service JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 298 of 2490

7. Chec k

that the pinion sp

igot radial run-out.

0,08

mm MAX TIR.

If t

hi

s specification is exceeded, contact Jaguar Service.

8. Re

fer to the illustration.

R

e

new the driveshaft fixings.

9. Re

fer to the illustration.

E

n

sure that the bear

ing is central.

10. Refer to the illustration.

Page 326 of 2490

Fr

ont Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the vertical link only. DO NOT loosen any other caliper bolts.

Raise front of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to section <<74.20.05>>.

Page 331 of 2490

R

ear Brake Disc Runout Check Vehicles Without: Brembo Brakes

Special Service tools

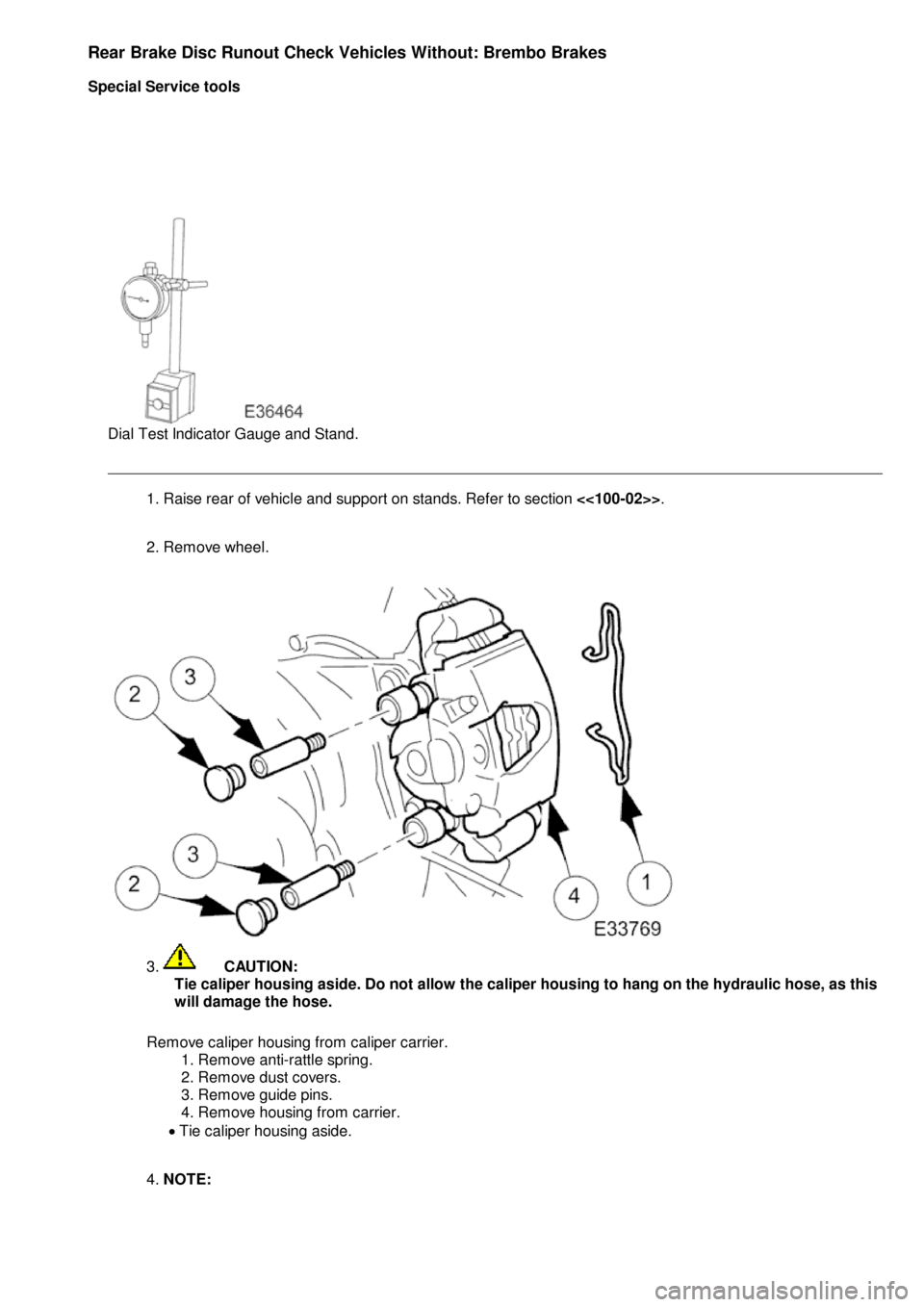

D

ial Test Indicator Gauge and Stand.

