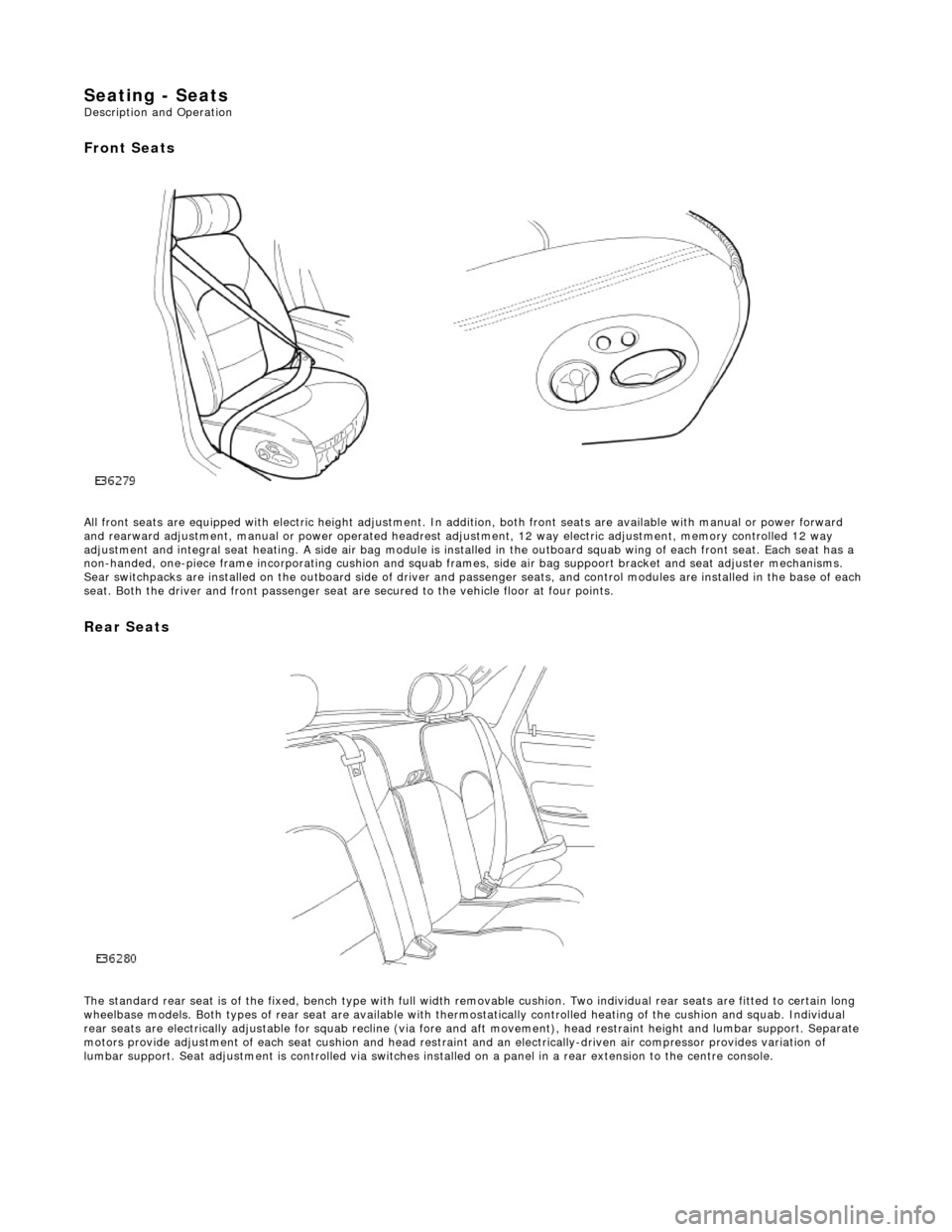

Seating - Seats Description and Operation

Front Seats

All front seats are equipped with electric height adjustment. In addition, both front seats are available with manual or power forward

and rearward adjustment, manual or powe r operated headrest adjustment, 12 way elec tric adjustment, memory controlled 12 way

adjustment and integral seat heating. A side air bag module is installed in the outboard squab wing of each front seat. Each se at has a

non-handed, one-piece frame incorporating cushion and squab frames , side air bag suppoort bracket and seat adjuster mechanisms.

Sear switchpacks are installed on the outboa rd side of driver and passenger seats, and control modules are installed in the bas e of each

seat. Both the driver and front passenger seat ar e secured to the vehicle floor at four points.

