service JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 486 of 2490

P a

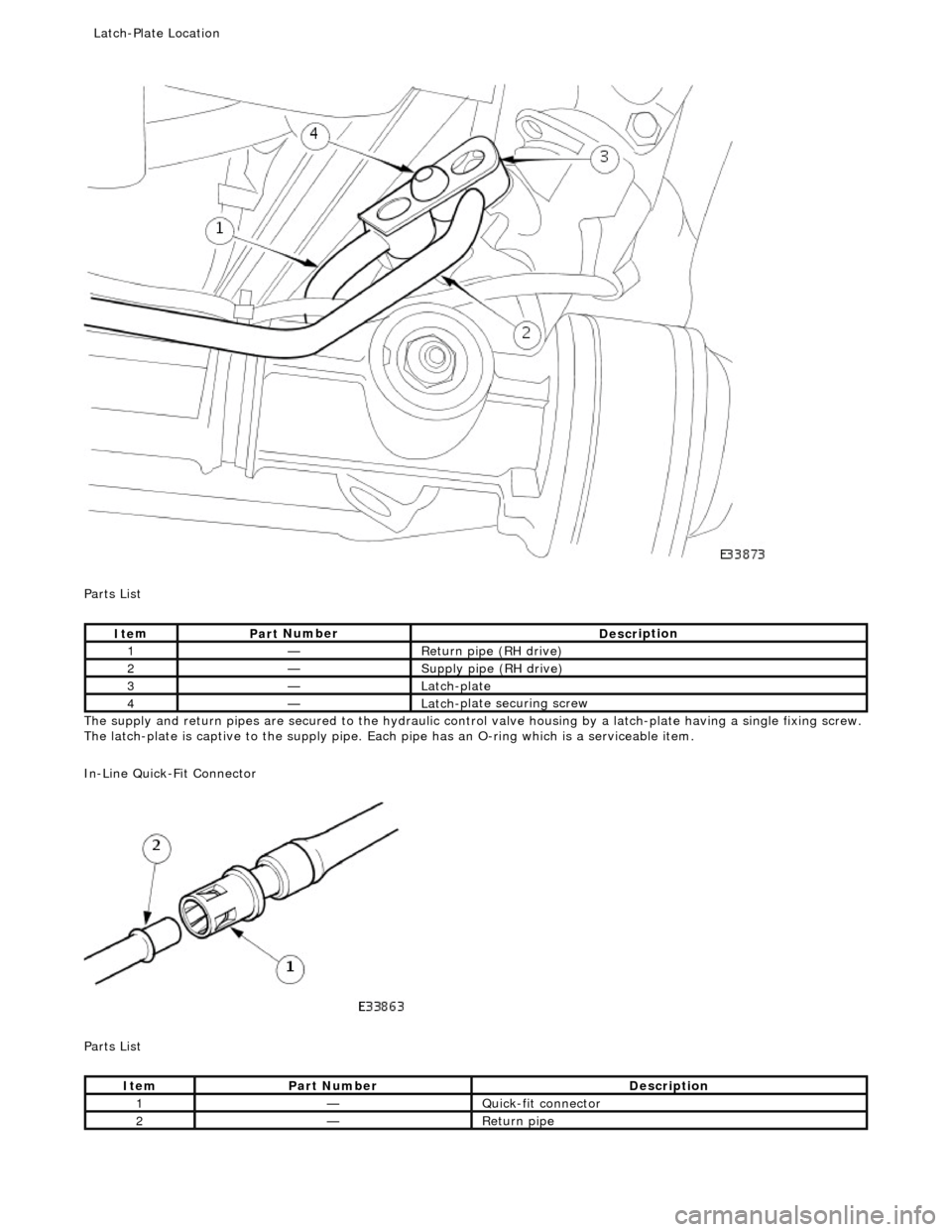

rts List

The supply and return pipes are secured to the hydraulic control valve housing by a latch-plate having a single fixing screw.

The latch-plate is captive to the supply pipe. Each pipe has an O-ri ng which is a serviceable item.

In-Line Quick-Fit Connector

Parts List

Ite

m

Par

t

Number

De

scr

iption

1—Return

pipe (RH drive)

2—Supply pipe (RH

drive)

