battery JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1311 of 2490

Pinpoint test F: P0715

With EM007 and EM046 disconnected, measure the insulation resistance between EM007/016 and EM007/044 1

Is the resistance > 10 MOHM?

Yes GO to E8

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

E8: END

Perform appropriate service drive cycle and check for the

presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST F : P0715

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

F1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present

Page 1316 of 2490

Pinpoint test G: P1722

With EM007 and EM046 disconnected, measure the insulation resistance between EM007/014 and EM007/042 1

Is the resistance > 10 MOHM?

Yes GO to F8

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

F8: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST G : P1722

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

G1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1321 of 2490

Pinpoint test H: P1726

Pinpoint test I: P1730, P1734, P1779

G8: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST H : P1726

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

H1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to H2

H2: RENEW TRANSMISSION

Renew the transmission 1

Has the transmission been renewed?

Yes GO to H3

H3: END

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST I : P1730, P1734, P1779

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

I1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1331 of 2490

Pinpoint test K: P1789, P1793

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to J2

J2: RENEW TCM

Renew the TCM 1

Has the TCM been renewed?

Yes GO to J3

J3: END

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST K : P1789, P1793

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

K1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to K2

K2: CHECK FUSE

Page 1333 of 2490

Pinpoint test L: P0710

With EM007 and LS008 disconnected, measure the

resistance between EM007/054 and LS008/007 1

Repeat for EM007/055 and LS008/007 2

Is the resistance < 0.5 OHM?

Yes GO to K5

No Inspect harness / connector EM007, LS008, EM051, splice

EMS42 for damage, corrosion, bent / pushed back pins.

Repair as necessary and te st the system for normal

operation.

K5: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST L : P0710

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

L1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1339 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Electronic Pressure Control (EPC) Solenoid

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Raise the vehicle on a suitable lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

пЃ¬Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two fixings which secure the fluid pan .

пЃ¬Remove the fluid pan and all traces of gasket material.

4. Disconnect regulator / solenoid connectors.

5. Remove RH rear valve body securing screws.

Page 1341 of 2490

3. NOTE: Ensure extreme clea nliness and never reuse

transmission fluid.

Using a new gasket, install the fl uid pan and tighten the fixings

to the specified torque figure.

4. Connect the battery and fit the battery cover..

пЃ¬Reset the radio and the clock.

5. Refer to (44.24.02) for fluid fill procedure.

Page 1348 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Main Control Valve Body

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Raise the vehicle for access.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

пЃ¬Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

пЃ¬Remove the fluid pan and all tr aces of gasket material.

4. Remove the fluid filter, (44.24.07).

5. Remove the input speed sensor.

• NOTE: M5 fixing.

1. Remove the screw from the input speed sensor securing bracket and pu ll the sensor clear.

пЃ¬Disconnect the harness multiplug.

Page 1351 of 2490

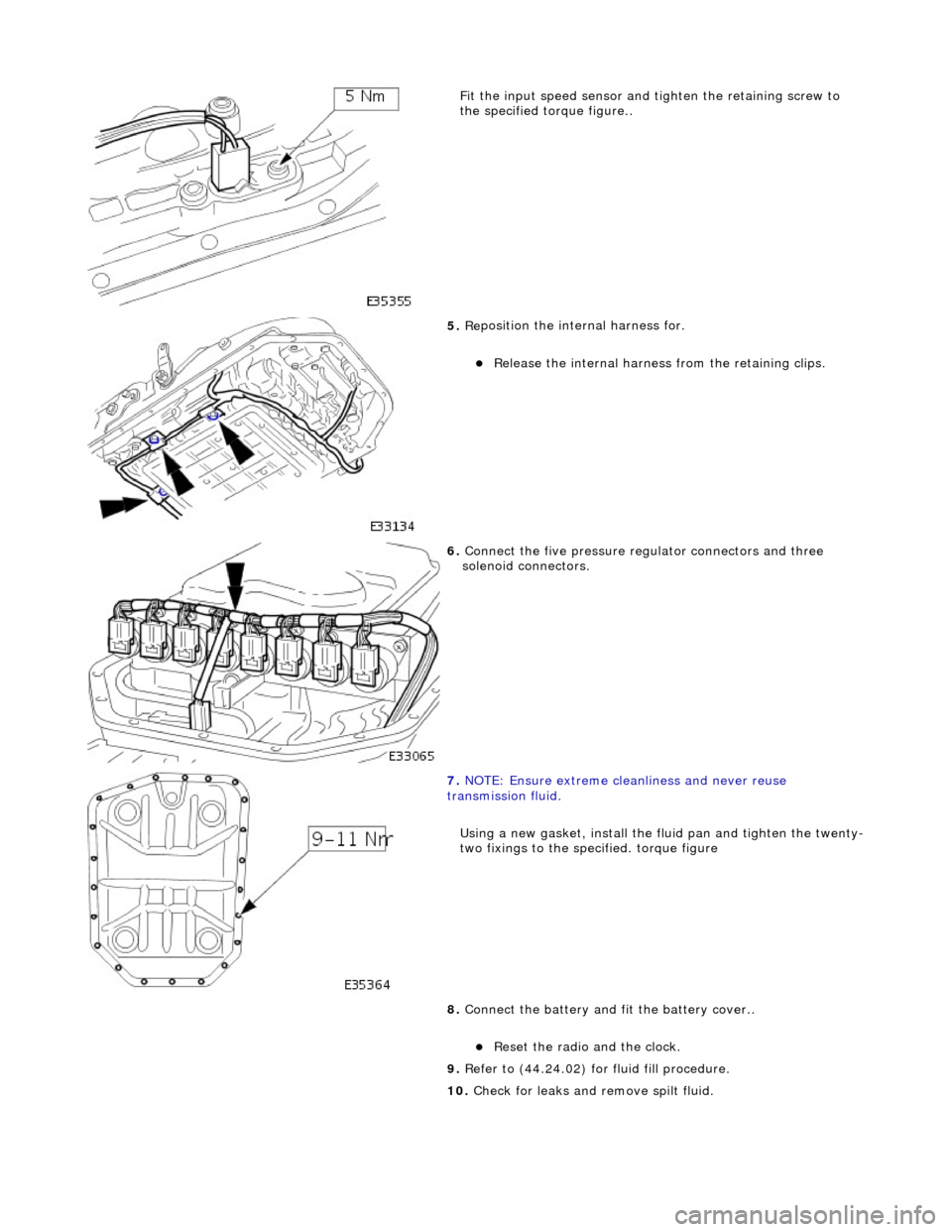

Fit the inpu

t speed sensor and

tighten the retaining screw to

the specified to rque figure..

5. Re

position the inte

rnal harness for.

пЃ¬R

elease the internal harness

from the retaining clips.

6. Connect

the five pressure re

gulator connectors and three

solenoid connectors.

7. N

OTE: Ensure extreme clea

nliness and never reuse

transmission fluid.

Using a new gasket, install the fl uid pan and tighten the twenty-

two fixings to the specified. torque figure

8. Connect the battery and fit the battery cover..

пЃ¬Reset th

e radio and the clock.

9. Refer to (44.24.02) for fluid fill procedure.

10. Check for leaks and remove spilt fluid.

Page 1352 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Output Shaft Speed (OSS) Sensor

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

пЃ¬Remove the battery cover.

2. Raise the vehicle on a lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

пЃ¬Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

пЃ¬Remove the fluid pan and all tr aces of gasket material.

4. Remove the output speed sensor.

• NOTE: M6 fixing.

1. Release the screw which secures the output speed sensor bracket and pull the sensor clear.

5. Disconnect the multiplug from the speed sensor.