Rear Seats

The standard rear seat is of the fixed, bench type with full wi dth removable cushion. Two individual rear seats are fitted to certain long

wheelbase models. Both types of rear seat are available with thermostatically controlled heating of the cushion and squab. Indi vidual

rear seats are electrically adjustable for squab recline (via fore and aft moveme nt), head restraint height and lumbar support. Separate

motors provide adjustment of each seat cushion and head restraint and an electrica lly-driven air compressor provides variation of

lumbar support. Seat adjustment is controll ed via switches installed on a panel in a rear extension to the centre console.

Page 2122 of 2490

Seating - Front Seat

Removal and Installation

Removal

1. Move the seat fully rearward and slacken and remove the

front securing bolts.

2. Move steering wheel to fully forward position.

3. Ensure that squab is fully upright, then move the seat fully

forward.

4. WARNING: FOLLOWING DISCONNECTION OF THE

BATTERY A PERIOD OF AT LEAST ONE MINUTE MUST BE

ALLOWED TO ELAPSE BEFORE WORKING ON A FRONT SEAT WITH

A SIDE AIRBAG FITTED.

Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

5. Remove the slider covers an d slacken and remove the two

rear securing bolts.

6. Supporting and positioning the seat for access, disconnect

multiplugs.

Disconnect side air bag harness multiplug.

Release from retaining brackets and disconnect seat

harness multiplugs.

Disconnect seat control module harness multiplug.

Cut through and remove any ti es securing harnesses to

seat frame.

7. NOTE: Securing bolt remains captive with belt anchor.

Slacken and remove seat be lt anchor securing bolt.

