drive plate JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 589 of 2490

I

nstallation

18

.

Remove the tensioner assembly.

1. Remove the tensioner.

2. Remove the tensioner back-plate.

19

.

Remove the chain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

20. Remove the chain from the VVT unit and from the crankshaft

sprocket.

21

.

If necessary, remove the sp rocket from the crankshaft.

No

te the orientation of the

sprocket relative to the

sprocket for the B-Bank drive (half a tooth out of line) and

remove the sprocket.

22. Clean and inspect all relevant components.

1. If removed previously, fit the sprocket to the crankshaft.

Page 605 of 2490

Engine - Crankshaft

Rear Seal4.0L

NA V8 - AJ27/3.2 L NA V8 - AJ26

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Crankshaft Rear Oi

l Seal Remover /

Replacer.

303 - 538

1. Open the engine compartment and fit paint protection sheets.

2. Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

3. Remove the transmission. Refer to Operation 44.20. 01 in

Section 307-01A.

4. Remove the drive plate. Refer to Operation 12.53.13.

5. F

it and align the seal removal tool 303 - 538 to the crankshaft.

1. Unscrew the two nuts towards the head of each bolt to allow the bolts to fit fully into the crankshaft.

2. Unscrew the center bolt until it is below the face of the main tool and position the tool to the rear of the

crankshaft.

3. Lightly tighten the two bolts so that they fully locate in the crankshaft.

6. Hold the tool against th

e cran

kshaft and lightly and evenly

tighten the two nuts to the face of the tool; to secure the tool

and to hold it parallel to the face of the crankshaft.

