JAGUAR X308 1998 2.G User Guide

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G User Guide

Page 92 of 2490

10. NOTE

: It is not necessary to re

move Special Tool from spring

at this stage.

Remove spring assembly and Special Tool 204-111 from

suspension turret.

11. Lower vehicle to working heig ht and support on stands.

12 . Re

move tiestraps securing wheel speed sensor harness to

upper wishbone.

13 . R

emove wheel speed sensor se

curing screw and withdraw

sensor from vertical link.

14. Remove nut securing tie rod oute r ball joint to steering arm.

Page 104 of 2490

31

. Ensuri

ng graduation mark remains aligned, finally tighten

wishbone front eccentric bolt to 113-153Nm.

32. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 116 of 2490

Align sp

ring pan with lower wishbone bolt locations.

Rot

ate tool adjuster to gradua

lly increase spring tension.

P

r

ogressively install but do no

t tighten spring pan securing

bolts.

Ti ghten spring pan

securing bolts to 70-90Nm.

Ensure spri

ng

lower rubber seat is correctly positioned in

spring pan.

6. WARNING: WHE N

ROTATING TOOL ADJUSTER, ENSURE

THAT TOOL STEM DOES NOT TU RN AND DISTURB POSITION OF

DOWEL IN SUSPENSION TURRET.

Remove Special Tool 204-111 from suspension.

Rotat

e adjuster of Special Tool to release tension on

spring.

R otate

tool stem to release dowel from turret.

With

draw tool and adaptor

.assembly.

7.

Lower vehi cle to work

ing heig

ht and support on stands.

8. Install road wheel. Re fer to Section 100-02.

9. Raise vehicle, remove stands and lower vehicle onto road

wheels.

10. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

11. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 130 of 2490

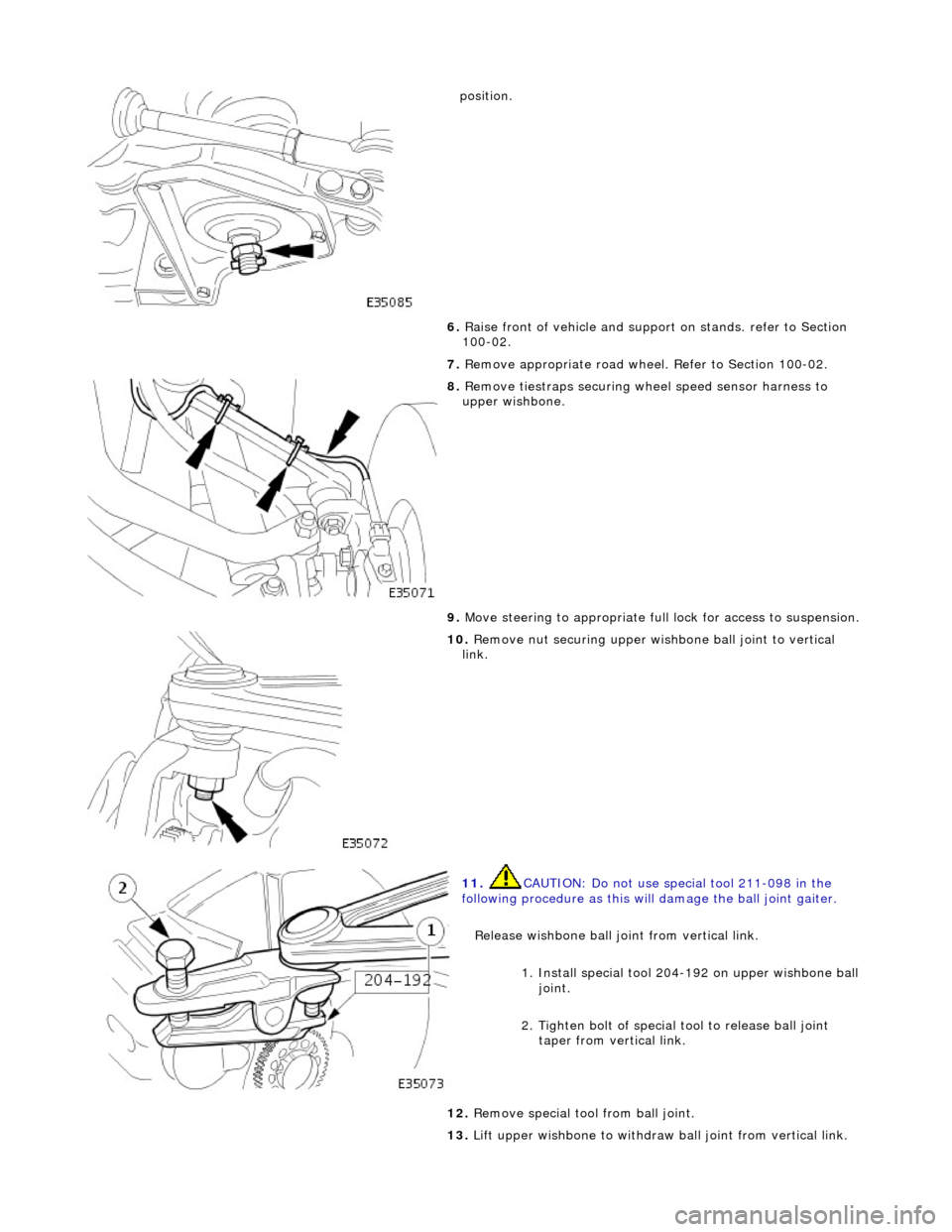

positio

n.

6. Raise front of vehicle and support on stands. refer to Section

100-02.

7. Remove appropriate road wheel. Refer to Section 100-02.

8. Remove t

iestraps securing wheel speed sensor harness to

upper wishbone.

9. Move steering to appropriate full lock for access to suspension.

10. R

emove nut securing upper wish

bone ball joint to vertical

link.

11 . CAUTI

ON: Do not use special tool 211-098 in the

following procedure as this will damage the ball joint gaiter.

Release wishbone ball joint from vertical link.

1. Install special tool 204-192 on upper wishbone ball joint.

2. Tighten bolt of special tool to release ball joint

taper from vertical link.

12 . Re

move special tool from ball joint.

13. Lift upper wishbone to withdraw ball joint from vertical link.

Page 134 of 2490

17.

R

elease dowel of special tool 204-114 from suspension turret

slot.

18. Raise vehicle for access an d remove special tool from

suspension.

19. Fully lower vehicle.

20. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 140 of 2490

slots.

Install rotor nut spring-clip.

Inst al

l spring clip in hub retaining holes and castellated

slots of the rotor nut.

9. Inst al

l disc shield.

1. Position disc shield on vertical link.

2. Install bolts.

10. Install vertical link and hub as sembly on vehicle. Refer to

60.25.38.90.

11. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 146 of 2490

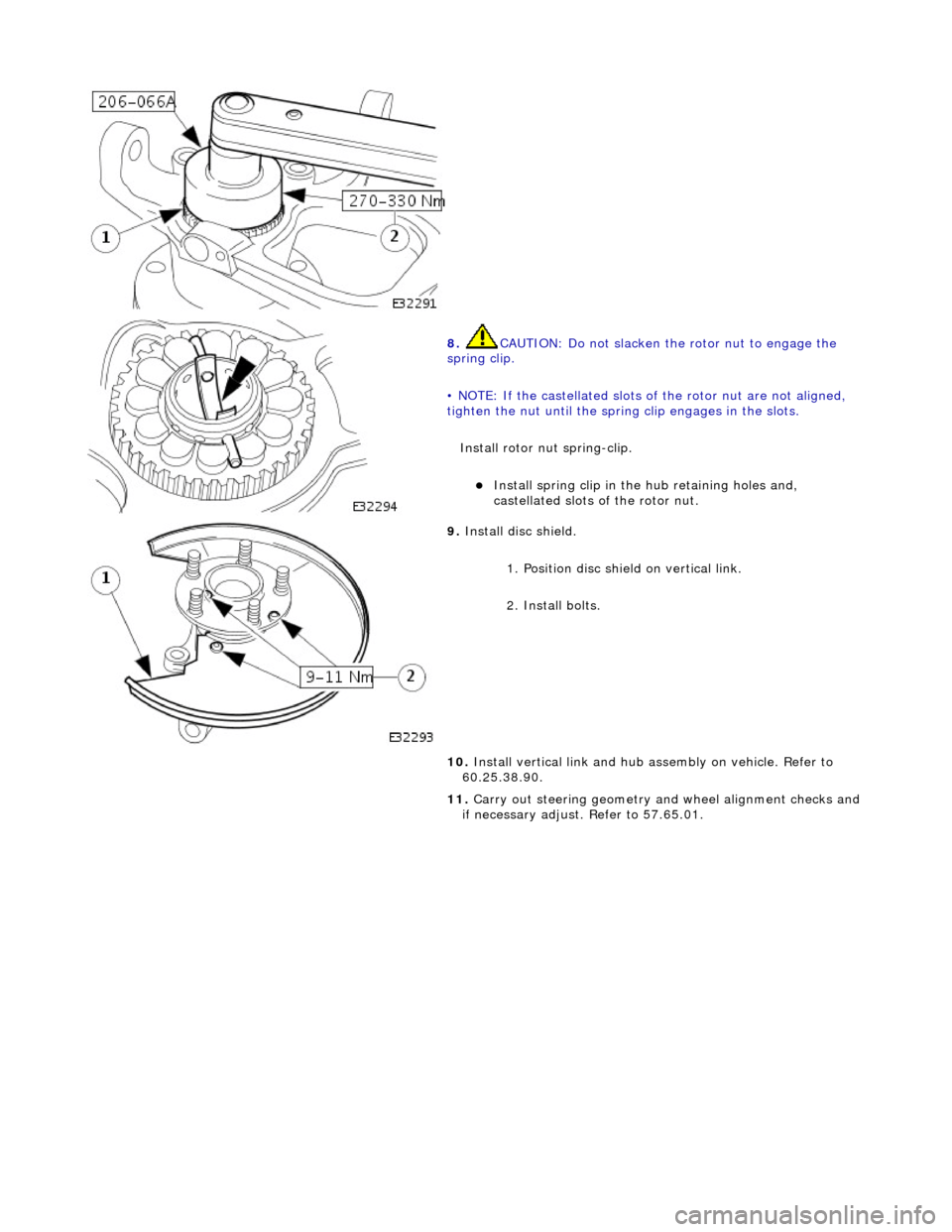

8.

CAUTIO

N: Do not slacken the rotor nut to engage the

spring clip.

• NOTE: If the castellated slots of the rotor nut are not aligned,

tighten the nut until the spring clip engages in the slots.

Install rotor nut spring-clip.

Inst

all spring clip in the hub retaining holes and,

castellated slots of the rotor nut.

9. Inst al

l disc shield.

1. Position disc shield on vertical link.

2. Install bolts.

10. Install vertical link and hub as sembly on vehicle. Refer to

60.25.38.90.

11. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 152 of 2490

tigh

ten the nut until the spring clip engages in the slots.

Install rotor nut spring-clip.

Inst al

l spring clip in hub retaining holes and castellated

slots of the rotor nut.

9. Ins t

all disc shield on vertical link.

1. Position disc shield.

2. Install bolts.

10. Install vertical link and hub as sembly on vehicle. Refer to

60.25.38.90.

11. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 154 of 2490

THAT TOOL STEM

DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Engage dowel of special tool 204-111 in suspension turret and

rotate to position across slot.

8. Lower vehicle onto stands.

9. Ro

tate tool adjuster to tension spring.

10 . R

emove wheel speed sensor se

curing screw and withdraw

sensor from vertical link.

11 . R

emove nut securing tie rod oute

r ball joint to steering arm.

12. Release ball joint from vertical link.

1. Install special tool 211-098 on tie rod outer ball joint.

2. Tighten tool bolt to rele ase taper pin from vertical

link.

Page 157 of 2490

3. Install nu

t securing upper ball jo

int to vertical link and tighten

to 60-80Nm.

4. P

osition tie rod ball joint taper

pin on steering arm and install

and tighten securing nut to 71-85Nm.

5. Inst

all wheel speed sensor.

Posi

tion wheel speed sensor on vertical link.

Inst

all sensor securing bolt

and tighten to 8-10Nm.

6. Remove wire temporarily securing vertical link to road spring.

7. Install br ake disc.

8. Release tension on road spring.

R

otate adjuster of special tool 204-111 to release spring

tension.