Page 2149 of 2490

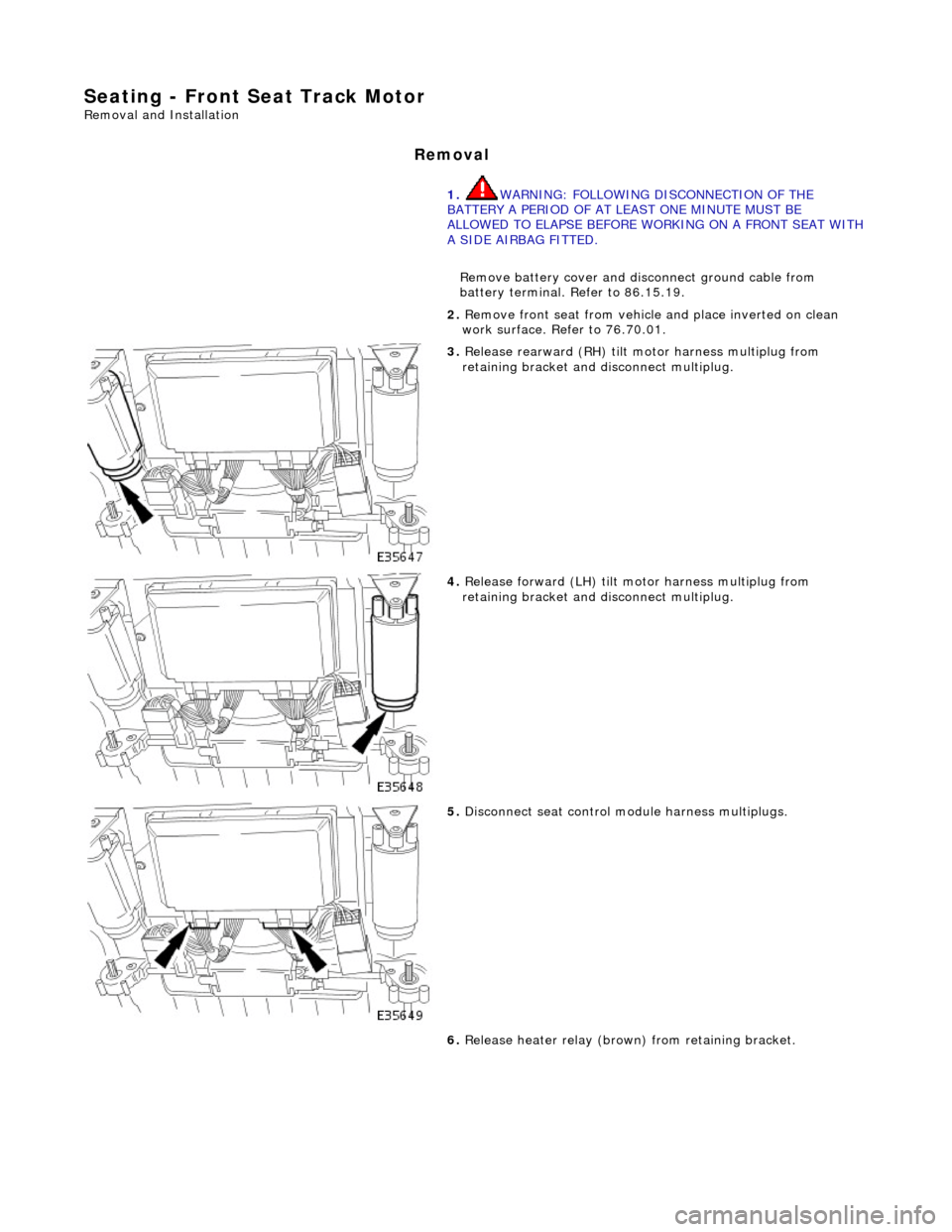

Seating - Front Seat Track Motor

Removal and Installation

Removal

1. WARNING: FOLLOWING DISCONNECTION OF THE

BATTERY A PERIOD OF AT LEAST ONE MINUTE MUST BE

ALLOWED TO ELAPSE BEFORE WORKING ON A FRONT SEAT WITH

A SIDE AIRBAG FITTED.

Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove front seat from vehicle and place inverted on clean

work surface. Re fer to 76.70.01.

3. Release rearward (RH) tilt motor harness multiplug from

retaining bracket and di sconnect multiplug.

4. Release forward (LH) tilt motor harness multiplug from

retaining bracket and di sconnect multiplug.