7. Secure the oil seal to the tool using the three self-tapping

Page 607 of 2490

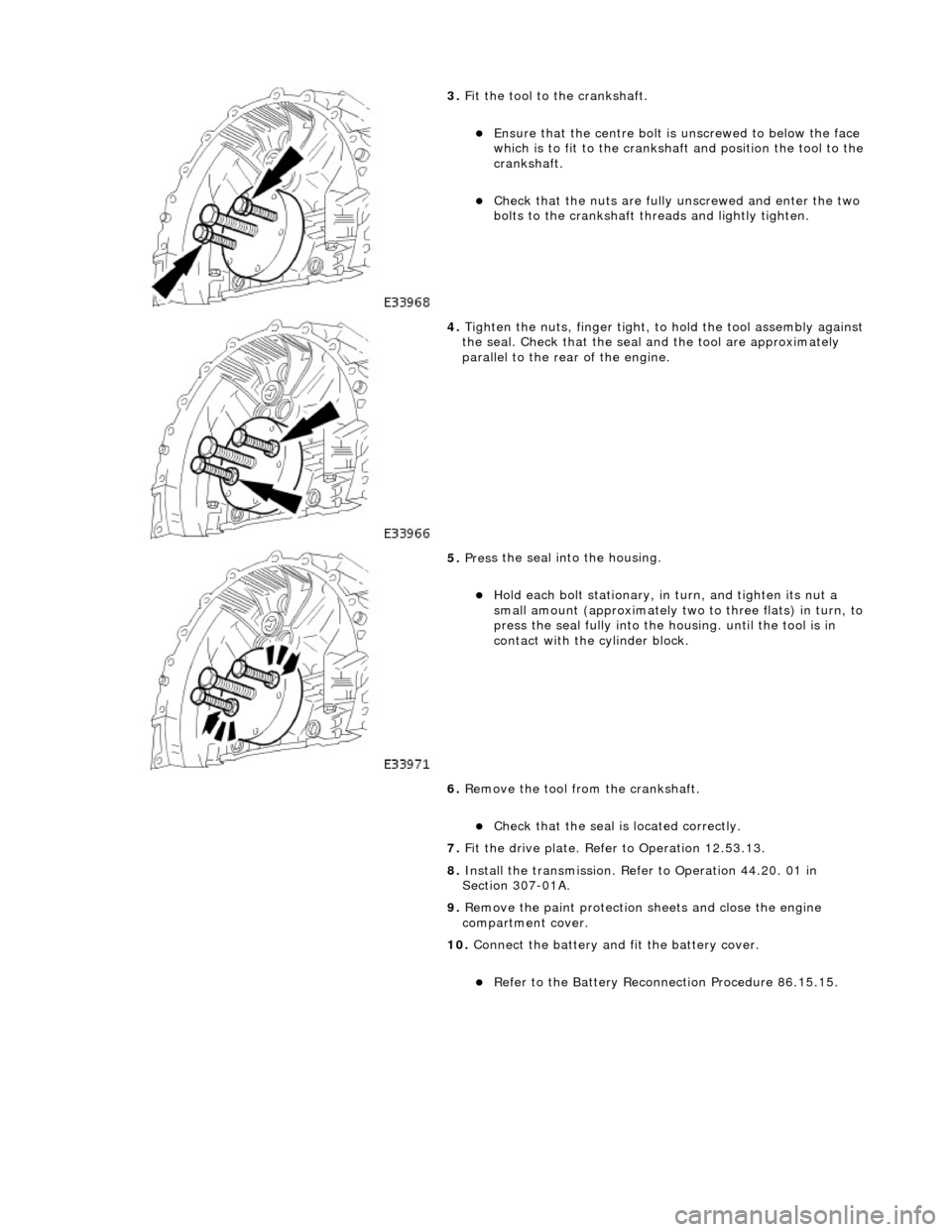

3.

F

it the tool to the crankshaft.

E

nsure that the cent

re bolt is unscrewed to below the face

which is to fit to the crankshaft and position the tool to the

crankshaft.

Chec

k that the nuts are fully unscrewed and enter the two

bolts to the crankshaft thre ads and lightly tighten.

4. Tigh

ten the nuts, finger tight, to hold the tool assembly against

the seal. Check that the seal and the tool are approximately

parallel to the rear of the engine.

5. Pres

s the seal into the housing.

Ho

ld each bolt stationary, in

turn, and tighten its nut a

small amount (approximately two to three flats) in turn, to

press the seal fully into the housing. until the tool is in

contact with the cylinder block.

6. Remove the tool from the crankshaft.

Chec

k that the seal is located correctly.

7. Fit the drive plate. Refer to Operation 12.53.13.

8. Install the transmission. Refer to Operation 44.20. 01 in

Section 307-01A.

9. Remove the paint protection sheets and close the engine

compartment cover.

10. Connect the battery and fit the battery cover.

Re

fer to the Battery Reconnection Procedure 86.15.15.