1

. Raise rear of vehicle and support on stands. Refer to section

<<100-02>>.

2. Remove wheel.

3

.

C

AUTION:

Tie caliper housing aside. Do not allow the caliper housing to hang on the hydraulic hose, as this

will damage the hose.

Remove caliper housing from caliper carrier. 1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

4. Remove housing from carrier.

Tie caliper housing aside.

4. NOTE:

Page 334 of 2490

Rear

Brake Disc Runout Check Vehicles With: Brembo Brakes

Special Service tools

Di

al Test Indicator Gauge and Stand.

1.

WA

RNING:

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

CA

UTION:

Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts

throughout the vehicle. These devices restrict the number of times a nut or bolt can be used. See

section <<100-00>> for information.

CA

UTION:

The Brembo caliper is aligned to the brake disc when it is first installed to the vehicle, therefore,

care must be taken not to disturb this alignment. When removing the caliper; remove the bolts

that secure the anchor bracket to the hub carrier only. DO NOT loosen any other caliper bolts.

Raise rear of vehicle and support on stands. Refer to section <<100-02>>.

2. Remove wheel. Refer to operation <<74.20.05>>.

Page 361 of 2490

Front Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High Performance brake ca liper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise front of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove front wheels. Refer to operation.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Remove 'R' clips.

2. Withdraw pins from caliper.

3. Remove anti-rattle spring.

4. Discard brake pads.

Page 387 of 2490

Rear Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High performance brake caliper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise rear of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove rear wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Discard brake pads.

Page 458 of 2490

The

measurement of the maximum system pressure, (which is

governed by the pressure relief valve) is achieved by

inserting the Service Tool (pressure gauge and adaptors) into th e fluid circuit of the power steering system. Run the engine

at idle speed, turn the st eering from lock to lock and read the ma ximum pressure recorded on the gauge.

Installin

g Test Equipment

To

in

stall the pressure test equipment:

Pla

c

e a suitable drain tray be

low the power steering pump.

Install a hose clamp on

the re

servoir to pump hose prior to disconnecting any hoses, to avoid unnecessary loss of

fluid.

Disc

onnect the hose from the power st

eering pump high pressure outlet.

Install the pu

mp outlet to hose adaptor (5

). Do not omit the 'O' ring seal (9).

Connect the power steering

pump

adaptor to control valve hose (6) of the test equipment.

Install th e adaptor (4) in th

e high

pressure hose previously removed from the power steering pump outlet.

Conn

ect the connector (3) of the test equipment hose (2) to the adaptor (4).

R

e

move the hose clamp fro

m the reservoir hose.

Start th

e engine.

With the control valve (7) OPEN and the engine idli ng, the following system pressures may be checked:

Du

ring turning.

W

h

en the steering is

held on full lock.

With

the steeri

ng at rest.

• CAUTIONS:

To avoid excessive heating of the po wer steering pump, do not close the valve for longer than 5 seconds maximum.

Do not drive the vehicle with the test equipment installed.

With the control valve (7) CLOSED the power steering pump maximum ou tput pressure can be checked.

Removing Test Equipment

To

remove the test equipment:

Install a hose clamp

on

the reservoir to power steering pump hose.

Re

movi

ng the test equipmen

t is a reversal of the in stallation instructions.

Install a new '

O

' ring seal (9) to the power steering pump high pressu

re outlet to hose connection.

Instal

l the original hose to

the power steering pump.

Re

move the clamp from the reservoir to

the power steering pump hose.

Top-up the reservoir flui

d.

Ble

e

d the power steerin

g system. For additional information,

REFER to Power Steering System Bleeding

- in thi

s section.

