engine ignition JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 525 of 2490

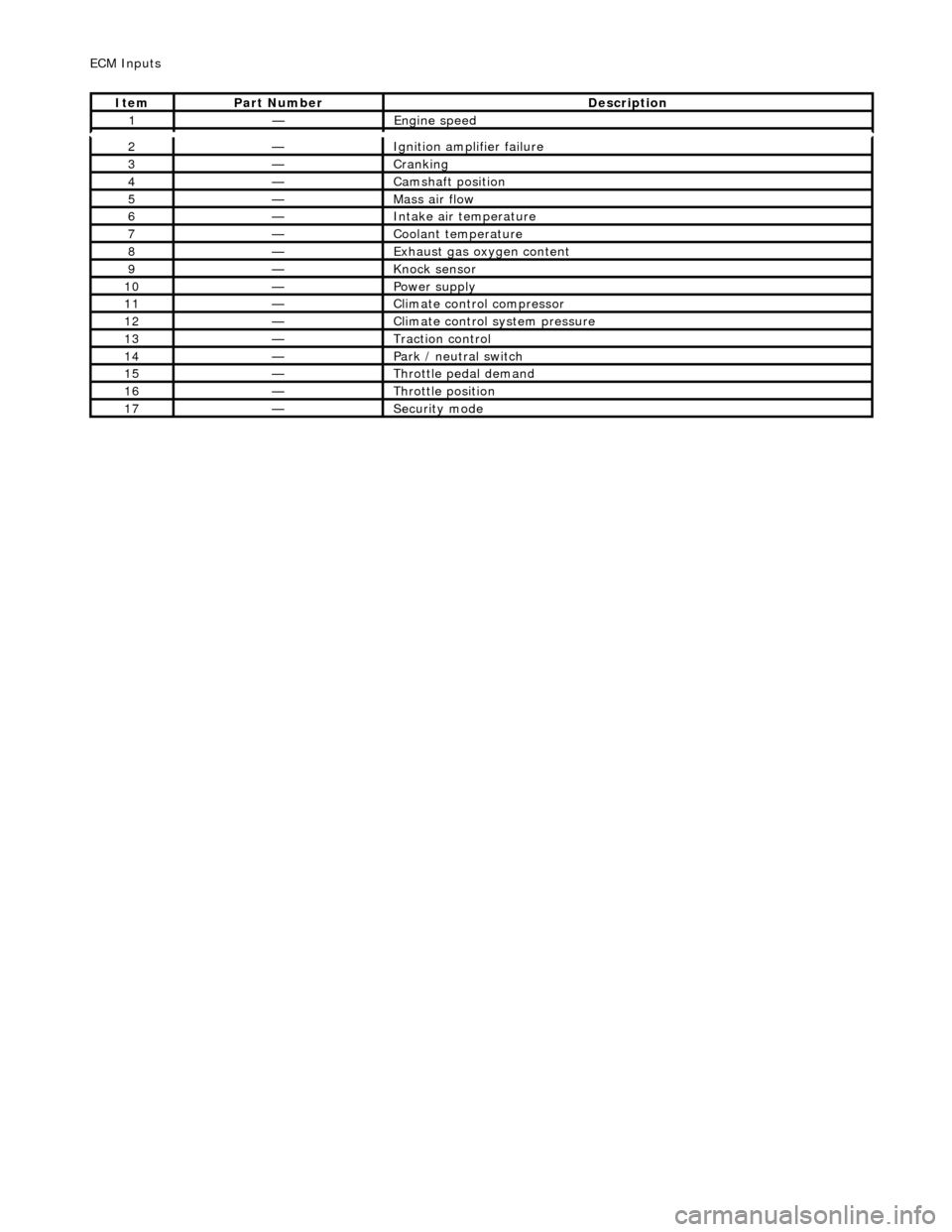

2—Ignition ampl

ifier failure

3—Crankin

g

4—Camshaft position

5—Mass ai

r flow

6—Inta

ke air temperature

7—Coo

lant temperature

8—Exhaus

t gas oxygen content

9—Knock

sensor

10—Power supply

11—Cl

imate control compressor

12—Cli

mate control system pressure

13—Traction contr

ol

14—Park / neutral

switch

15—Throttle pedal demand

16—Thro

ttle position

17—Securi

ty mode

ECM In

puts

It

em

Par

t Number

De

scription

1—Engine

speed

Page 527 of 2490

E

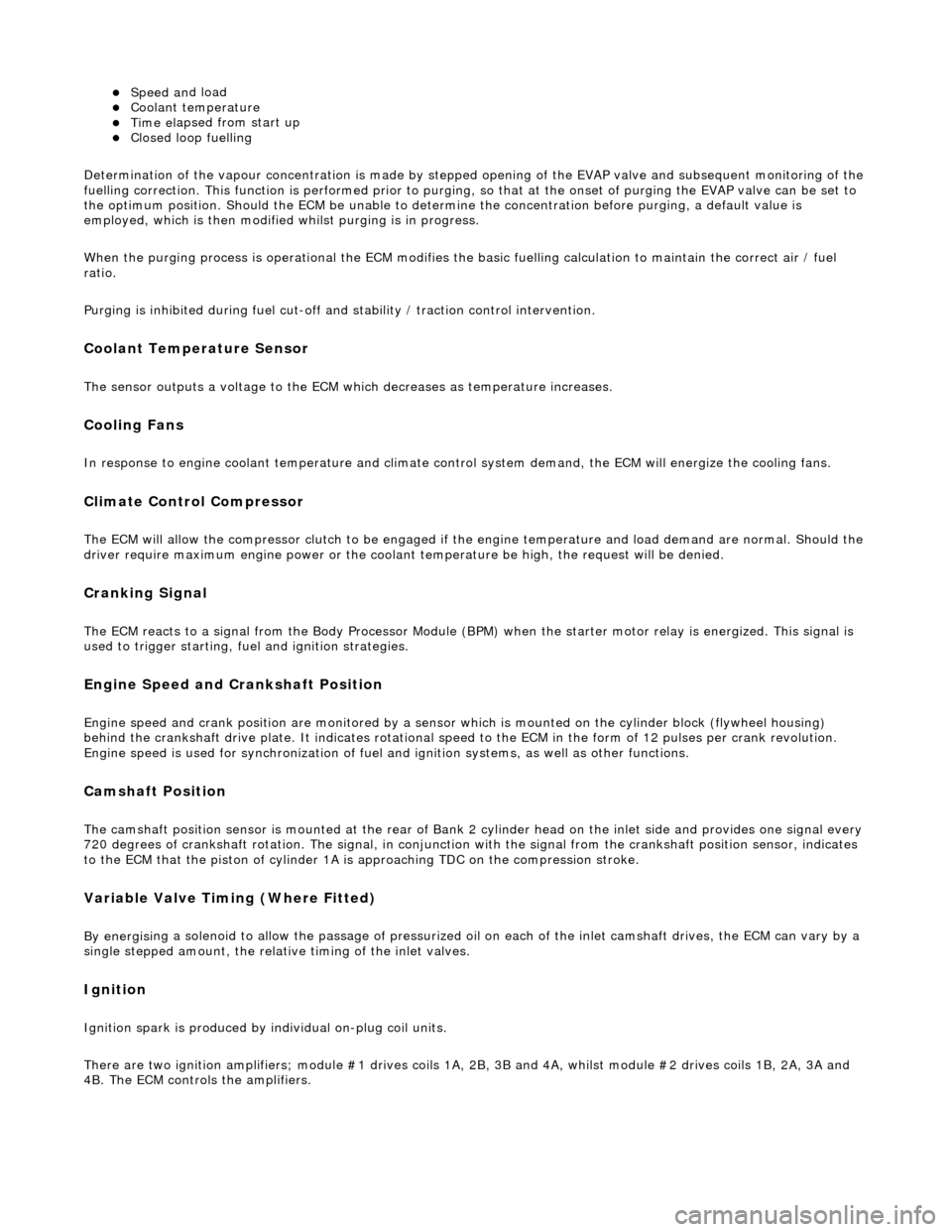

ngine Management System Components

Electronic Throt

tle

The

electronic throttle assembly, in resp

onse to signals from both the driver and the ECM, adjusts idle speed, sets the

throttle valve to the position requested by the driver's accelerator / throttle pedal, cruise and traction control, power

limitation and catalyst warm-up.

Mass

Air Flow Meter

The sensor i

s located in the air flow mete

r assembly and outputs an analogue voltag e to the ECM. This sensor measures air

flow into the engine inlet system and is calibrated to measure kg / hour.

In

take Air Temperature

Th

e intake air temperature sensor is loca

ted in the air flow meter assembly and outputs an analogue voltage to the ECM.

The ECM will substitute a default value eq ual to 50°C should this sensor fail.

Fuel Injectors

The eigh

t bottom fed fuel injectors are located in the fuel rails. Th

e fuel injectors are electromagnetic solenoid valves

controlled by the ECM. The pulse time for the injector combined with the fuel pr essure determines the volume of fuel

injected to the manifold.

Fue

l Delivery

The fu

el pump provides fuel to the fuel rail where the circulat

ing pressure is controlled by a pressure regulator valve; excess

fuel is returned to the fuel tank.

The pressure regulator valve is controlled by manifold depression so that fuel delivery pressure is maintained at

approximately 3 bar above manifold pressure.

Fuel Pump

Relay

The ECM controls thi

s component for normal

engine running. The security system may disable this relay via communication

with the ECM.

Fuel Lev

el Sensing

The tank fuel

is measured by the fuel le

vel sensor . This signal is used by the ECM as an in put to certain diagnostics.

Eva

porative Valve

Excess vapour

formed in the fuel tank is

absorbed into the evaporative emission pu rge control canister. While the engine is

running, the fuel absorbed in the canister is gradually purged back into the engine. The rate of purging is governed by

engine operating conditions and vapour concentration level. Operating conditions which affect the purge rate are:

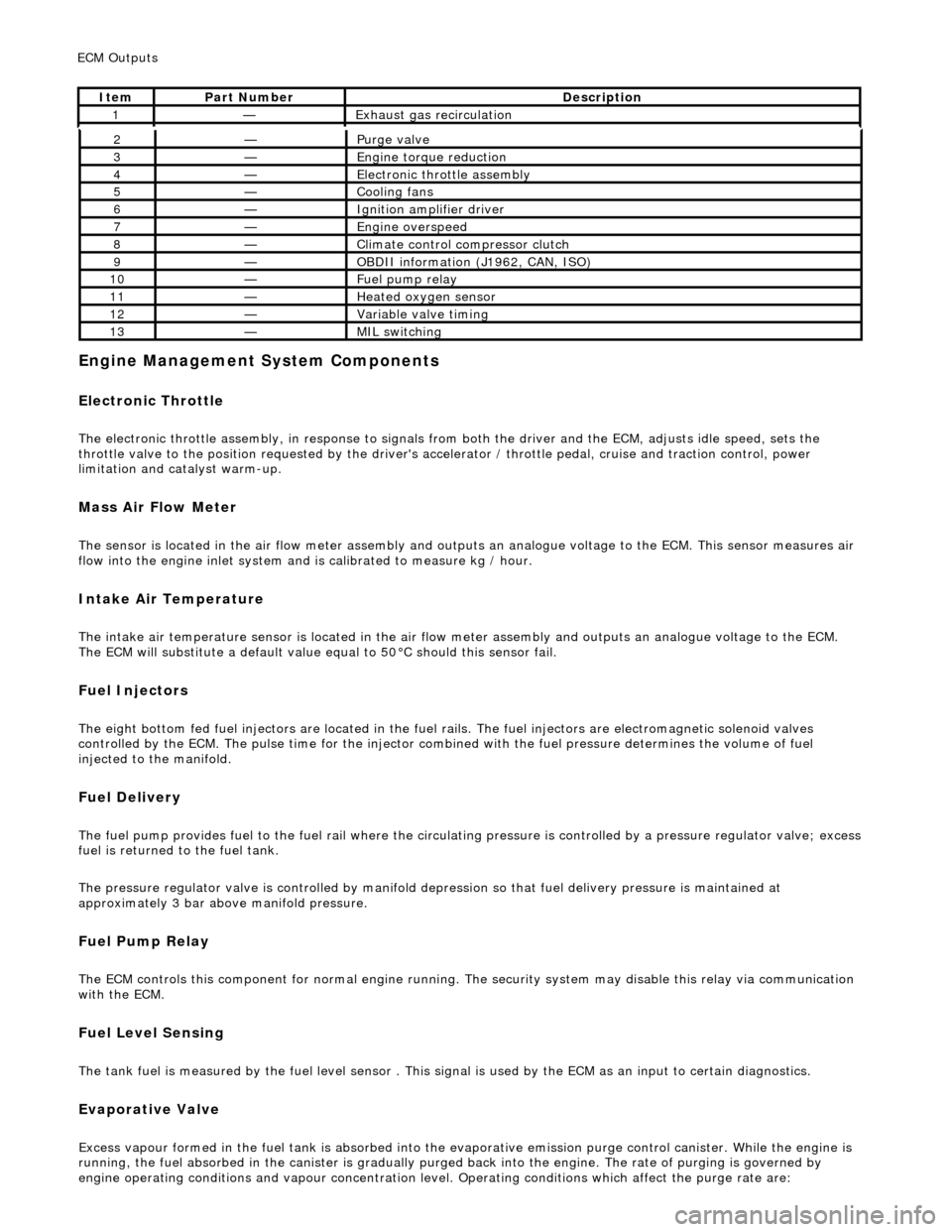

2—Purge

valve

3—Engine

torque reduction

4—E

lectronic throttle assembly

5—Coo

ling fans

6—Ignition amplifier driver

7—Engine overspeed

8—Cli

mate control compressor clutch

9—O

BDII information (J1962, CAN, ISO)

10—F

uel pump relay

11—Heat

ed oxygen sensor

12—Vari

able valve timing

13—MIL sw

itching

ECM Out

puts

It

em

Par

t Number

De

scription

1—Exhaus

t gas recirculation

Page 528 of 2490

Speed an

d load

Coo

l

ant temperature

Ti

me el

apsed from start up

Cl

osed l

oop fuelling

Determination of the vapour concentration is made by stepped opening of the EVAP valve and subsequent monitoring of the

fuelling correction. This function is performed prior to purging, so that at the onse t of purging the EVAP valve can be set to

the optimum position. Should the ECM be unable to determine the concentration before purging, a default value is

employed, which is then modified whilst purging is in progress.

When the purging process is operational th e ECM modifies the basic fuelling calculation to maintain the correct air / fuel

ratio.

Purging is inhibited during fuel cut-off and stability / traction control intervention.

Coolant Temperature Sen

sor

Th

e

sensor outputs a voltage to the ECM which decreases as temperature increases.

Cooling Fans

In response to engi

ne coolant temperat

u

re and climate control system demand, the ECM will energize the cooling fans.

Climate Control Compressor

The E

C

M will allow the compressor clutch to be engaged if th

e engine temperature and load demand are normal. Should the

driver require maximum engine powe r or the coolant temperature be high, the request will be denied.

Cranking Signal

The ECM reacts to a signal fr

om th

e Body Processor Module (BPM) when the starter motor relay is energi

zed. This signal is

used to trigger starting, fu el and ignition strategies.

Engine Speed and Cranksh

aft Position

Engine

speed and cran

k position are moni

tored by a sensor which is mounted on the cylinder block (flywheel housing)

behind the crankshaft drive plat e. It indicates rotational speed to the ECM in the form of 12 pulses per crank revolution.

Engine speed is used for synchronization of fuel an d ignition systems, as well as other functions.

Camshaft Position

The ca

mshaft position sensor is mounted at

the rear of Bank 2 cylinder head on the inlet side and provides one signal every

720 degrees of crankshaft rotation. The signal, in conjunction with the signal from the crankshaft position sensor, indicates

to the ECM that the piston of cylinder 1A is approaching TDC on the compression stroke.

Variable Valve

Timing (Where Fitted)

By energi

si

ng a solenoid to allow the pass

age of pressurized oil on each of the inle t camshaft drives, the ECM can vary by a

single stepped amount, the relati ve timing of the inlet valves.

Ign

ition

Ignit

i

on spark is produced by

individual on-plug coil units.

There are two ignition amplifiers; module #1 drives coils 1A, 2B, 3B and 4A, whilst module #2 drives coils 1B, 2A, 3A and

4B. The ECM controls the amplifiers.