Page 610 of 2490

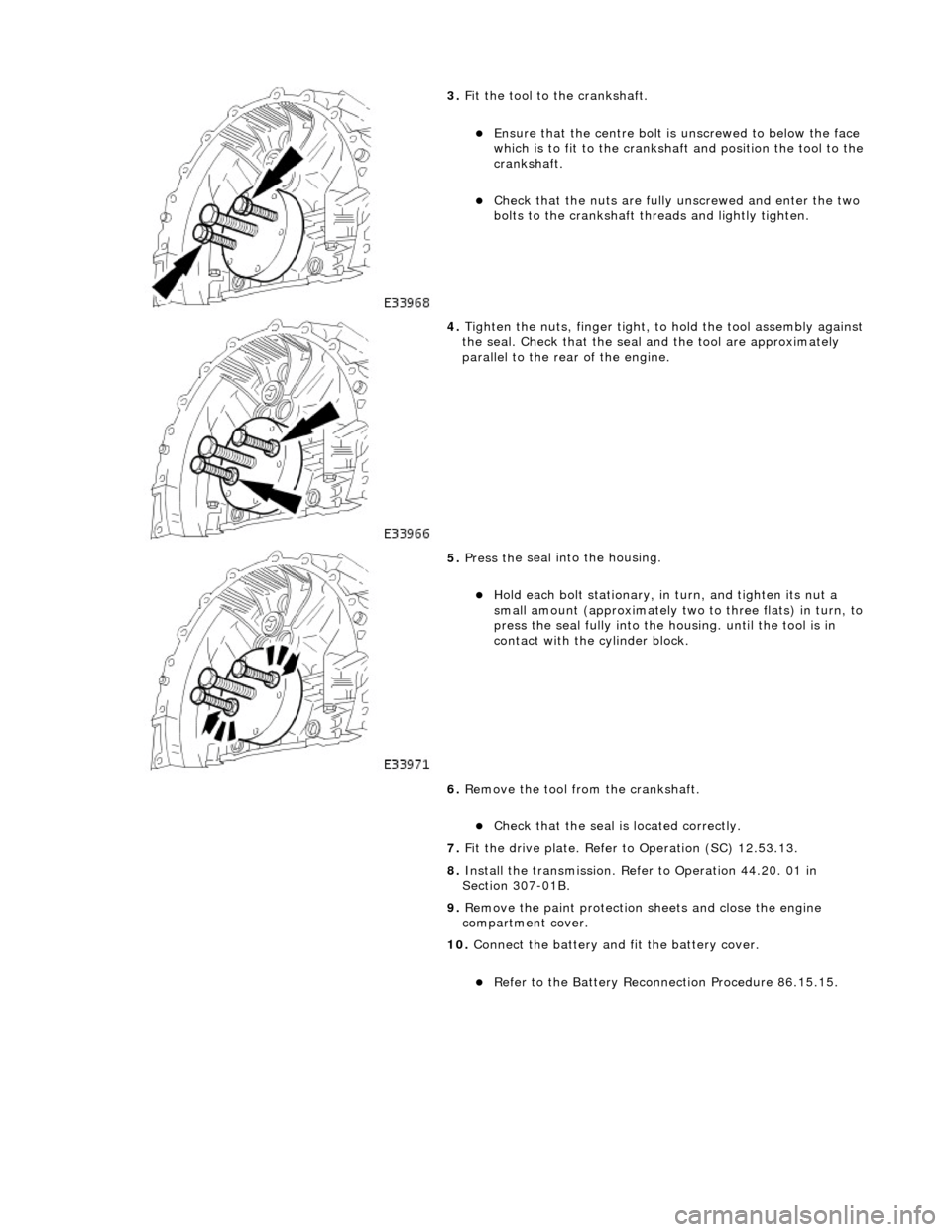

3.

Fit

the tool to the crankshaft.

En

sure that the cent

re bolt is unscrewe d to below the face

which is to fit to the crankshaft and position the tool to the

crankshaft.

Chec k that

the nuts are fully unscrewed and enter the two

bolts to the crankshaft thre ads and lightly tighten.

4. Tight

en the nuts, finger tight, to hold the tool assembly against

the seal. Check that the seal and the tool are approximately

parallel to the rear of the engine.

5. Pres s th

e seal into the housing.

Ho

ld e

ach bolt stationary, in

turn, and tighten its nut a

small amount (approximately two to three flats) in turn, to

press the seal fully into the housing. until the tool is in

contact with the cylinder block.

6. Remove the tool from the crankshaft.

Chec k that

the seal is located correctly.

7. Fit the drive plate. Refer to Operation (SC) 12.53.13.

8. Install the transmission. Refer to Operation 44.20. 01 in

Section 307-01B.

9. Remove the paint protection sheets and close the engine

compartment cover.

10. Connect the battery and fit the battery cover.

Re

fe

r to the Battery Reconnection Procedure 86.15.15.

