transmission JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1492 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L NA V8 -

AJ27/3.2L NA V8 - AJ26 - Se lector Lever Indicator Disc

Removal and Installation

Removal

Installation

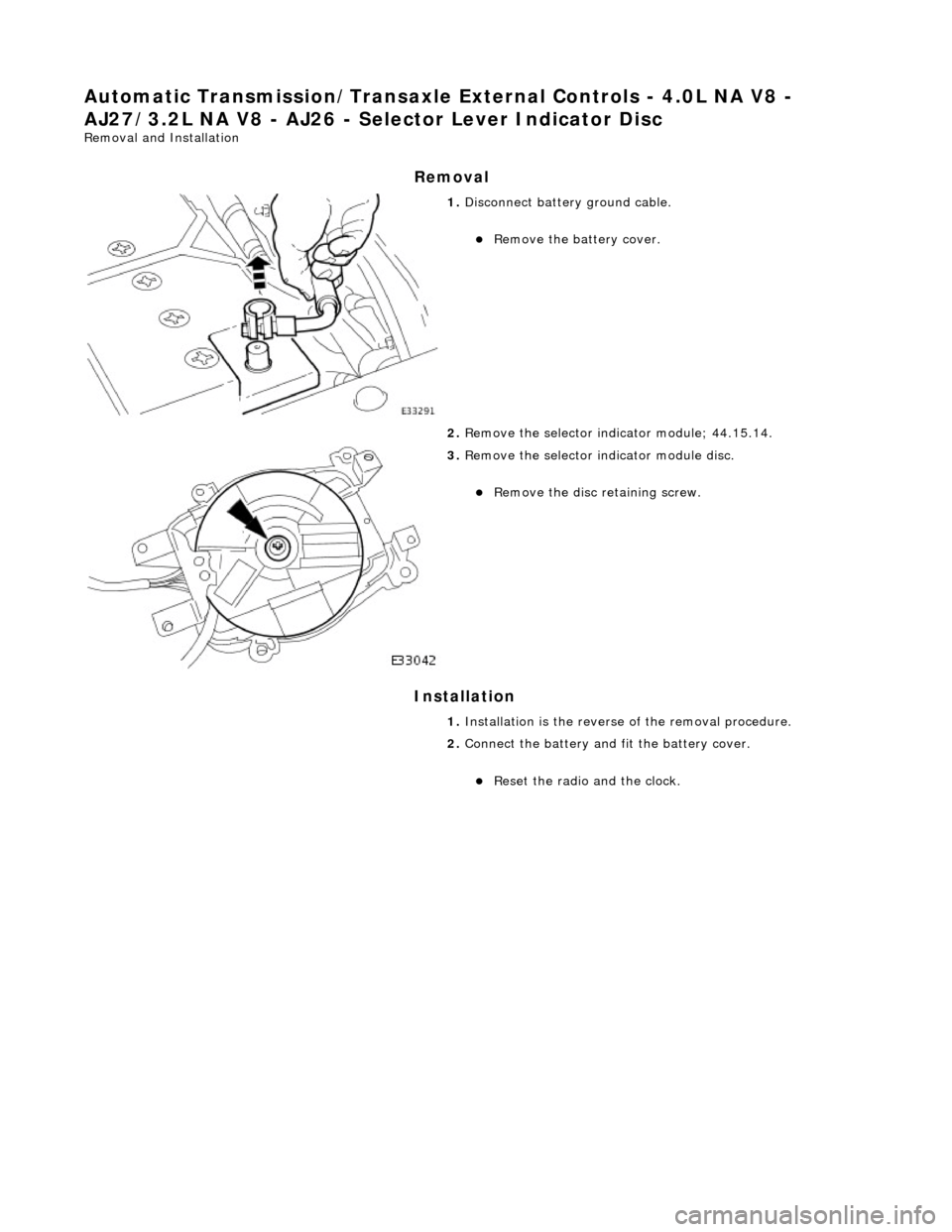

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Remove the selector indicator module; 44.15.14.

3. Remove the selector indicator module disc.

пЃ¬Remove the disc retaining screw.