Page 529 of 2490

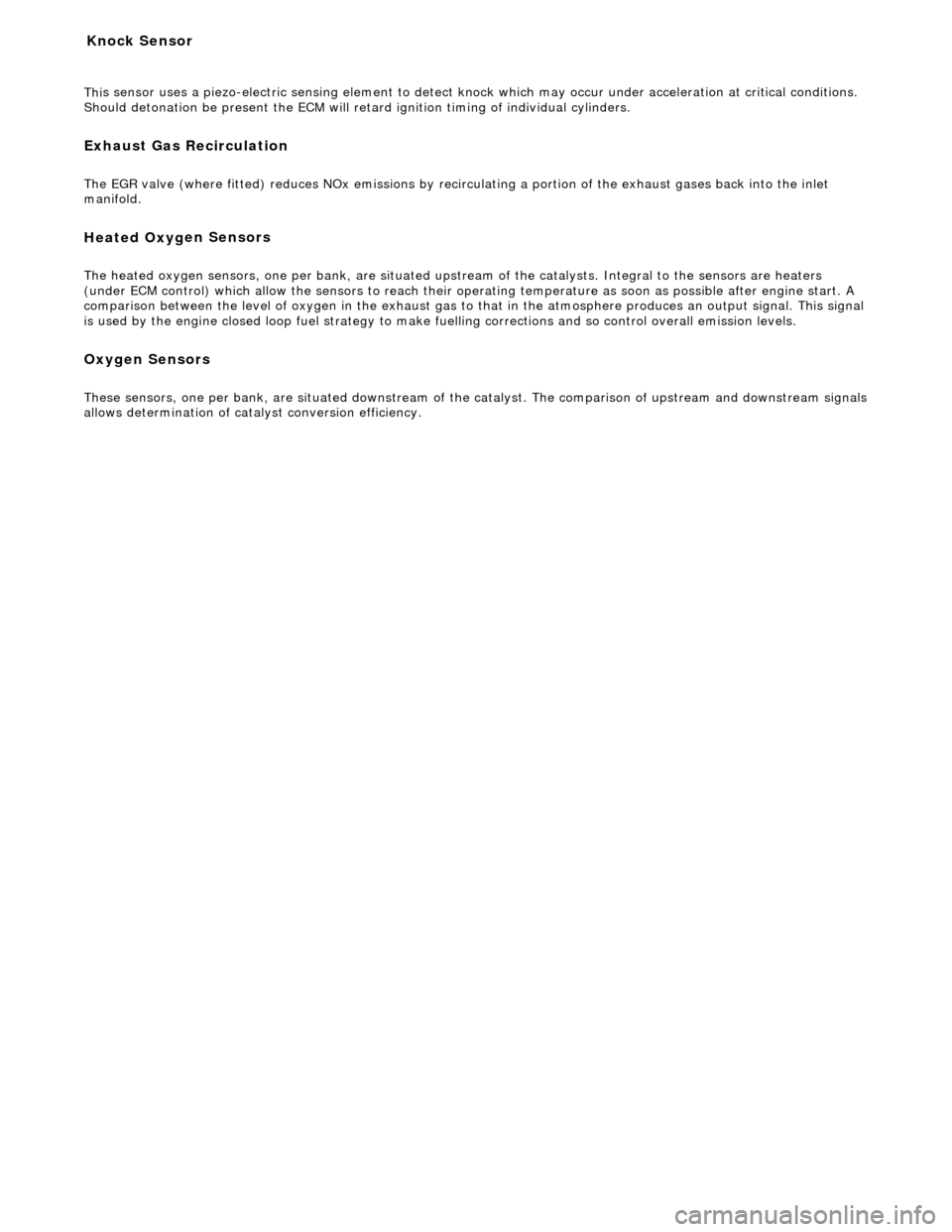

Thi

s sensor uses a piezo-electric sensing element to detect kn

ock which may occur under acceleration at critical conditions.

Should detonation be present the ECM will retard ignition timing of individual cylinders.

Exhaust G

as Recirculation

The EGR

valve (where fitted) reduces NOx

emissions by recirculating a portion of the exhaust gases back into the inlet

manifold.

Heated Oxyg

en Sensors

The h

eated oxygen sensors, one per bank, are situated upstream of the catalysts. Integral

to the sensors are heaters

(under ECM control) which allow the sensor s to reach their operating temperature as soon as possible after engine start. A

comparison between the level of oxygen in the exhaust gas to that in the atmosphere produces an output signal. This signal

is used by the engine closed loop fuel strategy to make fuelling corrections and so control overall emission levels.

Oxygen Sensors

Thes

e sensors, one per bank, are situated downstream of the

catalyst. The comparison of upstream and downstream signals

allows determination of cata lyst conversion efficiency.

Knock Sensor

Page 548 of 2490

En

gine - Valve Clea

rance Adjustment

Gene

ral Procedures

S

p

ecial Tool(s)

Tappet adjustment

3

03-

540

Ai

r gun, fan nozzl

e

303-590

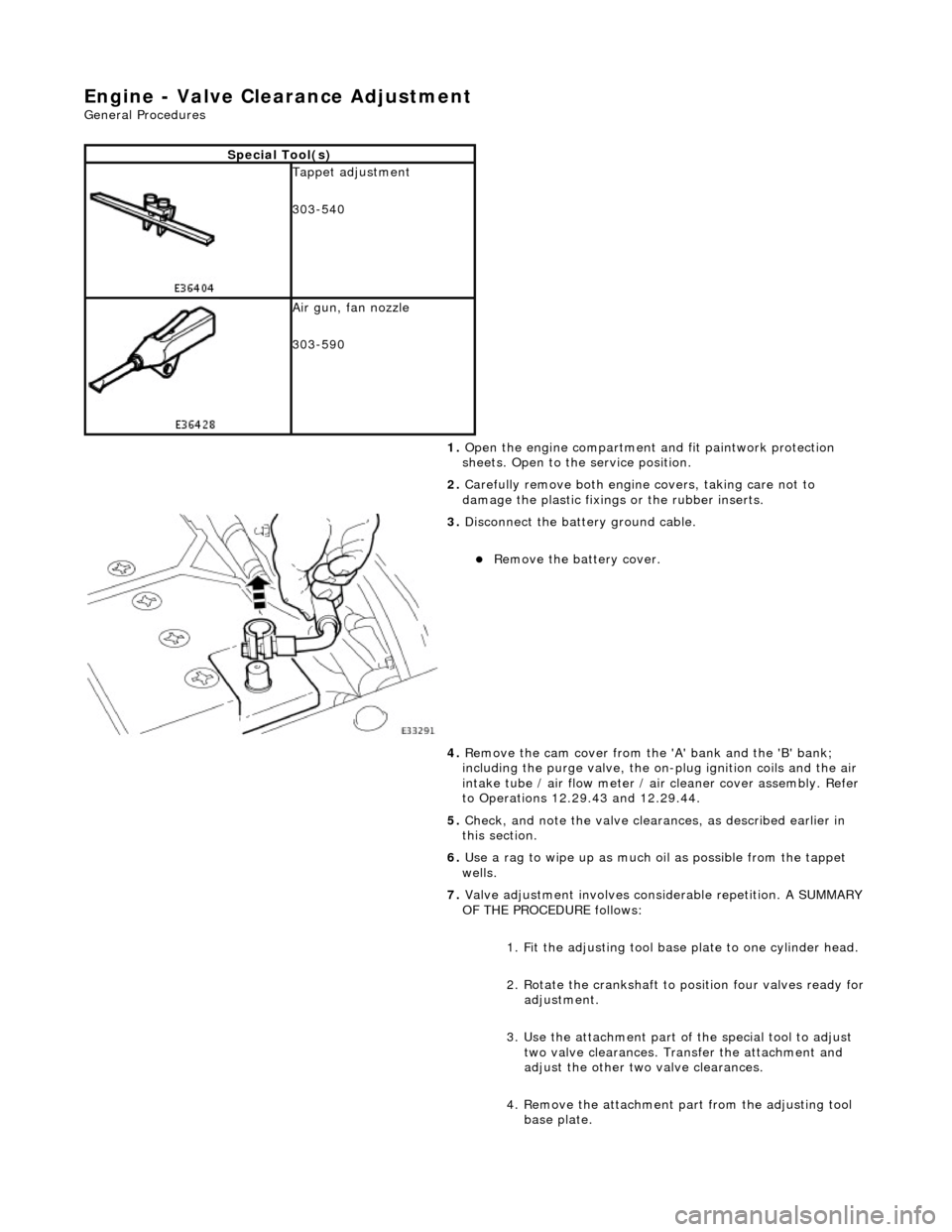

1. Open the engine compartment and fit paintwork protection

sheets. Open to the service position.