Page 613 of 2490

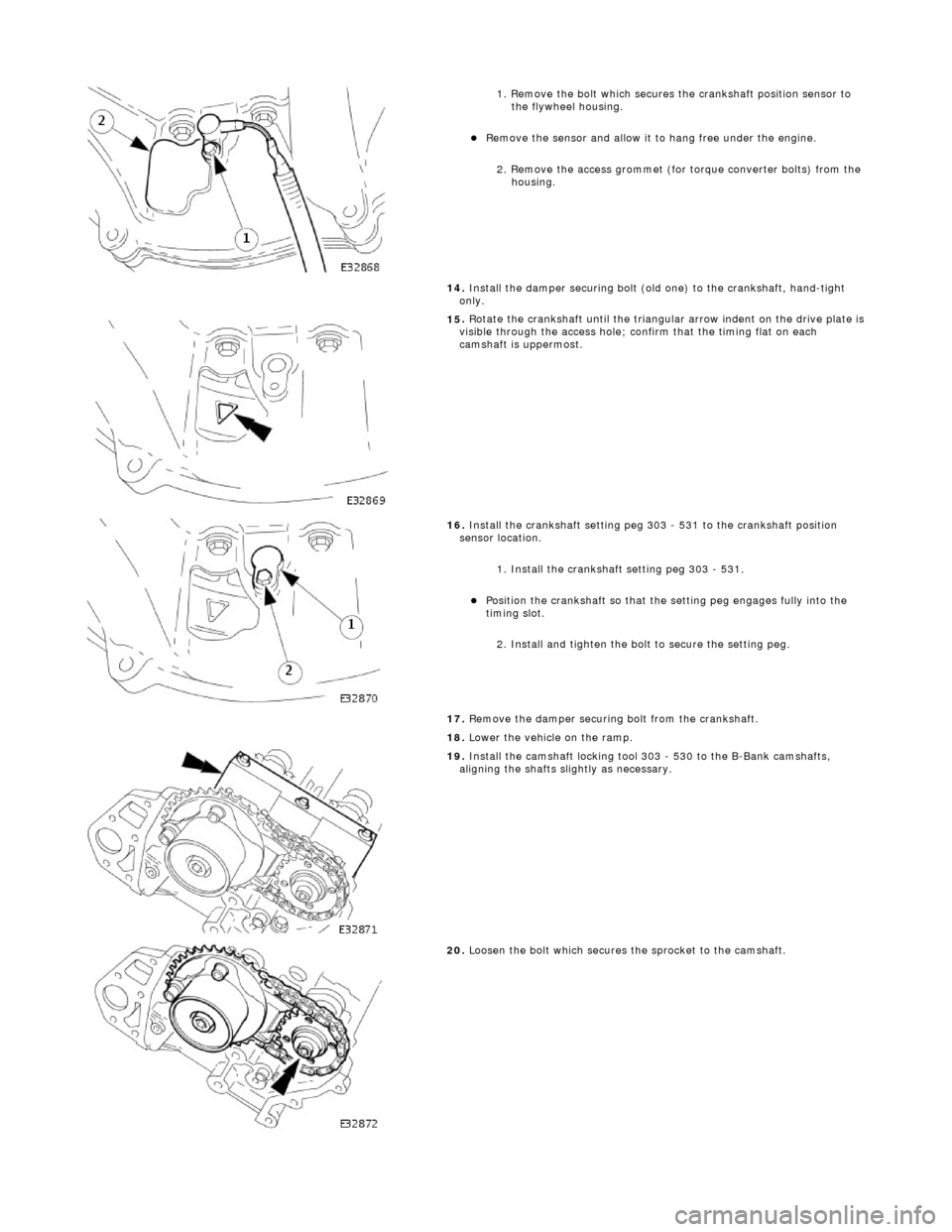

1

. Remove the bolt which secures the crankshaft position sensor to

the flywheel housing.

R

emove the sensor and allow it to hang free under the engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

14. Install the damper securing bolt (old one) to the crankshaft, hand-tight

only.

15

.

Rotate the crankshaft until the triangular arrow indent on the drive plate is

visible through the access hole; confirm that the timing flat on each

camshaft is uppermost.

16

.

Install the crankshaft setting peg 3 03 - 531 to the crankshaft position

sensor location.

1. Install the crankshaft setting peg 303 - 531.

Position

the crankshaft so that the setting peg engages fully into the

timing slot.

2. Install and tighten the bolt to secure the setting peg.

17. Remove the damper securing bolt from the crankshaft.

18. Lower the vehicle on the ramp.

19

.