3—Latc

h-plate

4—Latch-

plate securing screw

It

e

m

Par

t

Number

De

scr

iption

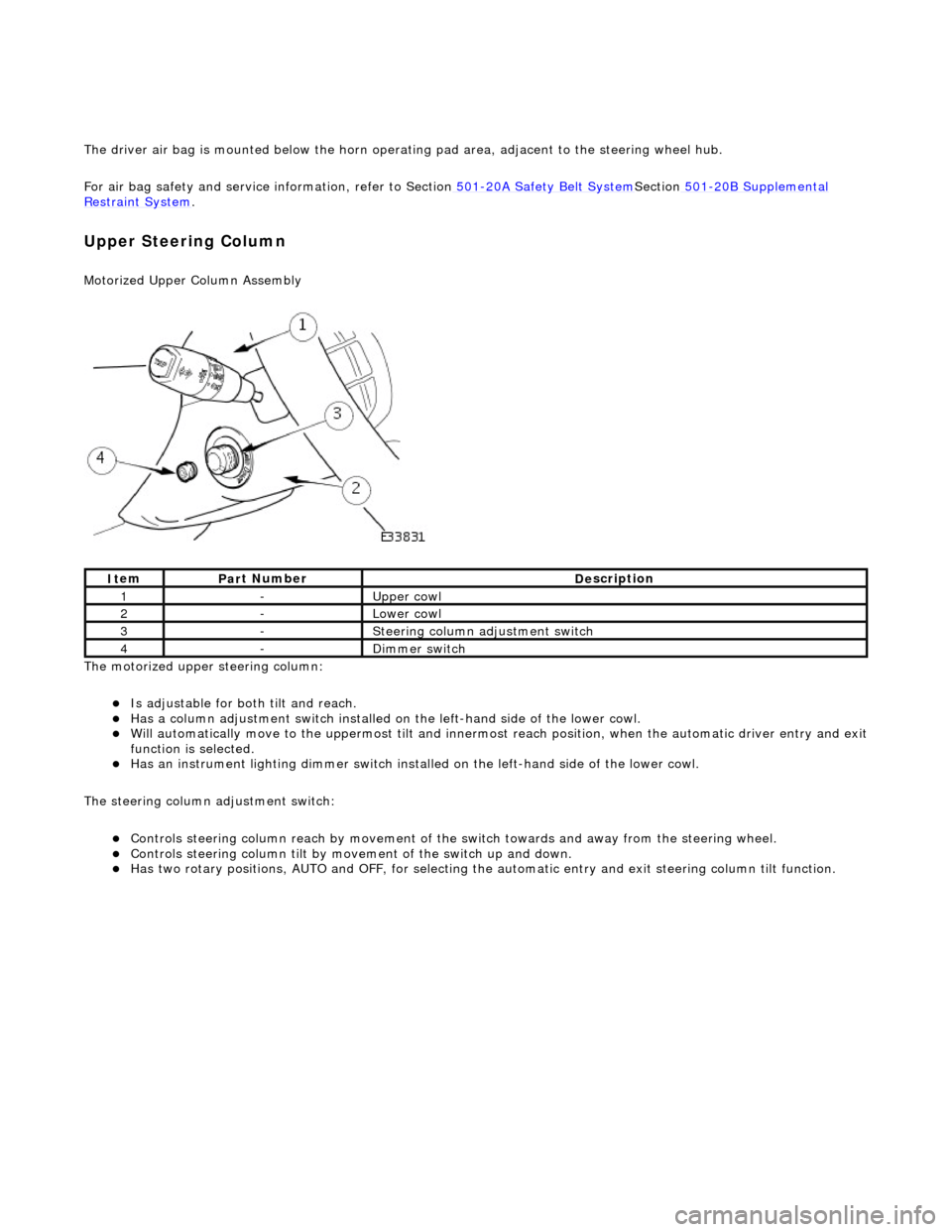

1—Qu

ic

k-fit connector

2—Return

pipe

Latch

-Plate Location

Page 487 of 2490

m

ember. The quick-fit connector O-rings are not serviceable.

Special tool JD 182 is required to disconnect the quick-fit connector.

Hydraulic System

P

arts List

Hydraulic System

Op

erating Principle

The rot

ary motion of the steering wheel is converted, via the st

eering rack pinion, to the lateral motion of the rack. Steering

assistance is provided by pressurized fluid being directed against a piston operating within the rack cylinder. Rack

movement is achieved by diffe rential pressures being applied on either si de of the rack piston, caused by unequal

restrictions within the hydraulic control valve.

The main components of the hydraulic control valve are the rota ry distributor, control sleeve and hydraulic reaction piston.

It

em

Par

t Number

De

scription

1—F

luid reservoir

2—Pum

p

3—Pressure and fl

ow limiting valve

4—Supply line

5—R

eturn line

6—Steeri

ng rack

7—Pin

ion

8—O

perating cylinder and piston

9—Hydrau

lic control valve

10—Hydraulic reaction

piston

11—Control

sleeve

12—R

otary distributor

13—F

luid cooler

A

quick-fit connector with double O-ring se

als is incorporated in the return line and is clipped to the right-hand chassis side

Page 507 of 2490

The driver air bag is moun

ted below the horn operat

ing pad area, adjacent to the steering wheel hub.

For air bag safety and service information, refer to Section 501

-20A Safety Belt

System

Sectio

n

501

-2

0B Supplemental

Re

straint System

.