1. Installation is th e reverse of the re moval procedure.

2. Connect the battery and fit the battery cover.

пЃ¬Reset the radio and the clock.

Page 1493 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L NA V8 -

AJ27/3.2L NA V8 - AJ26 - Selector Lever Switch

Removal and Installation

Removal

Installation

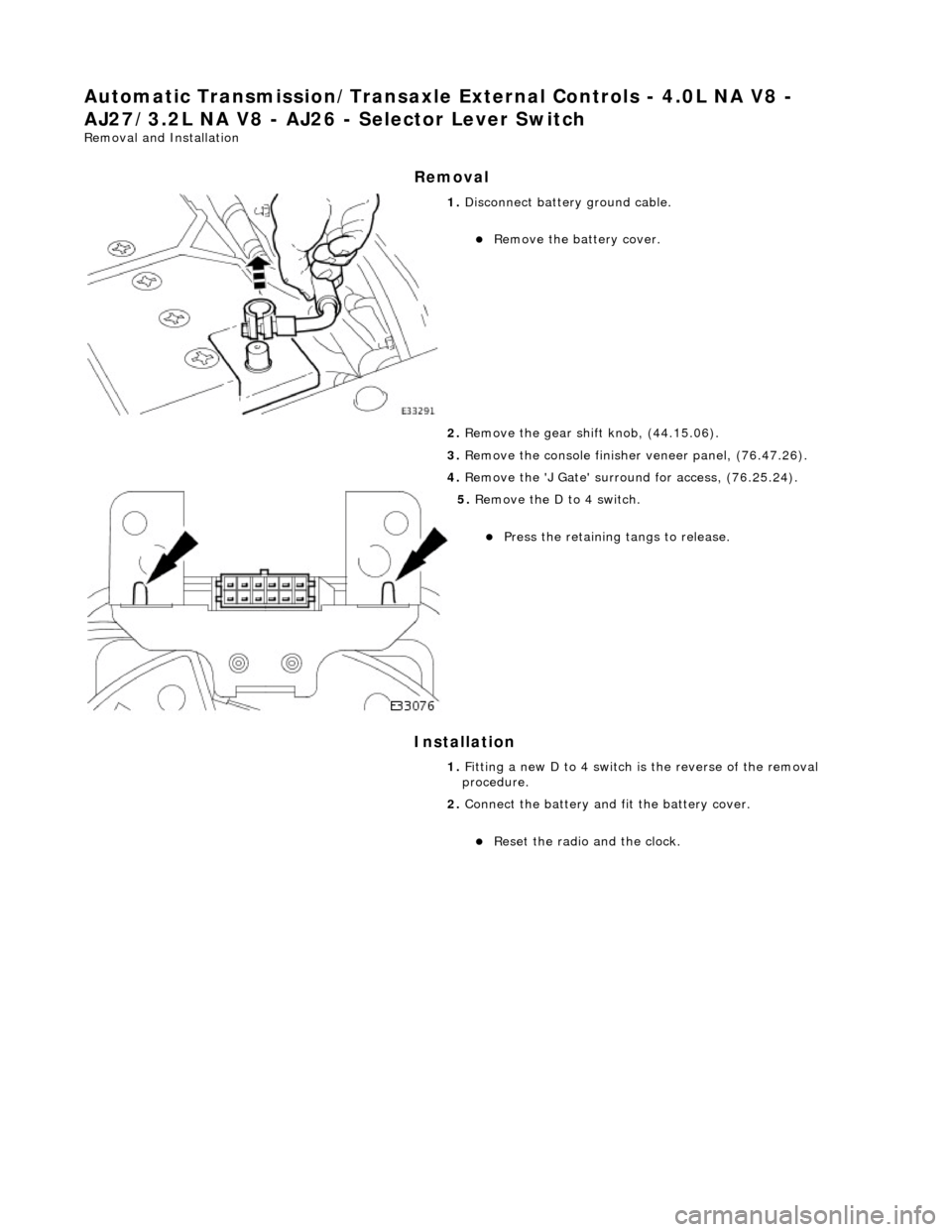

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Remove the gear shift knob, (44.15.06).