Install the camshaft locking tool 303 - 530 to the B-Bank camshafts,

aligning the shafts slightly as necessary.

20

.

Loosen the bolt which secures the sprocket to the camshaft.

Page 623 of 2490

Re

position the sprocket (and the VVT unit) for the most advantageous

position for use of the tool.

R

emove the tool.

25

.

Install the primary timing chain.

R

eposition the VVT unit forwards on the cam journal (do not rotate it)

to allow the chain to cl ear the head casting. Disconnect the primary

chain from the Ty-strap.

1. Install the primary chain to position over the crankshaft sprocket and the VVT unit sprocket. There mu st be no slack on the drive

side of the primary chain and the VVT unit must not be rotated on

the camshaft.

26

.

Install the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Install the retaining / pivot bolt and tighten it to 14 Nm.

27

.

Push the primary chain tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Re

move the wire.

28

.

Assemble the tensioner.

1. Install the two mounting bolts to the tensioner.

2. Locate the tensioner back-plate to the two bolts.

29. Install the tensioner to the cylinder block.

1. Position and align the tensioner to the cylinder block and to the mating slot on the rear face of the tensioner blade.

2. Install and tighten the two bolts to 12 Nm.

Page 629 of 2490

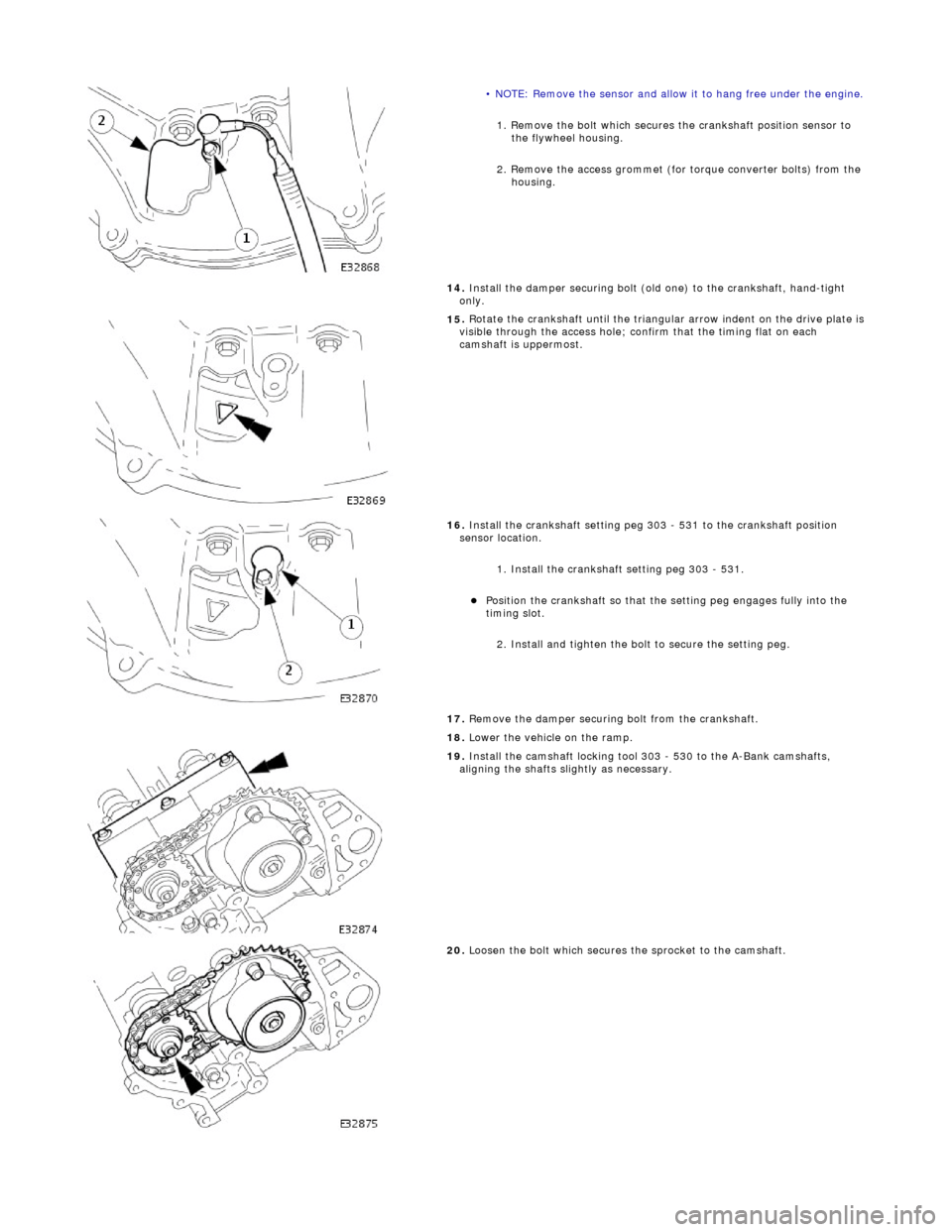

• N

OTE: Remove the sensor and allow it to hang free under the engine.

1

. Remove the bolt which secures the crankshaft position sensor to

the flywheel housing.

2. Remove the access grommet (for torque converter bolts) from the housing.

14. Install the damper securing bolt (old one) to the crankshaft, hand-tight

only.

15

.

Rotate the crankshaft until the triangular arrow indent on the drive plate is

visible through the access hole; confirm that the timing flat on each

camshaft is uppermost.

16

.

Install the crankshaft setting peg 3 03 - 531 to the crankshaft position

sensor location.

1. Install the crankshaft setting peg 303 - 531.

Position

the crankshaft so that the setting peg engages fully into the

timing slot.

2. Install and tighten the bolt to secure the setting peg.

17. Remove the damper securing bolt from the crankshaft.

18. Lower the vehicle on the ramp.

19

.

Install the camshaft locking tool 303 - 530 to the A-Bank camshafts,

aligning the shafts slightly as necessary.

20

.

Loosen the bolt which secures the sprocket to the camshaft.