5. Disconnect seat control module harness multiplugs.

6. Release heater relay (brown ) from retaining bracket.

Page 2153 of 2490

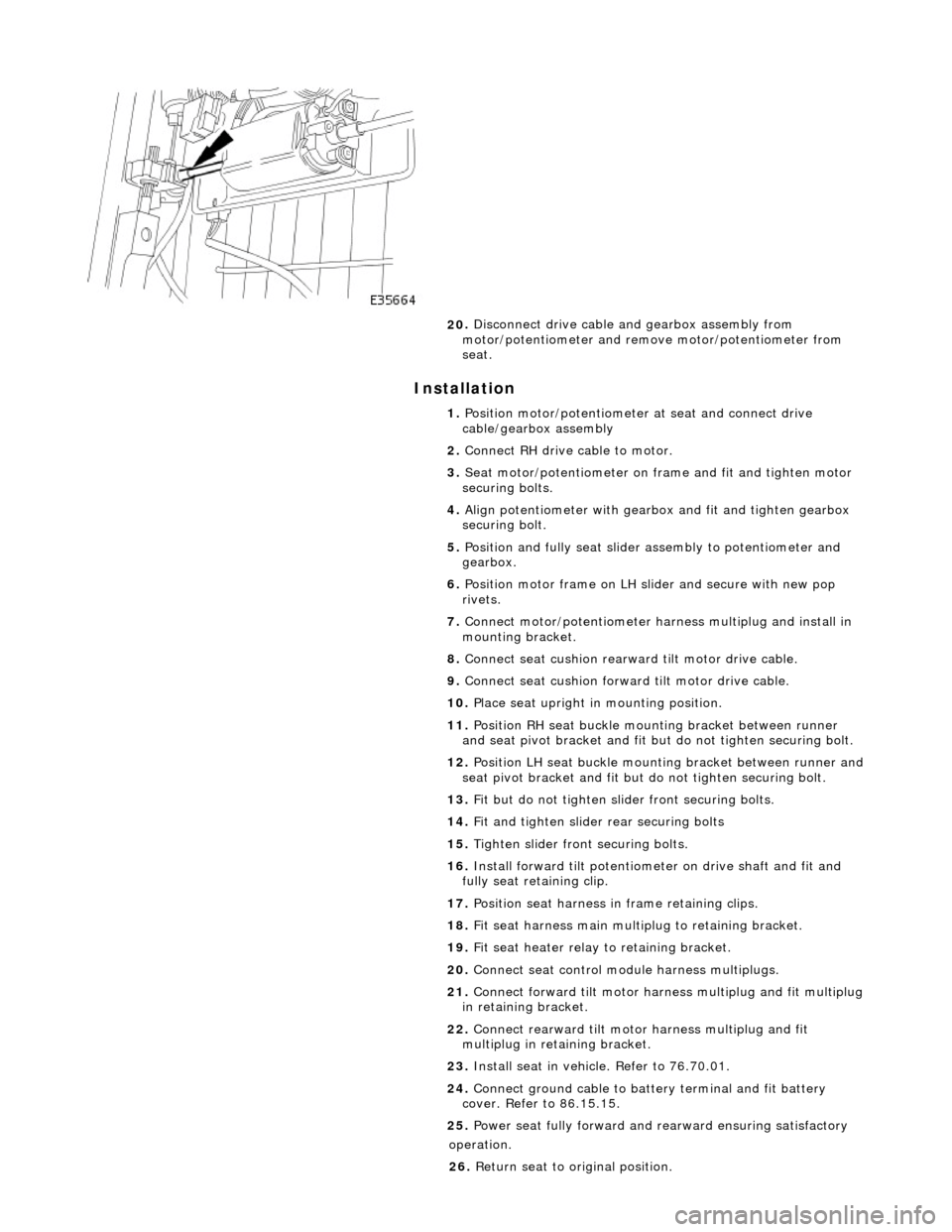

I

nstallation

20

.

Disconnect drive cable and gearbox assembly from

motor/potentiometer and remo ve motor/potentiometer from

seat.

1. Position motor/potentiometer at seat and connect drive

cable/gearbox assembly

2. Connect RH drive cable to motor.

3. Seat motor/potentiometer on fra me and fit and tighten motor

securing bolts.

4. Align potentiometer with gearbo x and fit and tighten gearbox

securing bolt.

5. Position and fully seat slider assembly to potentiometer and

gearbox.

6. Position motor frame on LH sl ider and secure with new pop

rivets.

7. Connect motor/potentiometer harness multiplug and install in

mounting bracket.

8. Connect seat cushion rearward tilt motor drive cable.

9. Connect seat cushion forwar d tilt motor drive cable.

10. Place seat upright in mounting position.

11. Position RH seat buckle mounting bracket between runner

and seat pivot bracket and fit but do not tighten securing bolt.

12. Position LH seat buckle mounting bracket between runner and

seat pivot bracket an d fit but do not tighten securing bolt.

13. Fit but do not tighten slider front securing bolts.

14. Fit and tighten slider rear securing bolts

15. Tighten slider front securing bolts.

16. Install forward tilt potentiome ter on drive shaft and fit and

fully seat retaining clip.

17. Position seat harness in frame retaining clips.

18. Fit seat harness main multiplug to retaining bracket.

19. Fit seat heater relay to retaining bracket.

20. Connect seat control module harness multiplugs.

21. Connect forward tilt motor harn ess multiplug and fit multiplug

in retaining bracket.

22. Connect rearward tilt motor harness multiplug and fit

multiplug in retaining bracket.

23. Install seat in vehicle. Refer to 76.70.01.

24. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

25. Power seat fully forward and rearward ensuring satisfactory

op

eration.

26. Return seat to original position.

Page 2184 of 2490

4.

Fully raise glass and using linen tape, secure to top of door

frame.

5. Fit door glass lift motor. Refer to 86.25.04.

6. Fit door module. Refer to 86.80.34.

7. Reposition PVC inne r weathershield.

8. Position water shedder and carefully pass harness multiplugs

through penetration.

9. Ensuring door mating surfaces ar e clean and dry, firmly seat

water shedder.

10. Fit door casing. Refer to 76.34.01.

11. Connect ground cable to batter y terminal and fit cover to

battery. Refer to 86.15.15.