3. Remove the console finisher veneer panel, (76.47.26).

4. Remove the 'J Gate' surroun d for access, (76.25.24).

5. Remove the D to 4 switch.

пЃ¬Press the retaining tangs to release.

1. Fitting a new D to 4 switch is the reverse of the removal

procedure.

2. Connect the battery and fit the battery cover.

пЃ¬Reset the radio and the clock.

Page 1494 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L NA V8 -

AJ27/3.2L NA V8 - AJ26 - Selector Lever Knob

Removal and Installation

Removal

Installation

1. Remove the select or lever knob.

1. Slacken the ferrule, rotate clock-wise.

2. Rotate the knob coun ter-clockwise to remove.

1. Refer to the illustration

1. Fit the knob.

2. Tighten the ferru le to the specified torque figure.

Page 1495 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L NA V8 -

AJ27/3.2L NA V8 - AJ26 - Selector Lever Assembly

Disassembly and Assembly

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Remove the shift le ver knob, 44.15.06.

3. Remove the J-gate surround, Section 501-05.

4. Remove the console finisher ve neer panel, Section 501-12.

5. Remove the center console assembly, Section 501-12.

6. Remove the indicator module, 44.15.14.

7. Detach the selector cable from the gear shift assembly.

1. Remove the inner cable to selector lever nut.

2. Slacken one outer cable locknut, keeping one positioned for reference on reassembly.

8. Remove the gear shift assembly.

пЃ¬Remove the four fixings.

9. Remove the slide plate.

пЃ¬Remove the four screws.

Page 1499 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L SC V8 - AJ26 -

External Controls

Description and Operation

Introduction

Operator gearshift control is effected by:

пЃ¬The selector lever пЃ¬Accelerator pedal position пЃ¬Kickdown пЃ¬The mode switch

Operator's Selector Module ('J' Gate)

Page 1501 of 2490

Selector lever:

Gear selector positions are:

пЃ¬P Transmission mechanically locked, starting available * пЃ¬R Reverse gear пЃ¬N Neutral gear, no power to the rear wheels (starting available) пЃ¬D Drive gear, all 5 forward gears available (see Performance Mode Pushbutton) пЃ¬4 Upshift to 4th gear only пЃ¬3 Upshift to 3rd gear only пЃ¬2 Upshift to 2nd gear only

Gearshift Interlock Manual Override*

The interlock system which locks the sele ctor in P and prevents the ignition key from being removed except when P is

selected, may be manually overridden in the event of an emergency.

1. 1. With the parking brake applied

2. 2. Remove the access blank using a suitable Torx bit

3. 3. Insert a small screwdriver into the vacated hole

4. 4. Push the screwdriver downwards, gently, and hold whilst simultaneously moving the selector from P towards R ,

but do not engage R until the tool has been removed

5. 5. An audible warning may be heard when operation 4 is carried out

6. 6. With the selector in N and the access bl ank replaced, the vehicle may be started

Range Selection

пЃ¬The selector lever transmits operator demand to the transmission and TCM by means of a cable and Dual-Linear

Switch (DLS).

пЃ¬The lever operates the transmission assemb ly selector shaft, only for P R N D , by means of a cable. Movement of the

lever across the gate to 4, 3 and 2 positions disengages th e cable from the selector lever and engages the DLS which

controls gear selection electronically.

Gear selector module:

пЃ¬Provides illumination of the decal relevant to the gear sele cted. This information is provided by CAN from the TCM. пЃ¬Illuminates the security system Active LED on the gear selector surround, in response to an output from the BPM.