Page 638 of 2490

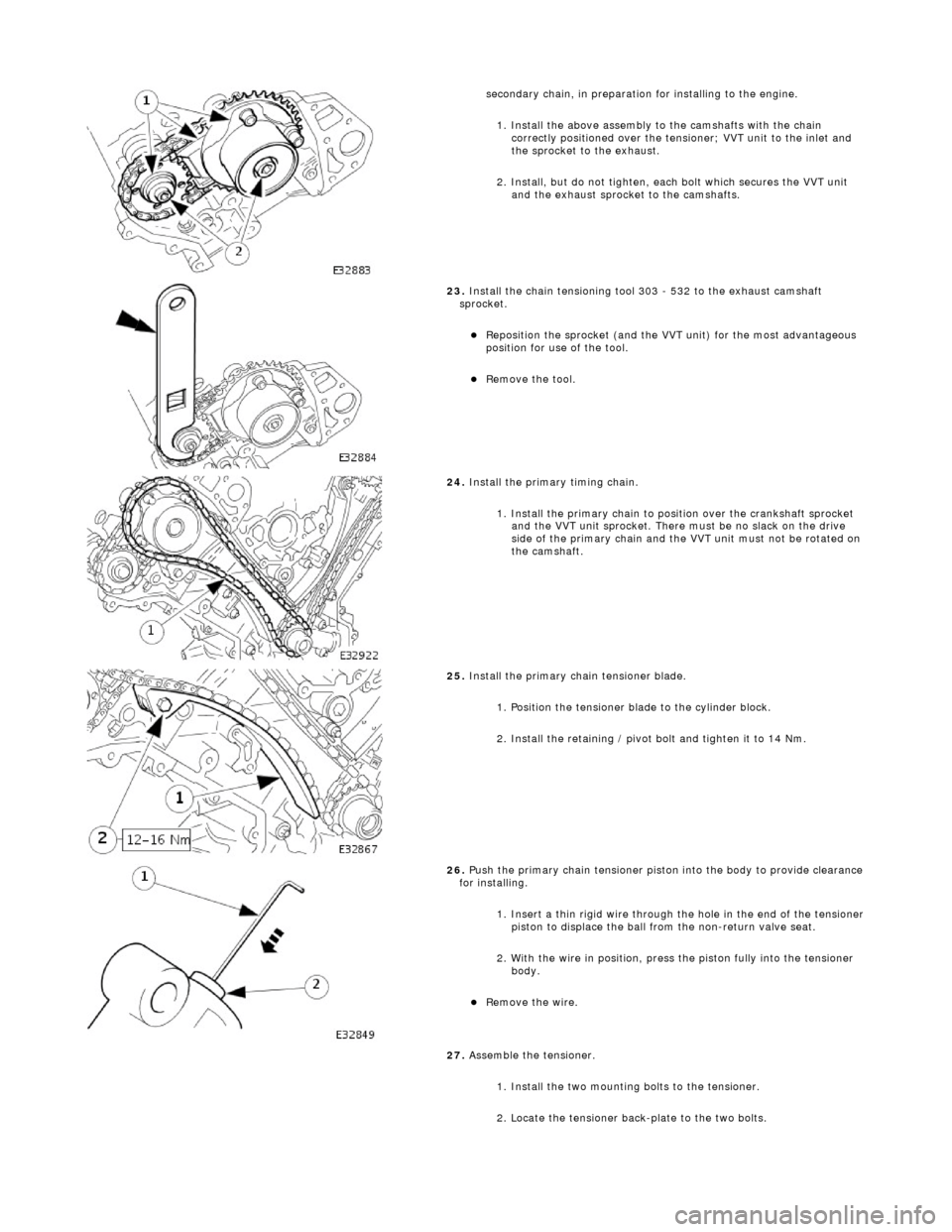

se

condary chain, in preparation for installing to the engine.

1. Install the above assembly to the camshafts with the chain correctly positioned over the tensioner; VVT unit to the inlet and

the sprocket to the exhaust.

2. Install, but do not tighten, each bolt which secures the VVT unit and the exhaust sprocket to the camshafts.

23 .

Install the chain t

ensioning tool 303 - 532 to the exhaust camshaft

sprocket.

Re p

osition the sprocket (and the VVT unit) for the most advantageous

position for use of the tool.

Re

move the tool.

24 . Install the

primary timing chain.

1. Install the primary chain to position over the crankshaft sprocket and the VVT unit sprocket. There mu st be no slack on the drive

side of the primary chain and the VVT unit must not be rotated on

the camshaft.

25 . Install the pri

mary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Install the retaining / pivot bolt and tighten it to 14 Nm.

26 . P

ush the primary chain tensioner piston into the body to provide clearance

for installing.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

Rem

ove the wire.