Page 2188 of 2490

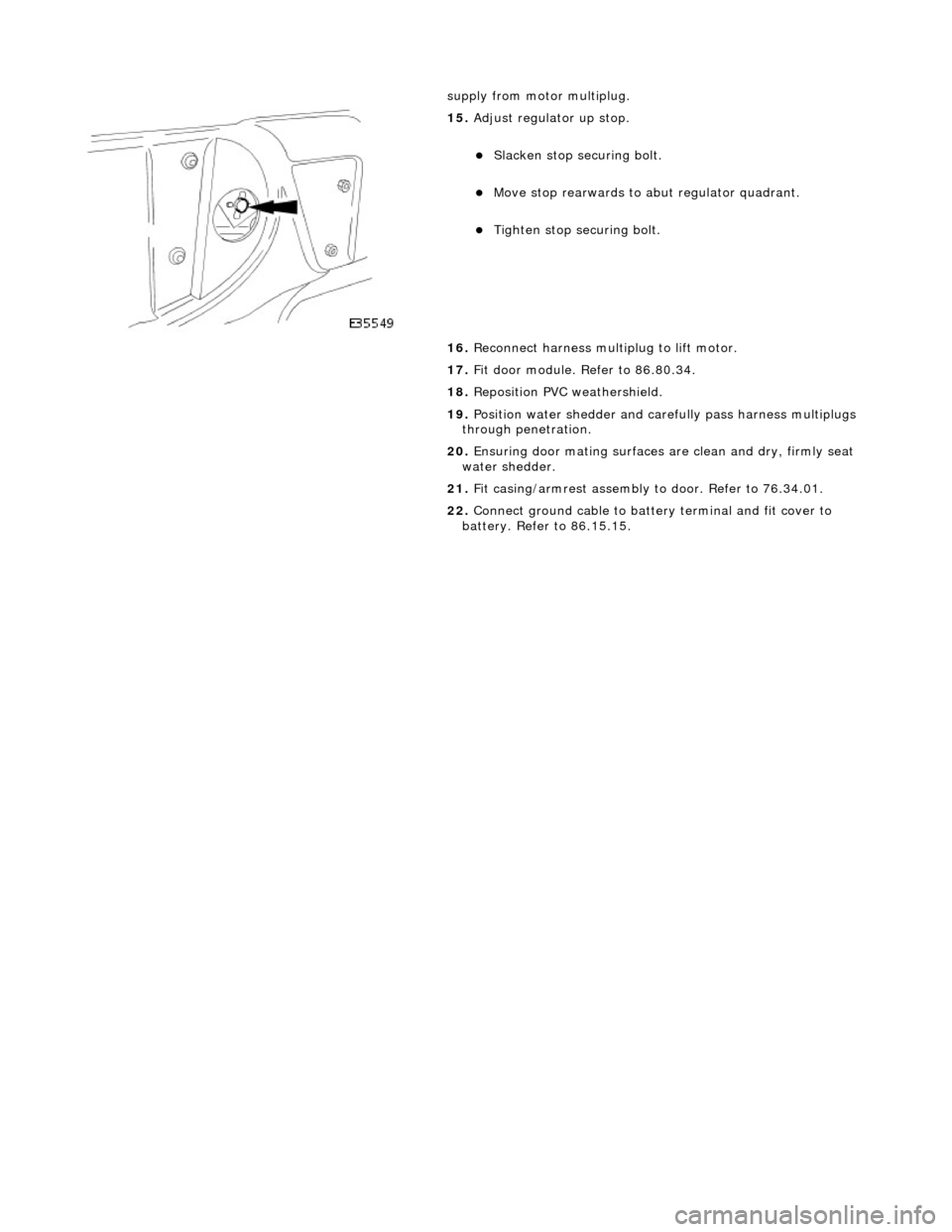

supply from motor multiplug.

15.

Adjust regulator up stop.

Slacken stop securing bolt.

Move stop rearwards to abut regulator quadrant.

Tighten stop securing bolt.

16. Reconnect harness multiplug to lift motor.

17. Fit door module. Refer to 86.80.34.

18. Reposition PVC weathershield.

19. Position water shedder and carefully pass harness multiplugs

through penetration.

20. Ensuring door mating surfaces ar e clean and dry, firmly seat

water shedder.

21. Fit casing/armrest assembly to door. Refer to 76.34.01.

22. Connect ground cable to batter y terminal and fit cover to

battery. Refer to 86.15.15.