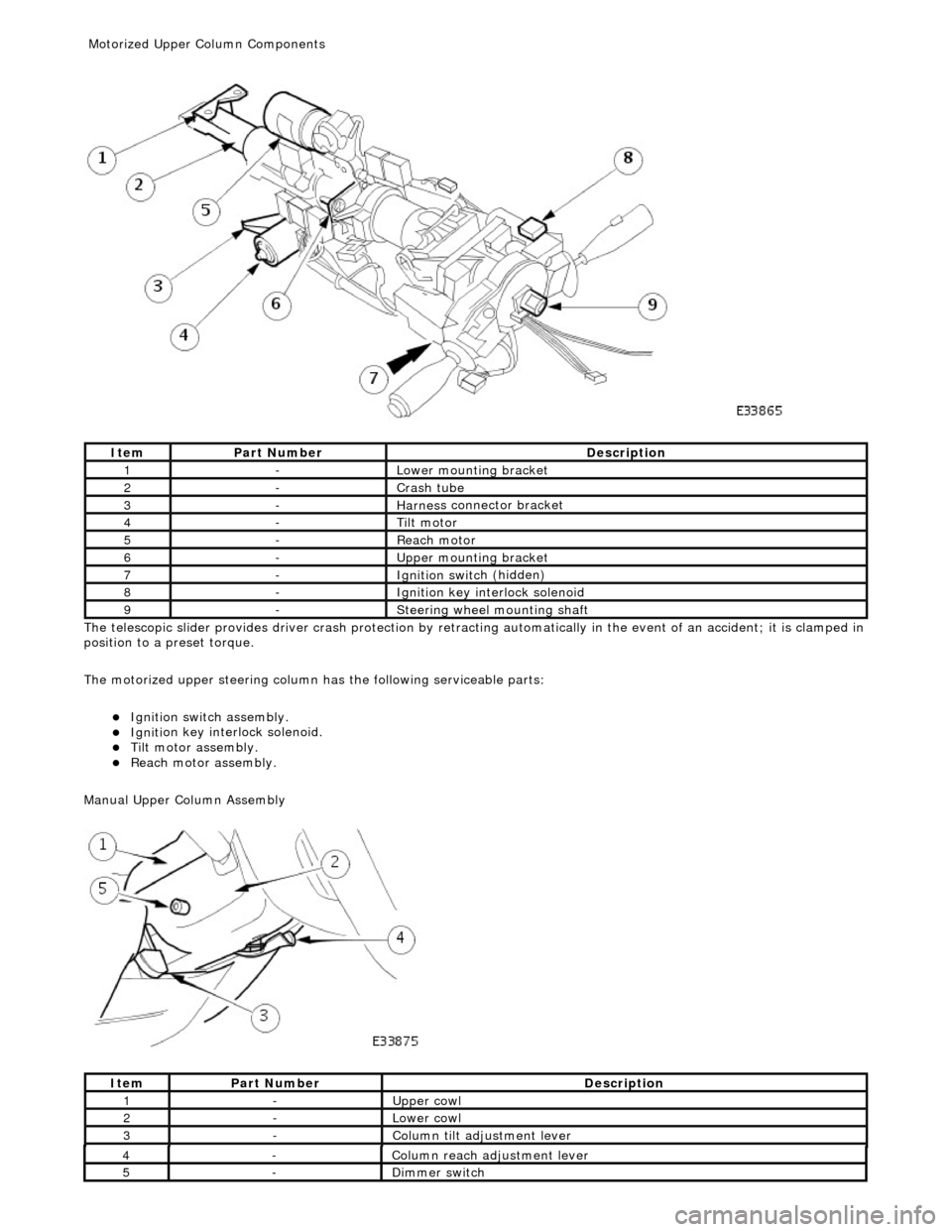

Upper Steering Column

Motorized Upper Colu

mn Assembly

The motorized upper steering column:

Is adjustable for both til

t and reach.

Has a col

umn adjustment switch installed on

the left-hand side of the lower cowl.

W

ill automatically move to the uppermost tilt and innermost reach position, when the automatic driver entry and exit

function is selected.

Has an instrument li

ghti

ng dimmer switch installed on the left-hand side of the lower cowl.

The steering column adjustment switch:

Controls steeri

ng column reach by

movement of the switch towards an d away from the steering wheel.

Controls steeri

ng column tilt by mo

vement of the switch up and down.

Has two

rotary positions, AUTO and OFF, for selecting the

automatic entry and exit steering column tilt function.

It

em

Par

t Number

De

scription

1-Upper

cowl

2-Lower cowl

3-Ste

ering column adjustment switch

4-Di

mmer switch

Page 508 of 2490

The te

lescopic slider provides driver crash

protection by retracting automatically in the event of an accident; it is clamped in

position to a preset torque.

The motorized upper steering column has the following serviceable parts:

Igniti

on switch assembly.

Igni

ti

on key interlock solenoid.

Ti

lt

motor assembly.

Reach motor assembly.