Stee

ring Fault Diagnosis by Sympt

om Charts

Leakage

52

11-0

11-03/1

Pump High Pressure Ou

tlet

to Hose Adaptor

621

1

-011-02

Pump Adaptor

to Contro

l Valve Hose

721

1

-011-01

Control Valve

82

11-

011

Pressure Gauge

9-'O

'

Ring Seal

Cond

iti

on

Possib

l

e Sources

Acti

o

n

Co

nfirm

the position of the fluid

leak.

CLEAN th

e area of the leak.

In

s

pect the area and confirm the exact position of leak.

Make sure the fluid

is not from anoth

er system on

the vehicle.

Page 465 of 2490

Description of General Stee

ring System Noises

Boom

Rh

ythmic sound like a drum roll or distant

thunder. May cause pressure on the ear drum.

Buzz

Low-pitched soun

d, like a bee. Usually associated with vibrations.

Chatt

er

Rapidly rep

eating

metallic sound.

Chuckle

Rapid noise that soun

ds like

a stick against the spokes of a spinning bicycle wheel.

F

eedback (knocking noises in the

steering gear) - condition where roughness is felt in the steering

wheel by the driver when the vehicle

is driven over rough surfaces

REF

ER to Section 211

-0

3 Steering Linkage

.

Steeri

ng gear

retaining bolts

loose or damaged.

CAU

TION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this instruction

will result in the steering gear warranty to become

invalid.

CHECK

and TIGHTEN the steering gear

retaining bolts.

INST

ALL new retaining bolts as necessary.

For additional information,

REFER to Section 211

-0

2 Power Steering

.

L

oose suspension

bushing, bolts or ball joints.

TIGHTE

N or INSTALL new components as

necessary. For additi onal information,

REFER to Section 204

-01

Front Suspension

.

Steeri

ng column

retaining bolts loose.

CAU

TION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this instruction

will result in the steering gear warranty to become

invalid.

CHECK

and TIGHTEN the steering column

retaining bolts/nuts and pinch bolts if required. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Exce

ssive wear in

steering column assembly.

CHECK

for steering column for wear in the

universal joints and be arings. If wear is

present, INSTALL a new steering column as

necessary. For additi onal information,

REFER to Section 211

-0

4 Steering Column

.

Ni

bble (Shimmy) Oscillation of the

steering wheel (not vertical which is SHAKE). This is driven by road wheel imbalance.

Road wh

eel

imbalance.

CHECK

for road wh

eel imbalance.

CHECK for

rele

vant SERVICE

BULLETINS/SERVICE ACTIONS for the

vehicle on Jaguar Communications Online (JCOL) or in hard copy form.

S

teering wheel

replacement.

CHECK for

rele

vant SERVICE

BULLETINS/SERVICE ACTIONS for the

vehicle on Jaguar Communications Online (JCOL) or in hard copy form.

Rac

k replacement.

CHECK for

rele

vant SERVICE

BULLETINS/SERVICE ACTIONS for the

vehicle on Jaguar Communications Online (JCOL) or in hard copy form.

Page 480 of 2490

The steering rack assembly :

Is mounted on the

rear face of the

front suspension crossbeam by two forg ed mounting brackets with resilient

bushes. The bushes are handed (pinion side and non-pinion side) and are orientated according to the vehicle range

application.

Convert s

the rotary motion of the steering wheel, via the steering gear pinion, to the lateral motion of the rack.

F

e

atures a variable ratio steering

rack with integral hydraulic po wer steering cylinder and piston.

Has a hydrauli

c control valve with Servotronic co

ntrol and positive center feel torsion bar.

The basic steering rack assembly is not serviceable. The following components are serviceable items:

Transfer pipework

.

Servotronic valve. Cent

ralizing cap.

O

u

ter ball joint.

Rac

k

gaiter.

Clips and

fittings.