Page 2191 of 2490

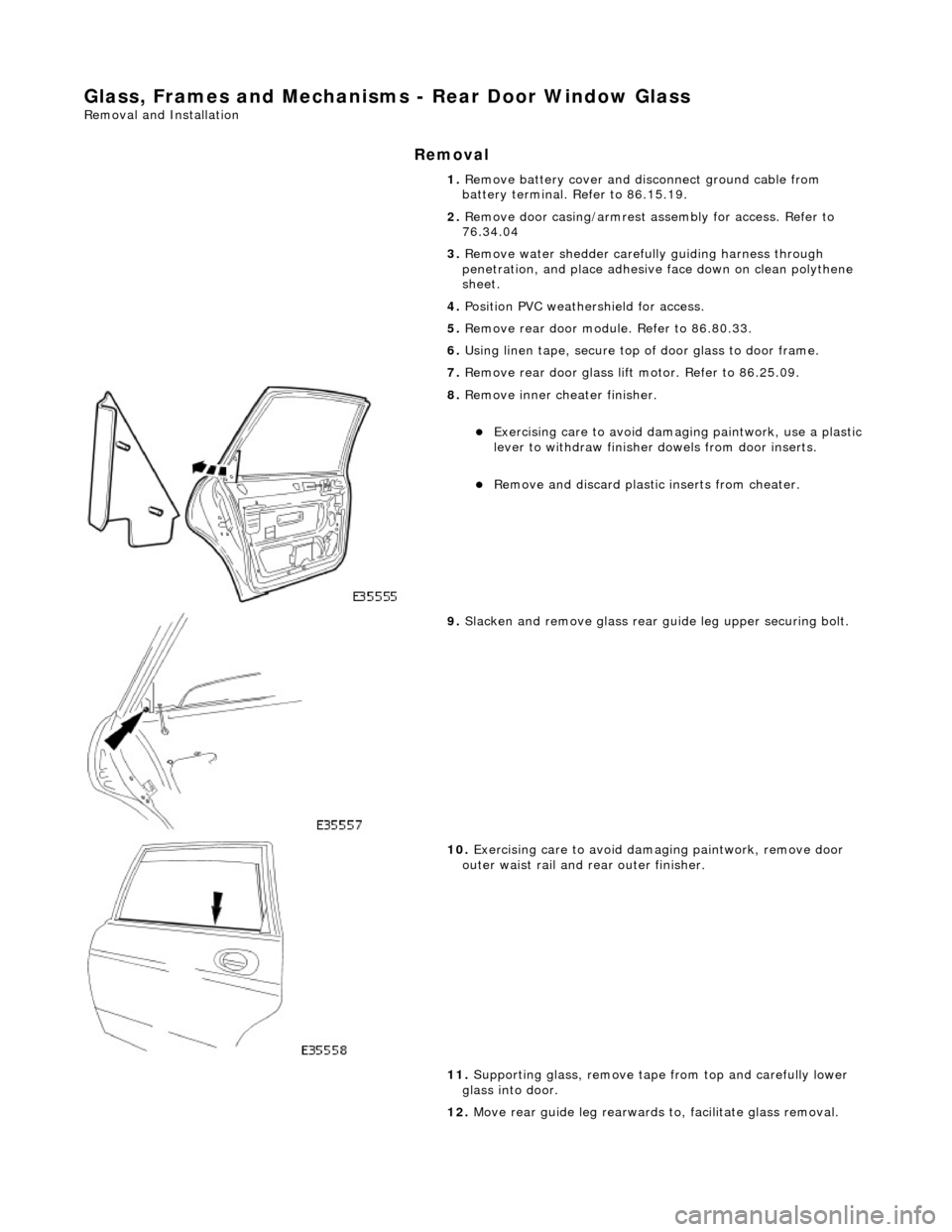

Glass, Frames and Mechanisms - Rear Door Window Glass

Removal and Installation

Removal

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove door casing/armrest as sembly for access. Refer to

76.34.04

3. Remove water shedder carefu lly guiding harness through

penetration, and place adhesive face down on clean polythene

sheet.

4. Position PVC weathe rshield for access.

5. Remove rear door module. Refer to 86.80.33.

6. Using linen tape, secure top of door glass to door frame.

7. Remove rear door glass lift motor. Refer to 86.25.09.

8. Remove inner cheater finisher.

Exercising care to avoid dama ging paintwork, use a plastic

lever to withdraw finisher dowels from door inserts.

Remove and discard plasti c inserts from cheater.

9. Slacken and remove glass rear guide leg upper securing bolt.

10. Exercising care to avoid damaging paintwork, remove door

outer waist rail and rear outer finisher.

11. Supporting glass, remove tape from top and carefully lower

glass into door.