2. Carefully remove both engine covers, taking care not to

damage the plasti c fixings or the rubber inserts.

3. Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

4. Remove the cam cover from the 'A' bank and the 'B' bank;

including the purge valve, the on-plug ignition coils and the air

intake tube / air flow meter / air cleaner cover assembly. Refer

to Operations 12.29.43 and 12.29.44.

5. Check, and note the valve cleara nces, as described earlier in

this section.

6. Use a rag to wipe up as much oil as possible from the tappet

wells.

7. Valve adjustment involves considerable repetition. A SUMMARY

OF THE PROCEDURE follows:

1. Fit the adjusting tool base plate to one cylinder head.

2. Rotate the crankshaft to position four valves ready for

adjustment.

3. Use the attachment part of the special tool to adjust two valve clearances. Transfer the attachment and

adjust the other two valve clearances.

4. Remove the attachment pa rt from the adjusting tool

base plate.

Page 551 of 2490

E

ngine - Valve Clearance Check

Gen

eral Procedures

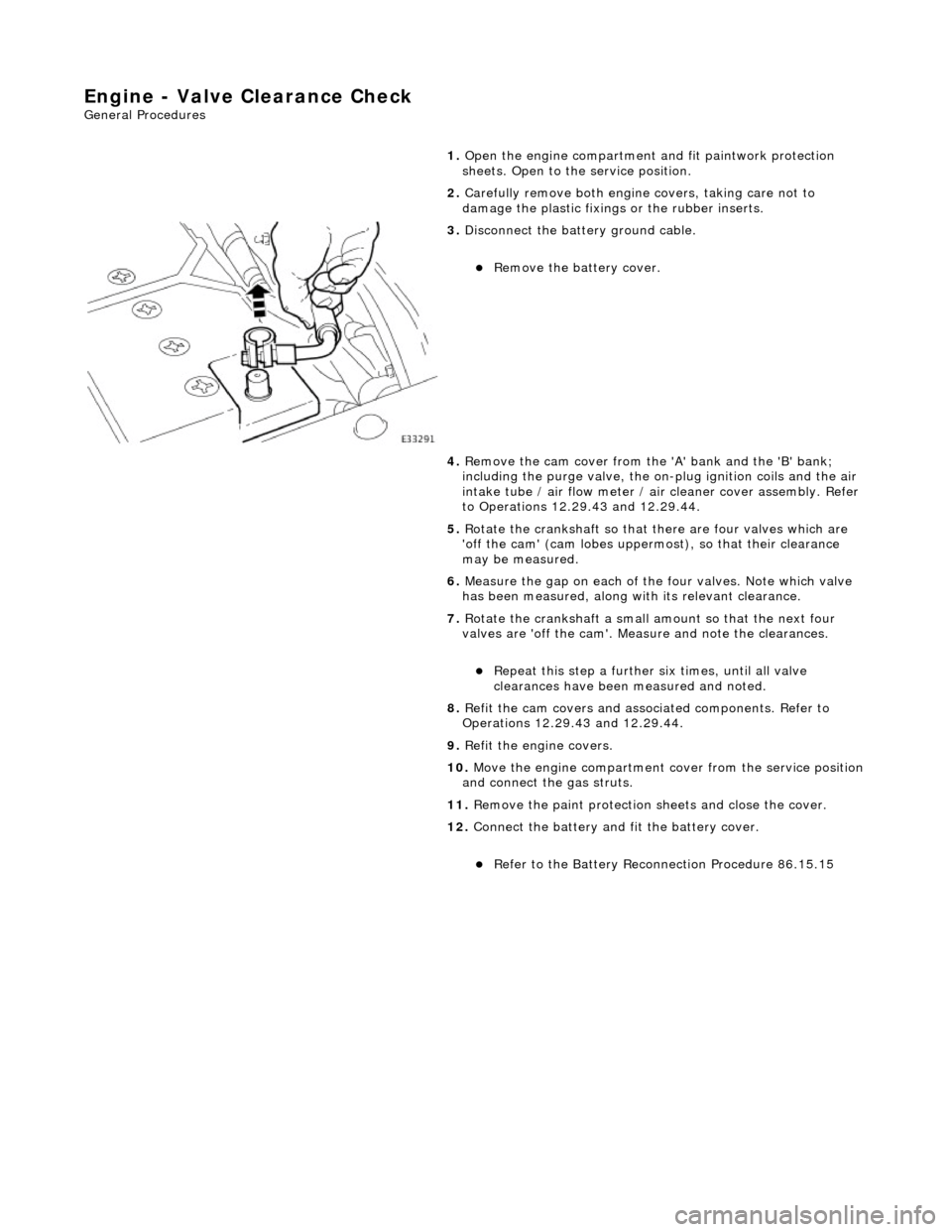

1.

Open the engine compartment and fit paintwork protection

sheets. Open to the service position.

2. Carefully remove both engine covers, taking care not to

damage the plasti c fixings or the rubber inserts.

3. Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

4. Remove the cam cover from the 'A' bank and the 'B' bank;

including the purge valve, the on-plug ignition coils and the air

intake tube / air flow meter / air cleaner cover assembly. Refer

to Operations 12.29.43 and 12.29.44.

5. Rotate the crankshaft so that there are four valves which are

'off the cam' (cam lobes upperm ost), so that their clearance

may be measured.

6. Measure the gap on each of the four valves. Note which valve

has been measured, along with its relevant clearance.