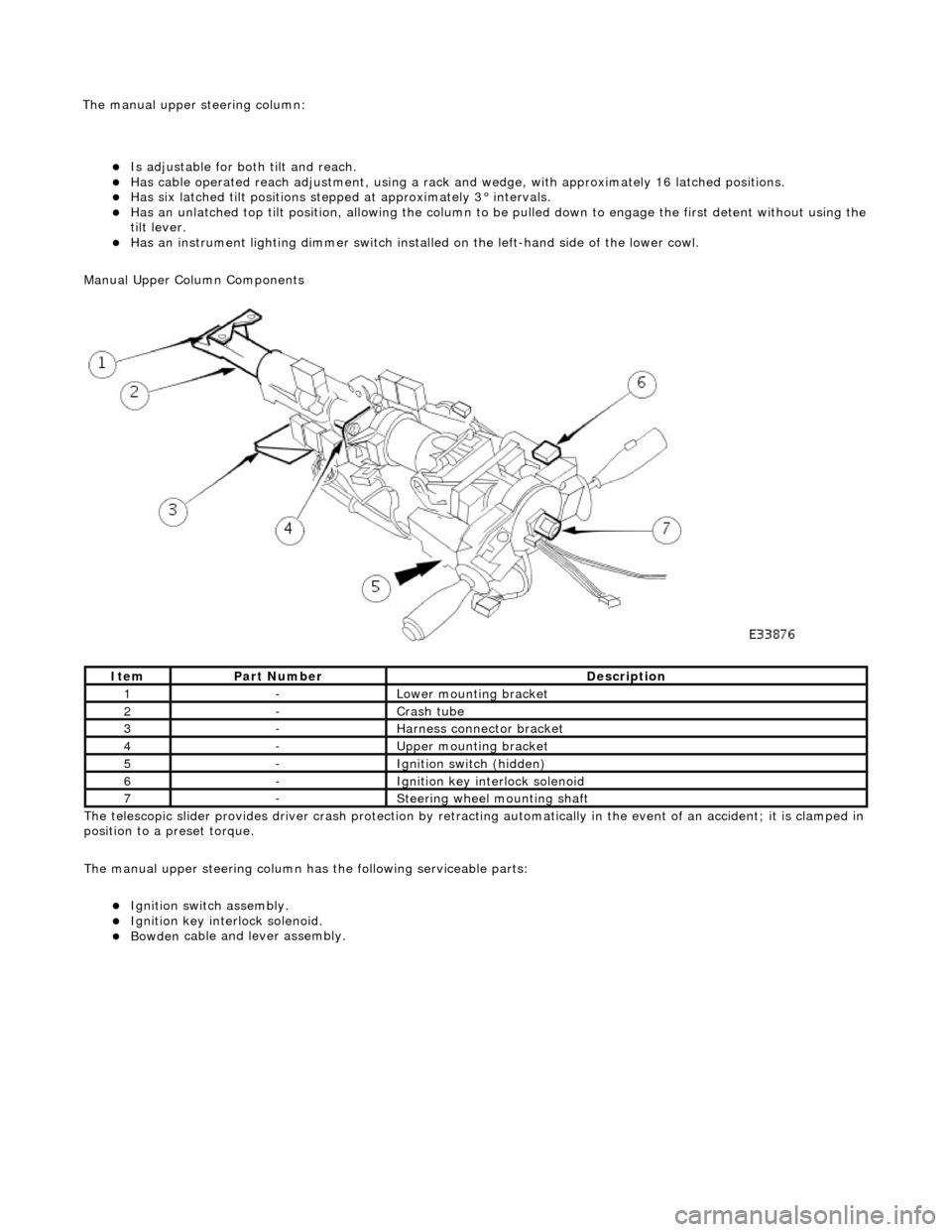

Manu al Upper Column Assembly

Ite

m

Par

t

Number

De

scr

iption

1-L

o

wer mounting bracket

2-Crash tube

3-Harnes

s c

onnector bracket

4-Tilt motor

5-Reach m

otor

6-Upper

moun

ting bracket

7-Ignition switc

h

(hidden)

8-Igni

ti

on key interlock solenoid

9-S

t

eering wheel mounting shaft

It

e

m

Par

t

Number

De

scr

iption

1-Upper

cowl

2-Lower cowl

3-Colu

mn tilt adjustment lever

4-Col

u

mn reach adjustment lever

5-Di

mm

er switch

Motorized Upper Co

lumn Components

Page 509 of 2490

Is adjustable for both til

t and reach.

Has ca

ble operated reach adjustment, using a rack an

d wedge, with approximately 16 latched positions.

Has si

x latched tilt positions steppe

d at approximately 3° intervals.

Has an u

nlatched top tilt position, allowing the column to be

pulled down to engage the first detent without using the

tilt lever.

Has an instrument li

ghti

ng dimmer switch installed on the left-hand side of the lower cowl.

Manual Upper Column Components

The telescopic slider provides driver crash protection by retracting automatically in the event of an accident; it is clamped in

position to a preset torque.

The manual upper steering column has the following serviceable parts:

Igni

tion switch assembly.

Igni

tion key interlock solenoid.

Bowden

cable and lever assembly.

It

em

Par

t Number

De

scription

1-L

ower mounting bracket

2-Crash tube

3-Harnes

s connector bracket

4-Upper

mounting bracket

5-Ignition switc

h (hidden)

6-Igni

tion key interlock solenoid

7-S

teering wheel mounting shaft

The manu

al upper

steering column:

Page 522 of 2490

diverter val

ve (if fitted) and oil filter.

Main

bearings

which are grooved in the upper positions and plain in

the lower positions. They are manufactured from

aluminium / tin material.

A c

rankshaft with under

cuts and rolled fillets for extra strength.

Fracture

-split connecting rods in sintered-forged steel.

Brackets

bolted to the front of

the cylinder

block are used to mo unt all accessories.

A sin

gle, seven ribbed vee belt

drives the accessories.

An au

tomatic belt tensioner for the front accessory drive,

incorporating a wear indicator.

An advanced en

gine management system inco

rporating electronic throttle control.

The un

it meets the requirements of the CARB OBDII USA legislation.