27. Assemble the tensioner.

1. Install the two mounting bolts to the tensioner.

2. Locate the tensioner back-plate to the two bolts.

Page 665 of 2490

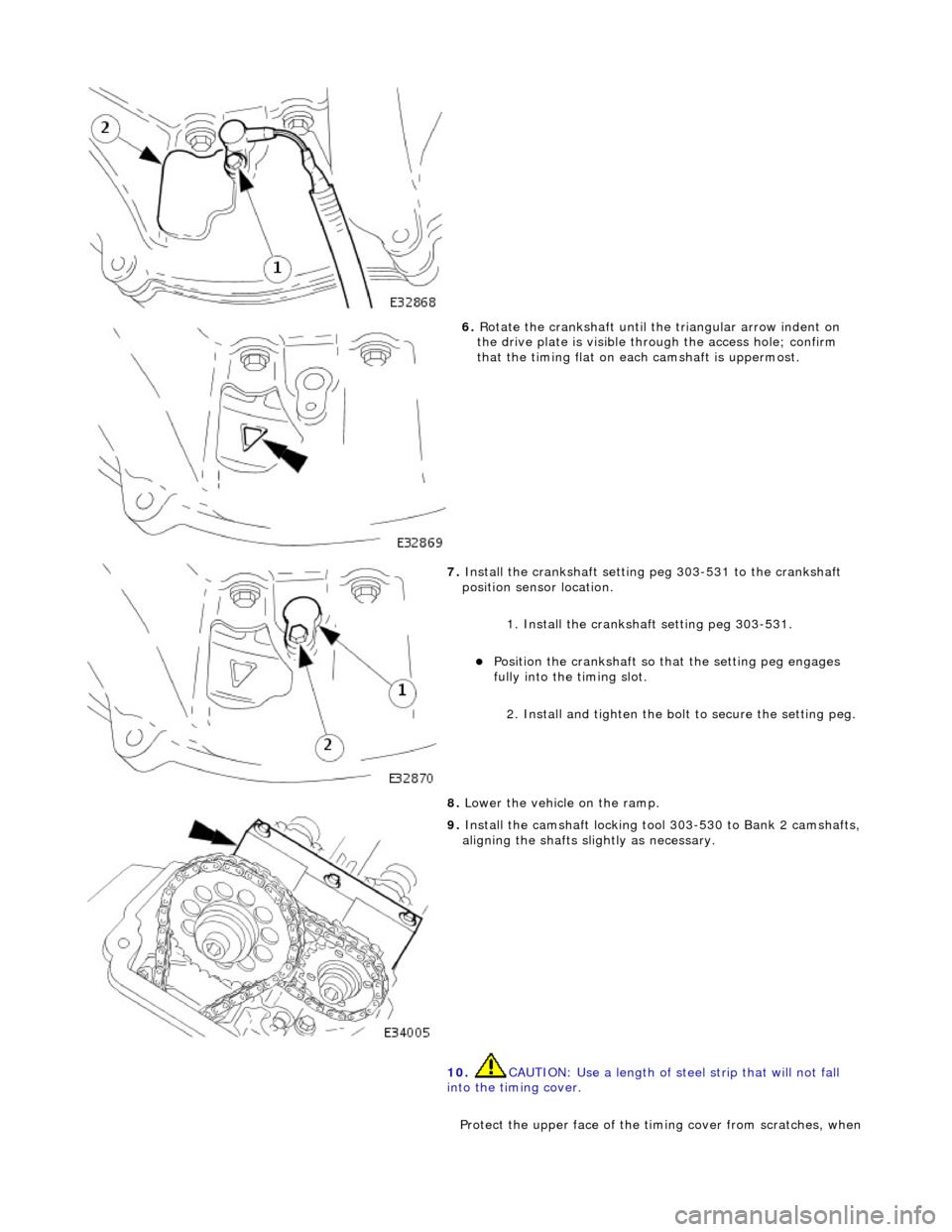

6. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

7. Install the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

8. Lower the vehicle on the ramp.

9. Install the camshaft locking tool 303-530 to Bank 2 camshafts,

aligning the shafts sl ightly as necessary.

10. CAUTION: Use a length of steel strip that will not fall

into the timing cover.

Protect the upper face of the ti ming cover from scratches, when

removing the bolt which secures the sprocket.

1. Place a flat piece of stee l strip along the timing cover

horizontal jointing face, adjacent to the exhaust

camshaft sprocket.

2. Secure the steel strip in place with adhesive tape.

11. A ball-ended hexagon drive bit is required to remove the

sprocket securing bolt. A suitable tool is available from Snap On as (FABLM10E) Long Series 10mm AF.

Page 669 of 2490

6. Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

7. Install the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

Position the crankshaft so that the setting peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

8. Lower the vehicle on the ramp.

9. Install the camshaft locking tool 303-530 to Bank 2 camshafts,

aligning the shafts sl ightly as necessary.

10. CAUTION: Use a length of steel strip that will not fall

into the timing cover.

Protect the upper face of the ti ming cover from scratches, when