7. Rotate the crankshaft a small am ount so that the next four

valves are 'off the cam'. Measure and note the clearances.

Re

peat this step

a further six times, until all valve

clearances have been measured and noted.

8. Refit the cam covers and associated components. Refer to

Operations 12.29.43 and 12.29.44.

9. Refit the engine covers.

10. Move the engine compartment cover from the service position

and connect the gas struts.

11. Remove the paint protection sheets and close the cover.

12. Connect the battery and fit the battery cover.

Re

fer to the Battery Reconnection Procedure 86.15.15

Page 644 of 2490

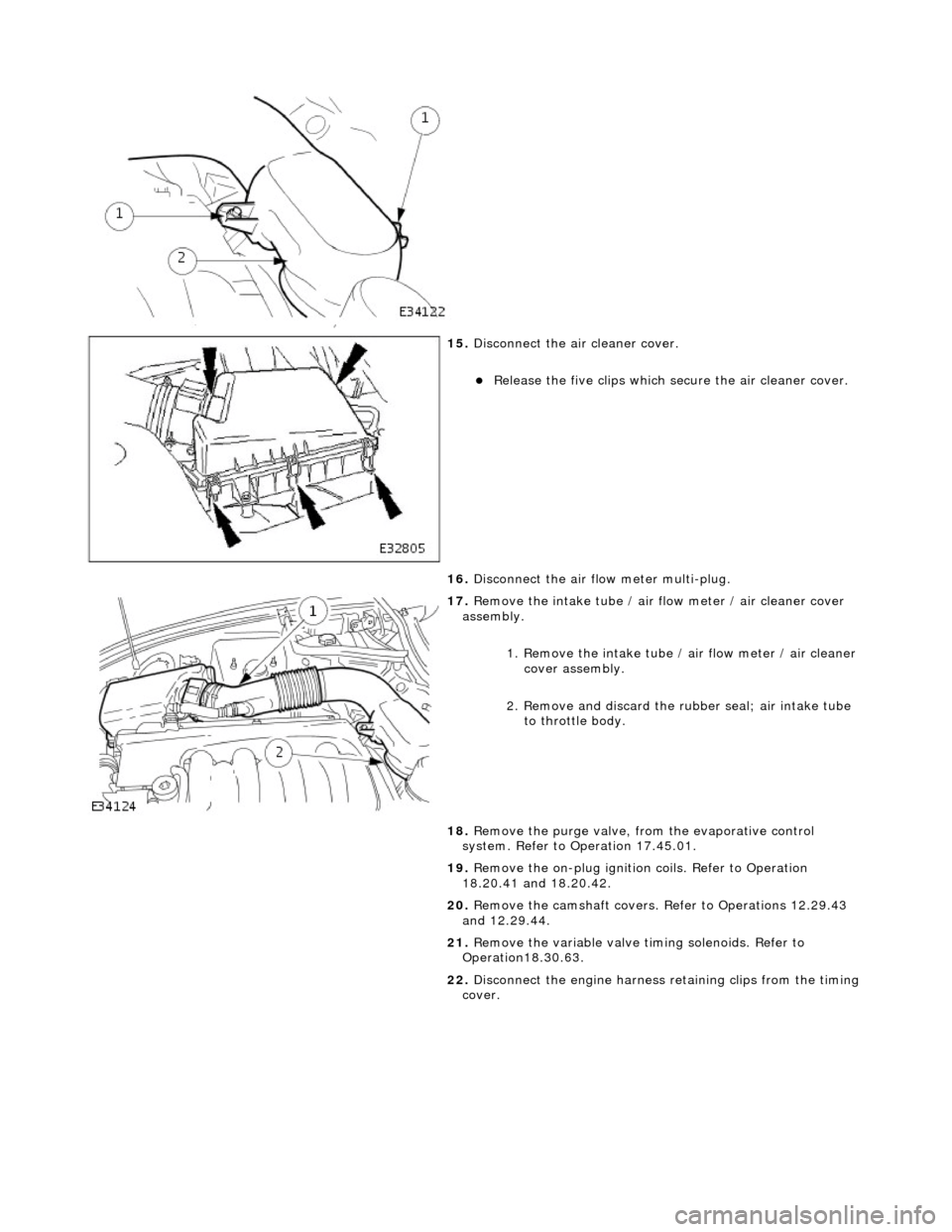

15. Di

sconnect the air cleaner cover.

R

e

lease the five clips which se

cure the air cleaner cover.

16. Disconnect the air flow meter multi-plug.

17 . R

emove the intake tube / air

flow meter / air cleaner cover

assembly.

1. Remove the intake tube / air flow meter / air cleaner

cover assembly.

2. Remove and discard the ru bber seal; air intake tube

to throttle body.

18. Remove the purge valve, fro m the evaporative control

system. Refer to Operation 17.45.01.

19. Remove the on-plug ignition coils. Refer to Operation

18.20.41 and 18.20.42.

20. Remove the camshaft covers. Refer to Operations 12.29.43

and 12.29.44.

21. Remove the variable valve ti ming solenoids. Refer to

Operation18.30.63.

22. Disconnect the engine harness retaining clips from the timing

cover.