Ancillary Systems

The an

ci

llary systems, driven by the engine, each have a

detailed Description and Operation along with Diagnostic

Procedures, and Removal and Installation instructions ; refer to the following sections of this manual:

Power Steeri

ng Pump - Section 211-02

Ai

r Conditioning Compressor - Sectio

n 412-03

Engine

C

ooling Pump - Section 303-03

Generator

- Sectio

n 414-02

The drive belt, idler pulley and automatic tensioner are described in Section 303-05.

The engine starting system is described in Section 303-06.

En

gine Management and Emission Control System

Engine Control Modu

le (ECM)

Engine

management and exhaust emissions are controlled by the ECM, which has the

following main functions:

Fu

el injection

Idle

s

peed

Ignition Ev

aporative loss system

Engine

cooling fans Clim

ate control compressor clutch demand

The microprocessor within the ECM receiv es signals from various sensors and other modules and uses a pre-determined

program to compute engine management functions.

Adaptive functions are incorporated in the ECM to cater for co ntinuous adjustments to its computations to suit prevailing

conditions. Because the system also controls emissions to suit all modes, neither CO levels nor idle speed require service

attention or adjustment, except if an error should occur.

On Board Diagnostics are controlled by the ECM with the continuous monitoring of incoming signals and the subsequent

verification against what the module expects to 'see'. Should a si gnal be incorrect or missing, the ECM will substitute a fixed

value to provide the 'limp home mode' and alert the driver of the problem. Fixed values may be adopted for:

Transmission oil

temperature

Mechanica

l

guar

d position

Throttle blade angle Camshaft position

Inta

k

e air temperature

Diagnostic trouble codes (DTC), including OBD II codes, are stored in the ECM memo ry and can be read by an appropriate

retrieval tool.

Should either the ECM or TCM fa il, ensure that the control housing cooling fan is operating correctly. Failure of the cooling

fan MUST be rectified before renewing a control module and details of a fa n failure should accompany a returned control

module.