Transmission Switches

Performance Mode Pushbutton

7—Connector - Climate control

8—Solenoid - Gear selector

9—Security system Active LED

Page 1502 of 2490

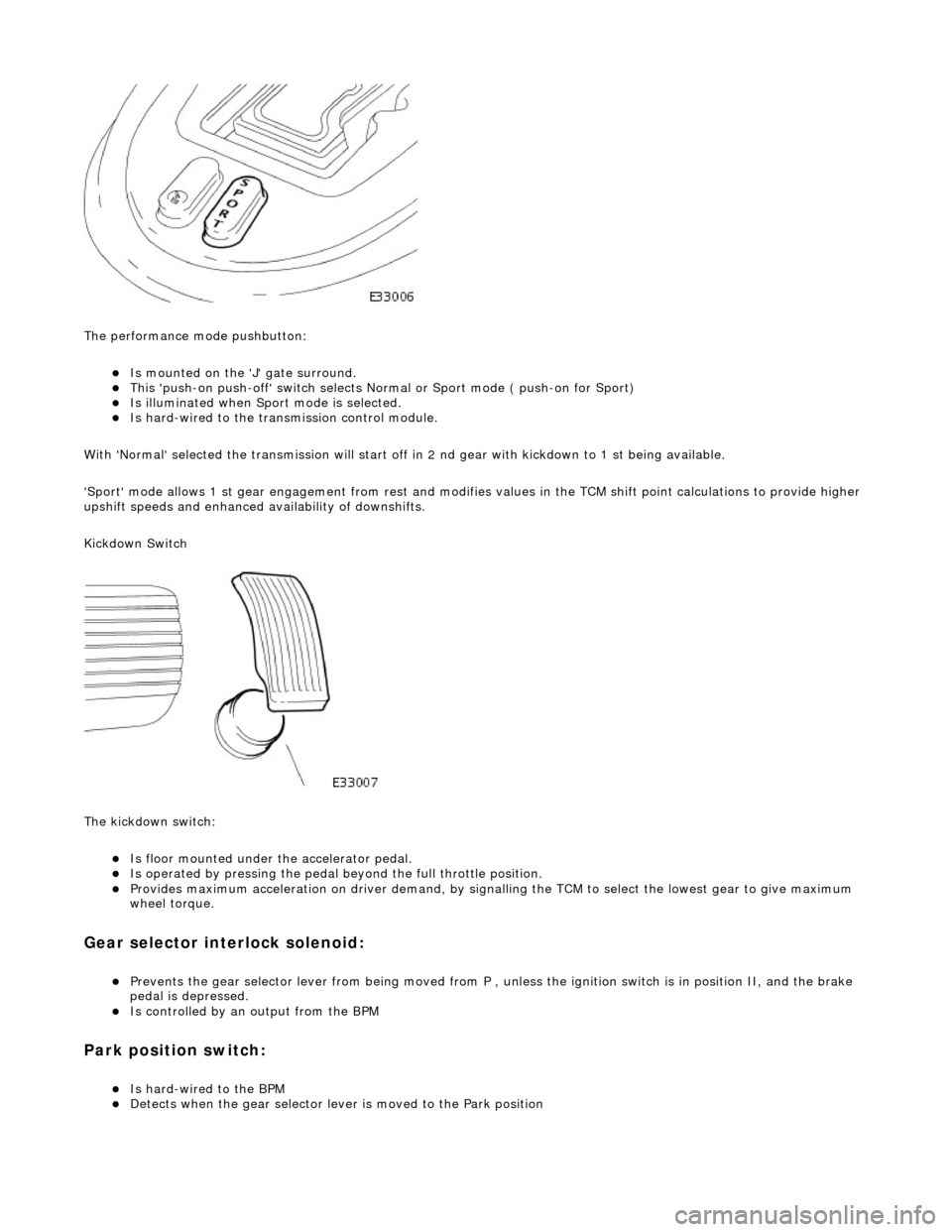

The performance mode pushbutton:

пЃ¬Is mounted on the 'J' gate surround. пЃ¬This 'push-on push-off' swit ch selects Normal or Sport mode ( push-on for Sport) пЃ¬Is illuminated when Sport mode is selected. пЃ¬Is hard-wired to the transmission control module.

With 'Normal' selected the transmissi on will start off in 2 nd gear with kickdown to 1 st being available.

'Sport' mode allows 1 st gear en gagement from rest and modifies values in the TCM shift point calculations to provide higher

upshift speeds and enhanced availability of downshifts.

Kickdown Switch

The kickdown switch:

пЃ¬Is floor mounted under th e accelerator pedal. пЃ¬Is operated by pressing the pedal beyond the full throttle position. пЃ¬Provides maximum acceleration on driver demand, by signalling the TCM to select the lowest gear to give maximum

wheel torque.