Page 653 of 2490

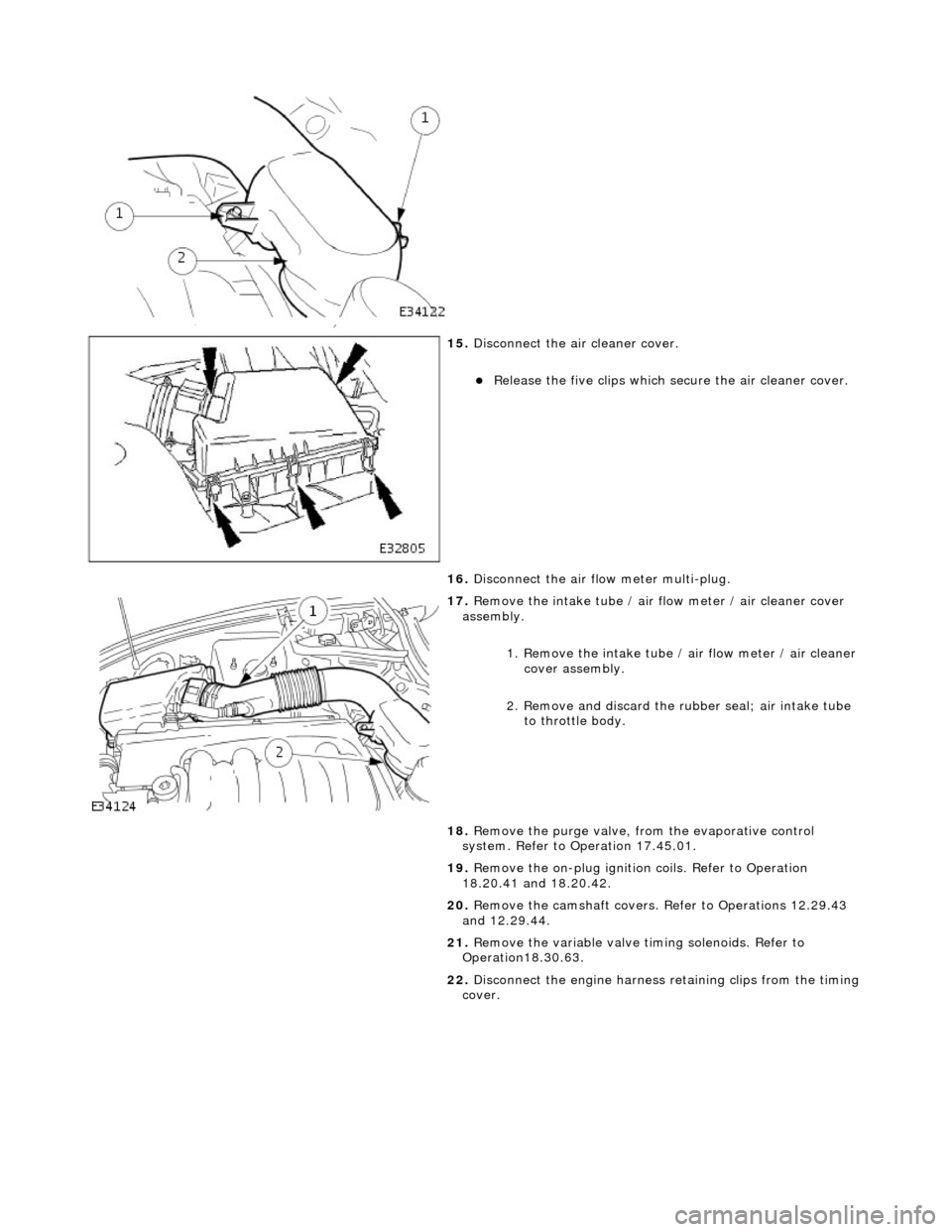

15

.

Disconnect the air cleaner cover.

R

elease the five clips which se

cure the air cleaner cover.

16. Disconnect the air flow meter multi-plug.

17

.

Remove the intake tube / air flow meter / air cleaner cover

assembly.

1. Remove the intake tube / air flow meter / air cleaner

cover assembly.

2. Remove and discard the ru bber seal; air intake tube

to throttle body.

18. Remove the purge valve, fro m the evaporative control

system. Refer to Operation 17.45.01.

19. Remove the on-plug ignition coils. Refer to Operation

18.20.41 and 18.20.42.

20. Remove the camshaft covers. Refer to Operations 12.29.43

and 12.29.44.

21. Remove the variable valve ti ming solenoids. Refer to

Operation18.30.63.

22. Disconnect the engine harness retaining clips from the timing

cover.