Page 535 of 2490

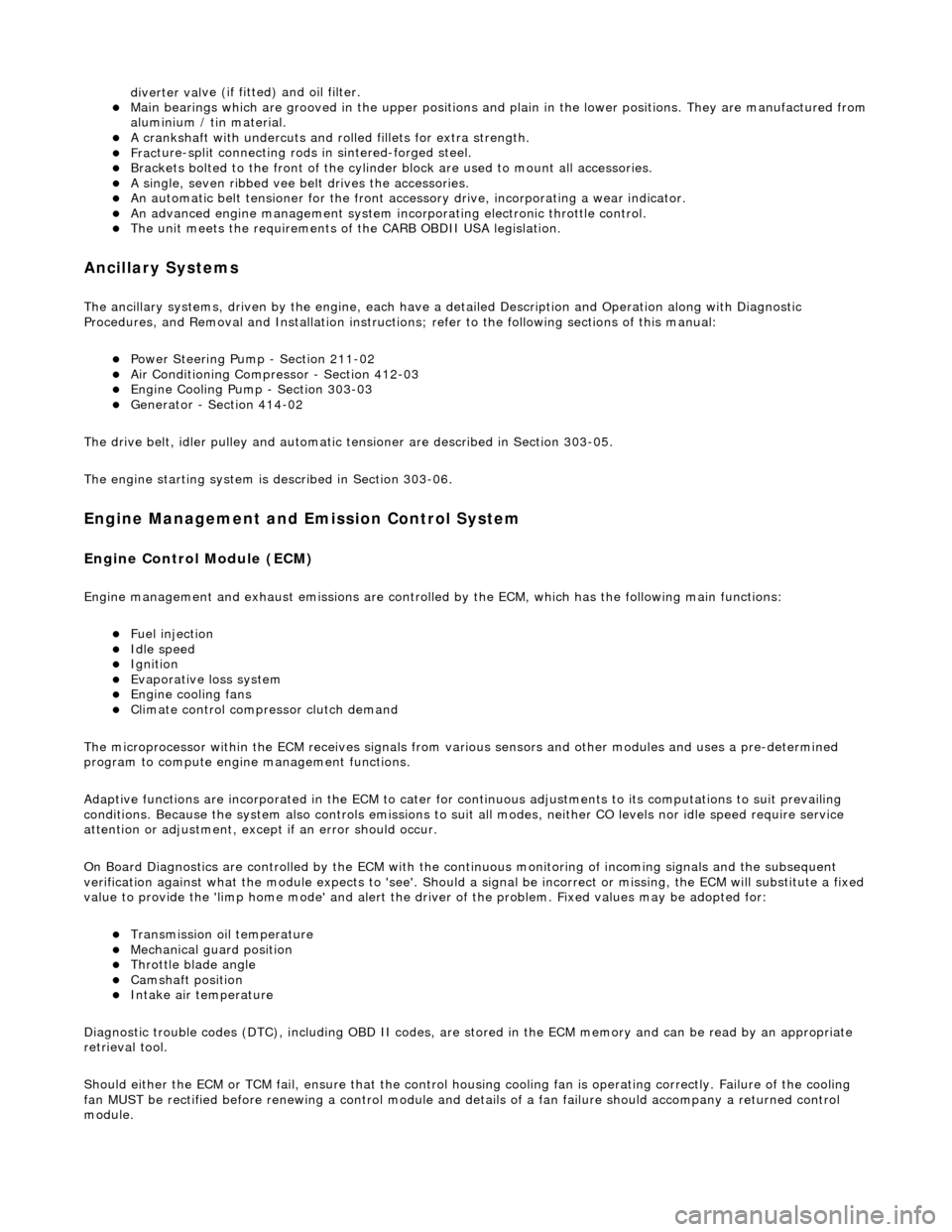

Pin

point test B: P1393 (P1398) VVT solenoid circuit high input

W

ith EM014 disconnected, measure the resistance

between EM014/009 and ground EM016L

1

I

s the resistance < 0.5 OHM?

Yes Reconnect EM014, EM015, PI031 or (PI032)

GO to A6

No Inspect harness / connector EM014, ground stud and

splice EMS37 for corrosion, damage, bent or pushed back

pins and repair as required. Test the system for normal

operation.

A6

: END

Perform

appropriate service drive cycle and check for the

presence of DTC.

1

Has

the fault code cleared?

Yes STOP

No Contact Jaguar Service

P

INPOINT TEST B : P1393 (P1398) VVT SOLENOID CIRCUIT HIGH INPUT

•

NOTE: References in brac

kets are for Bank B (2)

T

EST CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1

: RETRIEVE DTCS

•

NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Page 540 of 2490

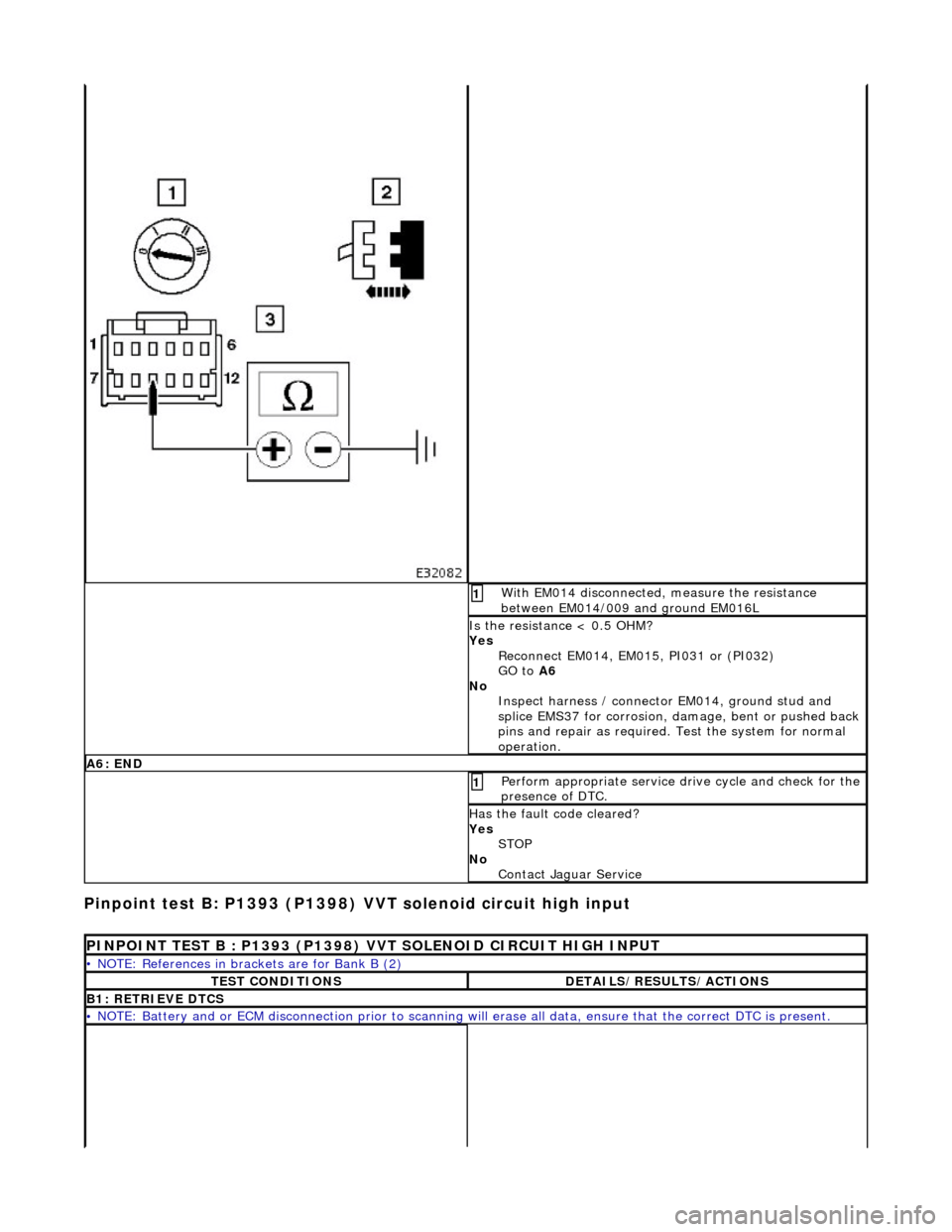

Pinpoint test C: P1396

VVT solenoid malfunction

W

i

th EM015, EM014 PI031 and PI032 disconnected,

measure the insulation resistance between EM015/009

and EM015/008

1

I s

the resistance > 10 MOHM?