Gear selector interlock solenoid:

пЃ¬Prevents the gear selector lever from being moved from P , unless the ignition switch is in position II, and the brake

pedal is depressed.

пЃ¬Is controlled by an output from the BPM

Park position switch:

пЃ¬Is hard-wired to the BPM пЃ¬Detects when the gear selector lever is moved to the Park position

Page 1503 of 2490

Dual-Linear Switch (DLS)

The TCM detects gear selection by means of a switch fitted to the 'J' gate; the DLS contains two multi-track slider switches,

of which the upper controls P R N D and the lower 4 3 2 .

Output from the DLS is changed as the select or lever is moved, thus indicating selected gear position. The parallel signal is

input to the TCM by 4 discrete logic wires W0, W1, W2 and W3. The particular sequence, or gray code, will indicate which

shift position is selected, as shown in the following table where 0 = low and 1 = high:

Gray code

Transmission Unit Gear Selector

The gear selector at the transmission unit:

пЃ¬Is connected to the operator's selector module by cable пЃ¬Operates the selector valve, at the electro-hydraulic control unit

Selector PositionW3W2W1W0

P0111

R1110

N1101

D0100

41000

30010

20001

Page 1504 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L SC V8 - AJ26 -

External Controls

Diagnosis and Testing

Problem Solving - Transmission Shift

Quick Reference Fault Chart

Special Tool(s)

Digital multimeter

Generic scan tool

SymptomPossible SourcesAction

Shift stuck in P Selector cable seized

*GO to 44.15.08

*

Interlock solenoid not operating

*GO to PDU

*

Interlock latch seized

Transmission faulty

*

*Mechanical check

*

Operator sequence error

*Correct the sequence

*

Vehicle rolls on P Incorrect cable adjustment

*GO 44.15.07

*

Faulty parking pawl (transmission internal)

*Mechanical check

*

R does not engageIncorrect cable adjustment

*GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

N not achievedIncorrect cable adjustment

Transmission faulty

*

*GO to 44.15.07

*

D does not engageIncorrect cable adjustment *GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

Transmission faulty

*Mechanical check

*

Lower ratios will not holdExcessive engine temperature

DLS fault

*

*GO to PDU

*

Shift lever position not visually correctIncorrect DLS adjustment

*GO to 44.15.07

*

Shift lever has no effect upon the

transmission and resistance cannot be

feltCable disconnected or broken

Transmission selector problem

Shift lever drive pin adrift

*

*

*Mechanical check

*

Shift lever position not align correctly

following manual selection of lower

ratiosSliding block drive pin displaced - following road debris contact

*Mechanical check. Renew the selector if

damaged, or re-align the drive pin and

sliding block

*

Shift lever detent indistinct in 3

causing poor locationDLS detent fault

*GO to Renew the DLS

*

Shift may be moved from P without

brake pedal operationInterlock latch fault

*Mechanical check

*

Solenoid permanently activated

*GO to PDU

*

Engine may be started in positions

other than P or N Incorrect cable adjustment

DLS fault

*

*GO to 44.15.07

*

Shift lever vibrationLoose selector assembly

Cable isolation fault

*

*Mechanical check

*

Noise / rattle from 'J' gateDebris in the mechanism

*Clean

*

Worn 'J' gate track gasket

allowing lever and moulding to

contact

*GO to 44.15.05

*

Page 1505 of 2490

Shift Selection and Gear Position

Symptom Chart

Pinpoint test A: P0705

Loose selector disc seal

*

SymptomPossible SourcesAction

DTC P0705 Transmission range sensor circuit

malfunctionSelector cable maladjusted

Linear switch maladjusted

Linear position switch fault

Harness fault

Connector pins(s) bent, loose or

corroded

*

*

*

*

*GO to Pinpoint Test

A

*

PINPOINT TEST A : P0705

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: STATUS / RELATIONSHIP CHECK

Move the selector lever sl owly from P to 2 and back,

noting the illumination / positi on relationship as follows: 1

Does state illumination match the lever position in each

direction of travel?

Yes

GO to A4

No GO to A3

No With lever at D (when moving from 2 to P ) is 3 or 4

illuminated?

Yes GO to A3