Page 657 of 2490

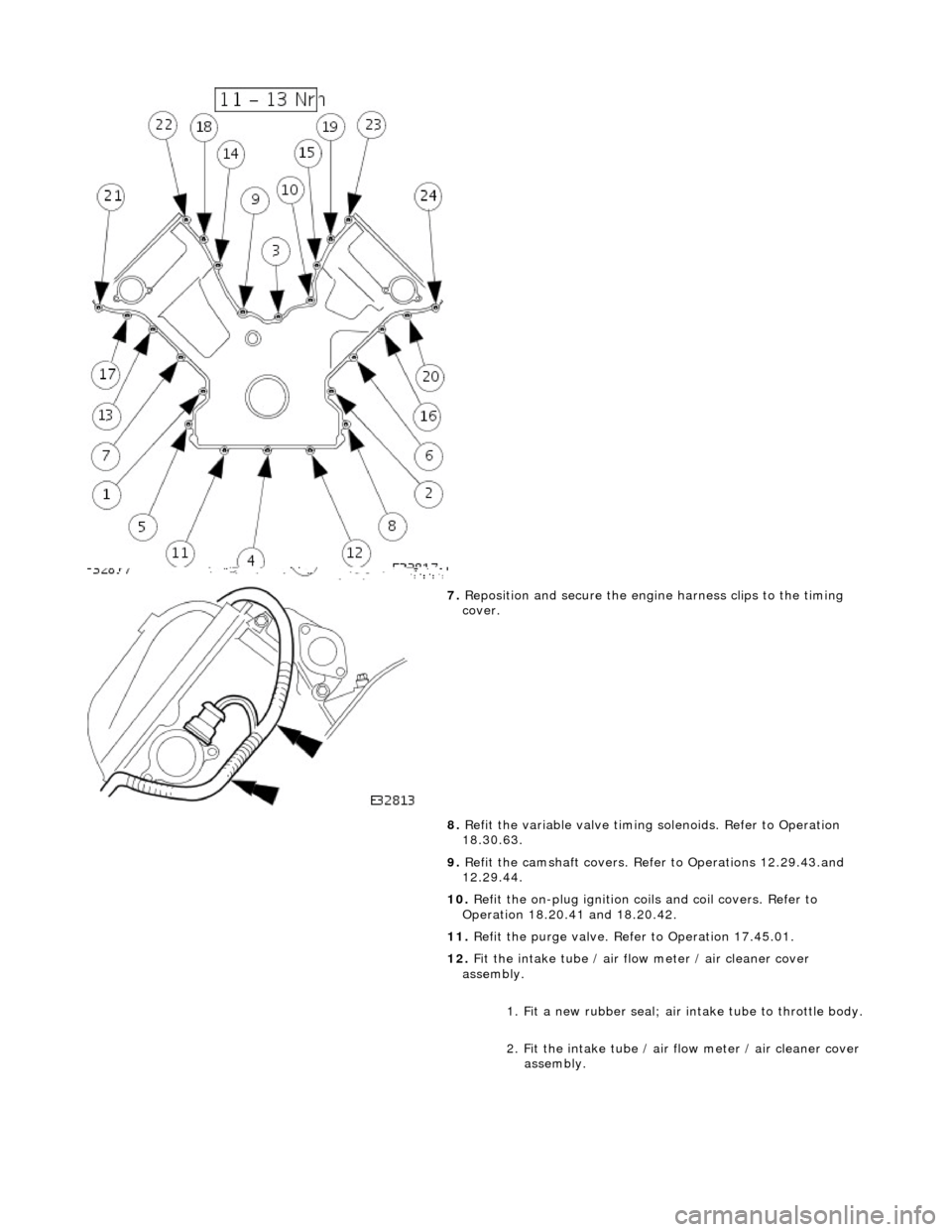

7. Reposition and secure the engine harness clips to the timing

cover.

8. Refit the variable valve timing solenoids. Refer to Operation

18.30.63.

9. Refit the camshaft covers. Refer to Operations 12.29.43.and

12.29.44.

10. Refit the on-plug ignition coils and coil covers. Refer to

Operation 18.20.41 and 18.20.42.

11. Refit the purge valve. Refer to Operation 17.45.01.

12. Fit the intake tube / air flow meter / air cleaner cover

assembly.

1. Fit a new rubber seal; air in take tube to throttle body.

2. Fit the intake tube / air flow meter / air cleaner cover

assembly.

Page 704 of 2490

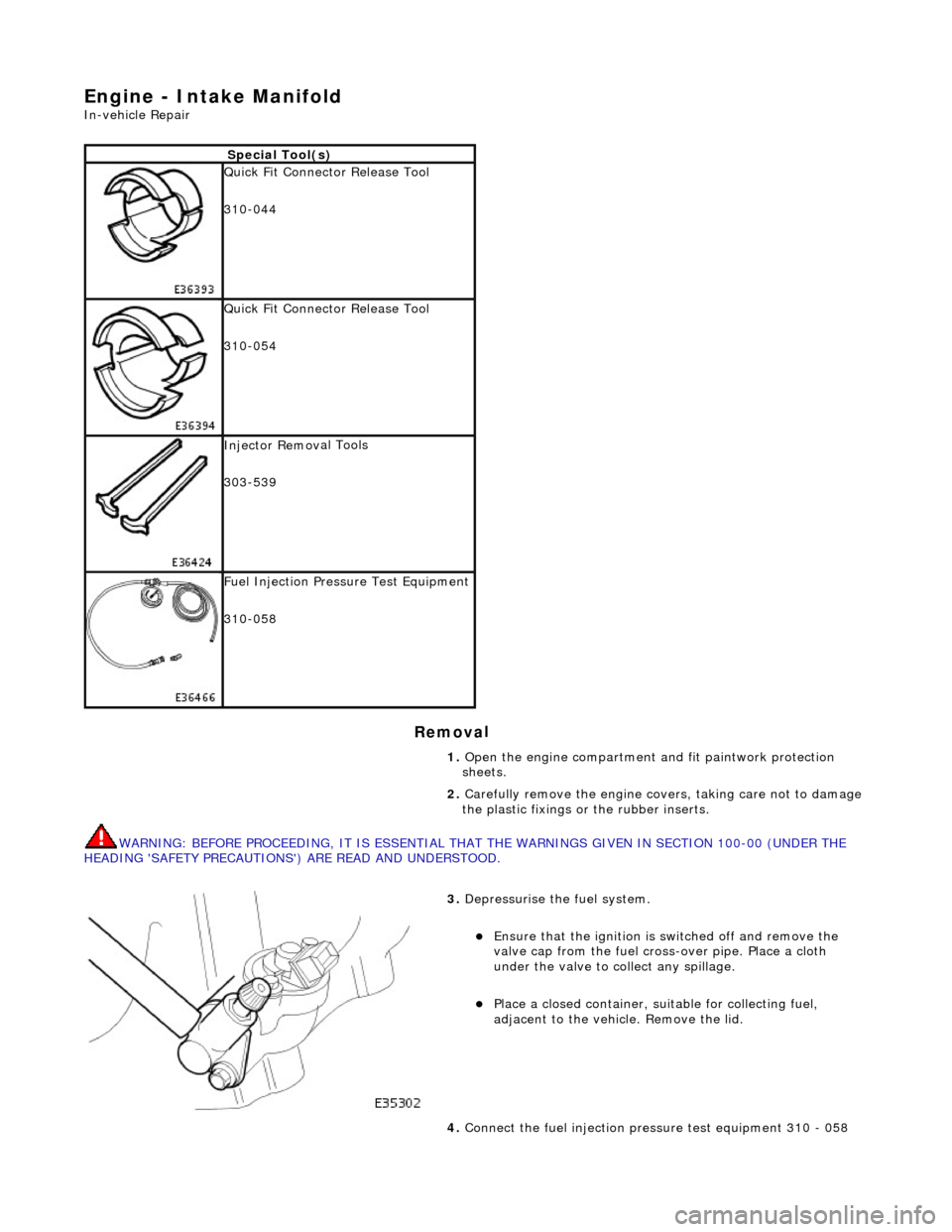

Engine - Intake Manifol

d

In-v

ehic

le Repair

Remov

a

l

W

A

RNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNINGS GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

S p

ecial Tool(s)

Qu

ic

k Fit Connector Release Tool

310-044

Qu ic

k Fit Connector Release Tool

310-054

Inject or Remov

al Tools

303-539

F u

el Injection Pressu

re Test Equipment

310-058

1. Open the engine compartment and fit paintwork protection

sheets.

2. Carefully remove the en gine covers, taking care not to damage

the plastic fixings or the rubber inserts.

3. Depress

urise the fuel system.

E

n

sure that the ignition is

switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

Pla c

e a closed container, su

itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

4. Connect the fuel injection pres sure test equipment 310 - 058