Yes Reconnect all connectors

GO to B7

No Inspect EM015 and PI031 (PI032) for corrosion, bent /

pushed back pins or locate and repair the harness /

connector PI001/016 (PI001/027). Test the system for

normal operation.

B7: EN

D

Perform

a

ppropriate service drive cycle and check for the

presence of DTC

1

Has th

e fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TES

T C : P1396 VVT SOLENOID MALFUNCTION

T

E

ST CONDITIONS

D

E

TAILS/RESULTS/ACTIONS

C1

: RETRIEVE DTC

S

•

NOTE

: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

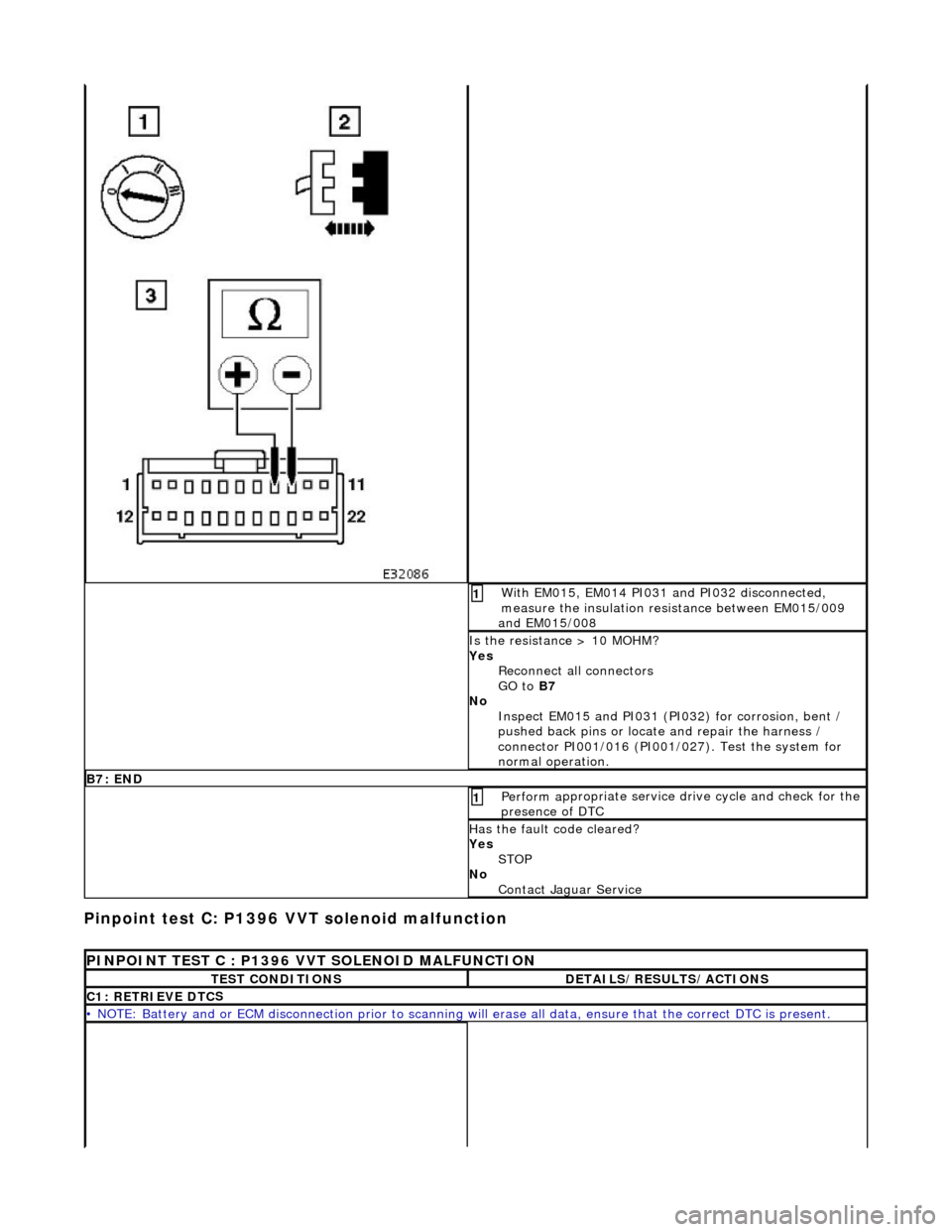

Page 547 of 2490

W

ith EM014 disconnected, measure the resistance

between EM014/009 and ground EM016L

1

I

s the resistance < 0.5 OHM?

Yes Reconnect EM014, EM015, PI031 or (PI032)

GO to C10

No Inspect harness / connector EM014, ground stud and

splice EMS037 for corrosion, damage, bent or pushed

back pins and repair as required. Test the system for

normal operation.

C9

: CHECK MECHANICAL CONDITION

R

emove the VVT(s) and ensure

that there is no foreign

matter blocking the oil passageway

1

OK

?