Steering Rack Components

It e

m

Par

t

Number

De

scr

iption

1—Front

su

spension crossbeam

2—Steeri

ng rack housi

ng

3—Hydraulic

control valve housing

4—Moun

ting bracke

t

5—Gait

er

6—Tie

rod

7—O

u

ter ball joint

Steering R

a

ck Assembly

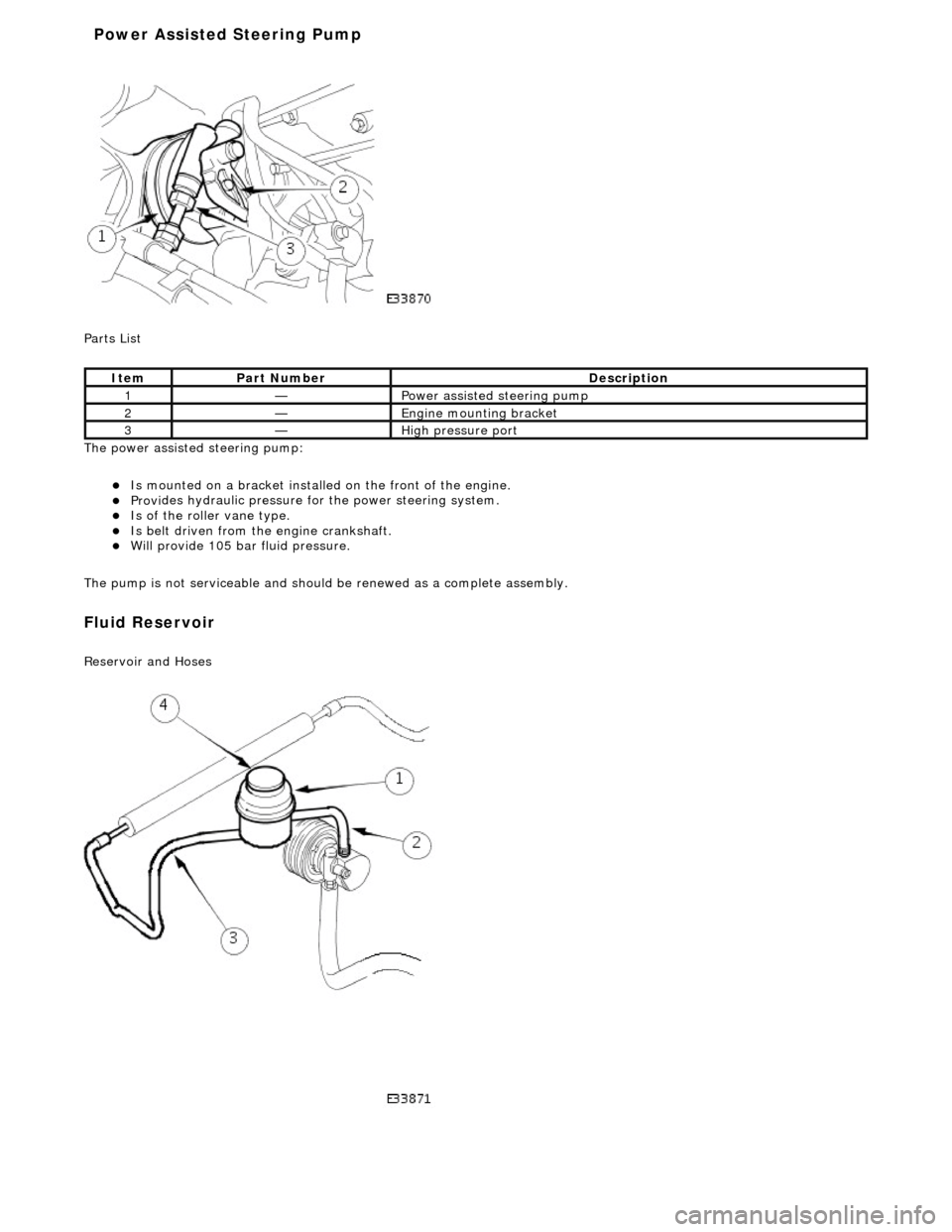

Page 484 of 2490

P a

rts List

The power assisted steering pump:

Is mo u

nted on a bracket installe

d on the front of the engine.

Provides hydraul

ic pressure fo

r the power steering system.

Is of the roll

er vane type.

Is belt driven from th

e en

gine crankshaft.

Will provide 1

05 bar f

luid pressure.

The pump is not serviceable and should be renewed as a complete assembly.

Fluid Reservoir

Re

servoir and Hoses

Ite

m

Par

t

Number

De

scr

iption

1—Power as

si

sted steering pump

2—Engine

m

ounting bracket

3—High

pressure port

Power Assisted Steering Pump