12. Move rear guide leg rearwards to, facilitate glass removal.

Page 2193 of 2490

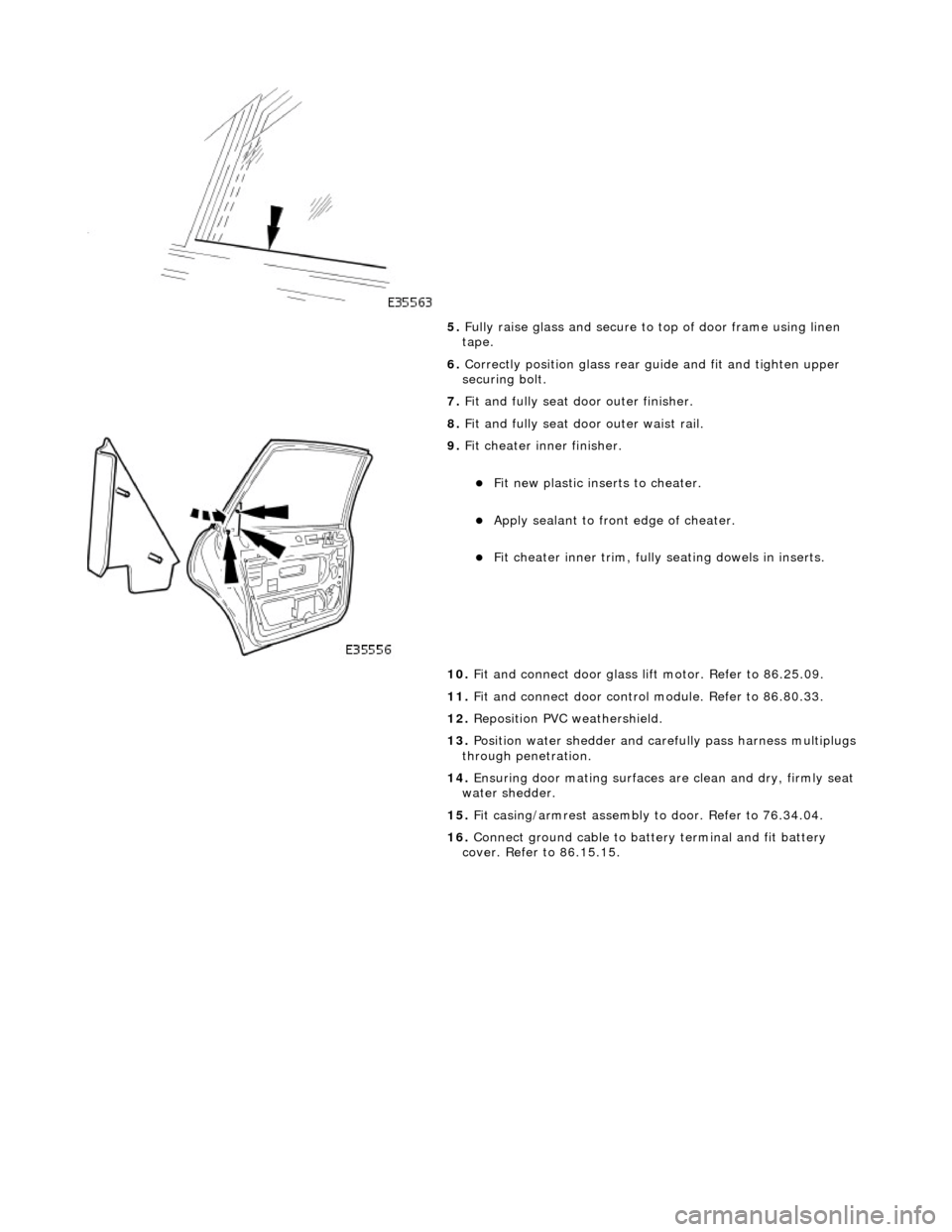

5. Fully raise glass and secure to top of door frame using linen

tape.

6. Correctly position glass rear guide and fit and tighten upper

securing bolt.

7. Fit and fully seat d oor outer finisher.

8. Fit and fully seat door outer waist rail.

9. Fit cheater i nner finisher.

Fit new plastic inserts to cheater.

Apply sealant to front edge of cheater.

Fit cheater inner trim, fully se ating dowels in inserts.

10. Fit and connect door glass lift motor. Refer to 86.25.09.

11. Fit and connect door control module. Refer to 86.80.33.

12. Reposition PVC weathershield.

13. Position water shedder and carefully pass harness multiplugs

through penetration.

14. Ensuring door mating surfaces ar e clean and dry, firmly seat

water shedder.