Yes GO to C10

No Rectify as required

C

10: END

Perform

appropriate service drive cycle and check for the

presence of DTC.

1

Has

the fault code cleared?

Yes STOP

No Contact Jaguar Service

Page 548 of 2490

En

gine - Valve Clea

rance Adjustment

Gene

ral Procedures

S

p

ecial Tool(s)

Tappet adjustment

3

03-

540

Ai

r gun, fan nozzl

e

303-590

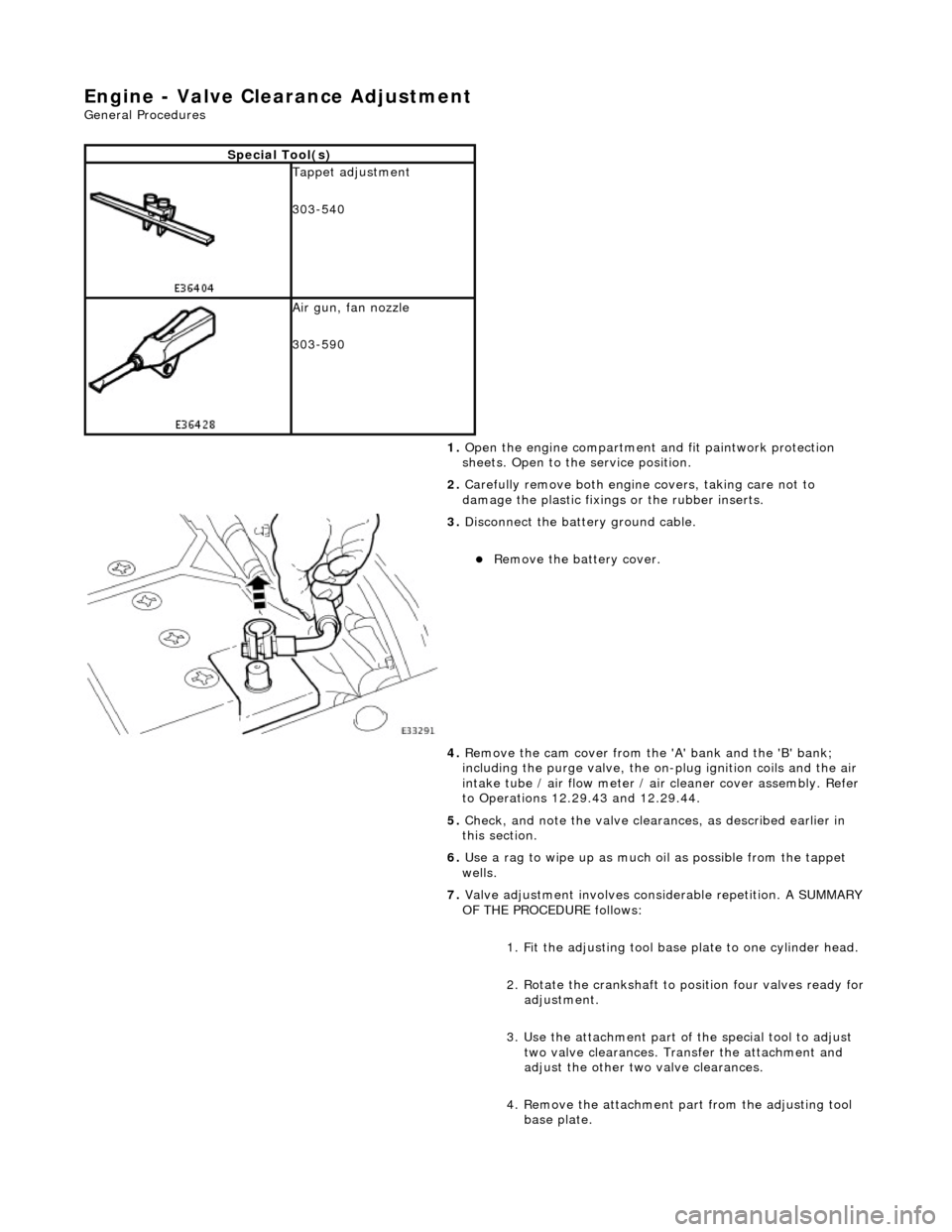

1. Open the engine compartment and fit paintwork protection

sheets. Open to the service position.

2. Carefully remove both engine covers, taking care not to

damage the plasti c fixings or the rubber inserts.

3. Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

4. Remove the cam cover from the 'A' bank and the 'B' bank;

including the purge valve, the on-plug ignition coils and the air

intake tube / air flow meter / air cleaner cover assembly. Refer

to Operations 12.29.43 and 12.29.44.

5. Check, and note the valve cleara nces, as described earlier in

this section.

6. Use a rag to wipe up as much oil as possible from the tappet

wells.

7. Valve adjustment involves considerable repetition. A SUMMARY

OF THE PROCEDURE follows:

1. Fit the adjusting tool base plate to one cylinder head.

2. Rotate the crankshaft to position four valves ready for

adjustment.

3. Use the attachment part of the special tool to adjust two valve clearances. Transfer the attachment and

adjust the other two valve clearances.

4. Remove the attachment pa rt from the adjusting tool

base plate.