15. Fit casing/armrest assembly to door. Refer to 76.34.04.

16. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

Page 2195 of 2490

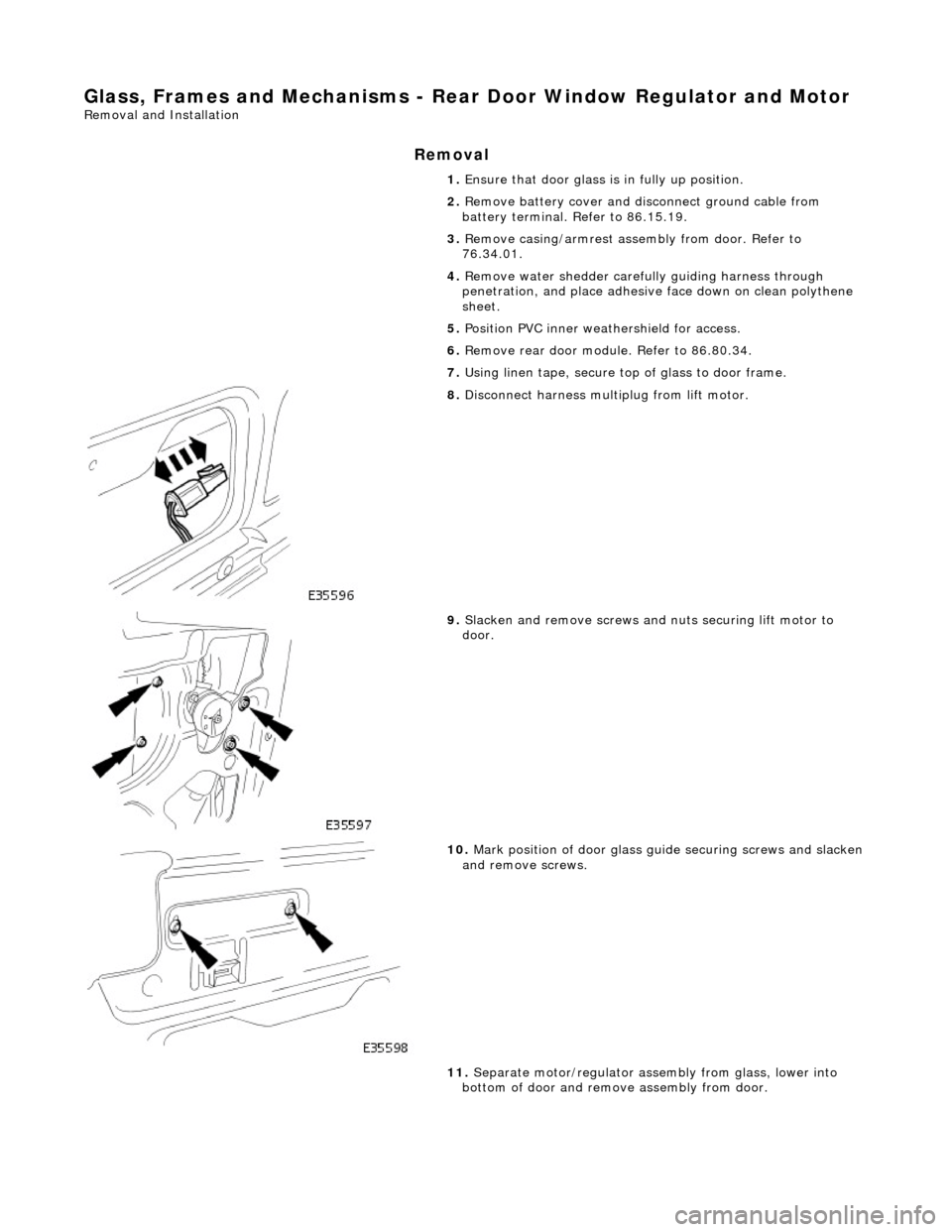

Glass, Frames and Mechanisms - Rear Door Window Regulator and Motor

Removal and Installation

Removal

1. Ensure that door glass is in fully up position.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove casing/armrest asse mbly from door. Refer to

76.34.01.

4. Remove water shedder carefu lly guiding harness through

penetration, and place adhesive face down on clean polythene

sheet.

5. Position PVC inner weat hershield for access.

6. Remove rear door module. Refer to 86.80.34.

7. Using linen tape, secure to p of glass to door frame.

8. Disconnect harness mult iplug from lift motor.

9. Slacken and remove screws and nuts securing lift motor to

door.

10. Mark position of door glass gu ide securing screws and slacken and remove screws.

11. Separate motor/regulator assembly from glass, lower into

bottom of door and remove assembly from door.